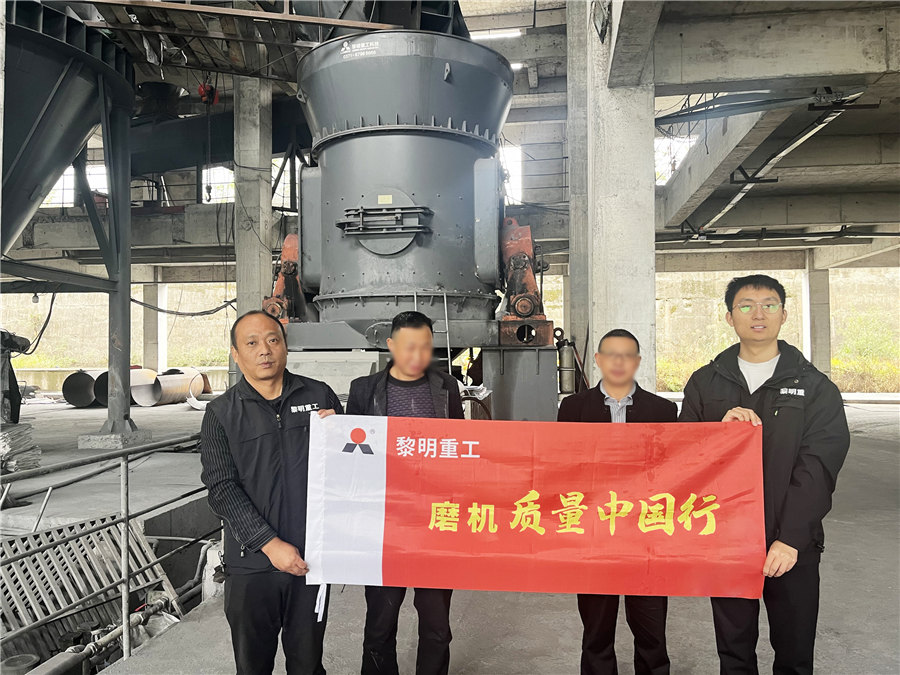

1000 tons of sodium alum stone steelmaking plant steel slag vertical mill Raymond mill

.jpg)

The recycling and reuse of steelmaking slags — A review

2019年7月1日 Steelmaking slag and bauxaline (a byproduct of creating aluminum products) were chosen as candidates as they are both low cost byproducts from industrial processes 2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants Steel slag in China: Treatment, recycling, and management2007年3月1日 Pilot plant trials successfully demonstrated the viability of recycling million of tons of steel plant dusts and sludge that are now typically land filled, and typically converting them An overview of utilization of slag and sludge from steel industries2005年2月1日 Steelmakers have made attempts to reduce slag volumes in the individual unit processes and to strive towards slagless steelmaking by recycling slags internally A much (PDF) Industrial uses of slag The use and reuse of iron and

.jpg)

Steel slag in China: Treatment, recycling, and management

Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can 2023年11月20日 Considering global steel production of 1878 million tonnes in 2020, the associated slag byproducts possess a significant resource of major components like FeO, A Review on Environmental Concerns and Technological 2019年5月23日 Steel slag is the waste generated in the steelmaking process and includes ferric oxide and the impurities of some infusible matters It is the byproduct when slagforming Comprehensive Utilization Technology of Steel Slag2021年9月24日 This paper takes a critical look at the developments toward steel slag recycling and utilization, leading to resource conservation and greenhouse emission control Various BOF Steel Slag: Critical Assessment and Integrated Approach for

.jpg)

Research on the Properties of Steel Slag with Different MDPI

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three 2020年10月15日 Capturing CO 2 by steel slag (SS) via mineralization is regarded to be an excellent choice due to the high basicity of the slag In this paper, recent research on the steel Cotreatment of Waste From Steelmaking Processes: Steel Slag 2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, An overview of utilization of slag and sludge from steel industries2021年9月1日 The steel slag used in this study with a specific surface area of 1173 m 2 /kg was obtained from Hebei Jianye Steel Plant (Tangshan, China) and was classified as a basic oxygen furnace (BOF) slag Environmental benefit assessment of steel slag utilization and

