300,000 dry powder limestone production line finished product warehouse

active lime production line CHAENG

CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging "turnkey” service Active lime production line Cement Grinding Station Cement production line Chaeng HomeChaeng (Great Wall Machinery) can undertake the EPC 2001500 t d active lime production line, including the reach report, civil engineering, designing equipment, installation and debuggingActive Lime Production Line Great WallCHAENG is a cement industry equipment manufacturer with more than 60 years of experience, can provide not only slag grinding equipment, but also complete turnkey solutions for grinding slag grinding plant CHAENG

.jpg)

active lime production line equipmentChina Pengfei Group Co,Ltd

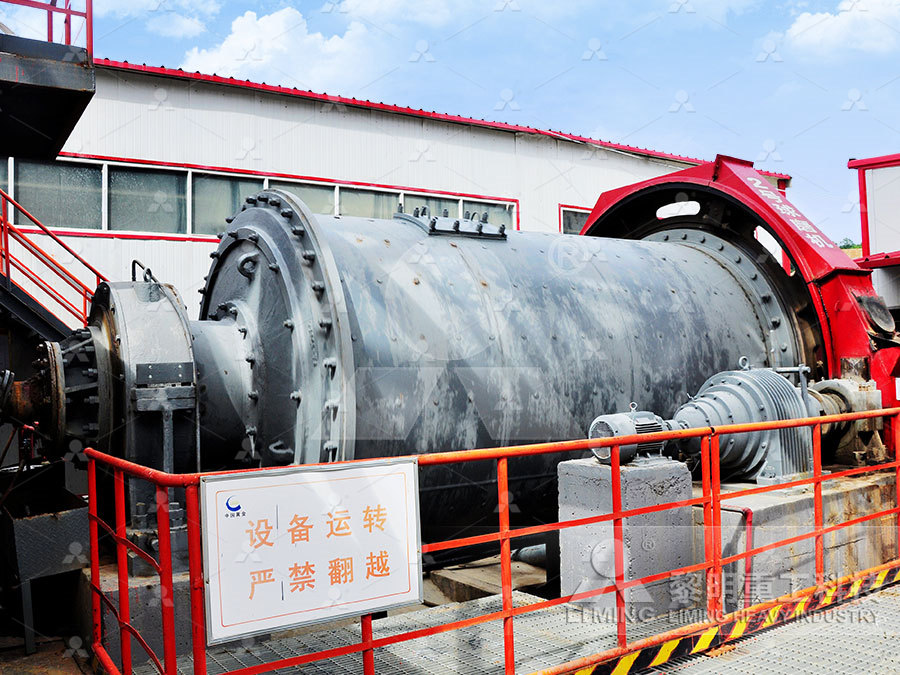

Description:We, Jiangsu Pengfei Group Co, Ltd supply complete equipments for active lime production line with capacity below 1200 ton per day The active lime is widely used in steel After ultrafine grinding, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other products Materials: Calcium limestone grinding plant CHAENGThe company's limestone powder production line uses Liming Heavy Industry's patented product LM vertical roller mill The entire production line has a reasonable process layout, stable Limestone powder production lineLIMING HEAVY INDUSTRY CO, We, Jiangsu Pengfei Group Co, Ltd supply complete equipments for active lime production line with capacity below 1200 ton per day The active lime is widely used in steel production, 600 tons of active lime production line equipment

.jpg)

800TPH Limestone CrushingSBM Industrial Technology Group

The production line was next to the cement plant The whole layout was compact including 6 areasbuffer hopper area, crushing plant, screening plant, product warehouse, raw material DSJ Series Drying Hammer Mills; SMTR series roller screening crusher; after coarse crushing of semifinished products by belt conveyor to counterattack crusher further broken, 700800 700800 tons per hour limestone crushed stone production line 2024年1月23日 If a powder form is needed, limestone particles are transported to a limestone grinding mill via a conveyor belt system for the final fine grinding This step aims to obtain the Limestone crushing and screening production line introduction2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine

