How to collect and handle the dust generated by stone powder crushing

Guidance for Controlling Silica Dust from Stone Crushing with

Reductions in respirable dust in stone crusher mills can be accomplished through engineering controls including process enclosures or containment, dust collection or local exhaust 2007年2月1日 The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust Remedies to this Improved dust capture methods for crushing plant ScienceDirect2022年5月5日 The most efficient method of controlling dust generated in a crushing plant is the use of dust suppression systems within a methodology and understanding of your process, mechanical stressors, enclosures, weather How do you control dust in a crushing plant?This paper presents the CFD modeling of airflow inside of a mill building to demonstrate airflow patterns that will affect the generation and subsequent dispersion of dust due to crushing, Improved dust capture methods for crushing plant Academia

.jpg)

Environmental Guidelines for Stone Crushing Units py

Stone crushing sector is an important industrial sector engaged in producing crushed stone of various sizes (40 mm20 mm10 mm crushed sand, stone dust etc) depending upon the 2010年9月4日 Stone dust produced from stone crushing is the main concern to establish it as an appropriate alternative of sand and to minimize pressure on the sand as natural resources HugeMinimizing the stone dust through a sustainable way: a 2012年1月1日 Scope of this paper is to make an open call for a design, fabricate and conduct an insitu performance test, of an INDIGENOUS design of a dust extraction system The sole aim is to create(PDF) Stone Crushers and Dust Problem ResearchGateMention of any company or product does not constitute endorsement by the National Institute for Occupational Safety and Health (NIOSH) In addition, citations to Web sites external to NIOSHDust Control Handbook for Industrial Minerals Mining and

Minimizing the stone dust through a sustainable way: a case study

Stone dust produced from stone crushing is the main concern to establish it as an appropriate alternative of sand and to minimize pressure on the sand as natural resources Huge amounts 2024年4月10日 Ongoing research examines the potential health effects of distinct dust types generated in granite quarries Understanding the particulate size distribution, chemical Critical assessment of the effectiveness of different dust control 2023年6月3日 Environmental pollution study was undertaken in the stone crushers of Chitrakoot area, UP, to asses the dust exposure risk in stone crushersEnvironmental Impact Assessment of a typical Stone Crushing Plant2024年3月13日 Afterfilters: Some dust collectors can be equipped with afterfilters to collect ultrafine dust, vapors, or gasphase emissions A HEPA afterfilter is used when very clean conditions must be maintained for production Dust Collection Basics for Powders Bulk Solids

How do you control dust in a crushing plant?

2022年5月5日 Silica dust from stone crushing can be a major factor in a person developing silicosis, leading professionals to catalog it as an occupational lung disease Complications from developing silicosis can also cause patients to > Knowing the ignition sensitivity of the powder and ensuring that no potential source of ignition of sufficient energy to ignite the dust cloud exists in the process Protection > Explosion venting > Explosion suppression > Explosion containment The overall strategy for assessing the dust explosion hazards of a powder is summarized in Figure 1SAFETY GUIDE – A Strategic Guide to Characterization and 2019年11月11日 The aim of this study was to assess the effects of stone crushing dust pollution on three commonly cultivated fruit plant species (Vitis vinifera L, Morus alba L, and Prunus armeniaca L) and on the health of workers working at crushing plants The trial was carried out on fruit plant species grown close to the stone crushing units located near the northwestern Dust exposure risk from stone crushing to workers and locally the lungs, thus increasing the importance for the control of respirable silica dust generated from stone crushing units Figure 1 Stone crushing operations create large quantities of respirable dust Workers exposed to respirable silica dust have an increased risk of developing lung diseases such as silicosis or tuberculosis Engineering ControlsGuidance for Controlling Silica Dust from Stone Crushing with

How to Control Dust in Crushing Plant 911Metallurgist

2020年11月8日 Preliminary to the design of exhaust ventilation for the Ray property, rafter dust samples collected from the old crushing plant were analyzed and sent to dust collector manufacturers, who determined the settling rate, The unit is designed to handle two—2in or four 1½in hoses continuously Jorge November 8, 2020; 12:29 pm;Crushing stone efficiently requires a welldesigned process and the right combination of crushing equipment and screeners By understanding the options available and their specific uses, operators can ensure that crushed stone meets project requirements while minimizing waste and improving sustainabilityThe Ultimate Guide on How to Crush Stone: Techniques and bulk dust, respirable dust, and total dust for each stone had comparable amounts of crystalline silica, suggesting that crystalline silica content in the bulk dust could be representative of that in respirable dust generated during grinding Granite generated more dust per unit volume of Characterization of the Emissions and Crystalline Silica Content of 2024年5月3日 Where to Buy Stone Dust (Including How Much to Buy) You can buy stone dust at most stone yards, quarries, and from some excavation companies Most of these places will deliver the product to your property for a fee You may also be able to buy bagged stone dust at your local home improvement store, possibly under an alternative nameStone Dust: What It Is, Uses, and Where to Buy It The Spruce

