How much is the fine for ore powder making

Making Metal Powder MPIF

In this process, molten metal is separated into small droplets and frozen rapidly before the drops come into contact with each other or with a solid surface Typically, a thin stream of molten metal is disintegrated by subjecting it to the impact of highenergy jets of gas or liquid In principle, the technique is applicable to 展开The present study deals with the utilization of fines generated from comminution process (crushing, grinding and screening) of the Run of Mines into value added products ie fluxed iron ore pellets(PDF) The utilisation of iron ore fines : Technical 2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke)(PDF) Iron Ore Sintering: Process ResearchGate2016年10月28日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product with suitableIron Ore Sintering: Raw Materials and Granulation

Direct Reduced Iron ByProduct Fines (DRI D): A Guide to Handling

DRI (A) or (B) typically contains 9094% total Fe, of which 8090% is metallic Fe (typical metallisation being 9296%) There are two principal sources of fines generation during the However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the Iron Ore Pelletizing Process: An Overview IntechOpen2013年2月23日 Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh (0074 mm) with additives like bentonite and then shaping them into near Introduction to Iron ore Pellets and Pelletizing processesDirect reduced iron (DRI), also called sponge iron, [1] is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) into iron by a reducing gas which contains elemental carbon (produced from natural gas or coal) Direct reduced iron Wikipedia

A review of ironmaking by direct reduction processes: Quality

2019年1月1日 It has been estimated that approximately 6575% of sponge iron production cost is attributed to the cost of raw materials (Indian Bureau of Mines, 2011) As a measure to 2020年6月3日 A new route for making steel from iron ore based on the use of hydrogen to reduce iron oxides is presented, detailed and analyzed The main advantage of this steelmaking route is the dramatic reduction (90% off) in CO2 Hydrogen Ironmaking: How It Works MDPI2019年6月11日 World resources are estimated to be greater than 800 billion tons of crude ore containing more than 230 billion tons of iron The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it Sintering: A Step Between Mining Iron Ore and 2023年8月17日 Making black powder provides the foundation for dazzling fireworks displays and explosive effects The use of a ball mill is essential in the production of this pyrotechnic mixture As the ball mill turns, the balls within Using a Ball Mill for Black Powder Production: How It

.jpg)

Best method to produce very fine powder : r/labrats Reddit

If you have a steel ball tissue grinder/cell lyser that should do the trick If you really want to get it fine, put it in a sample jar (for grinding), freeze the jar in liquid nitrogen for ~5 minutes and run it in the grinder with smallmedium steel balls at a high rate of oscillations2023年1月28日 What is iron ore pellet Iron ore pellets are made by adding a small amount of additives to the fine ore powder (200 mesh, that is, the ore powder with a particle size of less than 0074mm accounts for more than 80%, and the specific surface area is more than 1500cm2/g), adding water to the pelletizer, relying on capillary force and mechanical force of Iron ore pellets for blast furnace a technical guide MAXTON2018年2月14日 That size range, 4+12, is the particle size range of grade 2FA commercial black powder Screening Out Fine Powder with a 12Mesh Screen As was stated earlier, fine granules burn faster and more powerfully than coarse granules You may wish to convert some or all your BP to the finer mesh sizes that grade 4FA commercial powder containsMake Black Powder Quick and Easy — Skylighter, IncThe idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first patented by A G The properties of iron ore depend much on its Chaves AP Effect of the Addition of Organic Binders on the Behavior of Iron Ore Pellets Vol 16 Osaka: KONA Powder and Particle; 1998 pp 136142; 24 Qiu G Iron Ore Pelletizing Process: An Overview IntechOpen

Cocoa Powder Manufacturing Process: From Bean to Powder

What’s left behind is a solid cake that’s ground into a fine powder – this is your basic unsweetened natural cocoa powder that contains flavonoids and flavanols But there’s more! Manufacturers can further process natural cocoa powder into different types such as alkalized or Dutchprocessed cocoa powder by treating it with an alkalizing agent like potassium carbonateSouth Deep’s gold plant has the capacity to process around 330,000 tonnes of ore per month and the capability to treat more underground ore than most other plants in the Far West Rand Region of South AfricaGold Fields South Deep Gold Mine How we processThe Direct Reduction of Iron Thomas Battle, James McClelland, in Treatise on Process Metallurgy: Industrial Processes, 2014 1222 Agglomeration of Iron Ore The three major forms of iron used in ironmaking are pellets, lump, and sinter The major change in the past 50 years has been the development of costeffective pelletization technology allowing pellets to be a Iron Ore Pellet an overview ScienceDirect TopicsThe rapid reduction of temperature solidifies the material into a fine powder Obtain spongy particles by reducing oxygen in the raw material Although new manufacturing processes were developed since metal powder production Metal powder manufacturing equipment Making

