Lime kiln fuel preparation coal mill

22 Lime Kiln Principles And Operations TAPPI

the kiln where fuel is burned to form an approximately cylindrical flame Heat transfer from this flame and the hot combustion gases that flow up the kiln dries, heats, and calcines the counter New PFR lime kiln process with blast furnace gas and oxygen Production of high reactive lime is now possible with inexpensive blast furnace gas A new and innovative Parallel Flow New PFR lime kiln process with blast furnace gas and oxygenThis paper covers the modeling and control aspects of Lime Kiln process The lime kiln control in recovery section of paper mill along with heat and mass transfer in reaction, radiation, and Modeling, Control and Instrumentation of Lime Kiln Process: A The most common fuels used in lime kilns are natural gas and fuel oil as they are readily available Fuel oil is more efficient in terms of heat transfer and results in higher kiln capacity 26 Lime Kiln Combustion, Heat Transfer and Optimization 2019

Impact of cofiring biofuels and fossil fuels on lime kiln operation

ABSTRACT: Lime kilns are used to calcine lime mud to produce lime for reuse in the causticizing plant of pulp mills With significant increase in fossil fuel costs and the sustained drive to 2021年9月15日 In the industrial lime kiln used for this study, the two coals were mixed in order to achieve the desired fuel properties Coal 1 represents a coal fuel with a high heating value and Coal ash and limestone interactions in quicklime productionIn this work, a technoeconomic assessment of carbon dioxide capture from limekiln flue gas of a pulp and paper mill (Mill A) and a linerboard mill (Mill B) using a Monoethanolamine (MEA) Carbon dioxide capture from the Kraft mill limekiln: processfuel suppliers, research institutes, and pulp mills that burn alternative fuels in lime kilns The information was systematically analyzed for each fuel type to assess the impacts of its use on Current status of alternative fuel use in lime kilns

Global survey on lime kiln operation, energy

2011年8月1日 Responses were received from 59 pulp mills, totaling 67 lime kilns This paper discusses the key findings from the survey with respect to kiln design parameters, operating data, controlAGICO group teaches some details in operation lime rotary kiln, which are needed to be noticed In general, those factors are materials When entering the tube mill and vertical mill with drying, this value can be relaxed to a certain Lime Kiln Operation Lime Kiln Process AGICOThe kiln feed raw materials commonly contain 001% Cl, so taking account of the fact that the raw material to clinker ratio is usually about 16 and for a SF or PC kiln the coal consumption is about 12t coal per lOOt clinker, there will be a tolerable maximum of 01% chloride in the coal fuel for many SP or PC kilnsCOAL PREPARATION AND FIRING INFINITY FOR CEMENT EQUIPMENTThe lime kiln control in recovery section of paper mill along with heat and mass transfer in reaction, radiation, and convection in limekiln is also presented This paper also explores the possibilities of improving the control of the lime kiln by reviewing the literature of various control techniques including both the conventional and the modern onesModeling, Control and Instrumentation of Lime Kiln Process: A

.jpg)

