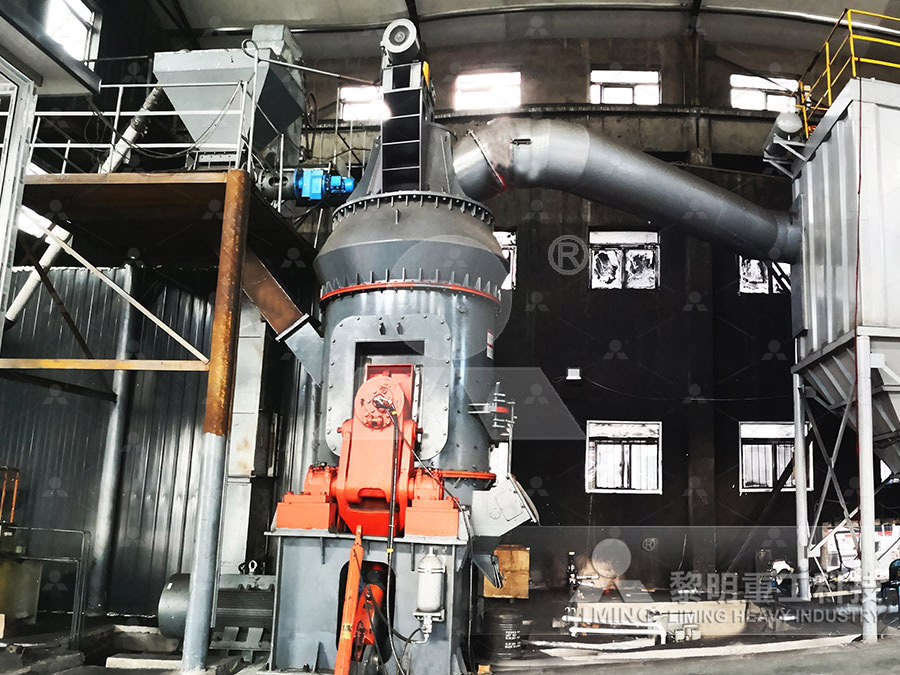

Hydraulic system vertical mill

Hydraulic system vertical roller mill operation PDF

2015年3月25日 This type vertical roller mill including the hydraulic station, connected with the grinding roller cylinder and hydraulic pipe and other componentsVertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsThe quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design Describing the key VERTICAL ROLLER MILLS A holistic VRM approachThe core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Operation Manual: HRM1700M Vertical Roller Coal Mill

It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such Analysis of vertical roller mill performance with changes in material Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy Vertical roller mill Wikipediahydropneumatic spring system which consists of hydraulic cylinders, hydraulic accumulators and hydraulic unit, and the table driven by electrical motor through high efficiency vertical planetary VERTICAL ROLLER MILLS AMCL

.jpg)

Cement mills and raw mills for high throughput rates

MVR vertical roller mill from Gebr Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availabilityIn combination with the conventional drive, the MVR mill ensures small to medium output rates, reliably and on the long term Up to six grinding rollers may be swung out separately, using MVR vertical roller mill with planetary gearbox Gebr PfeifferA vertical roller mill is an energysaving mill that meets market demand gearbox, stand, hydraulic system, and other parts The following are key parts of the vertical mill: 1 Grinding roller Grinding rollers (usually 2–4) are the heart Energysaving and Efficient Vertical Roller Mill Fote • Mill motor speed • Mill air flow/mill differential pressure • Temperature after the mill • Pressure before the mill • Grinding stock feed • Classifier speed • Mill fan speed • Water spraying • Hot gas • Fresh air Manipulated variables Disturbance variable Process measured value RelauchLMmaster 6 250814 11:47PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

Hydraulic System Vertical Roller Mill Operation StudyMode

The working principle of the hydraulic system vertical roller mill The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of the grinding roller mill, to replace the inside parts or repairThe highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill With our proven LiftandSwing System, wear parts can be replaced rapidly through one single maintenance doorCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsA Vertical mill consists mainly of motor, planetary gearbox, grinding table, grinding rollers, The hydraulic roller swingout device provides for ease of maintenance Low operation pressure of the hydraulic system reduces potential oil leakage and mill vibration, providing for smooth operation and reduced maintenanceVertical Roller Mills LNV TECHNOLOGYA roller mill incorporating the system of the present invention has the further advantage that it is selfcompensating for wear of the grinding components Internal leakage is inherent to virtually all hydraulic systems Therefore, oil must be added to the system periodically to maintain the prescribed nominal grinding pressure setpointVertical roller mill with improved hydropneumatic loading system

