Coal mill: model ZGM113G

《ZGM113G型中速辊式磨煤机使用和维护说明书[全文]》

2016年5月31日 zgm113g型中速辊式磨煤机使用和操作说明 星级: 18 页 zgm113g型中速辊式磨煤机使用和操作说明 星级: 24 页 zgm113g型中速辊式磨煤机使用和操作说明 星级: 18 2015年5月4日 通过改造, 彻底解决了传动盘密封环频繁泄漏等问题 , 不仅节约了维护费用, 提 高了磨煤机运行的安全性 , 减少 了维护工作量, 而且提 高 了现场文明生产水平。 改造经验 ZGM113G型中速辊式磨煤机传动盘密封系统改造,ZGM113G型 Study results show that the fineness R 90 of pulverized coal is within 4%~13% under various test conditions, and the uniform index n is within 066~117; the air flow rate at air ring area is ZGM113GII型中速磨煤机性能试验与运行特性 Power Equipment制粉系统为正压冷一次风机直吹式系统,各配有6台黎明重工设备总厂生产的zgm113gⅠ型中速磨,正常运行时五运一备。 2021年5月份,景德镇发电厂对#1机组磨煤机动态分离器改造,通过 ZGM113G型磨煤机动态分离器改造性能试验及分析百度文库

ZGM113G型煤磨机提产改造应用实践

2023年7月25日 ZGM113G型立式磨煤机存在磨内压差高、振动值偏大、吐渣量大、研磨效率低、产量无法满足水泥生产要求等问题,通过分析研判煤磨机实际运行工况和提产内外部影响因 An introduction is being presented to the performance,features and working principle as well as related auxiliaries of the ZGM113G medium speed coal mill,especially to its hydraulic pressure Application of ZGM113G Medium Speed Coal Mills对zgm113gⅡ型磨煤机进行特性试验及相关分析,找出了制粉系统运行不合理的原因,并指出了调整方向。ZGM113GII型中速磨煤机性能试验与运行特性 百度学术摘要 zgm113g型立式磨煤机存在磨内压差高、振动值偏大、吐渣量大、研磨效率低、产量无法满足水泥生产要求等问题,通过分析研判煤磨机实际运行工况和提产内外部影响因素,采取了加设热 ZGM113G型煤磨机提产改造应用实践【维普期刊官网

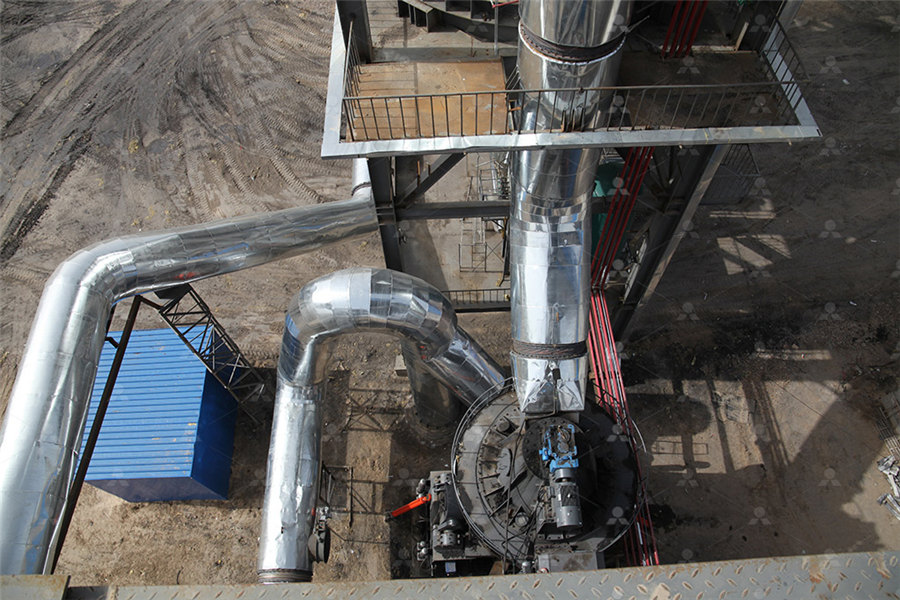

制粉项目-2023.11.17.jpg)

