Medium speed mill output 110TH

.jpg)

Speeds and Feeds Calculator Good Calculators

The Speeds and Feeds Calculator may be employed for calculations of estimated speeds and feeds (RPM and IPM) values on the basis of the parameters you have currently set based on Learn how to find the right CNC speed and feed rate for any material Use our free Milling Calculator to get accurate cutting data quicklyHow to find the right cutting data Milling Parameters StepcraftWith variablespeed mills, increasing mill speed directs ball impacts at the toe as both the lifter height falls and the lifter face angle increases with wear The impact point is usually tracked by Semiautogenous grinding (SAG) mill liner design and development2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of Modeling of a medium speed coal mill ScienceDirect

.jpg)

Advanced Simulation for SemiAutogenous Mill Systems: A

Modelling and simulation of semiautogenous (S AG) mills are valuable tools for helping to design control laws for a given application and subsequently to optimise its performance and process 2013年8月1日 The multiobjective optimization method we proposed shows that spindle speed of 1000 r/min, feed rate of 300 mm/min, depth of cut of 04 mm and width of cut of 15 mm are Multiobjective optimization of milling parameters ScienceDirect2023年4月11日 This work evaluates the tradeoffs between energy, heat generation and cutting quality during milling of medium carbon steel (EN8) alloy steel The effects of input process Modeling and multiobjective optimization of cutting parameters 30 % pigment loading and mixed grinding media size provides narrowest pigment particle size distribution of 128 nm with minimum energy consumption of 167 kWh/t Keywords: pigment Standardizing milling process parameters for the narrowest

.jpg)

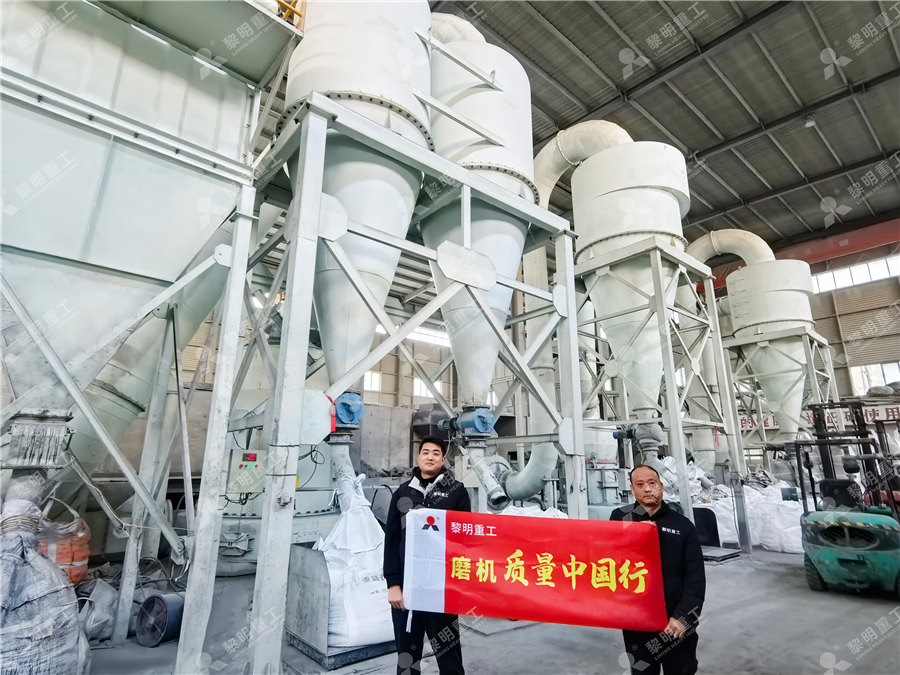

Three ring medium speed micro powder mill SBM

At present, the particle size of the finished fine powder of the three ring medium speed micro powder mill can be adjusted arbitrarily between 3253000 mesh, and the output can reach 0512 tons per hour2017年5月1日 Download Citation Modeling of a medium speed coal mill This paper presents a coal mill model that considers the effect of coal moisture on its accuracy This mathematical model is derived Modeling of a medium speed coal mill ResearchGateMTM Medium Speed Trapezium Mill MTM Series Trapezium Mill absorbs many advantages from various mills all over the world, such as trapezium working surface, flexible connection, roll linked pressure boost, etc Nowadays, ZENITH’s MTM mills have been widely used in construction, mining, chemical engineering, metallurgy, coal, electricity and steel industries, etcMTM Medium Speed Trapezium Mill Zenith Crusher2015年5月5日 In order to test the vibration characteristic of mediumspeed mill in the thermal power plants, the optimal placement of 12 candidate measuring points in X, Y, and Z directions on the mill was Sensor Placement Optimization of Vibration Test on MediumSpeed Mill

.jpg)