Vertical Shaft Lime Kiln for Cement Plant

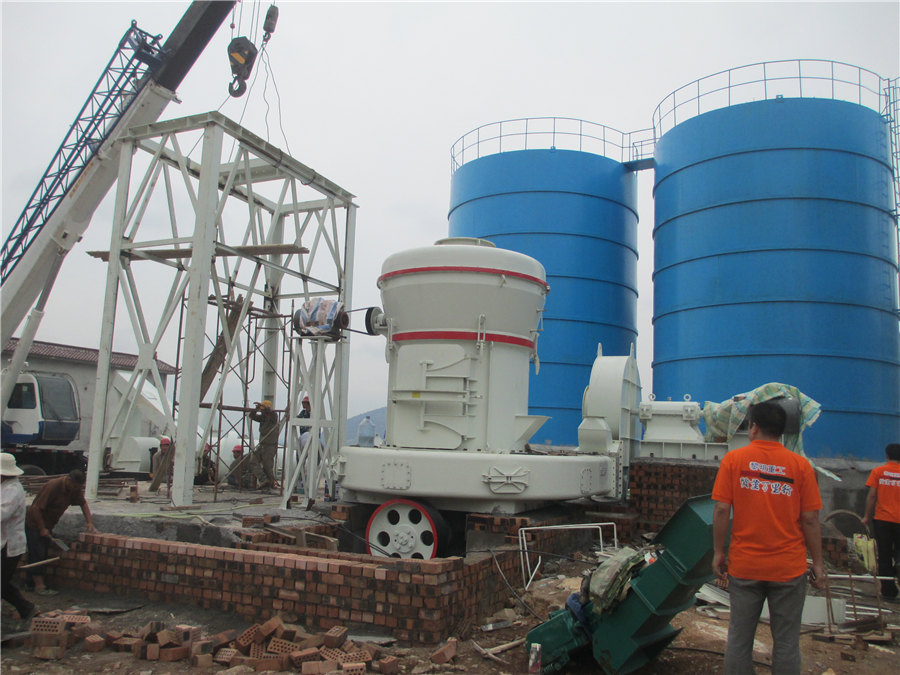

Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Lime Calcination Plant EPC solution for lime calcination CAPACITY: 50~1200TPD FUEL: coal gas, natural gas, and pulverized coal EQUIPMENT: vertical lime kiln (or rotary kiln), Raymond mill, jaw crusher, bucket elevator, separator, dust collector, etc Get QuoteLime Calcination Plant Lime Kiln Plant Output: 50–1200 TPDTypes of coal fuel rotary kiln for sale upon your needs Rotary Kiln for Liion Battery Material Preparation; Roller Hearth Kiln; Pusher Kiln; 05mm Tolerance Cement Rotary Kiln; KILN PARTS Our main business is rotary kiln equipment such as cement kiln, lime rotary kiln, and shaft kiln Direct Line: +86 : info Coal Fuel Rotary Kiln with Various Output and Length for Salethe fuel to the kiln and highquality metallurgy to withstand the acidic conditions of the fuel Application: Several “green” kiln fuels are identified to help reduce a mill’s carbon footprintAlternative “green” lime kiln fuels: Part II—Woody biomass, bio

Choosing Right Lime Kiln For Your Lime Calcination Plant

2024年8月1日 It is easy to see that, except for mechanized vertical kilns (not active lime kilns) and Melz kilns, the energy consumption of other kilns is higher than that of annular shaft kilns, and rotary kilns are only suitable for producing small particle lime with a size of 1040mmTwin Shaft Lime kiln; Lime Rotary Kiln; Contact; FREE QUOTATION FREE QUOTATION; Coal Mill in Cement Plant coal powder preparation has become an important part of cement The coal mill in a cement plant should be reliable and should be operated with great care, or it is easy to cause safety accidents In the process of grinding, storage Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillLime kiln equipment is an important equipment for producing lime, which is used for calcining lime It mainly includes the entire process of raw material preparation, fuel combustion, air burning, waste gas treatment, and Home; About Us; Our Service; The kiln can use natural gas, fuel oil, coal powder, coke oven gas, low calorific value Lime KilnsTCU Technologies Co LTD2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is scarce Subsequent hydration of lime would lead to the synthesis of slaked/hydrated lime Ca(OH) 2; the production of a tonne of Ca(OH) 2 emits ∼12 tonnes of CO 2 arising mainly from the Decarbonising the lime industry: Stateoftheart ScienceDirect

LIME KILNS, HEAT TRANSFER, CONTROL AND COMBUSTION

The composition of lime mud varies from mill to mill depending on many factors: wood species, the impurities in the makeup lime and refractory bricks used in the kiln, the efficiencies of slakers, causticisers, clarifiers and mud washers, and the burning conditions in the kiln On a dry basis, lime mud typically contains about 95 wt% CaCO 3 andtact in the kiln and the low surface area of lime nodules Depending on the fuel S content, kiln operating conditions, and lime mud characteristics, a portion of the SO 2 may pass through the kiln without reacting and contribute to increased SO 2 emissions In a study of the effect of burning highScontaining CNCG on the performance of an Current status of alternative fuel use in lime kilnsHere's a stepbystep process of how limestone is converted to lime in a kiln: Step 1 Raw material preparation: Limestone is crushed, screened, Lime kiln design and configuration Fuel: Coal gas Coal powder: Coal gas Coal powder: Coal gas Coal powder: Coal gas Coal powder: Coal gasLime Kiln for Lime Production Fote MachineryWe all know the importance of saving cement kiln fuel, lime rotary kiln, and shaft kiln Direct Line: +86 : info@rotarykilnfactory Address: 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, China Coal Fuel Rotary Kiln Oil Fuel Rotary Kiln Gas Fuel Rotary Kiln Electric Heating Rotary KilnKiln Fuel Cemnet Kiln AGICO

