Disc feeder specifications

Hoppmann Model Flexible Disc Centrifugal Feeder

Feeder Description Specifications Overview of the FT40 and FT50 Feeders Thank you for purchasing a Hoppmann Centrifugal Feeder Hoppmann feeders are easy to use, easy to Benchmark offers a complete line of Disk Feeders for highspeed automatic loading of rigid products with consistent thickness These feeders are ideal for restaurant packs or individual DISk FEEDER BenchmarkCurrently, we have formed a complete series with eight models and over 30 specifications ranging from φ1600mm to 3600mm According to different requirements and scenarios, our disk feeders come in various series: PDX Disk Feeder Material Feeding Equipment Zhongding2023年5月24日 Continuous feeding of materials that are not uniform in size and shape Less drive power; Airtight construction is feasible Applicable to large DISK FEEDER DS YOSHIKAWA, home of the Circle

.jpg)

Disc Feeder JXSC Machinery

Feeding capacity: 1888 t/h Max feeding size: ≤80mm Application: Commonly used in mining operations, construction, pharmaceutical manufacturing, gravel and aggregate processing industries; coal powder, cement, limestone, shale, Shibuya Hoppmann’s standard FT30 rigid disc centrifugal feeder is designed to feed a variety of products with its unique bowl design Product is metered into the bowl and brought out to the bowl rim where a series of qualifiers gently orient FT30 Rigid Disc Centrifugal Feeder Shibuya HoppmannHere are the specific differentiators between 2 Disc Feeder types: the DK and the DB Suited for materials with minimal dust concerns Offers intuitive operation and adjustment, providing Disc Feeder for Cement Plant cementmillequipment17 行 Round disc feeder is a kind of feeding equipment of volume measuring Round disc feeder is widely used in metallurgy, mine, building material, coal, generating plant etc to convey all kinds of material with no viscosityRound disc feederRound disc feederCMHE Cement

FEED DELIVERY CHAIN DISC FEED SYSTEM PigTek

FEED DELIVERY CHAIN DISC FEED SYSTEM Compact Drive Unit › Heavyduty durable stainless steel drive units capable of delivering up to 50 pounds (227 kg) per minute › Builtin Vibratory Feeder JXSC’s Vibrating Feeder is an instrument that uses vibration to “feed” material to a process or machine Our vibratory feeders use vibration and gravity to move material: Gravity determines the direction, either down or Vibratory Feeder Mineral Automatic Feed JXSC Disk Feeder Application fields: cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal dressings, and glass ceramics Processing ability: 14100t/h Power: 7515kw “40 years of senior Disk Feeder Hongxing Mining MachineryYoshikawa Corporation Circle Feeders Circle Feeders handle powder and granular materials, and use mass flow technology to prevent segregation and bridging Yoshikawa#39;s broad line of products range from ultralow rate DISK FEEDER DS YOSHIKAWA, home of the Circle

Production Machinery – Aquaculture Feeder – Specifications

Production Machinery – Aquaculture Feeder – Specifications 1 Scope This standard specifies the fabrication and performance requirements for aquaculture feeder 2 Normative References The following documents are referred to in the text in such a way that some or all of Disctype feeder PNS/BAFS PABES 287:2019 3Our 150 series feeder helps bridge the gap between the 100 and 200 Series feeders Like our entire disc feeder family, versatility is the key to its performance The design offers a 150mm (6”) in diameter feeding disc The base feeder design is sized to feed low rate feeding applications 06 to 500lb/hr (03226 kg/hr)150 Series Disc Feeder, 150mm (6”) Diameter Feeding Disc MahrShibuya Hoppmann’s standard FT30 rigid disc centrifugal feeder is designed to feed a variety of products with its unique bowl design Product is metered into the bowl and brought out to the bowl rim where a series of qualifiers gently orient the part for transfer to various downstream inline devices Product Specifications ANSIFT30 Rigid Disc Centrifugal Feeder Shibuya HoppmannFig 1 • FEEDER AT REST Feeder trough length is determined by the material’s static angle of repose and through slope The feeder trough must be of sufficient enough length to assure complete material shutoff when the feeder is at rest Fig 2 • FEEDER OPERATION The dynamic angle of repose is the angle the material seeksFABRICATED EQUIPMENT VIBRATORY FEEDERS