Vertical MillMedium Speed MillTCU Technologies Co LTD

The ZGM series medium speed roller coal mill products have a wide range of output adaptability and mature industrial applications At present, there are 8 models and a total of 21 output coal mill models, all of which have industrial application performance; We can also provide customized test grinding types for industrial testing of small specificationsHPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other componentsHP Series Medium Speed Bowl Mill2021年1月28日 The predictor variables (Wind Speed, Theoretical Power, Loss, xcom, ycom, T1) are returned as one array, following the required input shape of an LSTM layer, with a time step of 2weeks (2 x 7 Using Deep Learning to Forecast a Wind Turbines Power OutputThe mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves View in fulltext Similar The structure of MPS mediumspeed coal mill system

.jpg)

MPG Medium Speed Coal Mill北方重工 NHI

MPG medium speed coal mill is the product of upgrading MPS and MP medium speed coal mills In 1984, it cooperated with Germany Babcock Company for Liaoning Chaoyang Power Plant 2 × 200MW unit Augmentation Project provides 12 sets of MPS 212 medium speed coal mills, from which production and manufacture of MPS medium speed coal mills beganTaking hp1103 medium speed roller disc coal mill as the carrier, this paper mainly describes the common faults in the normal operation of this type of coal mill, and analyzes and judges each type ofSHPHGLXP VSHHGFRDOPLOO ResearchGate2015年1月15日 Download Citation Modeling and simulation of MPS medium speed coal mills To improve the safety and economy of coal mill operation, a dynamic mathematical model was established for MPS medium Modeling and simulation of MPS medium speed coal millsFinal grain size: 1 µm 40 µm Rotational speed: 1,000 rpm 2,200 rpm Output: 100 kg/h 4,000 kg/h microclassifier falls down to the mill where it is further ground The drive of the microseparator is independent and usually is made with a variable speed motor This allows a very Variable speed mill, Variable speed grinding mill DirectIndustry

ZGM型中速磨煤机提升出力改造与效果评估【维普期刊

摘要 为提高磨煤机出力,某发电公司对1台ZGM95N型中速磨煤机的主要碾磨部件如磨盘、磨辊等进行了改造,磨煤机由ZGM95N型改为ZGM95G型。 对磨煤机改造后的运行特性进行了试验研究,并对改造效果进行评估。基于磨煤单耗受多种展开更多 In order to increase the output of a ZGM95N type mediumspeed coal mill in a power Various factors affecting the output capacity of MPS255 medium speed coal mill for boiler no3 in Yuanbaoshan Power Generation Co Ltd have been analysed It is believed that the main causes resulting in reduction of the output capacity for said coal mill are as follows: wornout of the grind rollers, grind tray, nozzle ring, and unreasonable structure of said ringRETROFIT OF NOZZLE RING FOR MPS255 MEDIUM SPEED COAL MILL2021年6月29日 The research focuses on the mill speed as Find, read and cite all the research you need on ResearchGate Home; medium ratio of Φ90 mm 3462%, Φ70 mm 2692%, Φ60 mm 2308%, Effects of Mill Speed and Air Classifier Speed on Performance of Medium speed mills are widely used in largescale thermal power plants, which run at a setting speed of 50∼300 r/min, owing to their efficiency The schematic of a medium speed coal mill is Schematic of medium speed coal mill [5] ResearchGate

.jpg)

MV Drives, August 2012 ABB drives in mining Medium voltage

2012年9月19日 speed of the mill is tuned for optimal grinding and maximum throughput Mill can be operated at partial load; no process stop required VSDs adjust the speed according to charge volume Less wear and higher reliability Directonline start of the mill stresses the mechanical equipment, shortening its lifetime VSDs help optimize the mill speed to2011年8月1日 13112 Mediumspeed mill Mediumspeed mills are smaller than lowspeed units and are generally of the vertical spindle construction The speed of the grinding section of these mills is usually 75–225 rpm They operate on the principles of crushing and attrition Pulverization takes place between two surfaces, one rolling on top of the otherMill Speed an overview ScienceDirect TopicsLow Speed Medium Speed High Speed 17 to 20 Rev/min 30 to 100 Rev/min 500 to 1000 Rev/min Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill 13 BOWL Mill output at raw coal moisture and at Coal HGI 100110 31 Fineness Requirement 32 Duocast Roll Pulverizer Plant OM Aspects2018年3月15日 A grey box model was established for mediumspeed coal mill by combining the mechanism analysis method with data identification algorithm, which has higher accuracy and stronger robustness and Fault Diagnosis of a Mediumspeed Coal Mill Based on

