Assembly drawing of the inside of calcite mill

Grinding of Calcite to NanoSize: Effect of Mill Capacity

In this study, nanosized calcite was produced by conventional ball mill Firstly, the mill capacity (feed amount) was reduced, then, the effect of the grinding media type was investigated 2024年4月1日 Disc designs are effective for horizontal mill orientation, while pin designs are effective for vertical mill orientation The primary objective of this research is to examine the The impact of different stirrer designs and mill orientations on the 2021年10月1日 This paper initially aims to provide an insight on components’ interaction within ball milling and stirred milling and then comparison of the two outcomes Within the scope, the Effects of impact and attrition mechanisms on size distribution and 2002年1月28日 An experimental study on the ultrafine wet grinding of calcite in a batch stirred bead mill is reported The evolution of the size distribution and of the specific surface area of Changes of Surface and Volume Properties of Calcite

.jpg)

Dynamic image analysis of calcite particles created by different

2014年12月10日 The image analysis of calcite particles that ground in ball, rod and autogenous mills was successfully performed by employing 3D dynamic image analysis At least 6400 In this study, particle shapes of calcite mineral ground by different mills namely ball, rod and autogenous mills were measured using a new 3D analysis with random orientation technique Dynamic image analysis of calcite particles created by different millsESEM pictures of calcite powders ground in P9 mill for 1' (a), 3' (b), 10' (c), 24' (d), 60' (e) The above results underline the importance of a clear distinction between domain size as XRD line profile analysis of calcite powders produced by high Calcite mining and processing involve several steps to transform raw calcite into usable materials Here’s an overview of the typical process: Geologists conduct surveys to locate calcite How calcite is mined and processed

.jpg)

Grinding of Calcite to NanoSize: Effect of Mill Capacity

Figure 1 Nano calcite fabrication flow diagram [“topdown” approach] The primary function of grinding media is to crush and grind ore particles inside rotating mills, such as ball, rod, and semiautogenous mills, and sometimes in stirred mills such as Vertimill, SVM mills, Sala Agitated Mill, HIGMill, Tower Mill, and ISAMill [2]cost analysis 46 conclusions 47 recommendation 48 appendix 50 jit school of mechanical engineering page x [design of corn, wheat, millet and maize mill machine] june 1, 2015 part drawing 55 assembly drawing DESIGN OF CORN, WHEAT, MILLET AND MAIZE 2019年11月1日 In this study, we characterize dynamic wettability alteration at solid surfaces (eg, calcite, silica and illite) resulting from the selfassembly and adsorption of polyaromatic macromolecules The Influence of SelfAssembly of Polyaromatic ResearchGate2019年12月23日 A hammer mill has been designed with due considerations to standard design requirements drawings CHAPTER TWO 20 Inside the crushing chamber the main shaft assembly which moves DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

Comprehensive Guide to Creating Assembly Drawings in

There are several types of assembly drawings, each serving a specific purpose and providing different levels of detail: Exploded Assembly Drawing: This type of drawing shows the components of an assembly separated from each other, highlighting their individual shapes and relationships with other componentsExploded drawings are particularly useful for visualizing Download scientific diagram FIG URE 2 Assembly drawing of a synchronized mediumscale oil palm fruits processing mill from publication: Performance characterization and optimization of a FIG URE 2 Assembly drawing of a synchronized medium2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle Effect of Operating Parameters on the Breakage Process of Calcite PDF On Jan 1, 2017, Serkan Cayirli and others published The Effect of Stirred Mill Orientation on Calcite Grinding Find, read and cite all the research you need on ResearchGateThe Effect of Stirred Mill Orientation on Calcite Grinding

.jpg)