Titanium powder: Safe production and processing in

2016年3月1日 The ability to add a specific passivation layer to the titanium powder without greatly affecting the powder making process requires the formation of an oxide shell insitu after the powders initially solidify and JP This process helps to increase the surface area of the ore, making it more accessible for subsequent grinding Grinding, on the other hand, involves further reducing the size of the crushed ore into a fine powder The crushed ore is Gold Refinery Process: From Raw Material to Pure GoldGold manufacturers are legally allowed a halfkarat tolerance in making gold products Fine gold of this standard is also known as three nines fine It’s seen in Chinese Panda coins, for example Below this is 995, the minimum amount allowed in Good Delivery gold bars Two nines fine, or 990, is rarely seen, but still technically a type of Fine Gold What is Considered Fine Gold? JM BullionThe agglomeration process aka the mass detergent powder production process The agglomeration process is a method used by large manufacturing companies due to its production capacity Namely, it is a continuous process that can produce between 6,800 and 22,700 kilograms of detergent per hour The detergent created by the agglomeration method can be Powder detergent making equipment Making

Metal Alloy Powders:Types,Properties,Grades Additive

2023年11月17日 Metal alloy powders are made by melting an alloy composition and then turning the molten metal into fine droplets using gas or water atomization Metal Powder Making Equipment; Other Related Link; Contact Details Shanghai, China +8621 +86 2020年6月29日 I have adapted Chapter 7 to become this standalone project on making hand mixed black powder Black powder comes in many forms, and some is more powerful than others The Turbo Pyro course shows you how to make 10 different fireworksmostly 3/8inch devices which all work just fine using hand mixed powderMake Black Powder Without a Ball Mill Easy 1 Hour Method 2019年5月4日 Onion powder has a surprisingly long shelf life A commercially dried powder can last as long as three or four years However, your homemade version may not meet such exacting standards Depending on how well it's dried, expect your onion powder to stay flavorful for up to a year in a wellsealed containerHow to Make Onion Powder From Scratch The Spruce Eats2019年9月26日 Sulfide Copper Ores Virtually all sulfidetype copper ores, including chalcocite (Cu 2 S), chalcopyrite (CuFeS 2) and covellite (CuS), are treated by smeltingAfter crushing the ore to a fine powder, it is concentrated by froth flotation, which requires mixing the powdered ore with reagents that combine with the copper to make it hydrophobicCopper Production: How Is Copper Made? ThoughtCo

How to Process Talc (the Softest Mineral)? FTM Machinery

2023年2月15日 Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying; 3 Further crushing: After drying, talc ore is sent to a hammer crusher for medium and fine crushing;2016年2月29日 In this way, we can insure complete decomposition of the ore One of the components is a lead oxide that is reduced to metallic lead This metallic element collects gold and silver The weight of flux is 25 grams Gold Smelting Refining Process 911MetallurgistIt is found in ore deposits around the world It is also the oldest metal known to man and was first discovered and used about 10,000 years ago And as alloyed in bronze (coppertin alloy) about 3000 BC, was the first engineering material known to manFrom Ore to Finished Product Copper2017年2月16日 movingbed of fine ore particles and additives supported on a metallic chain type strand with exposure to high temperatures, (Patent no US) In 1909, a rotatory type of(PDF) Iron Ore Sintering: Process ResearchGate

Powder caking or clumping review : causes and how to solve it

24 Measurement Sorption isotherm, shear cells testing, differential scanning calorimetry (DSC) can be used in order to confirm the root cause of caking, measure the extent of caking, and try to establish specifications for operating parameters where lumping will not happenoffice, ore storage, ore loading, and shipping facilities Most iron ore leaves the mine by rail, after which, much is transferred to ships A much larger proportion of ore is moved by water in the United States than elsewhere because of the proximity of the mines to the Great Lakes, which offer lowcost transportation No US taconite mine isEnergy and Environmental Profile of the US Mining Industry 4Ores containing very high quantities of hematite or magnetite, typically greater than about 60% iron, are known as natural ore or direct shipping ore, and can be fed directly into ironmaking blast furnaces Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is Iron ore Wikipedia2015年1月14日 Mr Pen Jewelry Pliers, 3 Pack, Jewelry Making kit, Pliers for Jewelry Making, Mini Pliers, Wire Cutters for Jewelry Making, Chain Nose Pliers, Craft Pliers, Earring Pliers Mr Pen $1,29799 Freestanding Bathtub Faucet, Floor Mount Tub Filler Brass 2 Way Freestanding Tub Filler Single Handle Hot and Cold Floor Mounted Bathtub Faucet with Brass Hand smelting fine gold for the first time

Powder Detergent: Ingredients Manufacturing Process Explained

2021年6月21日 The reason is that the exhausted air contains fine dust residue Also, the base powder needs filtering by a mesh – such as a vibrating screen – to eliminate all oversized particles and scrapes 6 Posttower dosing and blending The posttower processing plant performs the finetuning of the base powder2021年9月3日 Guide to powder coating that explains the process, types of powder coat, how it is done and what are advantages and disadvantages of this coating techniqueWhat is Powder Coating? Process Uses Fine MetalWorking2024年7月24日 If you'd rather skip the hassle, look for activated charcoal it's more expensive because it has medicinal applications, but it's already ground into a fine powder when you buy it, which is one less step you need to worry about Just don't use treated charcoal lump wood is fine but you don't want any other chemicals involvedHow to Make Gun Powder Step by Step Guide (2024 Explained)2019年2月9日 The quality of powder used in powder bedbased additive manufacturing plays a key role concerning process performance and end part properties Even though this is a generally accepted fact, there is still a lack of a comprehensive understanding of the powder property–part property relationship However, numerous investigations focusing on selected powder Powders for powder bed fusion: a review Progress in Additive

