Energysaving ultracrushed barite grinding machine

Barite Grinding Production Line TAYMACHINERY

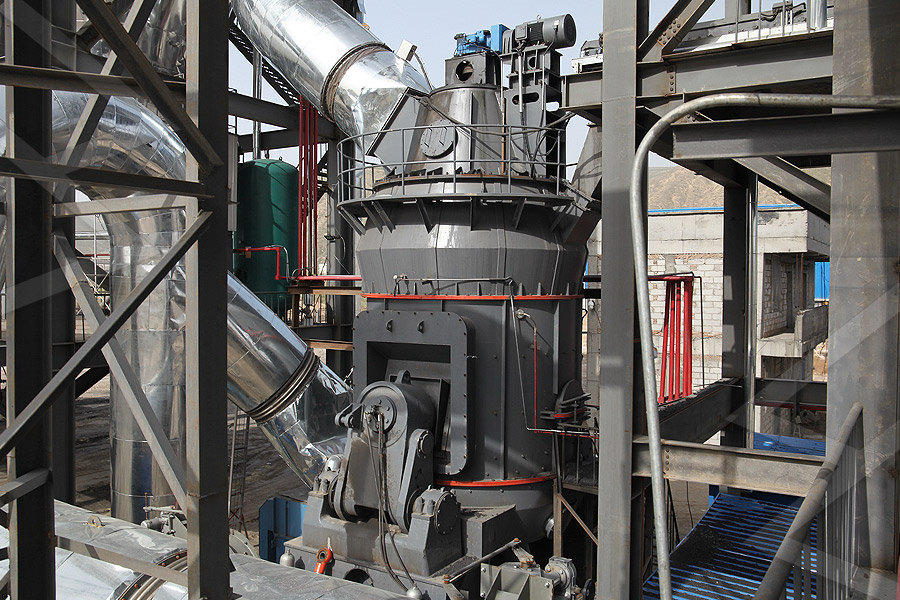

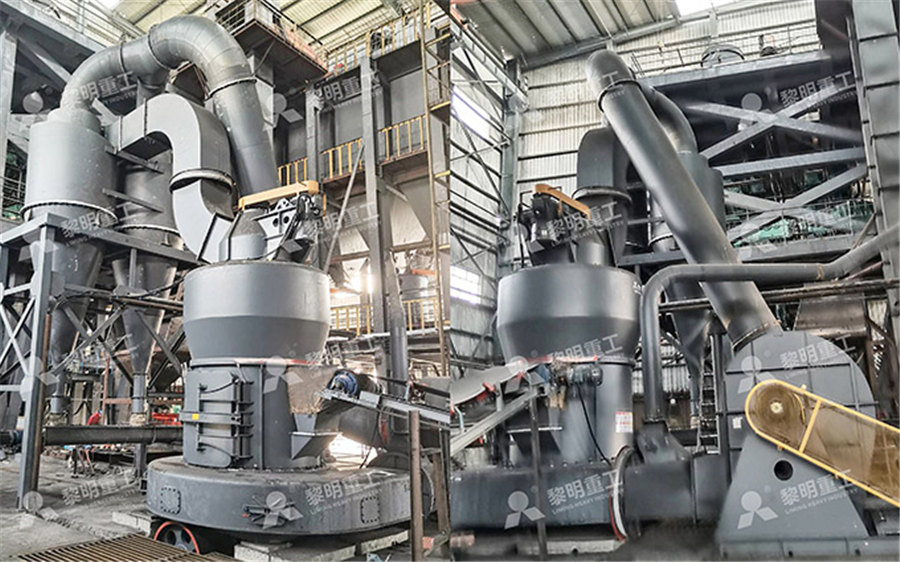

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high CLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging It Ultrafine Vertical MillUse the CLUM ultrafine vertical grinding mill independently developed and produced by SBM to grind barite to obtain fine barite powder of 1503000 mesh It can be used as a white pigment, Barite Ultrafine Vertical Roller MillHigh grinding efficiency and energy saving The production capacity of a single machine is large, it can reach 40t/h Adopt of single head and multi head classifiers, without secondary air HLMX Ultrafine Vertical Mill

