Battery ore grinding machine and its battery crushing

.jpg)

Crushing of large Liion battery cells ScienceDirect

2019年2月15日 Key to this is a sufficient liberation of components by crushing and grinding This study focuses on safety issues of mechanical processing and on the correlation between the material composition and the required specific mechanical energy input necessary to break the 2023年3月15日 Through experimental methods, the compressive and impact properties of columnar lithium batteries were studied, and the crushing product characteristics and crushing Research on the highefficiency crushing, sorting and recycling 2019年2月15日 Key to this is a sufficient liberation of components by crushing and grinding This study focuses on safety issues of mechanical processing and on the correlation between the Crushing of large Liion battery cells ScienceDirectA crucial step in the battery manufacturing process is the crushing and grinding of the extracted ores This step aims to reduce the size of the ores, making it easier to separate the metals The process of purifying ores for battery manufacturing

Crushing of Battery Modules and Cells SpringerLink

2017年12月13日 Crushing is a substantial process step for the following separation, as it transfers the battery cells or modules to a storable and conveyable bulk material Crushing 2023年10月19日 This study investigates the influence of the crusher settings as well as the pretreatment temperatures to find an optimum between the recovery of the coating and Influence of the Crusher Settings and a Thermal PreTreatment on 2019年2月15日 Key to this is a sufficient liberation of components by crushing and grinding This study focuses on safety issues of mechanical processing and on the correlation between the Crushing of large Liion battery cells Request PDF ResearchGate2024年9月23日 The Shenxiang Column Crusher, through its unique crushing principle, is capable of achieving fine crushing of raw materials Its stable particle control technology How Shenxiang Column Crusher Prepares Battery Cathode and

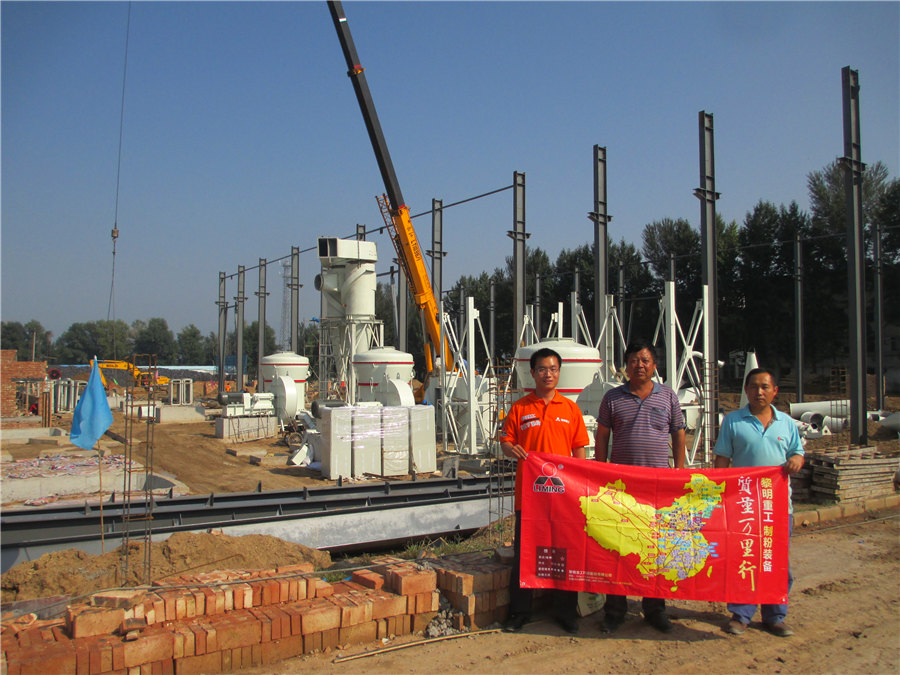

制粉项目-2023.11.17.jpg)

