Pulverizing process flow modification instructions

Review articleA concise summary of powder processing

2023年6月1日 The flow properties of a powder mixture are enhanced by growing the size and surface area of the particles—the uniformity of powder density increases and the strength The capability can be used to increase the pulverizer and boiler capacity with the present coal or to maintain the present boiler load with a coal that is more difficult to pulverize At Danskammer, Pulverizer Fineness and Capacity Enhancements at DanskammerSome of the largest opportunities for improving performance and reliability come from optimizing primary airflows such as reducing NO X, slagging and other furnace issues But before you Pulverizers 101: Part 3 Storm Technologies, Inc2003年10月1日 To understand the flow structures within the pulverizer, our study focused on the reference flow geometry, where there was no modification to the pulverizer Examining the BALANCING OF PULVERIZED COAL FLOWS TO BURNERS IN

.jpg)

DESIGN AND FABRICATION OF A MILL PULVERIZER Academia

This paper presents the development and performance evaluation of a size reduction unit for pulverizing, sieving and conveying material to the next processing stage in a plantain flour Today's coalfired utility boiler operation needs pulverizer designs to supply pulverized coal with required throughput and coal fineness, and also perform with lower specific power Coal Pulverizer Design Upgrades to Meet the Demands of Low Instructions for Operating and Maintenance The Sepor MiniPulverizer is a specialty piece of laboratory apparatus designed for pulverizing samples from 1 20 gramsOPERATING MANUAL Sepor MiniPulverizerThe highspeed universal pulverizer used in this research pulverizes the material by imposing strong impact, crush, and shear forces on the material through highspeed spinning blades Thermal optimization and experimental research of highspeed

.jpg)

Mikro Pulverizer Hosokawa Alpine

ProCess teCHnoloGies for toMorroWsM 2 / FUNCTION Mikro Pulverizers are highspeed hammer mills designed for continuous operation in harsh environments at peripheral speeds of Asphalt pulverizing is particularly useful for roads that have extensive damage, offering a way to restore them without completely starting from scratch Key Benefits of Asphalt Pulverizing for Road Maintenance 1 CostEffective: Asphalt pulverizing significantly reduces costs compared to traditional methods of road construction and repairAsphalt Pulverizing: A Quick Guide to the ProcessIf the process instance can't apply one of the modification instructions, it rejects the modification command For example, if one of the terminating element instances is not active As a result, the process instance is not modified and is Process instance modification Camunda 8 Docsair and its use in the coal pulverizing process Let’s think about the coal pulverizing process Raw coal with a preferred maximum size of about ¾” enters the mill Let’s use bituminous coal with 10% total moisture as an example The coal is dry to Pulverizers 101: Part 3 Storm Technologies, Inc

A green and efficient lignitefired power generation process

2024年5月1日 Nowadays coal supplies over a third of global electricity generation In China, Coal accounts for around 70% of primary energy consumption Statistics show that China's coalfired power generation in 2022 were 573 trillion kWh, accounting for 584% [1]With continued consumption of coal resources, the available highgrade coal is decreasing and the proportion the New Equipment Installation or Equipment Modification or Process Change is approved and will assign a Safety Equipment Engineer to oversee the installation or change 71 General Information 711 The first page of the New Equipment Installation or Equipment Modification or Process Change Checklist requires General InformationNew Equipment Installation, Equipment Modification or Process 1984年7月1日 Pulverizing Process The pulverizer consists of a horizontally rotating cylinder filled with steel balls whose fall produces the grinding impact The optimal pulverizing capacity is reached when the voids between the balls are filled with coal particles An excess of particles often causes a bad pulverization and an obstruction in the circuitNumerical Control System for a Pulverizing Plant ScienceDirectmodification, check Block 13B of the SF 30 No other specific authority need be cited Will the Government require the contractor to agree to the change (ie, sign the modification) prior to effecting the modification? No Yes Is the modification a Change Order pursuant to one of the “Changes” clauses in the contract?Contract Modification Authority Decision Help Guide

Genetic Modification: Definition, Types, Process, Examples

2019年5月28日 Genetic modification is any process by which genes are manipulated, changed, deleted or adjusted in order to amplify, change or adjust a certain characteristic of an organism It is the manipulation of traits at the absolute root – or cellular – level Consider the difference between routinely styling your hair a certain way and actually being able to control your hair's 2019年1月22日 PDF Tapioca is the most important tropical root crop Its starchy roots are a major source of dietary energy for more than 500 million people It is Find, read and cite all the research you (PDF) TAPIOCA PROCESSING ResearchGate2022年7月11日 The instruction pointer is automatically incremented to contain the address of the next instruction in memory The CPU executes the instruction within the instruction register Go to step 3; Steps 3, 4, and 5 are called an instruction fetch Notice that steps 3 – 8 constitute a cycle, the instruction execution cycle It is shown graphically Program Execution in the CPU GeeksforGeeksPDF On Jan 1, 2021, Bambang Soeswanto and others published The Development of Coffee Bean Drying Process Technology – A Review Find, read and cite all the research you need on ResearchGateThe Development of Coffee Bean Drying Process