Barite HCH Ultrafine Grinding Mill

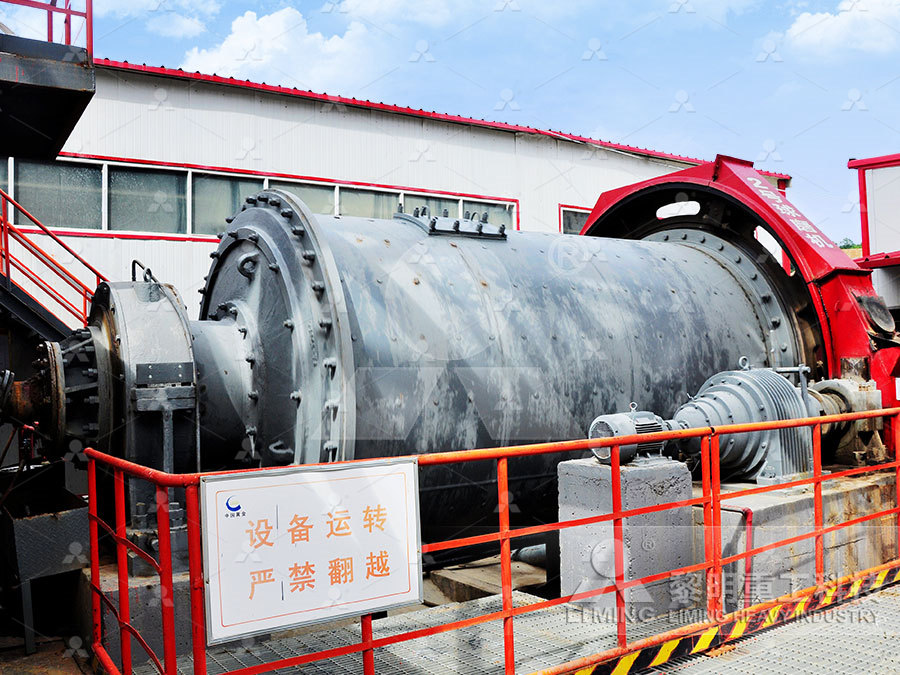

Barite HCH ultrafine grinding mill is especially suitable for ultra fine grinding With years’ accumulation of experience in RD, which is a new ultra fine pulverizing equipment designed The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and EnergyEfficient Advanced Ultrafine Grinding of ProQuestBall Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such ascement, silicate, new building material, refractory material, High Energy Saving Fluorite Graphite Barite Power Ball Mill Micro Powder Grinding Mill is suitable for the super fine grinding of all kinds of crisp materials whose Moh's hardness is below 7, such as calcium carbonate, barite, dolomite, calcite, Energy Saving 1500 Mesh Calcite Grinding Mill for Calcium

.jpg)

Energy efficient machine tools ScienceDirect

2020年1月1日 Fig 7 shows the share of fixed energy demand of individual components for different machine tools Two grinding machines, two lathes and two machining centres with different work spindle configuration were examined The hydraulic, cooling and lubrication systems in particular account for a high proportion of the overall energy demand2021年8月2日 Pure barite is colorless and transparent, generally white, light yellow, with glass luster Barite grinding mill Barite is mainly used in petroleum, chemical, paint, filler and other industrial sectors after barite grinding machine powder, of which 80 to 90% is used as a mud weighting agent in petroleum drillingBarite Ore Grinding MillCLIRIK MachineryBarite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powderBarite Ultrafine Vertical Roller MillBrief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been proved by thousands of customers that our ultra fine powder grinder has outstanding features, stable quality, easy operation, and maintenanceUltra Fine Grinding Mill SBM Ultrafine Powder Technology

.jpg)

Limestone Ultrafine Grinding Mill

Features: The limestone ultrafine grinding mill is a piece of energysaving and consumptionreducing equipment for processing limestone ultrafine powder Small footprint, strong complete set, wide application, simple operation, convenient maintenance, stable performance, highcost performance, it is an economical and practical ultrafine powder processing equipment2023年6月27日 This setup is a barite processing plant configured with a vibrating grizzly feeder, jaw crusher, log washer, spiral sand washer, vibrating screen, and belt conveyors The materials under the grizzly bar of the vibrating feeder go to 2 spiral sand washers through the material guide chute, the material above the grizzly bar feed to the jaw crusherWhat Is The Process Of Barite? Eastman Rock CrusherIt has comprehensive mechanical crushing properties such as rolling, grinding and impact, and it is widely used in talc,superfine pulverization of various nonmetallic minerals such as calcite, calcium carbonate, dolomite, potassium feldspar, bentonite, kaolin, graphite, carbon, etc, with Mohs hardness below 7 and humidity of 6%, it is truly energysaving, especially ultrafine Gypsum mills Hengtu Machinery1 High Efficiency: Under the same finished final size and the same motor power, the capacity of ultra fine grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30% 2 Energy Saving: compare with the comon stone powder grinding machine, the HGM minerals grinding machine can decrease about 20%~30% electrinic consumsultra fine grinding mill