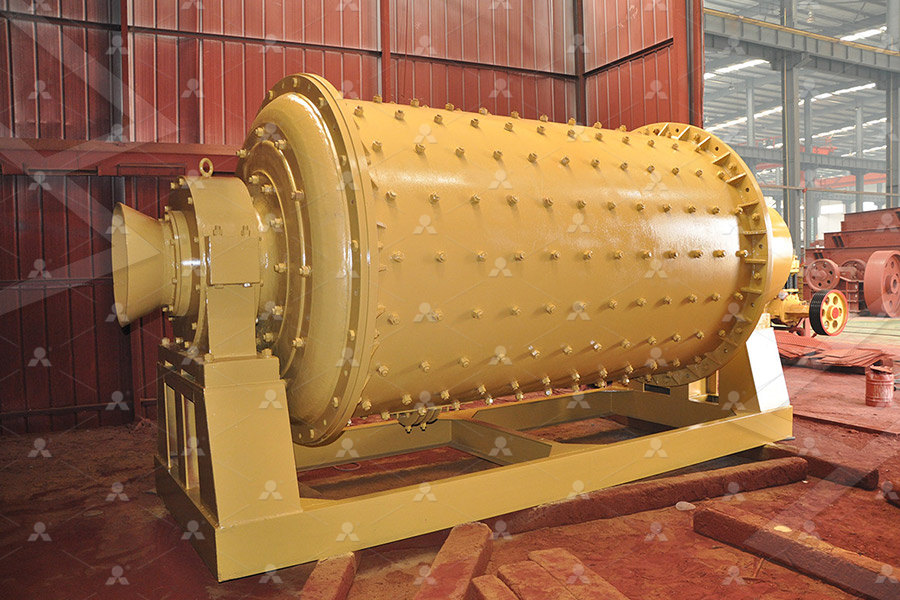

Ball Mills 911Metallurgist

2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and →Assembly drawings show how individual parts fit together to make a machine →A standard parts sheet contains purchased items inside the assembly to see clearly Section Hatch in Assemblies Section Hatch: Section hatch in adjacent parts are drawn in opposing directionsChapter 12 Assembly Drawings HCC Learning Web2021年4月3日 This paper presents a method evaluating in numerical value the magnitude of vibration component contained in the rotor angular velocity of a hammer crusher and a new structure to remove themDesign and Analysis of Rotor Assembly of Hammer Open the Properties panel using the Panels button at the lowerright of the design space then open the Page Options tab In the Formatting and Size region, enable the Template option to select a document sheet template from a precreated Creating the Assembly Drawing in Draftsman Altium

.jpg)

Ball Mill Maintenance Installation Procedure

2016年10月20日 If a spout feeder is to be used, it is generally supplied by the user, and should be mounted independently of the mill The spout should project inside the feed trunnion liner, it is advisable to refer to the assembly ASME Y14242012 [Revision of ASME Y14241999 (R2009)] Types and Applications of Engineering Drawings Engineering Drawing and Related Documentation PracticesTypes and Applications of Engineering Drawings ASMEDiscover the art of creating precise and comprehensive General Assembly Drawings that engineers swear by! It’s like cutting a cake in half to see the layers inside 3 Elevation Drawings Elevation drawings depict the exterior view of a project from different anglesGeneral Assembly Drawings: The Ultimate Guide to Precision and % 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 Grinding tests were carried out in a dry stirred ball mill both vertical and horizontal orientations with varyingThe Effect of Stirred Mill Orientation on Calcite Grinding

.jpg)

The Influence of Stirred Mill Orientation on Calcite Grinding

The Influence of Stirred Mill Orientation on Calcite Grinding Serkan Cayirli1 Hasan Serkan Gokcen2 Received: 28 September 2020/Accepted: 7 April 2021 # Society for Mining, Metallurgy Exploration Inc 2021 Abstract The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911Metallurgist2021年4月1日 Ultrafine grinding of calcite powder was studied under batch wet conditions in a laboratory stirred mill After grinding, the suspension was allowed to age at 30°C for 12 and 24 hThe Influence of Stirred Mill Orientation on Calcite Grinding2022年5月27日 General assembly shop drawings – involve overall components Outline assembly shop drawings – covering the exteriors of the assembled work Diagrammatic assembly shop drawings – involving symbols to represent the assembly Subassembly or unit assembly shop drawings – detailed assembly of a part or a unit Fitted assembly shop drawings Assembly Drawings: Everything You Need To Know BluEntCAD

Effect of grinding aids on the grinding energy consumed during grinding

2010年1月1日 Fig 1 shows the cumulative particlesize distribution of the products obtained after various grinding times without (Fig 1 a) and with grinding aids (Fig 1 b) Whether grinding aids were added or not, the tendencies of changes in particlesize distribution were similar to those shown in Fig 1However, the addition of grinding aids resulted in differences in the size > Engineering approaches have highlighted mill performance with mill modelling and the use of improved materials > Liner design ,with the advent of large diameter SAG mills, the issues of design, selection, monitoring and evaluation of mill performance is critical > Mill trajectory modelling can be used to great effect in improving liner designThe Selection Design and Application of Mill Liners for Large Wet 2021年11月10日 The nacelle is the ‘head’ of the wind turbine, and it is mounted on top of the support tower The rotor blade assembly is attached to the front of the nacelle The nacelle of a standard 2MW onshore wind turbine assembly The Parts of a Wind Turbine: Major Components Inside the crushing chamber the main shaft assembly which moves in an eccentric motion is located to crush the particles in the crushing chamber When feeding the crusher the eccentric 35 motion allows the articles to fall down and then be compressed to break apart between the main shaft assembly and concaveDEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

