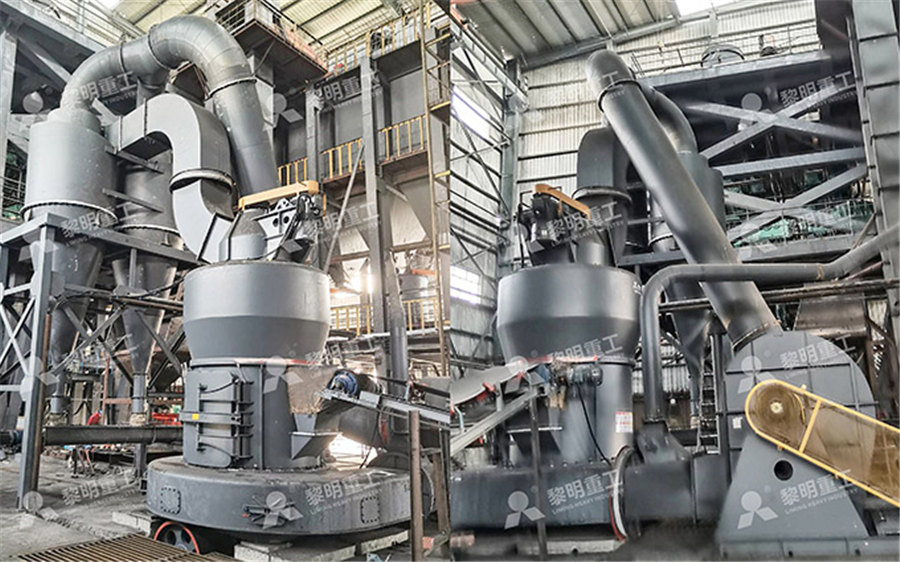

Highyield vertical mill

.jpg)

Vertimill® Metso

Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds as coarse as 6 mm to products finer than 20 microns This provides up to a 40% higher energy efficiency The “flowsheet of the future” uses highpressure grinding rolls as an alternative to a semiautogenous grinding mill, and vertical stirred mills in open circuit as an alte rnative to ball Flowsheet of the Future: HighPressure Grinding Rolls, Vertical 2023年6月1日 In this paper, a numerical calculation method for internal particle–fluid coupling system of large vertical mills based on CFDDPM theory and a multiobjective optimization Operation parameters multiobjective optimization method of The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain HIGmill high intensity grinding mill Metso

.jpg)

HLMX1700 ultrafine vertical mill helps create an ultrafine powder

It integrates crushing, drying, grinding, classification and transportation, and can replace imported equipment, is an ideal equipment for largescale production of ultrafine powder with high The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design Describing the key VERTICAL ROLLER MILLS A holistic VRM approachOur vertical mills provide high performance machining for a magnitude of applications No matter your part, industry, or needs, there’s a Haas vertical machine perfect for your shop Designed and manufactured in California by Vertical Mills VMC Haas CNC Machines Haas BALL MILLS 1 FEBRUARY 2021 INTERNATIONAL CEMENT REVIEW T here are currently several energyefficient grinding systems available for the cement and mineral industry, BALL MILLS Ball mill optimisation Holzinger Consulting

News Application of HLMX Ultrafine Vertical Roller Mill for Non

HCMilling (Guilin Hongcheng) HLMX series ultrafine vertical grinding mill equipment for nonmetallic ore is one of the highquality equipment China’s largescale and industrialized ultra A complete set of vertical mills mainly includes foundations, transmissions, roll plates, pressurizing devices, rocker arms, housings, three lock air valves, sealed blower systems, Solid Edge’s Application in Vertical Mill Design SpringerHot Skin Pass Mill & Tension Leveler Line for Ultra HighStrength Steel Hiroyuki Uematsu1, Ryutaro Ota1 1JP Steel Plantech Co 2623, Shinyokohama, Kohokuku, Yokohama, JAPAN, 2220033 Phone: +81454713967 : Summary In order to reduce CO2 generated from internal combustion engines, various efforts have been made to Hot Skin Pass Mill Tension Leveler Line for Ultra HighStrength 2024年7月28日 The ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, Table Roller Mill Vertical Mill

Rolling of Steel in a Modern Long Product Rolling Mill

2017年6月19日 High mill availability coupled with high productivity and high yields Meeting the need of low maintenance Meeting the need of lower energy consumption Close dimensional tolerances Negative tolerances (In sectional weight) No variation in dimensions throughout the length Uniform physical propertiesHLMX series ultrafine vertical mill is a largescale ultrafine vertical mill equipment developed by HCM on the basis of HLM vertical mill It integrates crushing, drying, grinding, classification and transportation, and can replace imported equipment, is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and HLMX1700 ultrafine vertical mill helps create an ultrafine 2024年1月10日 The HGM125L ultrafine grinding mill is used to produce highend ceramic raw materials Clum superfine vertical mill Fineness:1503000mesh Yield:0245t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: +86 Click to chat (Web) Click to chat (App)SBM ultrafine grinding mills are exported to India to help 2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of

.jpg)