Battery Shredders Battery Size Reduction Systems Franklin Miller

Our battery shredder systems are designed to handle spent or rejected batteries at various states of charge (SOC) levels The shredding process ensures efficient size reduction for subsequent Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction Industrial Ore, Mineral, Slag Crusher Mineral 2024年5月17日 Types and configurations of battery roller machines 21Horizontal battery roller machine: Regular maintenance and upkeep of the machine to extend its service life and maintain stable calcite, quartz, Introduction to Battery Roller Press Machine and Its 2020年1月23日 In the paper, two types of crushing tests of LiPo batteries are shown: in the first test, a semicylindrical punch crushed a battery previously cut while a digital camera, equipped with a highmagnification telecentric lens, recorded images of the lateral surfaces of the sample; in the second test, a whole fullyoperative battery was crushed by a semispherical punch while a Analysis of Deformations in Crush Tests of Lithium Ion Battery

Stamp Battery 911Metallurgist

2016年10月29日 The stamp battery must be regarded from two different points of view, (a) as a crushing machine, (b) as an amalgamating machine, and it should be remembered that the modifications designed to make it a more efficient crusher often reduce its power as an amalgamator, and vice versa Stamps were originally designed as crushing machines, and 2022年1月1日 Mechanical liberation of LIBs can be distinguished into crushing the battery modules or cells, milling electrode mixtures, and grinding black mass The main purpose of crushing ( Section 311 ) in terms of automated cell opening is the liberation of the complex compound structure by breaking up the bonds between the individual components or materialsMechanical and physical processes of battery recycling2017年5月21日 Autogenous, semiautogenous, and conventional rod millball mill grinding were considered: Conventional crushing and grinding plants are safe and conservative The ore can be tested by proven techniques and crushers and mills selected with assurance that they will meet performance requirementsCopper Ore Crushing, Grinding Flotation 911Metallurgist2015年12月26日 The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples of 2″ x 2″ (51mm X 51mm) This techniques allows for a rocktorock relative comparison The Bond’ Crushing Work Index is common to calculate the power needed to crush rocks from a given F80 size to a resulted P80 product sizeCrushing in Mineral Processing 911Metallurgist

(PDF) The Effects of Blasting on Crushing and Grinding

2003年1月1日 The Effects of Blasting on Crushing and Grinding Efficiency and Energy Consumption January 2003; crushing 40 million tons of ore per year, the savi ngs are $118 million per yearAt Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where technology and excellence converge Ore Crushing, Sand Making, Grinding Machinery Bellian Mining 2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding Grinding Modeling and Energy Efficiency in Ore/Raw Material China Crushing And Grinding Machine wholesale Battery Material Crushing Machine Battery Material Grinding Machine Micro Powder Pulverizer US$ 20000 / Set 1 Set (MOQ) Qingdao Rui Xintai Machinery Technology Co, LtdCrushing And Grinding Machine MadeinChina

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Crushing and Grinding Process JXSC Machine

2019年10月8日 1 Crushing and grinding improvement The ore size reduction process involves two steps: crushing and grinding The grinding process is the final operation of making the mineral to dissociate from the monomer and 2024年4月8日 The specific selection of crushing and grinding sections is based on the properties of the raw ore, material particle size, product fineness, and equipment type Each time a material passes through a stone crusher or Selection Of Lithium Ore Processing Plant EquipmentBernardo bench grinding machine DS 200 S 230 Volt Bernardo bench grinding machine DS 200 S 230 Volt : These universal bench grinding machine is designed for professional use The induction motor features top quality ball bearings to eliminate noise and maintenance Quality grinding wheels ensure optimal results when sharpening and 230 volt baby grinding machineThe standard capacity of this battery crusher and sorting system is 100,000t batteries per year, waste lead batteries (10% acid content) as raw material, the batteries will go through preliminary crushing machine to remove acid, then go to secondary crushing, vibrating screening, hydroseparator, heavy metal removal,water separationBattery Crusher, Battery Crushing and Sorting System

.jpg)