.jpg)

Hot Sale Barite Ultra Fine Powder Mill Shanghai Clirik Machinery

Barite Ultra Fine Powder Mill is an ultrafine powder mill independently developed by us The grinding fineness can reach 3000 meshes and is suitable for more than 1000 minerals (Mohs hardness less than 7) It is widely used in the fields of chemicals, construction, coatings, plastics, etc2021年10月26日 HGM superfine powder grinding mill The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency The production capacity is 40% higher than that of jet mills and stirring mills, and the energy consumption is only 30% of that of jet mills Equipped with multihead cage type powder concentratorGraphite Grinding Machine Powder Mill Equipment2021年10月13日 Fluorite fine powder grinding mill is an industrial ore grinding machine, which can grind The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind nonmetallic ore powder of 1503000 mesh The fluorite fine powder grinding mill is stable, energysaving Fluorite Fine Powder Grinding Mill SBM Ultrafine Powder 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy EnergyEfficient Advanced Ultrafine Grinding of

Vertical Barite Bauxite Grinding Mill Energy Saving Grinding Machine

Hefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 Home2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder 2023年3月21日 The vertical mill adopts a more advanced analysis machine, which can classify higher ultrafine powder, Largescale energysaving ultrafine production using ultrafine vertical mills 2 Grinding roller Under the action of the pressure of the grinding roller, the material is crushed by extrusion, grinding and shearingThe advantages of ultrafine vertical mill in the processing and 2021年7月28日 2 Grinding stage: Small pieces of material that meet the conditions will evenly enter the grinding chamber of the dolomite grinding millThey enter the chamber through the feeding system quantitatively, and grind into powder in the mill cavity 3 Classification stage: the ground material will pass through the classifier and the system’s airflow for classificationDolomite Grinding Mill SBM Ultrafine Powder Technology

Grinding Mill Machine,Grinding Mill Plant,Powder Grinding Mill

Introduction of Ultra fine Vertical Mill CLUM Ultra fine Vertical Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types Working principle of Ultra fine Vertical Mill The grinding disc is driving by motor through reducer The material falls to grinding disc from the feed opening2024年4月17日 4 types of barite grinding mills The fineness of barite powder is one of the crucial factors to consider when selecting a barite milling machine Barite powder grinding is generally classified into three fineness levels: coarse powder processing (≤ 100 mesh), fine powder processing (120 mesh–325 mesh), and ultrafine powder processing (400 Quick Pick: Compare 4 Top Barite Grinding Mills for Your Needs2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine mill, large processing capacity, energysaving, and consumption reduction Ultra Fine Wet Stirring MillIllite Ore Industrial Grinding Mill Machine SBM Ultrafine The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY

Coconut Shell Powder Making Machine

Product features: stable operation, high efficiency, energysaving, safety and environmental protection, small footprint, small investment, intelligent marble, dolomite, barite, etc), eggshells, shells The coconut shell powder making 2019年8月26日 Barite magnetic separation A wet magnetic separator is usually used to select some ironbearing materials such as siderite, which are used as barite feedstock for baryte based pharmaceuticals with very low iron content Barite flotation process 1 Grinding fineness: Flotation of barite generally requires grinding fineness—200 is 85 ~ 90% 2Baryte Processing Equipment, Process Flow, Cases JXSC Machine2019年1月16日 Energy and time savings are highly important aspects of green manufacturing Ultrasonic vibrationassisted grinding (UVAG) is a highefficiency, lowenergyconsumption processing method for optical components made from hard and brittle materials This work presents an experimental investigation of the specific grinding energy and the subsurface Estimation of Energy and Time Savings in Optical Glass 2022年9月30日 2 HGM Ultrafine grinding mill for rCB HGM Ultrafine grinding mill is also named HGM micro powder grinding millIt can be used for pumice, activated carbon, limestone, calcite, marble, talc, barite, gypsum, dolomite, bentonite, mica, pyrophyllite, sepiolite, diatomite, graphite, alumite, fluorite, potassium feldspar , Phosphate rock, pigment and other more than 100 kinds Recovered Carbon Black rCB Processing Grinding Mill Machines