What is process flow? Plus, how you can visualize it

2024年1月18日 Plan and document processes Unclear processes lead to disengaged team members, low morale, and tasks that fall through the cracks Instead, mapping out your process gives your team a better understanding of Create a process flow diagram online Break down complex processes into smaller steps with efficient process flows Create a process flow diagram on Canva Whiteboards and use it to visualize the big picture and your role within Free Process Flow Diagram Maker and Examples CanvaPrompt modification allows you to expand the capabilities of generative answers, or boosted conversations, by adding custom instructions This article shows you how to create custom instructions to your agent to get the desired response You can provide the agent with context, instructions, or other information relevant to your use caseUse prompt modification to provide custom instructions to your 2015年3月1日 Process flow sheets embody the material and energy balances between and the sizing of the major equipment of the plant Discover the world's research 25+ million members;PROCESS FLOW SHEET, Kolmetz Handbook of Process Equipment Design

Fumed SilicaBased UltraHighPurity Synthetic Quartz Powder via

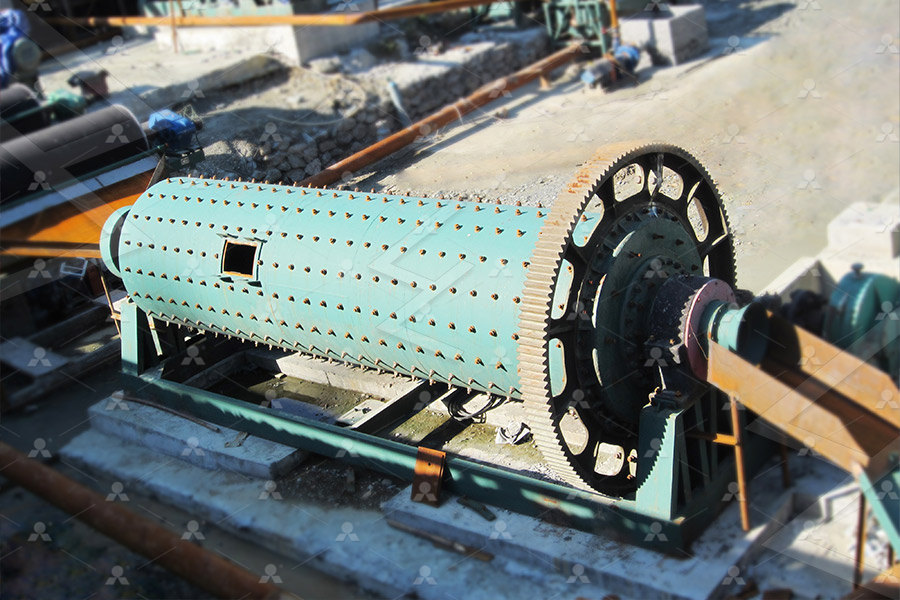

Synthesis process flow of the fumed silicabased ultrahighpurity quartz powder 22 Characterization The transmittance spectra of potassium silicate solutions at wavelengths ranging from 300 to 1000 nm and at wavenumbers ranging from 500 to 2000 cm −1 were measured via UV–visible spectroscopy (Cary 5000, Agilent Technologies Co, Inc, Santa 2024年10月12日 The spray drying process has a dual role, encapsulating bioactive compounds and pulverizing feed solutions A conventional onestage spray drying system is depicted in Figure 1 , with subsequent paragraphs explaining the fundamental steps of spray drying and addressing challenges associated with each stepRevolutionizing Spray Drying: An In‐Depth Analysis of Surface A mill pulveriser is a modification of a hammer mill that utilizes air flow to separate various particles The development of a mill pulveriser incorporates the design of a hammer mill and a blower A hammer mill is a type of crusher, which can be used for grinding rock, forage, grains or other large size particles into smaller pieces by the repeated blows of little hammersDESIGN AND FABRICATION OF A MILL PULVERIZERThe influence of pulverizing process parameter, such as electrical current of the driving motor, mill capacity, boiler production, coal types on mill vibration are investigated to identify the potential malfunction of beater wheel mills and their associated components for Pulverizer Wikipedia

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

ISO 9001 Processes, Procedures and Work Instructions

ISO 9001:2015 has relaxed the strict requirement for quality management documentation However, in order to satisfy the remaining documentation requirements and to properly implement the Quality Management System (QMS), ISO 9001 Processes, Procedures and Work Instructions are typically still employed Section 44 of the standard, titled Quality Management System and 2019年5月11日 Abstract Modifications to landscapes and flow regimes of rivers have altered the function, 2009) make it necessary to develop dynamic flow prescriptions defined by processbased links to ecological responses with Coupling landscapes and river flows to restore 2020年9月1日 The flow chemistry method is an ultrafast and continuous process for synthesising MOFs with tuneable characteristics, depending on the temperature, residence time and sludge volume [136] This method consists of four major parts: syringe system, microtubular reactor, temperaturecontrolled oil bath and glass vial to collect the productFacile directions for synthesis, modification and activation of 2019年10月31日 This process is used for pulverization into medium and smallsized objects (10 cm or less) <Shear pulverization> An object is cut into small pieces by a wedge, such as a cutter It is suitable for pulverizing fragile Pulverization 1: Definition and purpose THINKY