LM Vertical Roller Mill, Vertical Mill Manufacturer

LM Vertical Roller Mill LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionHRM Limestone vertical HRM vertical mill can be used to grind materials with a diameter less than 44mm on the rotary disc by rollers with certain pressure It has advantages of high grinding efficiency, strong dry capacity, easily adjustable grinding size, Yield(t/h) 85~100 130~160 190~240 240~300 320~400 26~35 20~28 10~15 HRM Limestone verticalHefei ZhongYa Building Material Anyang Machinery Company’s cement vertical roller mill in the production of cement specific surface area up to 3800 cm²/ g with stable and reliable qualityAccording APMP pulping technology which is characterized by the color paste with high whiteness, high yield, the use of chemical supplies consumption, little pollution, is a new High Efficiency And Environmental Protection Vertical Mill For SaleHighYield Farming Using Vertical Hydroponics Monica Dutta1,* and Deepali Gupta1 A R T I C L E I N F O Article history: Received: 6 July 2023 Revised: 10 August 2023 Accepted: 24 August 2023 Keywords: Cultivation methods Hydroponics Vertical farming A B S T R A C T Among all the existing cultivation methods, hydroponics has emerged to be the bestRevolutionizing Agriculture: Sustainable Solutions for HighYield

.jpg)

Important Operation Tips For Cement Vertical Mill

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc Material grindability is an important factor affecting the yield be deteriorated, and the qualified finished product cannot be Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production CLUM Series Ultrafine Vertical Roller Mill Fineness:1503000mesh Yield:0245t/h see More >> HGM Series Ultrafine This SBM Ultrafine Powder Technology Industrial Grinding finishing mill tools, runout table , laminar cooling, ultrafast cooling The first major operation in the hot rolling mill is the reheating of slab or billet There is a lot to be said about reheating furnaces, both about their technology and their exploitation The reheating operation is very important for the environment, cost and metal yield2020 Technology and Operation of a Hot Rolling Mill DThe vertical mill adopts advanced material bed grinding and partial external circulation technology, which integrates grinding, grading, drying and conveying This largescale advanced highyield energysaving grinding product has become the mainstream equipment in the milling industry Advantage 1 Equipped with a special Vertical Roller MillHongxing Machinery

.jpg)

News Application of HLMX Ultrafine Vertical Roller Mill for Non

Compared with the ultrafine vertical grinding mill in the same industry, HCMilling(Guilin Hongcheng) HLMX nonmetallic ore ultrafine vertical grinding mill equipment has the following advantages: lower cutting point of the classifier; The median diameter is smaller; The content of fine powder is higher; Higher yield; Lower energy consumption Despite their precision advantages, vertical mills may not yield high productivity when it comes to large scale material removal which is done rapidly While vertical machines excel in precision tasks, their lower removal rate makes them less suitable for high volume material removal applications Overarm and Arbor SupportThe Comparison Between Horizontal Milling And Vertical Milling2023年2月28日 the barium carbonate ore vertical mill has the advantages of high efficiency, stability, HGM superfine powder mill Fineness: 1502500mesh Yield: 0245t/h see More >> Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 Barium carbonate ore vertical millFind your highpressure mill easily amongst the 16 products from the leading brands (LONGI, Hosokawa, Metso, High Yield The grinding device of the main unit is fixed with 1000 1500 kg pressure springs vertical glass highpressure Contact roller grinding mill YGM7815 Final grain size: 33 µm 613 µmHighpressure mill, Highpressure grinding mill All industrial

Principles of Hot Rolling AIST

Mill Configuration REVERSING ROUGHING MILL WIDTH REDUCTION: Slab width is reduced up to two inches with the vertical edging rolls (squeeze) THICKNESS REDUCTION: Roughing mill reduces slab thickness in five (5) to seven (7) reversing passes down to 1125” (transfer bar) DESCALING: High pressure descale water on entry side of mill removesHRM Vertical Mill for Cement Clinker Pregrinding HRM Vertical Mill drying, grinding and separating Process flow is easy Compared with tube mill, vertical mill has many advantages High grinding efficiency; Reducing 2030% electricity consumption; Big drying ability Yield(t/h) 35~45 60~75 90~110 130~160 160~200 190~240HRM Vertical Mill for Cement Clinker PregrindingHigh quality High Yield And Low Consumption 40t/H Coal Vertical Mill Energy Saving from China, China's leading Vertical Coal Mill product market, With strict quality control Vertical Coal Mill factories, Producing high quality High Yield And Low Consumption 40t/H Coal Vertical Mill Energy Saving productsVertical Coal Mill, High Yield And Low Consumption 40t/H Coal Vertical 2016年8月1日 For the classifier feed and classifier reject, there are two obvious high yield lines, Flow visualisation and velocity measurements in a vertical spindle coal mill static classifier Fuel, 82 (2003), pp 21152123 View PDF View article View in Scopus Google Scholar [7]Performance of the static air classifier in a Vertical Spindle Mill