Crushing and Grinding Process JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as 2023年2月2日 Metal working process is one of the main activities in mechanical manufacturing industry; it is considered as a major consumer of energy and natural resources In material removal process, the selection of cutting parameters and cooling or cutting liquid is necessary to save energy and achieve energy efficiency as well as sustainability During the last two Optimization techniques for energy efficiency in machining Benefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the lifetime of its wearing Limestone Powder Grinding Mill MachineryThe bamboo powder making machine is an industrial ultrafine grinding mill independently developed and produced by SBM It can grind bamboo into bamboo powder of 1503000 mesh, and the fineness can be adjusted freely according to needs Bamboo powder has a wide range of uses and is a new type of energysaving and environmentallyfriendly raw Bamboo Powder Making Machine

.jpg)

What is barite ultrafine powder grinding mill?

2023年3月16日 Barite ultrafine powder grinding mill is a specialized equipment for grinding and processing barite into fine powder, which is also called barite ultrafine powder grinder or barite ultrafine mill This type of mill is capable of producing a wide range of particle sizes, from relatively coarse to very fine, with high efficiency and low energy consumption2020年7月1日 Two grinding machines, two To evaluate potential energy savings on machine tools, an over been used in the fi eld of conventional machine tools [42] In ultra(PDF) Energy efficient machine tools ResearchGateSBM provides reliable and energysaving technologies and solutions, and its products cover wet mills, coarse mills, crushers, powder surface coating machine, etc +17 [ protected] language >Shibang Industry SBM Ore Ultrafine Grinding Mill2021年10月11日 Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 1503000 mesh The industrial grinding mills independently Quartz Industrial Powder Grinder Machine SBM

.jpg)

Energy Saving Ball Mill Dongding Machinery

Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding proces 1 Bush bearing is replaced by rolling bearing, friction resistance being greatly lowered down,easy to start and Working Principle: 1 Crushed into materials smaller than 10mm by jaw crusher, lifted to the storage hopper by bucket elevator 2 Then the feeder is fed into the main machine cavity for grinding quantitatively, and the grinding roller installed on HCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra 2024年7月17日 FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export Base Based on high quality and perfect aftersales service, our products have been exported to more than 120 countries and regions FTM Machinery has become the first choice for over 2,000,000 customers Our customer service team is here to help you 24/7Types of Crushers: Choosing the Right One for Each StageWe are Bauxite Grinding Mill manufacturer provide Vertical Barite Bauxite Grinding Mill Energy Saving Grinding Machine Hefei Hengcheng Industrial Equipment Technology Co, Ltd 登录 免费注册Vertical Barite Bauxite Grinding Mill Energy Saving Grinding Machine

Energy consumption model and energy efficiency evaluation

2017年6月15日 Introduction Machine tools are the basic energy consumption devices in manufacturing, whose energy saving cannot be neglected (Liu, Wang, and Liu Citation 2013)The energy yearbook published by the US energy information administration in 2012, showed that machine tools electricity consumption occupied 75% of manufacturing electricity consumption, The limestone powder vertical grinding mill grinds materials by the principle of material layer grinding, with low energy consumption The power consumption of the grinding system is 20% to 30% lower than that of the ball mill, and the energy saving effect is more obvious as the moisture of the raw material increasesLimestone Powder Ultrafine Vertical Roller Mill Clirik Grinding 2021年8月3日 Kaolin ultrafine grinding mill is an industrial ultra fine stone powder making machine, Kaolin ultrafine grinding mill is an industrial ultra fine stone powder making machine, it can grind hard stones into fine powder +17 [ protected] energysaving, and environmental protection, long service life, etc More Kaolin Ultrafine Grinding Mill SBM Ultrafine Powder TechnologyThe crushed barite small pieces are sent to the silo by elevator and then evenly and quantitatively sent to the grinding chamber of the mill by the vibrating feeder for grinding Stage 3: Grading The powder classifier classifies the ground materials, and the unqualified powder is classified by the classifier and returned to the main machine for regrindingBarite Aggregate Processing JXSC Machine