Slag Micro Powder Trapezoidal Mill

.jpg)

Analysis and multiobjective optimization of slag

2020年7月1日 For slag powder process, operational stability of the vertical mill (indexed by the material layer thickness) is the primary concern for production 2024年1月2日 As a slag vertical mill manufacturer, HCM Machinery will introduce to you the slag micro powder process technology solution today This solution is included in the national Slag micron powder process technology solutionAs a new type of admixture for highperformance concrete, slag micro powder has the advantages of improving various properties such as compressive strength, tensile strength, shear strength, The role and advantages of slag micro powderSlag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an important role in the process It can reflect the dynamic Analysis and multiobjective optimization of slag powder process

Development of slagbased filling cementitious materials and their

2024年11月2日 This study addresses the issues of low strength and high cost associated with the backfill of ultrafine tailings in metal mines by developing a novel slagbased backfill 2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in Comprehensive utilization of steel slag: A review ScienceDirect2011年3月17日 The invention relates to a production process of steel slag micropowder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and Production process of steel slag micropowder Semantic ScholarGranule morphology of granulated blast furnace slag powders prepared with vertical mill (GBFSV) and close circuit ball mill (GBFSB) respectively were observed with SEMThe Vertical Mill Slag MicroPowders' Particle Size Distribution and

.jpg)

Effect of grinding method on properties of steel slag powder

Abstract Making the steel slag into powder by the mechanical comminuting process and applying it to the building materials production is an effective way of the steel slag recycling TheTGM series supper pressure trapezoidal mill is the star product of similar equipment in China LM Vertical Slag Grinding Mill; MB5X Pendulum Roller Grinding Mill; MTW European Type Grinding Mill; MW Micro Powder Grinding Mill; Straightthrough Centrifugal Mill; CASE Marble Processing Line; 15 Microns 5TPH Talc Grinding Plant in Th;Case Grinding mill, MTW European Type Trapezium Mill, Vertical 2023年7月19日 Homogenized microcrack crushing can fully retain the bearing capacity of concrete pavement, but local weak road base needs to be reinforced before being directly overlaid with hotmixed asphalt Therefore, indoor tests Mechanical Properties of SlagBased Geopolymer 2020年11月1日 The slag powder is blown to the upper part of the vertical mill by the hot gas Then the slag powder which meets the particle size requirement is screened out by the separator, and the slag powder which does not meet the particle size requirement will be reentered into the mill through the bucket elevator for regrinding [12], [20]Analysis and multiobjective optimization of slag powder process

.jpg)

