Coal mill reducer fan frequently breaks

.jpg)

TPS Coal Mills and Fan Performance PPT SlideShare

2019年5月8日 • A curve linking HGI and mill capacity provides information on mill performance with that coal • A curve linking moisture content of the coal with mill capacity shows what reduction in capacity will arise if the moisture is Mills are mechanical devices used to break different types of solid materials in small pieces by grinding, crushing or cutting In pulverised coalfired power plants, a pulveriser coal mill grinds Coal Mill an overview ScienceDirect Topics1997年8月1日 This paper describes the analysis results of the dynamic characteristics of coal grinding mills used in a large coalfired power generation unit The aim of the work is to Analysis of coal Mill Dynamic Characteristics Under Normal and 2015年8月1日 Power plant performance and reliability is highly influenced by coal mills that grind, dry, and transport coal to the furnace This paper presents a review of the current state Review of control and fault diagnosis methods applied to coal

.jpg)

Condition Monitoring in Thermal Power Stations

2024年11月19日 Condition Monitoring in Thermal Power Stations: Case Studies covers 25 case studies of all major areas of thermal power stations, which have suffered a lot of machinery This paper analyzes the case history of retrofit of coal mill exhaust fan including fan performance and erosion, and describes high efficiency, backward curved, centrifugal exhauster fan as well Case History: Retrofit of Coal Mill Exhaust Fan Study of Fan 2007年7月1日 Mitigating catastrophic critical fan failures helps ensure plant health and personnel safety Power generation plants throughout the world rely on critical process fans for Protecting Critical Process Fans from Catastrophic Failure2019年3月13日 To reduce air flow volatility of underground coal mine with improved PSO algorithm in main fans switchover process, an automatic control system of coal mine main fans A mine main fans switchover system with lower air flow volatility

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required In addition to the heavy duty process fans, we can supply cooling fans, auxiliary fans and every other type of fan required in a cement plant We can offer a full turnkey service of design Armored fan technology for cement process plants Chart Industries2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2023年5月8日 The disturbance occurs because it operates using LowRank Call (LRC) coal with high moisture, causing the changing in the operating pattern of the coal pulverizer mill, such as the coal flow rate setting and primary airCoal pulverizer mill system modeling for failure simulation

.jpg)

COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS PEC

an explosion Scrap metal in a coal mill is particularly dangerous during mill shut down or start up Coal Mill Operation Fires or explosions most likely occur during startup and shutdown of a coal mill system If a small amount of coal remains in the 2020年4月2日 : Fuel and firing system purposely to deliver light fuel oil or coal as one of the primary elements of fuel in an ideal condition for combustion to take place in the boiler combustion chamberAnalysis of the Coal Milling Operations to the Boiler Parameters2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal mill pulverizer in thermal power plants PPT SlideShare2024年11月19日 Coal Mill 2AB: Main Reducer Gearbox Bearing Deterioration – May 2020 Abstract Case Study 3 Coal Mill 1CD: Gearbox Intermediate Gear Damage – September 2019 Abstract chapter 5 7 pages Case Study 4 Coal Mill 1EF: Gearbox Input NDE Bearing Damage – September 2019 ID Fan Motor Trial (at Test Bench): Motor Bearing Condition Monitoring in Thermal Power Stations

.jpg)

Modeling and Parameter Identification of Coal Mill

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup 2023年5月17日 coal hammer mill is a type of industrial equipment used to grind or pulverize coal into fine particles for combustion in furnaces or other industrial processes It is a machine that utilizes highspeed rotating hammers or blades to impact What Is Coal Hammer Mill? SBM Mill Crusher2003年12月1日 Failure of a ball and race type coal pulverizer mill shaft has been analysed It was found that the shaft, made of EN 25 steel, failed by fatigueFailure analysis of coal pulverizer mill shaft Request PDFClarage’s years of fan knowledge gives us the unique ability to design a fan for any coal mill application Be it our HMF, special coal mill exhauster or a simple backward inclined impeller for general ventilation, we have it all With over 140 years of experience, we have been installing fans in coal mills since the beginningCoal Mill Ventilation Clarage

.jpg)

SHPHGLXP VSHHGFRDOPLOO ResearchGate

Journal of Physics: Conference Series PAPER OPEN ACCESS)DXOWDQDO\VLVDQGRSWLPL]DWLRQWHFKQRORJ\RI+3ERZOW\SHPHGLXP VSHHGFRDOPLOO To cite this article: Dou Jie 2021 J Phys: Conf Ser 2005 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Sectional view of MBF coal mill Download Scientific coal bunker/silo to the mill/pulverizer to be pulverized This coal feeder is in charge of controlling the amount of coal that enters the mill according to the needs of the fuel used in the boiler The need for fuel itself is very dependent on the amount of power generated Coal blocking often occurs, causing problems with the performance of ANALYSIS OF CONTROL SYSTEM MODIFICATIONS ON COAL Analysis of Coal Mill Operation Free download as PDF File (pdf), Text File (txt) or read online for free This document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties Analysis of Coal Mill Operation PDF Mill (Grinding) Scribd