DESIGN AND FABRICATION OF A MILL PULVERIZER

A tube mill is a revolving cylinder of up to five diameters in length used for fine pulverization of ore, rock, and other such materials; the material, mixed with water, is fed into the chamber from one end, and passes out the other end as a slurry Both types of mill include liners that protect the cylindrical structure of the mill from wear2014年4月14日 Request PDF Functionalizing Single Crystals: Incorporation of Nanoparticles Inside GelGrown Calcite Crystals Synthetic single crystals are usually homogeneous solids Biogenic single crystals Functionalizing Single Crystals: Incorporation of Nanoparticles Inside Download scientific diagram Drawing of the basic structure of a roller mill with two rotating/counterrotating rollers (crosssection) from publication: A study of operating parameters of a Drawing of the basic structure of a roller mill with two rotating This document provides instructions for installing a 16x22ft, 2800kW ball mill It outlines 8 key steps: 1) Prepare the foundation and install the trunnion bearing sole plates 2) Assemble and mount the trunnion bearings onto the sole plates 3) Assemble the trunnion ends to the mill shell 4) Lower the mill unit into the bearings and check clearances 5) Install the girth gear 6) 16' X 22' Ball Mill Installation Manual

The Influence of Stirred Mill Orientation on Calcite Grinding

2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with 2002年10月1日 A new form of biomineralization has been studied in the pineal gland of the human brain It consists of small crystals that are less than 20 microm in length and that are completely distinct from Calcite Microcrystals in the Pineal Gland of the Human Brain: 2019年1月1日 A grain size reduction hammer mill for crushing corn (Zea mays L) was designed depending on variety characteristics and by using computer aided design “ANSYS” softwareDesign and Evaluation of Crushing Hammer millThe main parts of Calcite raymond mill is grinding roller, grinding ring, grinding roller assembly, the plum flower frame, air flue, coupling, perching knife and so on Calcite raymond mill roller shell part is wearing part, so we must set up a structure can make timely, easily removed from the roll grinding machine body, so as to replace the Calcite raymond mill wear parts, but also easily to How To Replace Calcite Raymond Mill Parts

.jpg)

Dating Methods (Absolute and Relative) in Archaeology of Art

2020年10月26日 UTh and 14 C dating were used, for example, in Southern China, to compare minimum/maximum ages for UTh dating of naturalistic pictographs in an openair shelter, with 14 C AMS dating obtained from plant debris and microorganisms trapped inside of calcite crust, after an estimation of the contribution of geological carbon in calcium carbonate (Taçon et al 2012)2024年1月10日 Assembly drawing breaks down the design into simple parts, showing how everything fits together It's like having a roadmap for solving a puzzle you know where each piece goes to create the whole picture Stopping Mistakes and Saving Money Assembly drawing is like a safety net, catching mistakes before they happenAssembly Drawing: Importances and Types in Mechanical 2014年3月1日 This paper investigates the production of calcite suspensions by a wet grinding process in a stirred media mill The experimental setup allows the circulation mode process in the presence of sodium polyacrylate as additive The influence of different operational parameters on grinding results in terms of particle size distribution and rheological behavior of the Grinding of calcite suspensions in a stirred media mill: Effect of Inside the United States, there are a number of regulations from both the EPA and FDA that can influence the design and operation of a flour milling facility If the bins are contained inside a steel mill, then it is likely that they will be round steel construction and separately installed in the mill In other scenarios, Design Considerations for the Construction and Operation of

.jpg)

SAG Mill Liner Design 911Metallurgist

2016年6月6日 In analyzing the diaphragm assembly capacity, See Drawing A5914 If molten zinc is used to “set” or “back” the liners – be careful – consult mill supplier for proper procedure Note: rubber backing cannot be used with zinc filler 2009年7月1日 Gao et al [7] found that increasing the power consumed during grinding accelerated the size reduction dramatically, with only a small change in the energy efficiency of the process In an experiment using a stirred ball mill and grinding aids, Paramasivam and Vedaraman [8] studied the effect of the physical properties of liquid additives on dry grinding Effect of grinding aids on the kinetics of fine grinding energy 2024年4月29日 [ Ultimate Benchtop CNC Mini Mill Part 8: A Spindle for Our Mill ] Spindle Design [ CNC Mill Spindle: Bearings, Belt Drive, VFD, ATC, and Design Notes ] CNC Milling Machine Parts Home The cnc spindle is the heart of any DIY CNC It consists of a rotating assembly with a taper where tool holders may be C Milling Machine Spindle [Complete DIY Guide]2022年2月17日 Draftsman is a sophisticated yet easy to use drawing tool that is integrated within Altium Designer, for the creation of fabrication and assembly drawings Draftsman is a builtin extension that can be installed or removed manually by going to the Extensions and Updates page You can access the Extensions and Updates page by clicking on the user icon on the Creating Fabrication and Assembly Drawings In Altium Designer