PresentationHydraulic System in VRPM PDF Mill (Grinding)

This document discusses the hydraulic system used in vertical roller pregrinding mills (VRPM) The hydraulic system applies precise, adjustable force to rollers to grind clinker between the rollers and grinding table Hydraulic cylinders connect each roller to the system and allow individual roller force control The system functions like a shock absorber, using accumulators Vertical Roller Mill Hydraulic System Manufacturers, Factory, Suppliers From China, Welcome around the world consumers to speak to us for organization and longterm cooperation We'll be your reputable partner and supplier of auto areas and accessories in ChinaVertical Roller Mill Hydraulic System Factory, Suppliers These signals were acquired through FBG sensors on the vertical mill Among all the signals, the strain and displacement signals are always used to present the change of hydraulic loading pressure, the displacement and velocity of the piston in Full article: Reliability assessment of the vertical roller mill based The hydraulic system in a vertical roller mill is designed to provide a constant grinding pressure The pressure between the grinding media and the material being ground is typically in the range of 100300 MPa, and can be adjusted depending on the properties of the material being groundHow does Vertical Roller Mill Work? ball mills supplier

.jpg)

OK™ Raw and Cement Mill

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal Mill2019年10月10日 As the core control system of a rolling mill, the hydraulic automatic gauge control (HAGC) system is key to ensuring a rolling process with high speed, high precision and high reliability However, a HAGC system is typically a mechanicalelectrichydraulic coupling system with nonlinear characteristics The vertical vibration of the load easily occurs during the Bifurcation Characteristic Research on the Load Vertical MDPI2019年11月2日 The rolling mill with hydraulic system is widely used in the production of strip steel For the problem of vertical vibration of the rolling mill, the effects of different equivalent damping coefficient, leakage coefficient, and proportional coefficient of the controller on the hydraulic screw down system of the rolling mill are studied, respectively First, a vertical Research on the Vertical Vibration Characteristics of Hydraulic Screw

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Part 1: Structure of Vertical Roller Mill (VRM) Crusher shell: Covers the internal parts of the crusher and creates a crushing cavity Each roller has a hydraulic system for lifting and lowering, creating its own crushing pressure The rollers are lined with a OPERATION OF VERTICAL ROLLER MILL (VRM) NATIONAL Learn how vertical roller mill technology is transforming the cement industry Explore its benefits, efficiency, and ecofriendly features The grinding table rotates counterclockwise, and the grinding rollers are pressed against the table with a hydraulic system AdvantagesApplication of Vertical Roller Mill in Cement Production2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI 2014年4月1日 The latest innovative technology for vertical roller mills: Modular mill with modular drive system and swing mill solutions April 2014 DOI: 101109/CITCon2014(PDF) The latest innovative technology for vertical roller mills Advantages of vertical roller mill: The contact surfaces of the grinding plate and the grinding wheel are specially designed to ensure efficient and stable operation The roller hydraulic system has an adjustable spring rate that is applied to the Vertical roller mill Hengtu MachineryMill Fig1 Flow of Conventional Vertical Mill Grinding System Mill Kiln IDF (Kiln gas exhaust fan) Fig2 Flow of direct dust collection system Results Power consumption of fan(s) reduces about 3 to4 kWh/t Cost estimation When a mill with a production capacity of 420 t/h was newly constructed, the total cost was about 25 million US$ [1US$=¥ Vertical roller mill for raw Application p rocess materials