.jpg)

Beater wheel mill concept; 1coal and recalculation gasses; 2mix

Download scientific diagram Beater wheel mill concept; 1coal and recalculation gasses; In the analyzed case, excessive wear of the Hadfield steel beater of the fan mill was identifiedperformance is governed by uniform coal combustion by the burners and satisfactory coal fineness Adequate fineness for both west7 Optimum design Ensure optimum arrangement of the mill throat and the coal flow path to improve mill performance Source: Storm Technologies Inc Grinding surface Finer particles and air to rise to classifier “Blueprint” Your Pulverizer for Improved PerformanceRequest PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill 2023年6月25日 The large reducer supporting the vertical mill should be included in this column Once an accident occurs, the site maintenance is difficult, the technical content is high, and the maintenance cycle is long, which has a great impact on the normal production and operation of Large Vertical Mill Reducer Maintenance

LUOYANG HONGXIN HEAVY MACHINERY CO, LTD

The company is committed to the production of reducer, hoist, crusher, ball mill and screening equipment, coal washing equipment And provide a variety of equipment repair services and supply spare parts Location:Home Product Coal Mining Equipment VIEW ALL Main machine, sky wheel device, different types of Hammer break Impact Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture levelATOX® Coal Mill FLSmidth CementCoal Mill Ball Tube Detailed Info Free download as PDF File (pdf), Text File (txt) or read online for free The document provides details about the commissioning experience of ball tube mills supplied by BHEL for a 250 MW Coal Mill Ball Tube Detailed Info PDF Valve ScribdThe body of ZGM medium speed roller coal mill is composed of reducer, grinding device (grinding disc and three grinding wheels), loading device, sealing device, foundation plate, base, casing, Sealing fan 5115 Commissioning oil ZGM type Mediumspeed Rolling coal millpower

SHPHGLXPVSHHGFRDOPLOO IOPscience

longer service life and more convenient maintenance Hp1103 coal mill is a kind of HP coal mill Compared with similar coal mills, it has stronger adaptability to raw coal and is more suitable for large unit thermal power plants Taking hp1103 medium speed roller disc coal mill as the carrier, this paper mainly describes theSince the first application using an MPS mill to process pulverized coal in Germany in the mid 1960s, there have been over 2,000 different MPS mill installations operating in coalfired power plants worldwide As one of the most popular coal pulverizers in the utility industry, the MPS mill was first introduced into the US in the early 1970sCOAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS 132 Loesche Mills for Solid Fuels Coal Mill E 2016 Free download as PDF File (pdf), Text File (txt) or read online for free Loesche has been involved in processing solid fuels since 1925 Some key events include delivering their first coal mill in 1927 and introducing hydraulic systems in 1961 Their mills are distinguished by grinding without metal contact, suitability for 132 Loesche Mills For Solid Fuels Coal Mill E 2016A pulverizer coal mill works by grinding coal into a fine powder and then drying it in a hot air fan The coal powder is then blown into a combustion chamber where it is burned to generate heat The hot gases and heat energy produced from burning the coal powder then pass through a series of heat exchangers where the heat is transferred to water to produce steamHow does a Coal Mill Work? ball mills supplier

.jpg)