600 tons of active lime production line equipment

Finished lime is conveyed to bucket elevator through chain bucket machine by cooler,then into top sieving grain silo by elevator, qualified part ≧5mm conveying to finished product bin by belt conveyer, powder≦5mm conveying to powder binElectric discharge valve is provided in finished product warehouse and powder binThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERYFor small mineral organic fertilizer production line; The cost of a small mineral organic fertilizer production line is between US$50,000 and US$300,000 Such production lines usually include basic processing equipment such as crushers, mixers, granulators, dryers, and packaging machines For medium to large mineral organic fertilizer Mineral Organic Fertilizer Production Line $50,000$300,000The finished product mixed in the dry powder mixer is quickly discharged by pneumatic quick opening and put into the finished product silo for buffering and storage There is a flexible connection between the finished product silo and the packaging machine, and the packaging machine completes the measurement and packagingWhat Is Dry Mix Mortar Plant,Dry Mortar Mixing Machine FAQS

Cement Production Line CHAENG

2 Meng Electric Group: 1,500,000 T/A cement plant,The production line using new dry process cement technology, can reduce power consumption by 20% to 30%, greatly reduce production costs, improve the overall efficiency of enterprises 3 2022年5月12日 Slag is widely used in the construction market after being processed by the micropowder production line It can be used to produce concrete and can be used as a production material for cement +17Slag grinding mill micro powder production line SBM Ultrafine Powder 2024年8月9日 Collection: Fine limestone powder is collected in a cyclone or bag filter, while any remaining dust is captured by a dust collector Output: The finished powder is discharged and ready for use Key Considerations Fineness Requirements: Depending on the application, the desired fineness of limestone powder will dictate the choice of the grinder6 Types Of Limestone Dry Powder Grinder Machines2023年12月6日 Recently, the HGM100 ultrafine mill production line of a customer in Binzhou, Shandong, China has been installed and officially put into production The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, the grade of the finished product is quite high, and the actual Limestone ultrafine grinding production line customer site

160T/H Pet Food Production Line Price RICHI Machinery

Construction content: production workshop, finished product warehouse, raw material warehouse; Number of employees work system: The pet food line has a labor quota of 20 people, all of whom are nearby residents They do not have room and board in the factory They work 8 hours a day and 300 days a year2022年4月20日 Classification: Limestone is processed into finished products of various specifications through impact crushing according to user requirementsThe particle shape is good and can be classified by vibrating Limestone crushing and grinding production lineComplete Set of Process Technology Gypsum Powder Production Line, The milled finished products are sent to the finished product warehouse for storage; Zk Complete Active Lime Production Line for Limestone Production Line Complete Set of Process Technology Gypsum Powder 2023年2月15日 Advantages of dry wet production line 1 The finished sand and gravel aggregate has good appearance and beautiful particle shapes; 2 During the production process, the soil and stone powder are taken away by the The Differences between Dry Sand Production Line

slag grinding plant CHAENG

Production Line Limestone Grinding Line Materials: Calcium carbonate, limestone belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials: Steel slag Main 300,000: Designed production (t/h) 150: 90: 45: Raw materials input amount (t/h) 188: 125: Packaging and storage: The finished granular limestone fertilizer (soluble in water) are packaged and stored in a dry and cool place The limestone fertilizer production line has the character of less investment, quick results and good economic benefits The whole equipment process is compact, scientific and advancedLimestone Fertilizer Production LineLimestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production LineNickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials: Steel slag Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, Cement Grinding Plant CHAENG

Limestone Grinding Mill That You Need To Know Dry Mortar

2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Packaging and storage: The finished granular limestone fertilizer (soluble in water) are packaged and stored in a dry and cool place The limestone fertilizer production line has the character of less investment, quick results and good economic benefits The whole equipment process is compact, scientific and advancedLimestone Fertilizer Production LineThe processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20315mm, 18%; 1020 mm, 25%; 510 mm, 17%; 05 mm, 25% Considering the requirements of rock characteristics and product proportion, choose a twostage crushing scheme, which is jaw crusher + impact crusher combination Configuration and design of 1000tph limestone aggregate production 2020年4月30日 Looking at the design of the proposed ceramic product warehouse layout, the percentage of total travel distance savings in the finished product warehouse is 3776% Discover the world's research Finished Product Warehouse Layout Design Using

Dry Mortar Production Line MUHU (China) Co, Ltd

Automated Dry Mixed Mortar Production Line Introduction MUHU has produced dry mortar products for over 30 years, consisting of masonry mortar, plastering mortar, thermal insulation mortar, highstrength nonshrink grout, selfleveling Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle InventoryCORINMACHow does a twoshaft blade mixer work dry mortar production line compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc, and enjoys a good reputation in the marketAfter the China manufacturer dry powder mortar production line Tile Adhesive Mixing Machine mixer Dry mortar production line manufacturer CORINMACFeatures of tower dry mortar production line Tower dry mixed mortar production line is also known as the firstorder mortar production line All mortar raw materials are stored in the top, from top to bottom after weighing, mixing, finished product storage and packagingDry Mortar Production Line AIMIX Group

