LM240M vertical mill working principle

.jpg)

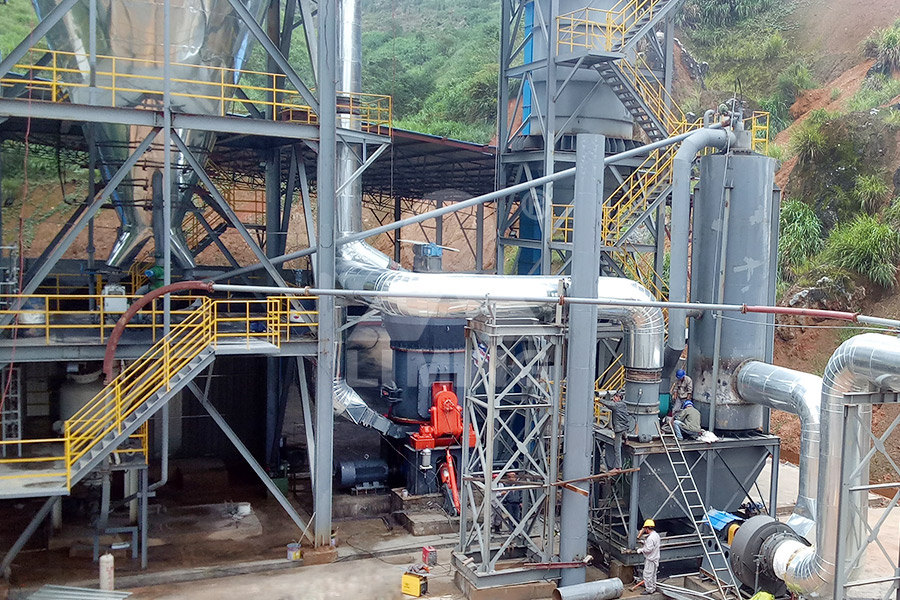

LM series vertical mill

WORKING PRINCIPLE The mill disk is driven by the gear box through electrical motor and the material will be fed to the center of the disk from the feeding port via an airlocking feeder and meanwhile the hotblast air will be blown into the LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, LM Series Vertical Mill LIMING(Shanghai)a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSWorking principle The main motor drives the grinding plate by the reducer, simultaneously the hot air enters the vertical mill body from the air inlet and the materials drop on the grinding plate Vertical Roller Mill (60045μm)

.jpg)

LM Vertical Grinding Mill SBM Mill Crusher

2023年3月15日 Working Principle The grinding plate rotates under the action of main motor of LM Vertical Grinding Mill and the reducer Meanwhile, hot wind enters the vertical mill After The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized Vertical Mill Shanghai Zenith CompanyThe working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it Raw materials are fed into the table and ground between the rollers and table The Working principle and characteristics of vertical millVertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials

.jpg)

LM Series Vertical Mill Liming Heavy Industry

LM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, stone industry, nonmetallic mineral It is used to grind granular and powdered The modular structure of larger roller grinding mills enables utilisation of the same components in different mill sizes Module components include grinding rollers, rocker arms, pedestals and LOESCHEMILLSWorking Principle The slag vertical mill is a negativepressure airsweep type grinding equipment, which dries the slag and grinds the slag When working, the main motor drives the grinding table to rotate through the reducer, and at the same time, the hot air enters the body of the vertical mill from the air inlet, and the material falls from the discharge port to the center of the grinding LM Vertical slag millGrinding mill machine, mineral mill, raymond mill The working principle of LM vertical mill is as follows: Under the driving of hydraulic pressure, the material is ground and the product powder is The Working Principle of LM Vertical Mill The working principle of LM vertical mill is as follows: Under the driving of hydraulic pressure, the material is ground and the product powder is By Shibang Industry Technology Group The Working Principle of LM Vertical Mill Facebook

LM Vertical Grinding Mills Working Principle

LM vertical grinding mills is widely absorb the advanced technology in the foundation of international wellknown company, combined with our thirty years of grinding equipment production experience, integrated design and LM Vertical Roller Mill is one advanced mill adopting top technology of Europe, and based on many years’ design and improvement LM Vertical Roller Mill can be widely used in such industries as cement,metallurgy, electric power, chemical industry, WORKING PRINCIPLELM Vertical Mill greatwallcrusherLM Series Vertical Roller Mill is used to pulverize materials, material can be pulverized into 80400Mesh with this mill Feed particle size : 070mm Production capacity : 4300 tons / hourLM Vertical Roller Mill, Vertical Mill ManufacturerThe LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by Working Principle After raw materials fall onto the center of grinding plate, large materials are broken directlyVertical Mill Shanghai Zenith Company