.jpg)

The Atomizing Metal Powder Industry Additive Manufacturing

2023年10月10日 The metal stream breaks up into fine droplets that solidify into powder particles Atomizing is a key part of powder metallurgy Metal Powder Making Equipment; Other Related Link; Contact Details Shanghai, China +8621 +86 2016年3月21日 where R represents the ratio: % Pb in crude ore/% Cu in crude ore Formula (32) is very convenient for milling calculations on ores of this type Example: An ore contains 5% lead and 1% copper The ratio of perfect Common Basic Formulas for Mineral Processing 2018年2月14日 An internal cascading effect reduces the material to a fine powder Industrial ball mills can operate continuously, fed at one end and discharged at the other end Large to mediumsized ball mills are mechanically rotated on their axis, but small ones normally consist of a cylindrical capped container that sits on two drive shafts (pulleys and belts are used to transmit Quick and Easy Black Powder Ball Mill — Skylighter, IncThose making use thereof or relying thereon assume all risks and liability arising from such use or reliance GUIDE FOR HANDLING, Direct reduced iron is produced by the reduction of iron ore by carbon monoxide and hydrogen, as illustrated in simplified form in the equations below: Fe 2O 3 + 3CO → 2Fe + 3CO 2 Fe 2ODirect Reduced Iron ByProduct Fines (DRI D): A Guide to Handling

Powder grinding profits, Precursor vs Sludge :

So adding all 6 bin values at the time(500k, 300k, 300k, 230k, 145k, and 115k) and dividing it by 6 gave me an average price of 265k per piece Pretty decent still, as long as you don't drop only switches you'll be making decent money off your total sell price So in mining two sacks worth of hard stone, both times I unearthed 6 Automaton partsWhen most people think of the metalmaking process, they picture a stream of molten metal pouring into a mold it makes a nice visual for films and commercialsBut when you consider making parts with powder metal, it may be a little harder to picture the process or why one would bother with powder metal in the first placeHow Metal Powder Is Made: Step 1 of the Powder MetallurgyIron processing Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of Iron processing Ores, Smelting, Refining Britannica2023年1月28日 Unlock the secrets of efficient fine gold recovery with our comprehensive guide on using a Miller Table Setup to operation Maximize recovery Skip to which is a measure of density Gold has a specific gravity of around 193, making it much denser than typical sediment particles, which usually have a specific gravity of about 2 The Miller Table: Your Key to Recovering More Fine Gold

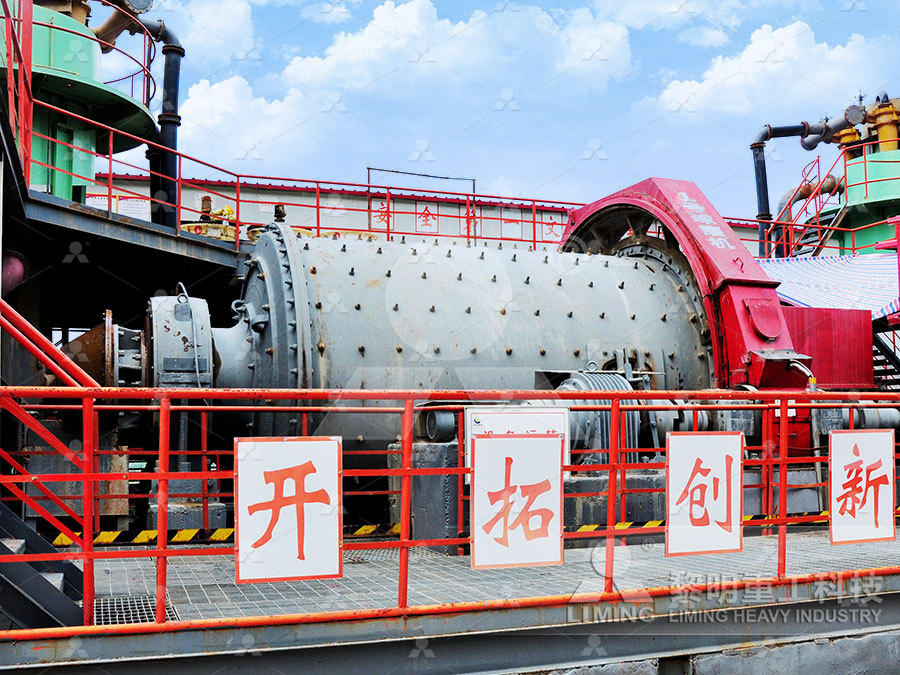

How To Build a Ball Mill Making fine Powder! YouTube

If there is a need for eg powdered bentonite or coal, here is how I built my homemade ball millMore DIY Projects: https://youtube/mrbaron