Highspeed multilevel mill Lavaris

The mill is driven by two electric motors with a maximum output of 75 kW and a maximum speed of 34,000 RPM for each motor Easy service and maintenance Tworotor mill for small and mediumsized services, production up to 300 kg/hourFind your highspeed mill easily amongst the 75 products from the leading brands (Guidetti, Fritsch GmbH, Rotational speed: 300 rpm 3,000 rpm Output: Rotor mills are used for highspeed size reduction of soft to mediumhard as well as temperaturesensitive or fibrous materialsHighspeed mill, Highspeed grinding mill All DirectIndustry2015年2月1日 Wei and Wang established a simple model for the mill Genetic algorithm was used to optimize the parameters of the model, and the multistage modelling method was proposed to match the conditions during start up and shut down [1]Shin and Li presented a model with two particle sizes and pressure drop dynamics [2]However, the effect of coal Modelling and control of pulverizing system considering coal MTM MediumSpeed Grinding Mill Features Upgraded Structure The innovative change of the spring connection structure not only reduces shock of large materials on the aixs and bearing, but also enhances crushing strength of rollers Energysaving Production Its electricity consumption is lower than that of ball mill of the same level by over 60%MTM MediumSpeed Grinding Mill Zenith Crusher

Medium Speed Mill Crusher Mills, Cone Crusher, Jaw Crushers

Medium speed trapezium grinder mill's output final size is between 30 mesh and 400 mesh, capacity: 2122 tons per hour, raw materials: barite, limestone, The structure of the MPS mediumspeed coal mill is shown in Figure 1 [1] Then the deviation between the model output and the actual value is computed by the designed distance measuring Schematic diagram of the working principle of MPS medium speed Generally, the outlet temperature of the mediumspeed coal mill is controlled at 100 to 120 degrees Celsius The material processed by the mediumspeed mill barrel is particles of various sizes and hardnesses These materials move inside the mediumspeed mill, constantly causing friction, scouring and impact on various parts of the mediumspeed The cylinder of the mediumspeed coal mill is lined with wear 210 MPSHPⅡ medium speed pulverizer can start without load 3 Equipment appearance The outline of MPSHPⅡ medium speed pulverizer is shown in Figure 203 4 Selection method The MPSHPⅡ medium speed pulverizer is selected by computer At the same time, the mill model can be selected by calculating different output coefficientsMPSHPⅡ type Mediumspeed coal millpower plant equipment

.jpg)

Output Voltage Characteristics of HVDC Electric Field Mill Sensor

licenses/bync/30/) which permits unrestricted noncommercial use, distribution, and reproduction in any medium, provided the original work is properly cited Output Voltage Characteristics of HVDC Electric Field Mill Sensor for Different Speed Variables of Rotating Electrode Young Sun Kim* and Jae Jun Park†milling capacity, milling efficiency, particle size output, and electrical energy consumptions The result of the evaluation showed that 28 m/s results in a “medium” corn grits collected at the grits outlet “Coarse” milled corn was observed at the operating speed of Design, Fabrication, and Performance Evaluation of a Hammer Mill The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills1310 The power of motor for HP bowl mill is smaller than that of other medium speed pulverizers 1311 The ventilation resistance of HP coal mill is smaller than that of other medium speed pulverizers, and the air pressure of primary air fan is smaller, which can reduce the investment cost of fan 14 Working principleHP Bowl type millspower plant equipment

.jpg)

Ball Mill Success: A StepbyStep Guide to Choosing the Right

2024年8月8日 Consider its hardness, abrasiveness, and chemical properties The desired characteristics of the final product, such as particle size, shape, and purity, must also be clearly defined Additionally, evaluate the milling conditions, including the type of mill, speed, duration, and whether the process is wet or dryModeling of a medium speed coal mill Yaokui Gaoa, Deliang Zengb,⁎,JizhenLiub a Key Laboratory of Measurement Control New Technology and System for Industrial Process, North China Electric Power University, Changping District, Beijing, China b State Key Laboratory of Alternate Electrical Power System with Renewable Energy Sources, North China Modeling of a medium speed coal mill دانشیاری2019年6月14日 本节课将会分为两个部分,总共四个小节,部分我们主要学习GPIO的输出,第二部分主要学习GPIO的输入,另外在第二部分也会讲一些C语言的知识。因为这个库函数里面用了大量的结构体、指针、枚举等知识。本节课部分总共有三个程序,个是LED闪烁,第二个是LED流水灯,第三个是蜂鸣器 STM32的GPIO配置不同输出速度会有什么影响? CSDN博客steam output and eventually power generation This paper tries to give the pulveriser mill specifications, functional, operational details and performance analysis at different operating loadsPulveriser Mill Performance Analysis Optimisation in Super

.jpg)

Sensor Placement Optimization of Vibration Test on Medium‐Speed Mill

MediumSpeed Mill LihuaZhu, 1,2 JunDai, 1 andGuoliangBai 1 School of Civil Engineering, Xi an University of Architecture and Technology, Xi an , China Department of Civil, Structural and Environmental Engineering, University at Bua lo, State University of New York, Bua lo,NY ,U SADownload scientific diagram Spring vibrationisolated foundation of mediumspeed mill from publication: Sensor Placement Optimization of Vibration Test on MediumSpeed Mill Condition Spring vibrationisolated foundation of mediumspeed mill