.jpg)

Process Instance Modify 《 [英文] The Camunda BPM Manual

Submits a list of modification instructions to change a process instance's execution state async A modification instruction is one of the following: Starting execution before an activity; Starting execution after an activity on its single outgoing sequence flow; Starting execution on a specific sequence flow; Cancelling an activity instance, 2022年12月11日 Process mapping is like creating a blueprint for how things get done in a business It’s a way of breaking down tasks step by step, so you can see what’s happening, spot any slowdowns, and make everything flow more smoothlyProcess Mapping Guide: Definition, Howto and Best PracticesWhile the process model contains sequence flows that define in which order activities must be executed, sometimes it is desired to flexibly start an activity again or cancel a running activity For example, this can be useful when the process model contains an error, such as a wrong sequence flow processinstancemodificationmd2024年8月29日 Aerated concrete block production process flow chart Use ProcessOn to Sort Out Process Flows and Draw Process Flow Diagrams The following are detailed steps to help you effectively use ProcessOn to draw process flow diagrams: Step 1: Create an Account and Log In 1 Visit the ProcessOn official website and create an accountHow to Draw a Process Flow Diagram? A Few Simple Steps to

.jpg)

DECISION MAKING FOR CONTROL OF COMBUSTION PROCESS

OF COMBUSTION PROCESS OF PULVERIZED COAL Kosta Boshnakov, Venko Petkov, Metodi Nikolov University of Chemical Technology and Metallurgy 8 Kl Ohridski, 1756 Sofia, Bulgaria Email: kb@uctm ABSTRACT A method and system for decision making and control (DMC) of combustion process of pulverizing fuelair mixture in large multiburner furnace is Process flow charts can offer several benefits for businesses, improving productivity and teamwork while eliminating unnecessary steps With Confluence Whiteboards, you can visualize and turn ideas into tasks Confluence brings everyone together in a connected workspace to move projects forwardProcess flow charts: Types, uses and benefits The Workstream2022年11月9日 The process of modification is properties charact eristic to changes for nativ e starch with the use o f physical, ch emical, gen etic or enzymatic methods Physical modifica tion (PDF) Starch modification techniques: an overview ResearchGateinsert a screwdriver between the oil pan and the case and pry gently to begin the draining process Remove the two from oil bolts slowly (about one turn at a time) and fluid will drain at a steady rate from the rear of the oil pan Drain the oil pan completely and keep it to hold bolts and small bolts and small partsInstallation/Modifications Instructions ATI Racing

.jpg)

Modification of production process structure and

2017年11月15日 Modification of production process structure and optimization of material flow for selected types of components computer simulation means November 2017 MM Science Journal 2017(11):18951900Simplified process flow diagram with OPRP and CCP location WS A HAZARDOUS AGENT CODES Distribution instructions (eg ambient, chilled, frozen) Storage instructions (eg ambient, Production process Step Hazard description Modification Date Partcipants Purpose Outcome (decisions/actions)OVERVIEW GUIDE OF THE HACCP WORKSHEETS World Bank2021年12月15日 As a rule, a work process covers a much longer period than procedures or work instructions This is because it requires multiple procedures and many work instructions to detail every task performed by many actors to accomplish a particular goal Work Process Structure Here’s a work process document structure to help you make your own Processes, Procedures, and Work Instructions: DifferencesFlow modification messages (also known as flowmods or FlowMods) tell the datapath to add, delete, or modify a flow in its flow table Registering flow classes Before a flow modification message can be constructed and sent via the controller service, Flow modifications Hewlett Packard Enterprise Support Center

Developing Process Flows Aptify Support

2022年3月8日 For information on Aptify Process Pipeline infrastructure and how to create Process Flows and Event Handlers, see Managing Process Pipelines) This topic describes how to design a process flow by providing stepbystep instructions for how one of the Process Flows included with the sample application was created2024年3月1日 On the other hand, the preparation process of Pal based functional materials, such as the optimization processes of physicochemical properties like acid treatment, alkali treatment, organic modification, and the construction process of organicinorganic or inorganicinorganic functional materials, usually involves the pulverizing treatment of PalInsight into the microstructure and physicochemical properties of 2023年8月2日 The milling process has evolved over time, employing various techniques to produce flour with different particle sizes and applications This paper discusses the advancements in the wheat flour The Latest Innovations in Wheat Flour Milling: A Reviewprocess flow diagram of calcium carbonate – Crusher South Africa Grinding is the required process when size reduction of below 520 mm is needed Grinding is a powdering or pulverizing process, Process flow sheets: Pulverizing Process Flow Crusher Mills

.jpg)

Process Improvement Through Flowcharting: A Guide to

2023年3月14日 Table of Contents hide 1 Problem Description 11 Creating Structure Text to Develop the Flowchart 111 Structured Text for Flowchart Development 112 Now Develop The Flowchart based on the Structured Text 113 Flowcharts for Process Improvement using Gap Analysis 114 StepbyStep Guide to Performing Gap Analysis for Process Improvement 115