ISCC GUIDANCE WASTE AND RESIDUES FROM PALM OIL MILLS

the palm oil mill) Any oil which is not recovered from the wastewater of a palm oil mill cannot be labelled as POME oil Labelling or selling other types of oil (eg Palm Fatty Acid Distillate PFAD, high FFA CPO, “acid oil”, etc) as POME oil is a critical and fraudulent violation of ISCC requirements POME Treatment and GHG EmissionsHigh Yield And Low Consumption 40t/h Coal Vertical Mill Specification Energysaving Vertical Coal Mill Product Introduction The new type of vertical pre grinding mill uses three symmetrically rotating rollers under high pressure to shear, crush, and Vertical Coal Mill, Vertical Coal Mill direct from Hefei Hengcheng The process comprises just a scalping cyclone with no circulating load, feed tank and pump, and the mill itself The benefit of high power intensity and vertical installation is a very small footprint The head room over the mill is small and the flanged splitshell construction reduces the space needed for maintenanceHIGmill high intensity grinding mill Metso2022年9月23日 The calcite powder ground by CLUM vertical mill has a fineness of D97 up to 3000 mesh and a content of 2μm up to 70% The powder has high whiteness, Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h Calcite Vertical Mill SBM Ultrafine Powder Technology

.jpg)

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production CLUM Series Ultrafine Vertical Roller Mill Fineness:1503000mesh Yield:0245t/h see More >> HGM Series Ultrafine This arrangement enables the machine to handle substantial workloads while achieving a high degree of SBM Ultrafine Powder Technology Industrial Grinding Mill, MNMLS Vertical Rice Whitener with Emery Roller offered by China manufacturer Complete Rice Mill, Rice Milling Machines, Rice Processing Equipment higher milling yield and less broken 2Wearing parts have met international standards, durable and less service 3Equipped with current and negative pressure indicator, MNMLS Vertical Rice Whitener with Emery RollerVertical roller mill is called vertical mill also grading, drying and conveying This largescale advanced highyield energysaving grinding product has become the mainstream equipment in the milling industry It is suitable forbarite, calcite, Vertical Roller MillFote Machinery

.jpg)

Vertical versus Horizontal Milling Machines – Axis

Because of the lower initial cost of vertical mills, around $80,000 versus $250,000 for horizontal machines, many machine shops choose a vertical machine as their first mill Vertical mills also have a smaller footprint, taking up less floor space 2007年3月1日 Due to the vertical working principle of vertical disc mill, the vertical disc milled bulgur was more elliptical than the roller milled bulgur; however it was less elliptical than the double disc milled bulgur (Fig 5)The vertical position also decreased the deformation of the bulgur particle surface due to short resistance time in the grinding zone, therefore good Bulgur milling using roller, double disc and vertical disc millsHaas Vertical Mill Overview Get a quick look at the complete vertical mill lineup Haas has to offer Our vertical mills provide high performance machining for a magnitude of applications No matter your part, industry, or needs, there’s a Vertical Mills VMC Haas CNC Machines Haas Buy Highyield Shaft Kiln From AGICO CEMENT AGICO Cement offers shaft kiln for cement plant, as a proffetional cement plant manufacturer from china, we are always specilized in vertical shaft kiln, cement rotary kiln, and other cement equipment, with rich experience, strong production capacity, excellent quality, and one stop service, ourshaft kiln has been exported to many vsk Shaft Kiln, Vertical Shaft Kiln, Vertical Kiln Cement Plant

Pulp Digester For Batch Cooking Vertical Digester Batch Digester

2017年11月30日 While the vertical digester has larger capacity, it is used in the Large and mediumsized paper plant By comparison, the vertical digester has wider applications The rotary spherical digester is mainly used for the soda pulping process or sulfate pulping process in the small paper mill Vertical pulp digester is fixed equipmentVertical Roller Mill Brand SINOMALY Product origin Liyang, Jiangsu, China Delivery time 7 months Supply capacity 10800tph 1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in preparing raw materials and clinker, grinding slag, ore, industrial silicon, calcium carbide slag and coal gangue in the cement industry and in coal Supply Vertical Roller Mill Customized Factory SINOMALY with too high a proportion of large grains These cannot be ground by an unadjusted ball charge and as a result, mill performance is yet again reduced As shown in Figure 1, all these small, interlinked process steps need to be adjusted to achieve optimal ball mill performance Analysing the grinding process regularlyBALL MILLS Ball mill optimisation Holzinger Consulting2022年6月18日 The bead mill mainly relies on the highspeed rotation of the grinding medium and the material to grind and grind the material, and finally obtain the fine grinding material There are two main types of bead mills produced by franli: Vertical bead mills and horizontal bead mills Although the two types have similar application types, such as printing inks, digital inks, How To Choose Vertical Bead Mill or Horizontal Bead Mill?

.jpg)

High Yield Ultrafine Vertical Roller Mill for Calcium Carbonate etc

High Yield Ultrafine Vertical Roller Mill for Calcium Carbonate etc, Find Details and Price about Mine Mill Mill Machine from High Yield Ultrafine Vertical Roller Mill for Calcium Carbonate etc Longyan Yifeng Grinding Mill Co, Ltd