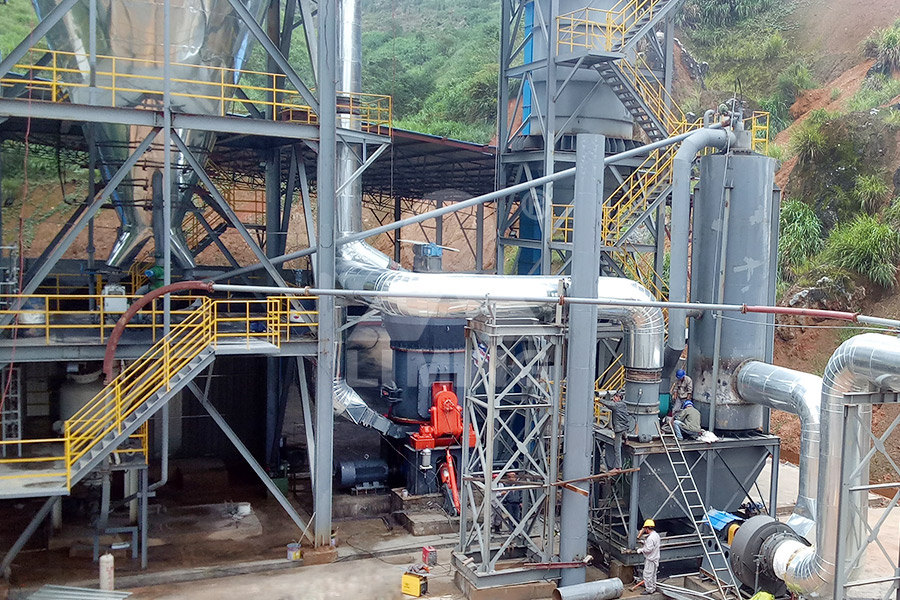

Gearbox/Gear Reducer/Vertical roller mill reducer

2011年7月18日 1 Vertical Roller Mill Reducer Product Introduction The vertical roller mill reducer is a key transmission part for the vertical mill, which not only transmits the torque but sustains the vertical load It is widely used in industries of construction material, power generating and metallurgy for raw material vertical mill, cement vertical mill, coal vertical mill and slag mill Reduction Gearbox for Coal Mill; Reduction Gearbox for Coal Mill Typical Application Coal Mill Features and Benefits Low noise operation by adopting high accurate bevel gear Overwhelming market shares in japanes domesstic utility thrmal power Reduction Gearbox for Coal Mill Hitachi Nico Transmission Co,LtdThe coal pulverizer mill at PLTU (coalfired steam power plant) Rembang is essential boiler equipment that processes coal raw materials into fine coal powder to perfect combustion in the furnace In the operation of 4 coal mill units, delay and selfcombustion often occurred due to using LowRank Call (LRC) coal with high moisture and volatile matter contentDecision Support System for Coal Mill Fault Diagnosis in Coal 2013年11月23日 24 REDUCER LUBRICATION • This is closed cycle lubrication system • This is required for the lubrication of gears and bearings • The oil is pumped to the different points in the reducer by motorized pumps • Oil is sprayed to the gears by means of nozzles in the gearbox at the mating plane • The bearings get oil through nozzles inside the gearbox • The pumps coal pulveriser PPT Free Download SlideShare

.jpg)

Investigation of Excessive Wear of Ashaka Coal Mill Riser Duct and

investigating the causes of Ashaka cement coal mill riser duct excessive wear rate through evaluating the abrasiveness of Maiganga coal and its effect on the abrasive and erosive wear and simulating the flow of the pulverised coal inside the coal mill outlet riser duct The work will have the following limitation 1• Bag Filter Exhaust Fan Fans with high capacity up to 2000000 m3/h and clean gas applications Special design of blades, with airfoil profile, can be used to increase the static efficiency of the fan, up to 86% • Cement and Coal Mill Fan Single or double inlet fans, with or without inlet regulating dampers, in order to meetCEMENT PLANTS APPLICATIONS Boldrocchi Group1997年8月1日 The mill may then be driven beyond its capability and be runback to its minimum speed due to very high mill dP (Fan and Rees, 1994a The effect of mill coal flow and airflow to the mill dP is very much mill settings and the mill control dependent 52 Constant Coal Flow vs Step Changed Air Flow Fig6 shows the results of test four Analysis of coal Mill Dynamic Characteristics Under Normal and Air Swept Coal Mill Working Principle First, the raw coal is fed into the feed chute by the feeding device Then, the hot air with a temperature of about 300 ℃ enters through the air intake pipe and begins to dry the raw coal while they are fallingAir Swept Coal Mill Coal Mill In Cement Plant AGICO GROUP

(PDF) ANALISA PENYEBAB KENAIKAN VIBRASI PADA BELT

2022年10月24日 ANALISA PENYEBAB KENAIKAN VIBRASI PADA BELT CONVEYOR (42 BC 06) DI AREA COAL MILL DI PABRIK II PT SEMEN BATURAJA TBK October 2022; Hasil efisiensi mill fan ini dengan ratarata 73,02%PERANCANGAN SLIDEGATE PADA INLET BOOSTER FAN (613FA13) DI COAL MILL Dara Mutia1), Haolia Rahman2), Abdul Khalim3) 1) Program Studi Konsentrasi Rekayasa Industri, Jurusan Teknik Mesin, Politeknik Negeri Jakarta, 16424 PERANCANGAN SLIDEGATE PADA INLET BOOSTER FAN (613FA13) DI COAL MILL Can GE service my boiler mills? YES Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacitiesWe provide customized maintenance solutions, and offer a full spectrum of highquality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutionsThis is the Power of YesBoiler Mill and Coal Pulverizer Performance GE Steam Power2012年5月1日 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow takeup rates and frequent plant shutdowns (Rees Fan, 2003)In typical coal fired power plants, Derivation and validation of a coal mill model for control

Fans in Cement Plants BrownleeMorrow Company

Raw Mill Baghouse Fan Kiln Exhaust Fan Clinker Cooler Fan Coal Mill Fan Typical Data volume flow: 100450 m 3/s temperature: ca 150 °C mech design temperature: 200 °C pressure increase:2,500 – 3,500 Pa Special Features Often with aerofoiled blades Fan control: in the majority of cases the speed control is performed by frequency converters p pAbstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal Mill