Process flow of lithium battery crushing and recycling equipment

2022年11月28日 At the same time, the power battery can be used as a battery production material after recycling Among them, cylindrical lithium batteries account for about 7080% of waste power batteries, and the dismantling of waste cylindrical lithium battery shells and cells has become the first key stepKERUI Machinery’s lithium battery recycling machine is capable of recycling various types of lithium batteries, including soft package battery, cellphone battery, shell battery, cylindrical battery etc Through processes such as shredding, drying, crushing, and screening, graphite powder, cobalt acid lithium, aluminum and copper can be Lithumion Battery Recycling Machine – GongYi City Kerui 2023年5月15日 Based on the JK Drop Weight test and principle of selective crushing, a multicomponent complex ore with its component minerals, ie, pyrrhotite, sphalerite, and quartz, was used to explore the impact crushing characteristics and relationship between the complex ore and its component minerals Results show that the order of impact crushing resistance is Impact Crushing Characteristics and Relationship between 2016年5月10日 In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost In some areas rainfall is high for prolonged periodsCrushing and Grinding Wet Sticky Ore 911Metallurgist

Ore Crushing SpringerLink

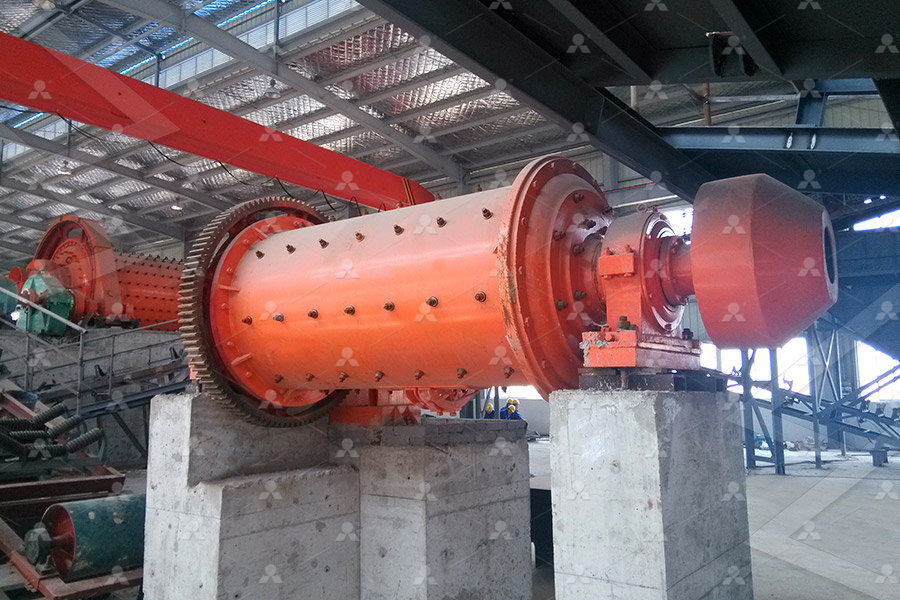

2023年7月22日 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three The main force in the coarse 2024年7月12日 EV Liion Battery Crushing Recycling Machine Time: 15:39:23 With the rapid development of electric vehicles, a large number of endoflife lithiumion batteries have become an urgent problem In order to realize the effective recycling of these batteries, the related crushing and recycling technology is particularly importantEV Liion Battery Crushing Recycling Machinenew lithium ion battery recycling machine crushing capacity 300kg/h Small Scale Waste Car Prius Liion Battery Recycling is used for dismantling and recycling the Laptop Battery, cellphone battery, (EV) Car Battery, soft package battery, Hard Shell Battery, shell batter cylindrical battery,LIPolymer Pouch Type Battery, Automotive Pack and Modules Batterles, Positive Waste Power Battery Crushing Treatment Equipment Recycling Machine 2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size Duan XX, Xiao QF (2012) Crushing and grinding, 3rd edn Metallurgical Industry Press, Beijing Google Scholar Sun CY (2015) Handbook for mineral processing engineers, vol 1 Metallurgical Industry Press, Beijing Google Ore Grinding SpringerLink

.jpg)

The difference between crushing and grinding

2021年5月24日 The process of turning small particle materials into powder materials by external force is called grinding or milling, and the machinery used is called grinding machinery The combination of crushing and grinding is referred to as smashing or grinding, and the machine used is referred to as pulverizing machine or grinding machineThe exact methods or machines used to crush and separate batteries may vary depending on the type, but they typically involve shredding, hammering, or grinding Material Recovery After the components are separated, the materials must be recovered Different batteries contain different materials that can be reused or recycledThe Importance of Battery Recycling Williams Crusher2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2023年5月27日 In addition to its role in lithium ore processing, ball milling has also been used in the synthesis of lithiumion batteries By using ball milling to prepare the electrode materials, researchers have been able to improve the performance and stability of lithiumion batteries, making them more efficient and durableBall Milling in Lithium Ore Processing: A Comprehensive Guide