Fish feeders Aquaculture ID

The Disc Feeders are easy to clean and need to be cleaned every morning before administering the feed for the next day This prevents the formation of molds Ideally the disc feeders are attached to a control unit, allowing individual adjustment of each feeder To the Aquaculture ID disc feeder control unit up to 20 feeders can be attachedOur 100 series feeders are our most popular feeder which offers the most versatility of all our feeders The design offers a 100mm (4”) in diameter feeding disc The base feeder design is sized to feed low rate feeding applications 01 to 200lb/hr (0005 to 90kg/hr) All rates can vary based upon the density, flowability, and size of the 100 Series Feeder Orbetron CorporateA physical prototype of a mechanized slotted rotary disc feeder was constructed and the behavior was studied experimentally by varying the speed the rotary disk 8 mm Diameter of the fixed disk Thickness of the fixed disk Number of slots 28 cm 12 mm 16 AC motor specification 1 phase , t1400 rpm ,1/4 HP Gear box 1:70 DC motor 10 Design and Performance Analysis of a Slotted Rotary Disk FeederDisk feeder manufacturers China JXSC who sells mineral feeder equipment , the feeding size: and the material is piled up on the disc without the wall of the receiving cylinder by its own weight Specification of Disc Feeder Model: Disk Feeder For Sale Mineral Feeder Manufacturers

.jpg)

PUREFEED DP4 Disc Feeder from Schenck AccuRate, Inc

Designed specifically for pharmaceutical processes, the PureFeed® DP4 is a highly innovative gravimetric feeder that can accurately meter dry pharmaceutical, nutraceutical, and even cosmetic powders at feed rates as low as 20 grams DiscSpreader ® Optimum material Request technical specifications Discover our Technology Center We test your material! Visit our TechCenter Book an appointment Products Windsifting Conveying Dosing Spreading DiscSpreader WesteriaA single Lfeeder can weigh and feed all kind of power , pellets and liquids, simply by changing feeders Compliance with HACCP, GMP Control accuracy : ±051% According to the results in our laboratory testing, we can propose the optimum system for a particular application and give the customer its specificationsLfeeder Yamato Scale Co, Ltd General Weighing Scale manufacturerEach disc is equipped with a scraper for cleaning it at each rotation and thereby prevent clogging atmos designs your screens on demand from many standards depending on the application and according to your needs We recommend the width and useful length of screening, but above all we adapt our equipment to your onsite constraintsATMOS Handling » Wobblers / Disc screens

DISk FEEDER Benchmark

DISk FEEDER PRODUCT HANDLING PrH PERFORMANCE, PACKAGED Benchmark offers a complete line of Disk Feeders ©2017 ProMach Inc ProMach reserves the right to change or discontinue specifications and designs shown in this brochure without notice or recourse Disk Feeder0917 CoNSTRUCTIoN Our rugged design and attention to detailSpecifications 2channel PLScontrol Operating voltage 24 VAC Effect 260 VA in hours, feeding interval in seconds, and add pauses; Adjusted according to the type of disc feeder which is connected Exchange at 19 liter disc feeder has exchange/rph 1,0 (selection 1), 25 liters disc feeder has rph 2,8 (selection 2), 25 liters has rph 6,0 Feeding automat control – disc controller Imenco AquaEx 2 displays our 4disc feeder sizes, the sizes are measured in “Inch diameter” Ex 2 – We first design it based off of your feeding specifications material chart Engineer – It is than rendered engineered to make sure it fits your application requirementsDisc Feeders: An Innovated Product Engineered the Right WayHeavy duty apron feeder, also called heavy plate feeder, is a feeding device designed for conveying larger, extremely heavy or abrasive bulk materialsIt can also be used to transport materials with various block sizes and densities from the warehouse to the crusher, conveyor or other working machinery in a horizontal or inclined direction This feeder also adopts a rugged Heavy Duty Apron Feeder JXSC Machinery