.jpg)

Hydraulic system vertical roller mill operation PDF SlideShare

2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller 2 Working Principle of Vertical Grinding Mill The Vertical Grinding Mill working principle is simple and begins with the jaw crusher crushing the raw material to the required size The crushed material is then added to the hopper (situated on the side of the hood) of the machineVertical Grinding Mill: How it Works, Application And AdvantagesIntroduction Vertical Machining Center: Definition, Components, Uses, Working Principle, Advantages Disadvantages: – The vertical machining center has existed for quite a while and stays a fundamental part of modern CNC innovation and development For machining different industrial parts Vertical machining centers are quiet efficientVertical Machining Center (VMC): Definition, Components, Uses, Working The basic working principle of a vertical mill involves the interaction of several key components At the core of the mill is a large vertical grinding table, which rotates at a controlled speed Above the grinding table, there are several rollers that apply pressure onto the material being groundIndepth understanding of the working principle of vertical mills

LM Vertical Roller Mill

Vertical Roller mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds The materials fall into the center of device through lock air feeder, Working principle The main motor simultaneously the hot air enters the vertical mill body from the air inlet and the materials drop on the grinding plate center from the feed opening and evenly move outwards due to centrifugal force Vertical Roller Mill (60045μm)2019年12月12日 SBM LM Vertical Grinding Mill Working principleFacebook: https://facebook/SBMmachine/In this video you can learn how our LM Vertical Grinding Mill woSBM LM Vertical Grinding Mill Working YouTubeWorking Principle The main motor drives the grinding table to rotate through the reducer, and at the same time, LM130K Vertical Mill For Dolomite In Sichuan Output size:150200 mesh, D95 LM130K Vertical Mill For Dolomite In Sichuan Output LM Vertical Roller Mill, slag vertical mill, coal vertical mill

LM Series Vertical Mill LIMING(Shanghai)

LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical indus : English French(français) Russian(русский) Spanish(español) HOME Working Principle Motor runs under the condition that speed reducer drives Nether millstoneLM Vertical Grinding Mill Under the situations that related technologies about vertical grinding mill gradually become mature and the technical advantages of vertical grinding mill become prominent, SBM releases LM Series Vertical Grinding Mill Its development absorbs successful foreign experienceLM Vertical Grinding MillSBM Industrial Technology GroupPLANETARY BALL MILL LM PM Laarmann Group BV Op het Schoor 6 6041 AV The Netherlands info@laarmann laarmann webshoplaarmann +31 6 23 40 00 33 • Quick and easy to clean Working principle impact, friction Feed size maximum 10 mm Number of grinding jars PLANETARY BALL MILL LaarmannHow Does a Vertical Roller Mill Work? The working principle of vertical roller mills is relatively simple In a rotating drum, grinding media (steel balls or ceramic beads) are fed through the mill’s inlet, and the particles are ground into smaller sizes by the mechanical forces generated by the motion of the drumHow does Vertical Roller Mill Work? ball mills supplier

HorizontalAxis Wind Turbine (HAWT) Working Principle Single

HorizontalAxis Wind Turbine Working Principle The horizontalaxis wind turbine (HAWT) is a wind turbine in which the main rotor shaft is pointed in the direction of the wind to extract power The principal components of a basic HAWT are shown in Figure 1 The rotor receives energy from the wind and produces torque on a lowspeed shafta Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2 µm 5 µm LoescheFig1 Flow of Conventional Vertical Mill Grinding System Mill Kiln IDF (Kiln gas exhaust fan) Fig2 Flow of direct dust collection system Results Power consumption of fan(s) reduces about 3 to4 kWh/t Cost estimation When a mill with a production Vertical roller mill for raw Application p rocess materials2024年3月9日 Vertical Bead Mill Working Principle Loading procedure Analogous to its horizontal counterpart, the mixture and grinding media are ushered into a vertical chamber Operational differences from horizontal Bead Mill Working Principle: How Do Bead Mills Work?