2 Electric Arc Furnace Steelmaking and Slag

An example of slag chemistries during stainless steel production from Holappa et al (2021) is given in Table 23 where significant quantities of chromium oxide are found in the EAF slag; however, due to the high reactivity of chromium with and composition adjustment The yield of iron/steel slag is about 300 kg/tp per ton of pig iron for blast furnace slag and about 100150 kg/ts per ton of molten steel for steelmaking slag In Japan, some 40 million tons of iron/steel slag are presently produced annually (Table 1) Technology UDC 669 054 82 : 669 184 244 66Processing and Reusing Technologies for Steelmaking Slag2019年1月1日 In an integrated steel plant, wastes (including solid, liquid and gas) are generated for every ton of steel produced In India, almost 100 million tonnes of steel is produced every year, and along Recent trends in slag management utilization in the steel 2016年1月21日 In fact, it is estimated that 7 to 75 million metric tons (77 to 83 million tons) of steel slag is used each year in the United States alone for a range of applications Because of its hydraulic property and the large bearing capacity it can provide, steel slag is often used as a road base course materialSteel Slag: The Incredible, Upcycable Byproduct of Steelmaking

.jpg)

Steel Slag Utilization — Overview in Indian Perspective

2016年8月31日 Current total productions of steel slag in India, are around 12 million tonnes per annum (Indian Minerals Yearbook, May 2016), which is far behind the developed countriesThe purified steel slag tailings has an iron content of less than 2% and a fineness of less than 10mm The metal material can be recycled back to the steel plant for sintering and steelmaking Steel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller millSteel Slag Grinding Plant CHAENGSteel slag is a byproduct generated during the steelmaking process As the largest steel producer in the world, China produces over 100 million tons of steel slag annually, accounting for approximately 15–20% of crude steel production (Rui et al 2022, Shi et al 2022)After steelmaking, the slag is placed in a slag heap and subjected to magnetic separation to recover Activation technology of steel slag for concrete exposed to 2018年8月1日 For example, Wuhan Iron and Steel Company used 170 thousand tons of steel slag as backfill in 1992, which resulted in a total foundation expansion of 390 m 2; Evaluation of the economic feasibility of a processing plant for steelmaking slag Waste Manage Res, 34 (2016), pp 107112 View in Scopus Google ScholarSteel slag in China: Treatment, recycling, and management

Electric Arc Furnace Steelmaking and Slag Formation,

2023年11月17日 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population centers), and the 2018年1月20日 Steel production has been targeted to be higher than as of now in future and the generation of slag will also be high Steel slag is presently used in various fields such as in construction (Lam (PDF) Preparation and Characteristics of Steel Slag 1 Introduction The basic oxygen steelmaking (BOS) process produced over 70% of the global crude steel in 2018, [] generating 100 to 150 kg of slag (“BOS slag”) for every tonne of crude steel produced BOS slag, a product of hot metal Basic Oxygen Steelmaking Slag: Formation, Reaction, 2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the (PDF) Application of Steel Slag as an Aggregate in ResearchGate

Recycling of steel plant mill scale via iron ore sintering plant

2012年4月1日 In an integrated steel plant, portion of mill scale, This paper presents an assessment on the wastes namely slag, dust, mill the waste generation factor developed was 3493kg per ton of 2010年9月1日 Request PDF Leaching of silica from vanadiumbearing steel slag in sodium hydroxide solution The work aims to selectively extract silica from vanadiumbearing steel slag by a leaching processLeaching of silica from vanadiumbearing steel slag in sodium 2014年1月1日 to 320 million tons, and steel slag about 140 to 220 million Pelletizing steel mill desulfurization slag Article Jul 50,000 tons of this slag is produced at one particular steelmaking plantSteelmaking Slag Beneficiation by Magnetic Separator and 2015年3月17日 Steel slag is a byproduct of the steel industry Understanding of the chemical, mineralogical, and morphological properties of steel slag are necessary for its use in sustainable practicesSteel Slag; Chemistry, Mineralogy and Morphology ResearchGate

.jpg)

Steel Slag Utilization — Overview in Indian Perspective

About 150180 kg steelmaking slag is generated per ton of steel may have a harmful impact on the environment Table 1: Plant wise Capacity of Iron and Steel Slag in the Country (IMY, 2012) Name and Liu, L (2000)Stability processing technology and application prospect of steel slagSteelmaking (in Chinese), 25: 748 (2000 2022年5月1日 Abstract Considering the BSSF steelmaking slag generated in a Brazilian steelwork, it would be worth to separate iron and calcium from it, with the objective of increasing its iron content, or Separation of Iron and Calcium from a BSSF Steelmaking Slag Table 1 summarizes the chemical composition of LD slag (Singh et al , 2013; Das et al , 2007; Waligora et al , 2010), Table 2 depicts the chemical composition and major phases of typical LD Flowchart of slag production in a modern steel plant2003年4月1日 About 150180 kg steelmaking slag is generated per ton of steel depending upon the quality of hot metal At present less than 50% of the slag is used in road making, construction and sinter making (PDF) Utilisation of LD slag — An overview

.jpg)