Battery Breaking and Separation STC

The battery breaking and separation plant can be integrated with some optional units like: Battery precrushing unit (inline or with intermediate storage buffer); Metallic fraction separation of fine metallic fraction (fine grids) from coarse fraction (large grids, posts and poles); Polypropylene washing, grinding and extrusion line;The first battery erected at the mine was Warde and Company's in November 1876, evidently financed by A Forsythe in Brisbane, from whom this expensive ten head stamp battery took its name This battery began crushing in February 1877 and the local proprietors, John Warde and Thomas E White, renamed it the Brisbane in March 1877Tyrconnel Mine and Battery Wikipedia2023年3月14日 Wash the raw nickel ore with a spiral washer Crushing: Use a jaw crusher and a cone crusher for crushing Grinding/Milling: After crushing, the ore is ground into 100 mesh in a ball mill Magnetic separation: Use a wet magnetic separator to separate pyrrhotite5 Critical Battery Minerals: Powering the Electric Vehicle (EV 2024年5月23日 1 Initial crushing and screening: Employing specialized jaw crushers and cone crushers to gradually crush large vanadium titanomagnetite ores Vibrating screens ensure the obtained ore reaches suitable processing fineness while effectively separating impurities 2 Fine grinding: Further refining the ore through ball mills or rod mills until the particle size is below Beyond Lithium: Vanadium Leads the New Era of Batteries

.jpg)

Crushing of large Liion battery cells ScienceDirect

2019年2月15日 With climate change mainly being caused by CO 2 emissions, in part originating from the combustion of fossil fuels, zero or low emission vehicles will see an increasing demand in the near future (Tian et al, 2014) While the number of sold EVs is growing steadily but slowly in the countries of the European Union and in the United States of America, the market in the 2024年9月15日 Lithiumion batteries play a crucial role in the transition to a sustainable energy system and are an essential component in the decarbonisation of transportation and traffic (Stampatori et al, 2020)According to calculations of the International Energy Agency (IEA), the production capacity of lithiumion batteries is expected to grow from 300 GWh in 2020 to over Fine grinding of pyrometallurgical battery slag and its influence 2023年12月1日 Mechanism of the dynamic behaviors and failure analysis of lithiumion batteries under crushing based on stress wave theory Eng Fail Anal, 108 (2020), Article View PDF View article View in Scopus Google Scholar [36] YJ Liu, Y Xia, BB Xing, Q ZhouDynamic crushing behaviors and failure of cylindrical lithiumion 2021年10月26日 Graphite grinding machine includes ultrafine mills, vertical mills, highpressure mills, electrodes, brushes, dry batteries, graphite fibers, heat exchangers, coolers, electric arc furnaces, arc lamps, pencil refills, etc SBM provides nonmetallic ore grinding/crushing and screening solutions The common choice of 1000 Graphite Grinding Machine Powder Mill Equipment

.jpg)

How Does The Graphite Grinding Plant Process?

2024年9月20日 2 Impact crusher The impact crusher can process materials with a side length of 100500 millimeters or less, with a maximum pressure resistance of 350 MPA It has the advantages of a large crushing ratio and with cubic material particles This machine is widely used in building materials, ore crushing, railways, highways, energy, transportation, cement, mining, 2019年1月1日 Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultrahigh frequency January 2019 E3S Web of Conferences 123(89 Research into the crushing and grinding processes of iron ore with its Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawalCrushing Plant Design and Layout Considerations 911 Metallurgist2023年4月25日 A complete coppernickel sulfide ore processing production line is crushing, grinding, flotation, and tailings treatment 11 Coppernickel sulfide ore crushing stage Adopt a twostage closedcircuit crushing process ① Use a jaw crusher for primary crushing ② Use a cone crusher for fine crushing2 Types of Nickel Ore: Processing Methods and Equipment