Vertical roller mill with improved hydropneumatic loading system

A roller mill incorporating the system of the present invention has the further advantage that it is selfcompensating for wear of the grinding components Internal leakage is inherent to virtually all hydraulic systems Therefore, oil must be added to the system periodically to maintain the prescribed nominal grinding pressure setpoint2013年5月1日 Based on vibration problems of a six roller cold rolling mill, hydraulicmachinery coupling vibration system dynamic model of the 2180mm 4stand tandem cold rolling mills was built integrated the software of MATLAB and ADAMS and simulated The simulation result was consistent with that of the field test data revealed by rolling mill vibration Through the Simulation on HydraulicMechanical Coupling Semantic Scholar2023年11月28日 They established the nonlinear dynamic equations of the vertical system of the rolling mill, based on D'Alembert's principle which contained the nonlinear stiffness of the hydraulic cylinder The researchers analyzed the relationship between the nonlinear stiffness of the hydraulic cylinder, the external force acting on the rolling mill system, and their influence Dynamics and stability analysis of rolling mill system during This paper investigates the adaptive fuzzy vertical vibration suppression control problem for the sixhigh rolling mill system Firstly, a new vibration model is established with the consideration of the coupling of mechanical and hydraulic systems and the unknown uncertainty on nonlinear rolling force Then, the adaptive active control strategy is proposed to suppress chatter of the Adaptive Fuzzy Vertical Vibration Suppression Control of the

.jpg)

Optimization Strategy of Rolling Mill Hydraulic Roll Gap Control System

2023年3月31日 Medium and heavy plates are important strategic materials, which are widely used in many fields, such as large ships, weapons and armor, large bridges, and super highrise buildings However, the traditional control technology cannot meet the highprecision control requirements of the roll gap of the thick plate mill, resulting in errors in the thickness of the 2021年1月29日 control system for Vertical Roller Mill", The 2nd international conference on Intelligent control and information processing [5] RVirendra, Dr BSudheer, P rem Kumar, JSuresh Babu and DRajani Increase productivity of vertical roller mill using seven QC toolsExplore topquality sawmill equipment at Sawmill Hydraulics, Inc Your Feedworks), Vertical Edgers, Log Turners, Drag Chain, Sawyer’s Booth, Double End Trimmer, Scragg Mills Mobile Mills Drop Belts, Computerized Setworks (HELLE TECH I II, SAWTECH SETWORKS, NEWTOTAL TECH), Band Mill Resaw Systems, Top Saws, Offbearers Home Sawmill Hydraulics, IncThis paper investigates the adaptive fuzzy vertical vibration suppression control problem for the sixhigh rolling mill system Firstly, a new vibration model is established with the consideration Vertical vibration diagram of rolling mill ResearchGate

Research on vibration characteristics of mill rolls based on

2021年4月1日 At present, the international scholars have studied the reasons of rolling mill vibration in several ways Johnson et al explored the nonlinear caused by deformation between the work roll and the backup roll, which led to the rolling mill system form the fifthoctave vibration by the establishment of rolling mill two degrees of freedom and four degrees of freedom 2020年1月1日 C Qian et al: Adaptive Fuzzy Vertical Vibration Suppression Control of the MechanicalHydraulic Coupling Rolling Mill System From (11), (13), (17) and (20), the derivativ e of V yields V = 2 ˙ µ(PDF) Adaptive Fuzzy Vertical Vibration Suppression 2023年7月4日 The vertical mill is “cylindrical surface plus plane,” the roller presser is “cylindrical surface plus cylindrical surface,” and the extrusion channel contact form of the cylinder roller mill is reducer, belt pulley, and gear shaft), the hydraulic system, the stand, the transverse leakproof device, the Roller Mill SpringerLinkWhile the Hydraulic Roller Press can be used to upgrade ball mill systems for energy efficiency and enhanced production benefits, it is also exemplary in upgrading your vertical roller mill The resulting benefits include increased production, without any increase in specific energy consumption, and increased availability of the overall grinding systemHydraulic Roller Press FLSmidth Cement

Chapter Six: Some Operating Guidelines Vertical Roller Mill

2022年4月6日 The auxiliary groups, hydraulic system, transport system (does not include feeding transport), dust removal system, draft (minimum rotation), and separator, working If the mill has a pneumatic 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particlesAnalysis of vertical roller mill performance with changes in 2017年1月17日 Online running condition monitoring of the vertical roller mill (VRM) As most faults of VRM relate to hydraulic pressure of loading system and mechanical vibration, Reliability assessment of the vertical roller mill based on ARIMA divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill and gear shaft), the hydraulic system,thestand,thetransverseleakproofdevice, the discharge device, the control system, etc Working principle: the material is fed by the feeder between two parallel, opposite, and synRoller Mill Springer