S型静态分离器在ZGM113G型磨煤机的应用及性能分析pdf

2019年5月20日 Based on its successful application in ZGM113G mediumspeed coal pulverizer, its superior performance is illustrated in reducing the pulverized coal fineness and pulverizing 2014年5月13日 每台锅炉配备 6台由黎明重工设备总厂生产的ZGM113G型中速 辊式磨煤机,每台磨煤机设计出力6657t/h,最大通风量101t/h,适宜磨制烟煤、部分贫煤和褐煤;正常 运 行 ZGM113G型中速辊式磨煤机传动盘密封系统改造 仁和软件A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Sectional view of MBF coal mill Download Scientific : pradeebhamit@gmail, npappa@rediffmail , vasanthi@annauniv Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill(PDF) Modeling and Control of Coal Mill Academia

sbm/sbm diagram for zgm113n coal millmd at main dihog/sbm

Coal Mill Type Zgm 95n Mill Chinagrinding roller coal mill type zgm 123g Coal Find the Right and the TopZGM95N 11E coal mill in the power plant,by analyzed,we found the main reason in grinder roll of coaletcof static rings for coal mills,a retrofit scheme was proposed on the structure of staticRetrofit for Nozzle Rings of ZGM113G Medium speed Coal coal mill model uml Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal Mill2020年8月14日 multisegment coal mill model using an evolutionary computation technique,” IEEE Transactions on Energy Conversion, vol 22, no 3, pp 718–727, 2007(PDF) Application of ModelBased Deep Learning Algorithm in Fault 2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples In order to obtain massive fault sample data effectively, based on the Modeling of Coal Mill System Used for Fault Simulation MDPI

A unified thermomechanical model for coal mill operation

2015年11月1日 From Fig 3, Fig 4, Fig 5, Fig 6 and Table 5, it can be seen that the measured outputs of the proposed model (mill differential pressure, current, outlet temperature) approach the onsite values very well and unmeasured outputs (pulverized fuel flow, mass accumulated inside the mill, outlet moisture content, moisture in accumulated coal inside the mill, mill 2024年9月4日 In this paper, seven different LSTM models are constructed based on different feature selection methods, including expert experience, correlation, and causality, and these models are used to analyze the realworld coal mill faults for early warning, and the results show that, i) compared with the feature selection methods based on expert experience and A Fault Early Warning Method for Coal Mills Based on Causality 2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns Therefore, an algorithm has been developed that enable online detection of abnormal conditions and malfunctions of an operating mill Based on calculated diagnostic signals and defined Detection of Malfunctions and Abnormal Working Conditions of a Coal MillVertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifier

Modeling of Coal Mill System Used for Fault

2020年4月7日 a coal mill model used for the precise control of outlet temperature of mixture and pulverized coal flow was developed and validated, in which th e action of classifier was included Reference [14]2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required particle size and temperature at the outlet channel throughout with better classifier performance are crucial indicators that characterize the coal mill performanceAn investigation of performance characteristics and energetic Modeling and Parameter Identification of Coal Mill 701 Fig 1 Sectional view of MBF coal mill It can be seen in the literature that modeling the pulverized coalair mixture temperature has not been advanced Almost all the models are based on heat balance where the coal mill body is considered as a lumpedModeling and Parameter Identification of Coal MillKey words: Coal mill classifier, Cut size, Nonswirling inlet, Particle image velocimetry, Impeller rotational speed 摘要: The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studiedThe flow field adjacent to two neighboring impeller blades was measured using the particle image velocimetry techniqueClassification performance of model coal mill classifiers with cip

.jpg)

[PDF] Modeling and Control of Coal Mill Semantic Scholar

2013年12月1日 Abstract The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation The 2023年9月15日 As the significant ancillary equipment of coalfired power plants, coal mills are the key to ensuring the steady operation of boilers In this study, a fault diagnosis model was proposed on the Fault Diagnosis of Coal Mills Based on a Dynamic Model2008 This paper presents a mathematical model for Tubeball mills which is developed based on the previous work The Particle Swarm Optimization (PSO) method is used to identify the unknown parameters of the coal mill model with the on Derivation and validation of a coal mill model for control2014年5月13日 摘要:内蒙古京隆发电有限责任公司zgm113g型中速辊式磨煤机随着运行时间的增加, 传动盘 碳精密封环部位频繁出现漏风、漏粉等现象,影响磨煤机的安全运行。 对磨煤机传动盘内、外部密封进行改造:在传动盘内部加装 金属密封护套,将传动盘外部的碳精密封环更换为橡胶密 ZGM113G型中速辊式磨煤机传动盘密封系统改造 仁和软件

.jpg)