Powder Mixing Production Line Siehe Group Co,Ltd

Project Background In 2022, SIEHE Group supplied a 3000L Horizontal Plough Mixer to a customer in Mexico After several years of material production, the customer expressed high satisfaction with the equipment's quality and subsequently ordered two sets of powder mixing production lines the horizontal plough mixer chosen for the mixing equipment for Picex Dry mix mortar production line is a dryscreened aggregate (such as sand) , Gelling materials (such as cement, coal ash), chemical additives, etc through measurement control, reasonable proportion, mixing homogeneity, mechanized production, product packaging or bulk storage and transportation to the site, as long as the work is done by adding a certain proportion of water The Performance of the Dry Mix Mortar Production LineFIER semiautomatic Dry Mixed Mortar production line Equipped with screw hoister, finished product warehouse, and automatic quantitative packing machine, the automatic measuring and packing of putty powder is realized, It saves the packing cost and manpower for youYour NO1 Dry Mortar Production Line ManufacturerFAIR2007年12月21日 When the choice of the raw material falls on marly limestone composed of 6520 wt% clays, the production process is obviously characterized by different temperatures and times and the finished Lime and Limestone: Chemistry and Technology, Production and

13 Warehouse Types: Definitions, Functions Examples

2024年4月29日 The 2 basic types of warehouse storage are: Production warehouses; Distribution warehouses; Production warehouses (also called “manufacturing warehouses”) are used by factories and other producers for storing raw materials, workinprogress (WIP) goods, and finished goods that are ready for shippingProduction Line Limestone Grinding Line Materials: Calcium carbonate, limestone, barite, heavy calcium carbonate, etc Capacity: 300,0001,000,000 t/a Equipment: GRMR vertical roller mill belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials active lime production line CHAENGOur company's dolomite crushing production line has the characteristics of customers with a complete set of solutions for sand and gravel aggregate production lines with an annual output of 300,0008,000,000 tons and they are discharged through the powder discharge pipe to be the finished product The unqualified products Dolomite Crushing Production Line CM Mining MachineryProduction Line Limestone Grinding Line Materials: Calcium carbonate, limestone, and the materials that meet the fineness requirements enter the finished product warehouse through the powder separator Henbei Xinji 600,000 tons/year GGBFS production lines, Xuchang 300,000 tons/year EPC turnkey GGBFS production line, Vertical Roller Mills

Dry Process Of Cement Production 3005000TPD AGICO CEMENT

At present, cement production mainly uses a new dry cement production method, which is mainly reflected in the raw material has been preheated by the high temperature of the preheater and the high temperature of the exhaust gas before entering the kiln, and nearly 90% of the calcium carbonate in the raw material is decomposed into calcium oxide in the decomposition furnaceLimestone is the main raw material for the manufacture of cement, lime and calcium carbide, and is an indispensable flux limestone in the metallurgical industry After ultrafine grinding, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other productslimestone grinding plant CHAENGProcess Qualified limestone deposited in the hopper, through hoist and transport into the top of siloPreheater top bin, is made up of 2 level control the feeding amount, and then through the discharging tube of the limestone and uniformly distributed in the preheater each roomLimestone is heated from 1150°C to 900 ° C by kiln flue gas in preheater, about 30% decomposition, then 600 tons of active lime production line equipmentProduction Line Limestone Grinding Line Materials: Calcium Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Bulk machine is a kind of packing equipment which is used in the transportation of dry powder mortar, cement, clinker Bulk machine CHAENG

How to organise a raw material warehouse Mecalux

2022年11月15日 A raw material warehouse plays a key role in the manufacturing process: it stores materials until they are needed on the production lines Managing goods that are difficult to handle — eg, plastics, abrasive materials and liquid components — makes stages such as storage and order picking more complex2021年10月22日 The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20315mm, 18%; 1020 mm, 25%; 510 mm, 17%; 05 mm, 25% Considering the requirements of rock characteristics and product proportion, choose a twostage crushing scheme, which is jaw crusher + impact crusher combination Configuration and design of 1000tph limestone aggregate production 2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of Evaluation of the Efficiency of Limestone Powder in Concrete and