Ways To Reduce Dust Produced by Concrete Grinding

2020年11月9日 At the end of the day, it’s you or your employee who need to know how to handle the dust in order to keep everyone safe Efficient training and preparation are key to making sure everyone stays healthy It’s essential to 2023年12月16日 Coal and gas outburst is a dynamic disaster that poses a significant threat to coal mines Energy analysis is an effective tool for understanding the mechanisms behind such outburst The energy sources and dissipation during outbursts were explored using a multifunctional test system, and the energy transformation relationship was analyzed based on Energy Evolution and Coal Crushing Mechanisms Involved in Coal A: For crushing rocks or granite, you can use equipment such as jaw crushers, cone crushers, or impact crusher plant These machines are commonly used in various applications to break down hard rock into smaller pieces Q: How to crush rocks into powder A: To crush rocks into powder, you can use a crusher or mortar and pestleHow To Crush Rock 6 Ways For You Aimix Group Construction Steps to Collect Crusher Dust: Install a Dust Extraction System: Place collection hoods or vacuum ports at key points where dust is generated (eg, near crushers, screens, and conveyors) Connect these hoods or ports to a central dust collector (baghouse, cartridge collector, or cyclone) Optimize the System:How to collect crusher dust?

Designing an Effective Dust Collection System: Essential

Understanding dust types and properties is essential for designing an effective dust collection system Assessing workspace layout and airflow needs, selecting the right collector design, filter media, and implementing safety measures explosion protection are all key considerations when creating a customized system2012年6月1日 Contrary to common belief, an offtheshelf shop vacuum system is not adequate for graphite dust as the filtering system is generally not suited to collect the fine particles of graphite To be efficient, a portable vacuum system must be equipped with a HighEfficiency Particulate Air (HEPA) filter that satisfies certain governmental standards of efficiencyHow to Deal with Graphite Dust, Part 1 MoldMaking Technology2018年10月23日 Mark Strebel explains how a dust control strategy in a limestone mine is preventing fugitive dust emissions Only a short drive from author Mark Twain’s boyhood home in the small town of Hannibal, Missouri on the banks of the Mississippi River, Continental Cement has been in operation since 1903Dust control strategy in limestone mine prevents fugitive dust 2018年8月8日 A real time casting tutorial from The Edinburgh Casting Studio Learn top tips from our expert team Follow our casting team as they teach you how to mix andHand Casting Tutorial: Guide To Mixing And Pouring Stone Powder

(PDF) Fines and Dust generation and control in Rock

2012年11月24日 Fine materials resulting from blasting have varied utilization Sometimes fines are considered useful in further metallurgical and chemical processing, while at other times fines are rejected and Industrial dust collectors are system allowing to extract dust at one or several location, transport it with the air flow and collect it in a receiver, often equipped with a filtration system, before releasing clean air Those systems are critical to ensure both a safe working area and making sure the air released in the environment is cleanDust collector system design : an overview (design, operation tips Different dust types require different collection methods and filtration techniques Wood dust, for example, behaves differently than metal filings or chemical particles Ensure that your system is designed to handle the materials you Mastering Dust Control: Intro to Dust Collection Systems2023年2月13日 In this study, we systematically characterized the airborne dust generated from grinding engineered and natural stone products using a laboratory testing system designed and operated to collect representative respirable dust samples Four stone samples tested included two engineered stones consistin Characterization of the Emissions and Crystalline Silica Content of

Baghouse: What Is It? How Does It Work? Uses, Types

Beyond the cement production line, air filtration is also necessary for stone crushing, grinding operations, and fly ash processing to ensure comprehensive dust control throughout the entire process Chemical Industry The chemical 2024年1月6日 On downcut concrete saws, the slot generated by the blade is an escape path for the dust to bypass the collection pickup point of the vacuum unless the collection point is further back on the slot to capture all the lighter weight dust particles (respirable dust consists of light small particles, usually between 001 and 5 microns)Controlling Concrete Dust43 Silica dust control plan A silica dust control plan is a practical tool for a PCBU that is informed by a risk assessment It can help a PCBU identify all potential tasks that may result in exposure, or possible exposure, to silica dust and the control measures to How to manage and control the risks from working with engineered stone Although no process waste water is generated from stone crushing units, however, water is used for sprinkling, conveyed to settling tanks of appropriate size which is recycled and reused in process 50 Environmental Guidelines for Stone Crushing Units The stone crushing units should adopt following environmental guidelines toEnvironmental Guidelines for Stone Crushing Units py