Chemical composition of iron and steel slag

The primary components of iron and steel slag are limestone (CaO) and silica (SiO 2)Other components of blast furnace slag include alumina (Alsub>2 O 3) and magnesium oxide (MgO), as well as a small amount of sulfur (S), while steelmaking slag contains iron oxide (FeO) and magnesium oxide (MgO)In the case of steelmaking slag, the slag contains metal elements 2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total Use of steel slag as sustainable construction materials: A review 2016年5月16日 In this study, aqueous mineral carbonation of Linz–Donawitz (LD) slag waste from Rourkela, Bokaro, and Tata steel industries was undertaken at a room temperature of 30°C and elevated CO2 (PDF) Sustainable Approaches for LD Slag Waste Management in Steel 2019年3月30日 Steel slag is a large discharge of industrial waste slag Chinese effective utilization rate of steel slag is only 20%, causing great harm to the environment and economyPhysical and Chemical Properties of Steel Slag and Utilization

.jpg)

Sustainable Approaches for LD Slag Waste Management in Steel

2016年5月16日 The average rate of generation of LD slag is approximately 150–180 kg per ton of crude steel in India []Researchers also found that this rate of production of LD slag somtimes reaches a high of 200 kg per ton of crude steel []In India, over 1215–1458 metric tons of steelmelting slag has been generated in the financial year 2013, and this rate is still increasing Capital Investment Costs Iron and Steelmaking Plant and Equipment Executive Summary Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free Report identifying current capital investment costs for iron and steelmaking plant and equipment including capacity versus cost charts Coverage includes ironmaking, steelmaking, flat and Capital Investment Costs Iron and Steelmaking Plant and2015年3月31日 Steel slag is a byproduct obtained from steel industry It is generated as a residue during the production of steel Because of the high disposal cost as a waste material and the overall positive Steel Slag as A Road Construction Material ResearchGate2019年1月1日 Reportedly, 150200 kg steelmaking or high furnace slag is produced per one ton of produced raw steel As reported in Turkey’s Slag Report annual slag production of Turkey has reached 54 million tons as of year 2014 [5]An Overview of Utilization of Blast Furnace and Steelmaking Slag

.jpg)

An Overview of Use of LinzDonawitz (LD) Steel Slag

Physical and chemical and mineralogical characteristics of LD steel slag It has been found that the density of LD slag lies between 3336g/cm 3 Due to its high Fe content, steel slag looks in appearance a loose collection, and appears 2023年11月3日 To address this concern, steel slag, a byproduct of steelmaking, is used as a partial replacement for fine aggregate to compensate for the loss of strength Steel slag emerges as a viable alternative as a partial replacement for natural aggregates when the natural aggregate usage in concrete fails to meet the required quantity and quality standardsStrength and Durability Properties of Steel Slag Incorporated Self 2024年10月1日 Qiu et al [8] carried out experiments of sodium hydroxide steel slag double alkali method of sintered flue gas desulfurization in a bubbling reactor, and found that the desulfurization rate could be maintained above 80 % for a long time under the optimal conditions, and the sodium hydroxide steel slag double alkali method of desulfurization could overcome Utilization of steel slag in air pollution and greenhouse gas 2020年10月16日 The iron and steel industry is an energyintensive sector, and large amounts of waste/ byproducts are generated during the steelmaking process, such as CO2, metallurgical slag, and wastewater(PDF) Cotreatment of Waste From Steelmaking Processes: Steel Slag

BOF Steel Slag: Critical Assessment and Integrated Approach for

2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of According to Indian Mineral Book 2018, steel slag output is approximately 2030 % by mass of the crude steel production in the country which yields around 195 million tons of solid steel slag production annually in India Majority of steel slag after metal recovery ends as waste dump or as land fill materialSteel Slag Road for Durable Infrastructure2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water Research on the Properties of Steel Slag with Different MDPI2015年12月27日 Slag generated from basic oxygen furnace (BOF) or LinzDonawitz (LD) converter is one of the recyclable wastes in integrated steel plants This paper deals with the present and possible use of LD An Overview of Use of LinzDonawitz (LD) Steel Slag in Agriculture

Carbon capture and storage technology by steelmaking slags:

2023年1月1日 So far, carbon dioxide sequestration by steel slag carbonization has been widely studied by many scholars Ding et al [8] proposed a new linear programming model to evaluate the economic cost of carbon dioxide capture and storage in Chinese steel plants, and believed that the adoption of carbon capture and storage technology in steel plants could obtain 2021年12月1日 As one of the important industries in the world, iron and steel industry plays an irreplaceable role In 2016, the world's crude steel output reached 163 billion tons [1]On average, each ton of steel production could accompany with 18 tons of CO 2 emissions [2]Globally, CO 2 emissions from iron and steel industry account for about 6–7 % of global CO 2 emissions [3]Carbonation of steelmaking slag presents an opportunity for