Handbook for Disc Springs Schnorr Corporation

Checklist for disc spring design Due to the relatively simple geometrical shape the complexity of disc springs in pro duc tion and application is very often un der ra ted There are possibilities for mistakes in outni l ni ga disc spring solution, which in e vi tab ly cause faulty design or even failures later onSpecifications Maximum Product Size 20” diameter (505 mm) Minimum Product Size 6” diameter (152 mm) Product Thickness003” to 10” (07 to 254 mm) Belt Speed 4000 in/min (102 m/min) and see how our SST Pizza Disc Feeder can benefit your company SST Pizza Disc FeederSST Pizza Disc FeederDisk Feedereijing million too Machinery Co, Ltd +8610 About Us Profile Products News Recruitment Message Contact Us Company Overview Recruitment Contractor Main Specification Page up 1Disk FeederProductseijing million too Machinery Co, LtdModel: GZG, ZSW Certification: ISO9001 Capacity: 80–1000t/h Specification: 650x2500mm–1500x5600mm Highlights: fully automatic, high efficiency, etcVibrating Feeder – Industrial Vibrating Feeder AGICO

.jpg)

200 Series Orbetron Corporate

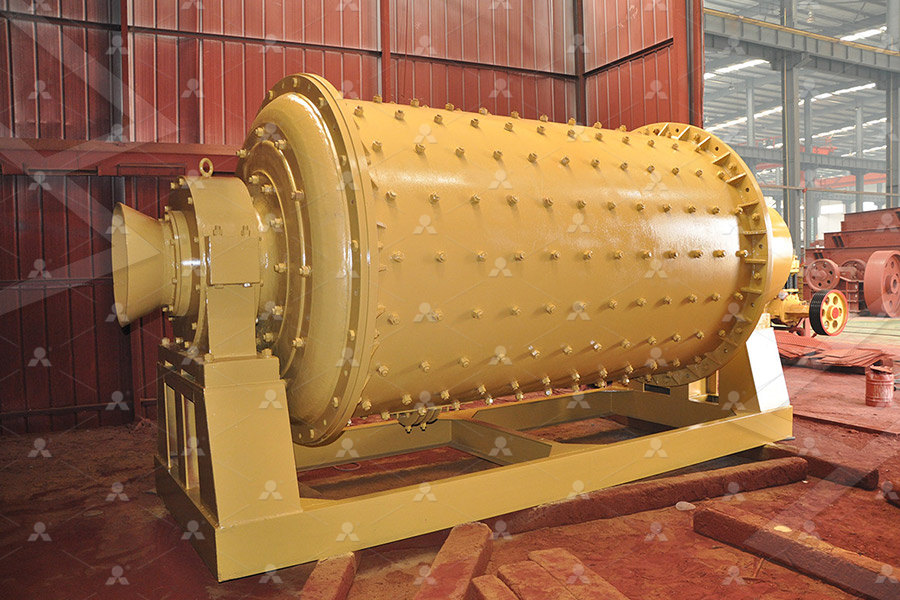

Our 200 series feeders are the largest of our Micro Disc Feeders The 200 series offers the same options, and versatility, which is the key to its performance The design offers a 200mm (8”) diameter feeding disc The base feeder design is sized to feed low rate feeding applications 01 to 800lb/hr (05362kg/hr)Disk Feeder is a cubage measuring feeding equipment; it supplies materials to the next procedure evenly and continuously; at the same time, it can bear relatively higher pressure It is a fine powdery material feeder suitable for noncohesive materials like coal powder, cement, chamotte, limestone, shale, gangue and clunchDisk feeder Hongxing MachineryDisc feeders, also known as disk feeders, are volumetric feeding devices widely used in pelletizing plants, sintering plants, chemical plants, and other industries The disc feeder is mainly composed of the driving device, machine frame, disk device, motor, etc The driving device drives the disc to rotate evenly through the gear Materials are fed onto the disc, which rotates Products Disc Feeder CVIC Iron Ore Disk Feeder CVICCAOur 150 series feeder helps bridge the gap between the 100 and 200 Series feeders Like our entire disc feeder family, versatility is the key to its performance The design offers a 150mm (6”) in diameter feeding disc The base feeder design is sized to feed low rate feeding applications 06 to 500lb/hr (03226 kg/hr)150 Series Feeder Orbetron Corporate