Improved dust capture methods for crushing plant

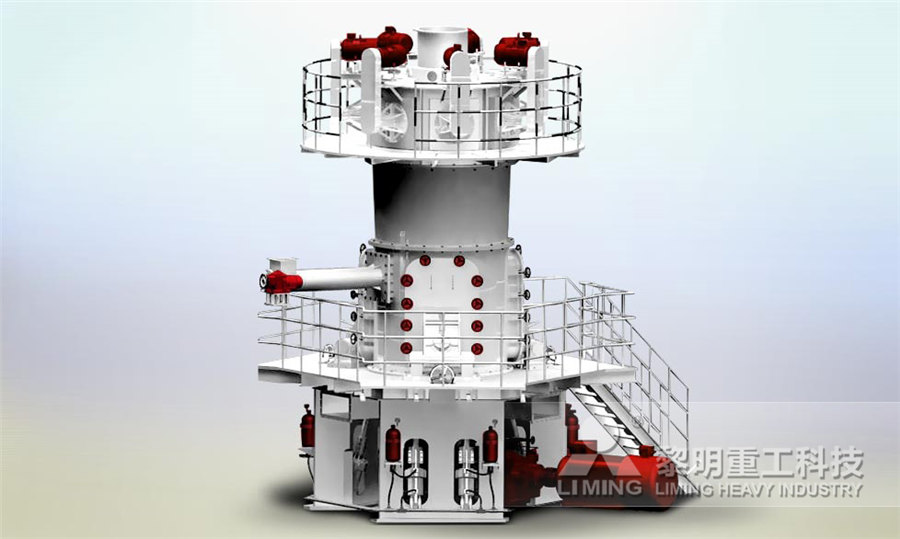

2007年2月1日 The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust Remedies to this problem include the retrofitting of shrouds, enclosures, local exhaust ventilation (LEV) systems and water suppression systems3 ways to reduce dust when grinding concrete Typically, concrete grinding is done using a heavyduty floor grinder with a diamond tool, unlike a handheld grinder, which typically weighs 500 pounds or more The diamond tools spin at high speed and the high pressure on the concrete causes it to break up into very small pieces – silica dustHow To Reduce Dust When Grinding Concrete? Concrete 2013年1月5日 A special dust sampling architecture was realised to collect the airborne particles in the crushing chamber near the source of dust generation during jaw operation The particles were collected using preassembled filters of Omega Specialty Instrument Co of 08 μm, and diameter of 25 mm using an isokinetic sampler model Digit ISO Zambelli at an aspiration rate The assessment of particulate matter emitted from stonecrushing 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing,

Dust Control Handbook for Industrial Minerals Mining and

CRUSHING, MILLING, AND SCREENING CONVEYING AND TRANSPORT BAGGING BULK LOADING CONTROLS FOR SECONDARY SOURCES OPERATOR BOOTHS, CONTROL ROOMS, AND ENCLOSED CABS HAUL ROADS Common dust control application illustrating nozzle positioning 62 Figure 22 Effect of 2023年9月22日 Crushing: Minimizing dust emissions during the crushing of raw materials Stacking and Reclaiming: Effective dust control for materials storage and retrieval Drying and Blending: Reducing emissions during the drying and Clearing the Air: Dust Collection Emission ControlIn the universe of landscaping and hardscaping, one material often gets overlooked, yet holds the key to many successful projects – stone dustThis byproduct of crushing stones is more than what it appears to be Also known Stone Dust: The Ultimate Guide to Using Quarry Dust 2023年11月6日 Even HEPA filters fail or become clogged, and some dust will always slip through It’s far better for it to be blasted outside than into the shop or another enclosed area Kits, diagrams, pipe and suction nozzles are available on the internet for “dust collection” and “dust collection network”5 Tips to Handle Lapidary Minerals Safely Rock Gem Magazine

.jpg)

Towards a theoretical understanding of dustiness

2019年9月20日 While there are plenty of experimental studies pertaining to the dust generation from and dustiness of powders, few of them aim at reaching a theoretical understanding of the phenomena In the present article, the literature on dustiness has been systematically reviewed with respect to its contribution to a better comprehension of the processes involved The 2016年11月7日 1 Evaluate your waste – to be able to handle the waste properly, the company first needs to determine whether the waste is hazardous or not, and whether handling of that particular waste is regulated by legislation For more information, see: Demystification of legal requirements in ISO 14001This step is often called classification or categorization of the waste7 Steps for Handling Waste According to ISO 14001 Advisera2022年10月11日 In this study, we systematically characterized the airborne dust generated from grinding engineered and natural stone products using a laboratory testing system designed and operated to collect Characterization of the Emissions and Crystalline Silica Content of 2022年12月26日 Collecting crusher dust can be done by using a dust collection system in the crushing plant This system is designed to capture and filter out dust particles from the air and then collect them in How to collect crusher dust? LinkedIn

Industrial Dust Collector MustHaves for Powder Applications

What kind of industrial dust collector do you need for bulk solids and powders? Learn about the musthaves when designing a dust collector for powderGoogle's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle Translate