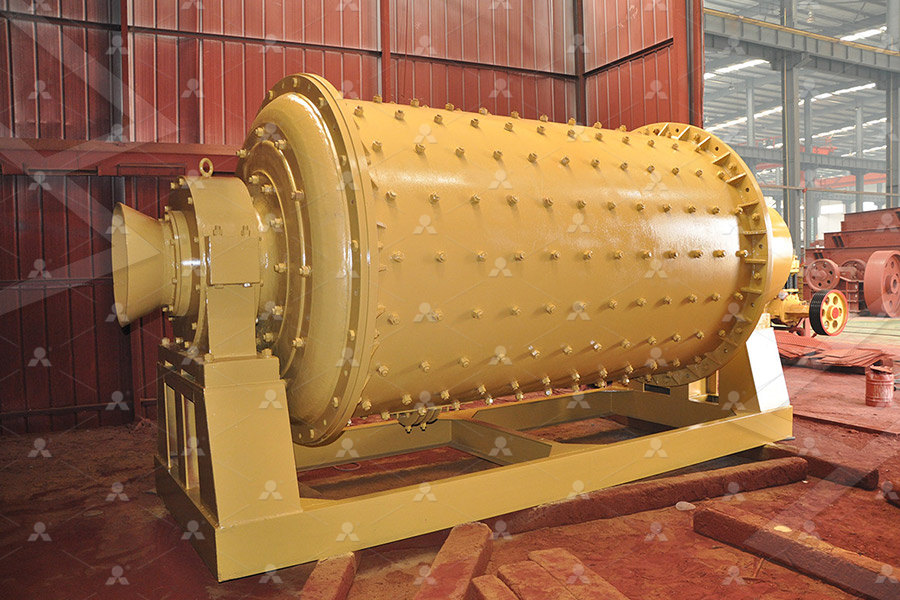

Slag mill, slag powder mill, slag uZhengzhou Vanguard

Slag grinder (also called slag micropowder mill and slag superfine mill) is a largescale grinding machine, which Vanguard absorbs advanced European technology and designs and improves It is highquality equipment for processing slag powderTGM series supper pressure trapezoidal mill is the star product of similar equipment in China LM Vertical Slag Grinding Mill; MB5X Pendulum Roller Grinding Mill; MTW European Type Grinding Mill; MW Micro Powder Grinding Mill; Straightthrough Centrifugal Mill; CASE Marble Processing Line; 15 Microns 5TPH Talc Grinding Plant in Th;Case Grinding mill, MTW European Type Trapezium Mill, Liming heavy industry has more than 30 years of experience in grinding mill design, R D and manufacturing Its products are widely used in nonmetallic ore milling, limestone milling, highway ore milling, heavy calcium processing, pulverized coal preparation, slag micro powder preparation and other fieldsGrinding mill machine, mineral mill, raymond mill, pulverizer Ball mill processing slag powder technology Process introduction The dried slag is sent to the mill through the metering and feeding equipment, and is ground into fine powder in the mill If necessary, a fine grinding classifier can be added in the mill to improve the fineness of the product Delivered to finished product parison of Three Different Processes for Slag Micropowder

Slag Powder Vertical Roller Grinding Mill

2022年6月17日 With the development of the solid waste slag industry, the special dry vertical mill for the equipment of the slag micro powder industry is a new type of powder mill to increase production and reduce consumption It has high grinding efficiency, fast powder separation efficiency and fine classification accuracy It is favored by the industry and is a new type of The main nickel slag vertical mill, also known as vertical roller mill, used in the nickel slag grinding micro powder process is a mechanical equipment device that grinds nickel slag through the relative movement between the grinding roller and the grinding disc based on the principle of material bed grindingNickel slag powder processing solutionLIMING HEAVY According to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per GGBS Vertical Roller Mill Great WallSBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ protected] language >Shibang Industry Technology Group, Shanghai Micro Powder Grinding Mill

.jpg)

The role and advantages of slag micro powder

LM slag vertical mill is a specialized equipment for grinding industrial waste into powder It integrates crushing, conveying, grinding, and drying, making it an ideal equipment for producing slag micro powder NEWS > LM130K Vertical Mill For Dolomite In Sichuan > LM130N Vertical Mill, Process slag, 325mesh, 6tph > 15 Microns 5TPH Talc Grinding 2023年7月1日 Steel slag powder (SSP) was selected as an inorganic micro powder filler instead of limestone powder (JTGF40–2004) Two types of inorganic micro powder fillers, SSP and LSP as the research objects, were selected to prepare asphalt The steel slag was mechanically ground by a ball mill and then sieved by 0075 mm to obtain Creep and fatigue properties of asphalt mastic with steel slag powder 2016年1月1日 Request PDF Preparation of microsize flake silver powder by planetary ball mill Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball Preparation of microsize flake silver powder by planetary ball millHCM Machinery as a steel slag micropowder vertical mill manufacturer, today to introduce you to the application prospects of ultrafine steel slag grinding 1 Current situation of resource utilization of steel slag: Steel slag powder has long been included News Application prospect of ultrafine steel slag grinding

Laboratory Preparation and Performance Characterization of Steel Slag

2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the lower cementitious activity and poorer volume stability of steel slag limit its high dosage in cementbased materials In this paper, steel slag ultrafine powder 2023年5月15日 In this process, steel slag and slag were mixed in a certain proportion into the feed bin The mixed materials were treated by vselector, highpressure roller, powder separator, and ball mill to produce steel slag and slag composite micro powder Table 3 illustrates the equipment types for SSCM prehensive utilization of steel slag: A review ScienceDirect2022年11月11日 By calculation from Equation (1) [22], the alkalinity coefficient of the steel slag is 222, which is higher than 18 lower than 25 This means that this kind of steel slag belongs to the Laboratory Preparation and Performance Characterization of Steel Slag 2023年6月28日 The utilization rate of steel slag in China is far behind that of developed countries The annual output of steel slag is still increasing, resulting in a large amount of accumulation, causing environmental pollution This paper summarizes and analyzes the relevant research on steel slag powder (SSP) as a cementitious material, studies the effect of SSP Effects of Steel Slag Powder as A Cementitious Material on

What Is The Market Prospect Of Steel Slag Vertical Roller Mill For Powder?

Recently, the steel slag powder production line with the largest production capacity in China was completed and put into operation in Shagang Group The total investment of this project is about 170 million yuan, and it is estimated that tons of steel slag powder will be produced annually Due to the high hardness of steel slag, the particle diameter of conventional ball mill 2022年3月7日 The main components of the three tailings slag are CaO, SiO 2, and Al 2 O 3 (Table 2), which are consistent with the main chemical components of limestone powder and red clay, it can be used as a mineralizer, especially the content of Fe 2 O 3And Fe 2 O 3 in lead–zinc tailings accounts for 1392% Nickel tailings contain relatively high MgO When they are Preparation of composite microslag based on the application of 2024年2月22日 The HLMX steel slag micropowder vertical mill produced by Guilin Hongcheng can solve this problem The steel slag powder produced by the HLMX steel slag powder vertical mill model can be directly ground to a steel slag 700 specific particle size without the need for regrinding by a ball mill, saving equipment space and energy consumption, and Can vertical mill produce ultrafine steel slag powder?HGM series Threering Micro Powder Grinding machine Performance and features: 1 high efficiency Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts The roller and ring are made of special material, which improve the grinding efficiency a lotHGM Series Threering Micro Powder Grinding Machine Clirik

How does the vertical mill grind steel slag?