Welcome to WBSEDCL

120502 Technical Specifications for 11KV 33KV Polymer Disc insulators (BS type) Dated:07 032020 170301 Technical Specification of 33 Control Relay panel for 33 KV Feeder Control with SCADA compatible Direction O/C E/F protection and 33/11 KV transformer Control panel with SCADA Compatible Differntial protection Currently, we have formed a complete series with eight models and over 30 specifications ranging from φ1600mm to 3600mm According to different requirements and scenarios, our disk feeders come in various series: PDX (internal gear), PDXII (external gear), PDXJ (cokingspecialized), and PDXG (hightemperaturespecialized)Disk Feeder Material Feeding Equipment ZhongdingDisk feeder is mainly composed of motor, decelerator, disc, scraper and feeding adjustment devices etc The disc rotates through the triangle belt, worm reducer, and vertical shaft by the motor Lower part of the disc set connected with the worm gear reducer, and the upper part connected with steel column of tank by the feed chuteDisk FeederDisk Feeder EquipmentDisk Feeder for Mineral A physical prototype of a mechanized slotted rotary disc feeder was constructed and the behavior was studied experimentally by varying the speed of rotation of disc, Number of magnet used are 4, 8 and 12 [7] Table 1: List Of The Specifications Of The (PDF) MAGNETIC DISC TYPE FEEDER IJAR Indexing Academia

50 Series Orbetron Corporate

Our 50 series feeders is our smallest feeder to date The design offers a 50mm (2”) in diameter feeding disc The base feeder design is sized to feed low rate feeding applications 0002 to 10lb/hr (1g/hr to 453g/hr)2020年5月19日 Orbetron disc feeders are the core of our business and have made us who we are today We have a product line of some amazing disc feeders, below is our 50 through 200 series diameter disc that illustrate the Disc feeders: An Innovated Product Engineered the Digital Dosing Disc Additive Feeders Single, Duo and Trio With A250 Controller Models: DD, SDD, Colorblend Part Number: 8820236100 within design specifications, following national and local safety codes This may include, but is not limited to OSHA, NEC, CSA, SPI, NEPA or CE and any other local, national andDigital Dosing Disc Additive Feeders Single, Duo and Trio With customers SPIROL Standard Disc Springs meet all material, dimensional tolerance, and quality specifications as laid out in DIN EN 16983 (formerly DIN 2093) but in diameter and thickness combinations that are not included in the DIN standard SPECIALS SPIROL will work with the customer to develop special Disc Springs to meet theDisc Springs SPIROL

Disc Feeder

The Danikor Disc Screw Feeder is an exceptionally reliable machine It uses a rotating disk to position one fastener at a time in a precise location for easy retrieval Fasteners can be picked up using either a magnet or vacuum This feeder is designed specifically for micro and mini screws in the electronics industry, ensuring zero jams2010年12月17日 Digital Dosing Disc Additive Feeders AEC Blend and Reclaim EN English Deutsch Français Español Português Italiano Român Nederlands Latina Dansk Svenska Norsk Magyar Bahasa Indonesia Türkçe Suomi Latvian Lithuanian český Digital Dosing Disc Additive Feeders AEC Blend and ReclaimFeeder Description 7 Overview of the FTF40RD FTF50RD Specifications Figures: 6 Figure 11 FTF40/50RD Feeder: Overall Exploded View 8 Figure 12 FTF40/50RD Feeder, Metric ANSI (Dual Drive): Overall Exploded View 9 Figure 13 FTF40RD Feeder Specifications 10 Figure 14 FTF50RD Feeder Specifications Safety Precautions 11 Model FTF40/50RD Centrifugal Feeders2002年8月1日 Download Citation Disc feeder provides high performance at feed rates below 50 g/h Plastic polymer products are often required in smaller production runs and on smaller machines to avoid over Disc feeder provides high performance at feed rates below 50 g/h

FT20RD Centrifugal Feeder Shibuya Hoppmann

Shibuya Hoppmann’s standard FT20RD centrifugal feeder is designed using a rigid disc to feed a variety of products with its unique bowl design Product is metered into the bowl and brought out to the bowl rim where a series of qualifiers gently orient the part for transfer to various downstream inline devices