Vertical Boring Mills: A Comprehensive Guide Machine Tool

2023年12月4日 Following these steps, protocols, and solutions will help in the smooth operation of a vertical boring mill, ensuring both quality results and a safe working environment Selecting the Right Vertical Boring Mill Factors to Consider: Size, Capacity, Features Selecting your mill is like choosing your battle gearIntroduction Hot Sale: Drying and grinding are two in one, and can dry while grinding Domestic largescale highend vertical coal mill LM vertical coal mill, also known as mediumspeed coal mill, is lunched by the company for the domestic market demand, the introduction of German advantages of integrated technology, combined with 30 years of advanced milling machine LM vertical coal millLM Vertical Grinding Mill LM series vertical roller mills are a excellent grinding equipment, which have the capacity of 24hours constant running Because of this automatic operation, this VRMs are popular in the condition, which needs easy monitor, large capaity, constant running, stable product quality, like large mineral powder plant, cement plant, GGBS powder plant, coal LM Vertical Grinding Mill Vertical Roller MillVertical milling machines are crucial tools in the world of machining, contributing to the creation of various products we use daily Their importance lies in their unparalleled versatility and precision in the creation of intricate components essential in Vertical Milling Machine Working Principle And Operations,

LM Vertical MillGreat Wall Company

Working Principle; Features; Main Specifications; LM series vertical mill is an efficient equipment which combines crushing ,drying, milling , separating and transporting together When LM series vertical mill plant works, main motor will drive the grinding disc with the reducer, Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLSAccording to 30 years’ research and development experience, basing on design of LM Vertical Mill, adopting technology about superfine vertical mill’ s grinding roller made in Germany, LUM series superfine vertical roller grinding mill was LUM Series Superfine Vertical Roller Grinding Mill

The working principle of LM vertical roller mill YouTube

Liming Heavy IndustryWorking Principle Vertical mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, bucket elevator to be transported to the feeder of vertical mill and was regrinding mill feed people Specifications – Technical Data 0086371LM Vertical MillWorking Principle: Material is ground on a rotary grinding plate that passes under large rollers, and forced off the grinding plate by centrifugal force, where it is then brought into the high efficiency classifier integrated with the vertical mill by the highspeed upward hot air LM Vertical Roller Mill – Jinghua Powder EngineeringWhat is Vertical Axis Wind Turbine or VAWT? The Vertical Axis Wind Turbine is a type of wind turbine and it is most frequently used for residential purposes to provide a renewable energy source to the home This turbine includes the rotor shaft and two or three blades where the rotor shaft moves vertically So, this turbine movement is related to the spinning of coins on the edgeWhat is Vertical Axis Wind Turbine : Working Its Applications

.jpg)

Vertical Milling Machine: Working, Main Parts, Advantages Of Vertical

Working of Vertical Milling Machine: In this milling machine workpiece is fixed without any movement, this used to feed against the cutting tool metal removed from the workpiece is done in the form of chips, we can move the head in up and down direction or any angles by this, we can perform many operations like grooves, slotsVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics Principle of Grinding for these mills are done by Attrition and Compression methodVertical roller mill Wikipedia2024年2月3日 The principle involves variable force, rotating blades having both knife and sharp edges with validated screen size to reduce particles in a controlled manner The mechanism involves the pulverization process ( Pulverization is the grinding and crushing of materials into small particles) knife blades are used to cut the large particles into small size particles, that Multimill; Working and principle in Pharmaceutical » PharmagudduVerticalAxis Wind Turbine Working Principle The VerticalAxis Wind Turbine (VAWT) is a wind turbine that has its main rotational axis oriented in the vertical direction VAWTs were innovative designs that have not proven as effective in general as HAWTs , but they have a few good features, including quiet operationVerticalAxis Wind Turbine (VAWT): Working, Types, Advantages

Understanding the working principle of lum ultrafine vertical mill

Understanding the working principle of lum ultrafine vertical mill The LUM ultrafine vertical mill is a revolutionary grinding equipment that has gained popularity in various industries due to its efficiency in producing ultrafine powders With advanced technology and innovative design, this mill offers a unique approach to material processing