2023年11月28日 The newly developed steel slag vertical mill produced by HCM Steel Slag Vertical Mill Manufacturer has successfully operated the vertical mill to grind steel slag through innovations in grinding component combination, use of new wearresistant materials, system and inmill iron removal, and micropowder sortingDolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9Dolomite Micro Powder Grinding MillA micro powder mill is a new product independently researched and developed by our company and is the advanced fine grinding equipment for the dry processing of nonmetallic ore superfine hardness is below 93, such as calcium carbonate, barite, kaolin, rare earth ore, hematite, talc, feldspar, and furnace slag Micro Powder Mill Features: 1Micro Powder Mill Hongxing Mining Machinery2024年11月2日 The quality variation of slag micropowder is also a significant factor; the incorporation of untested admixtures and activators into the slag micropowder can lead to significant strength fluctuations, particularly a reduction in strength at later stages accompanied by cracking, posing a significant risk to the safety and durability of the structureDevelopment of slagbased filling cementitious materials and their

Introduction of GGBS vertical roller mill Great Wall

According to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per 2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder Characteristics of Recycled Micro Powder Produced Using Construction 2021年8月1日 Steel slag micro powder is steel slag after special process grinding, is a byproduct in the process of steel production This paper studied the basic mechanical properties and crack control (PDF) Effect of Polyvinyl FiberSteel Slag Powder on Mechanical Slag Grinding Mill To reduce the blast furnace smelting temperature, a certain amount of limestone or dolomite needs to be added as a flux The product produced by the decomposition of the blast furnace and the waste ore in iron Slag Grinding Mill, Slag mill, Slag powder mill, Slag

.jpg)

60TPH LM353N Slag Grinding Mill In Fujian, ChinaLIMING

60TPH LM353N Slag Grinding Mill In Fujian, China Equipment: LM353N Vertical Mill, LM172N Vertical Mill Material: Water slag, gypsum, cement fuel Capacity: 5560T/H Output size: 400 SSa The annual output of slag micro powder is tons, 2005年2月1日 Steelmaking slag, an important metallurgical byproduct, is composed of a large amount of valuable components, including CaO, Fe t O, MnO, and MgO, all of which are required in the steelmaking (PDF) Industrial uses of slag The use and reuse of ②Ultrafine Grinding Mill: $14,600/set (the lowest price) It is an upgraded Raymond mill for making micro powder and fine powder Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, ceramics, and other industriesPowder Grinding Mills Engineered by FTM Fote Machinery2022年12月1日 Molten iron desulfurization slag (DS) is the tail slag produced in the predesulfurization process of molten iron Molten iron desulfurization produces approximately 7–9 kg/t of DS (Zhang and AnJun 2009)The main components of DS are Ca(OH) 2, CaSO 4, CaF 2, CaCO 3, CaS, and Ca 2 SiO 4 (Tong et al, 2016)With a pH above 125, DS is almost Application of molten iron desulfurization slag to replace steel slag

Micro Powder Roller Mill for Getting Ultrafine Powder DASWELL

Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water content less than 5%2021年9月30日 HGM micro powder mill The micro powder mill adopts a newly designed grinding roller grinding ring grinding curve, which improves the grinding efficiency The production capacity is 40% higher than that of jet mills and mixers, and the energy consumption is only 30% of that of jet mills HGM micro powder mill is equipped with a multihead cage Chalk Micro Powder Mill SBM Ultrafine Powder Technology2021年11月27日 According to the fineness of the material to be ground and the fineness of the discharged material, the powder grinding mills can be divided into six types: pendulum roller mill, highpressure suspension grinding mills, highpressure micropowder mills, straightthrough centrifugal mills, overpressure trapezoidal mills, and micro powder grinding millsWhat is Powder Grinding Mill? JXSC MachineFrom the coal powder preparation, heavy calcium and slag powder processing, to largescale nonmetallic mineral powder, power plant environmental desulfurization, limestone powder, building materials, chemical industry grinding engineering, professional technology covers the whole process chain of mineral processing, product processing range covers 03mm coarse CaseIndustrial Grinding Mill, Ultrafine Grinding Mill, Vertical Roller

Effect of Iron Tailings and Slag Powders on Workability and

2021年7月25日 When the ratio of iron tailings powder to mineral admixtures (slag powder and iron tailings powder) is less than 50%, the compressive strength of concrete with different ages has little difference from that with single slag powder, The maximum reduction of compressive strength of C30 and C50 concrete at 28d was only 20 and 102% compared with that of the