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring mill2009年1月1日 For example, reject coal rate, which is controlled by the air flow near the mill throat, can be reduced The model can also be used to further aid in identifying and reducing high temperature or CFD Modeling of MPS Coal Mill for Improved Performance and Safety2007年8月20日 This paper presents a multisegment coal mill model that covers the whole milling process from mill startup to shutdown This multisegment mathematical model is derived through analysis of energy transferring, heat exchange, and mass flow balances The work presented in the paper focuses on modeling Etype vertical spindle coal mills that are widely used in coal Development of a Multisegment Coal Mill Model Using an mill This newlydeveloped coal mill model provides a valuable tool that can be used to improve the pulverizer design and optimize unit operation For example, reject coal rate, which isCFD Modeling of MPS Coal Mill for Improved Performance and

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying 2008年7月1日 This paper presents and compares modelbased and datadriven fault detection approaches for coal mill systems The first approach detects faults with an optimal unknown input observer developed (PDF) Observer and DataDrivenModelBased Fault2007年10月1日 Wei et al [11] proposed a multisegment coal mill model that covers six milling processes (startup, standard milling, shutdown, idle and transit periods) with parameters identified in each processDevelopment of a Multisegment Coal Mill Model Using an 2008 This paper presents a mathematical model for Tubeball mills which is developed based on the previous work The Particle Swarm Optimization (PSO) method is used to identify the unknown parameters of the coal mill model with the on Derivation and validation of a coal mill model for control

.jpg)

(PDF) A Modeling and Optimizing Method for Electricity Current

2022年3月25日 This paper presents a coal mill model that considers the effect of coal moisture on its accuracy This mathematical model is derived through the analysis of mass flow, heat exchange, and energy 2016年1月18日 Next, the paper estimates the coal outlet mass flow of the coal mill by using extended Kalman filter (EKF), and the result is compared with the coal flow instruction Finally, we take the estimation of coal outlet mass flow as the new controlled variable and use inferential predictive control method to solve the coal mill control problemsThe Inferential predictive control method of coal mill IEEE Download scientific diagram Effect of mill outlet temperature on the coal moisture content from publication: An investigation of performance characteristics and energetic efficiency of vertical Effect of mill outlet temperature on the coal moisture contentAbstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal Mill

A Wear Condition Monitoring Model of Coal Mill Grinding

Download Citation On Oct 14, 2020, Yanping Li and others published A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM Find, read and cite all the research you need on 2014年5月14日 Abstract:Because the actual using coal type deviated from the designed one greatly, six coal mills should be put into operation when the unit load was above 500 MW in Inner Mongolia Jinglong Power Generation 600MW机组磨煤机增速改造及性能分析 仁和软件702 Journal of Power Electronics, Vol 9, No 5, September 2009 Fig 2 Mass balance model of coal mill Fig 3 Heat balance model of coal mill pf cc pf dM kM W dt =− (2)Modeling and Parameter Identification of Coal Mill ResearchGate2016年1月25日 I just finished designing an HO scale model railroad layout This layout is based on the steel mill and coal mine operations of the Union Railroad in Pittsburgh Pennsylvania The layout is 140" by 80" or about 115 ft by 65 feet Or if you prefer metric about 35 meters by 2 meters It's a very small table layoutModular HO Steel Mill Coal Mine layout Model Train Forum

Classification performance of model coal mill classifiers with

2019年12月1日 The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studiedReliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldReliable Coal Pulverizers and Mills » Babcock WilcoxTo mitigate the effects of the decreased output of a ZGM113 mediumspeed coal mill on the unit operation in a coalfired power plant, the flow field of the mill was optimized through simulation and analysis, and the inner structure of the mill was retrofitted Results show that after retrofitting, the inner flow field of the mill can be optimized in general, while the performance of the mill ZGM113型中速磨煤机流场优化改造 Power Equipment2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate

INVESTIGATION ON CLASSIFICATION EFFICIENCY FOR COAL

inside the coal mill was solved by the realizable k ε turbulence model (RKE) with a detailed 3D classifier geometry meanwhile the discrete phase model was used to solve the coal particles flow The steepest classifier blade angle of 40 o achieved the highest quality of classification where 6170% of the coal particles are less than 75μm2013年8月1日 Development and validation of coal mill model for improved coal mill control is presented and the parameters required to validate the model is estimated using Genetic Algorithm Coal mills are used to grind and dry the raw coal containing moisture and to transport the pulverized coal air mixture to the boiler Poor dynamic performance of coal mill causes Modeling and outlet temperature control of coal mill using Model