Lime Production Line AGICO Cement Plant

3Limestone Calcination Limestone in the preheater will be preheated by the hot air, then it will be discharged to rotary kiln through chute that connecting preheater and kiln, it will stay in the kiln for 152 hours for calcination, during lime calcination plant process, it will be calcinated with temperature around 1300 ℃, after which comes limestone decomposition and release of co2 Twin shaft kiln(TSK) Capacity: 300800t/d Limestone particle size: 30mm60mm,40mm80mm Twin shaft kiln(TSK) is a new type of double chamber parallel flow regenerative lime kiln developed on the basis of technical innovation of Maerz kiln, Parallel Flow Regenerative (PFR) Kiln, Twin Shaft Regenerative (TSR) Kiln, and other technologiesLime Calcination Plant Solution, Lime Production Equipment, Rotary Kiln for Liion Battery Material Preparation; Roller Hearth Kiln; Pusher Kiln; 05mm Tolerance Cement Rotary As an important cement kiln fuel, coal has been used in the cement industry for a Our main business is rotary kiln equipment such as cement kiln, lime rotary kiln, and shaft kiln Direct Line: +86 : info@ How to Accelerate Coal Powder Combustion Inside Rotary Kilns rate and lower thermal efficiency of the lime kiln Table 1 exemplarily shows a comparison of three different cases on a modern 500 t/d PFR lime kiln, operating in accordance with the convention 2 Flowsheet of stateoftheart PFR lime kiln 3 Flowsheet of BFGfired PFR lime kiln according to the new processNew PFR lime kiln process with blast furnace gas and oxygen

.jpg)

Coal Mill – Coal Mill In Cement Plant AGICO Cement Equipment

The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination However, due to the flammable and explosive Lithiumion Battery Material Preparation Rotary Kiln with Advanced Technology Our main business is rotary kiln equipment such as cement kiln, lime rotary kiln, and shaft kiln Direct Line: +86 : Rotary Kiln for Liion Battery Material PreparationMFO and diesel oil used for startup and backup due to if bark gasifier not stable and low performance Syngas burned in lime kiln to produce CaO Lime kiln designed can used 3 kinds of fuel such as MFO, LNG and syngas Each fuel (PDF) Life Cycle Assessment (LCA) in Pulp Paper LIME KILN PRODUCTION Selecting the right technology and machine size for fuel conveying, combustion air and air cooling systems to optimize fuel efficiency in the kiln for lime production plants According to the data available from the USGS (US Geological Survey), in 2018 the quicklime and hydrate lime market value in the Americas exceedsSIZE ACTUALLY MATTERS FOR LIME KILN PRODUCTION AERZEN

Air Swept Coal Mill Cement Plant Machinery

Air Swept Coal Mill Introduction The airswept coal mill produced by AGICO equipment structure, high grinding efficiency, strong adaptation to raw materials, which is the ideal equipment for pulverized coal preparation Airswept coal mill is mainly composed of feeding device, main lime raw materials, fuel options, and calcination 2021年9月15日 Two coals were used, representing coals with high and low heating value In the industrial lime kiln used for this study, the two coals were mixed in order to achieve the desired fuel properties Coal 1 represents a coal fuel with a high heating value and low ash content, while Coal 2 represents coal with a lower heating value and higher ash Coal ash and limestone interactions in quicklime production476 TAPPI JOURNAL VOL 14 NO 7 JULY 2015 Tall oil Depending on wood species, kraft mills typically produce 3050 kg/metric ton pulp (60100 lb/ton) of tall oil in their chemical recovery Impact of cofiring biofuels and fossil fuels on lime kiln operationThis is a petcoke/fuel oil cofire flame in a lime recovery kiln for a paper mill using the Matrix DENSIFEED fuel feed system for ground petroleum coke ThPetcoke Flame firing with Fuel Oil in Lime Recovery Kiln

.jpg)

Global survey on lime kiln operation, energy consumption, and

2011年8月1日 In late 2008, a survey on lime kiln operation and fuel usage was conducted through questionnaires distributed to pulp mills in nine countries Responses were received from 59 pulp mills, totaling quantity of chain in a modern lime kiln is 40 lineal hanging feet of standard 3/4” x 3” link chain per ton per day of total kiln product or 240 lbs of chain per ton per day of total kiln product The method of hanging the chain makes little difference in its effectiveness as a regenerative heat25 Lime Kiln Equipment Operation and Maintenance TAPPIA Kraft pulp mill utilizes a rotary lime kiln to regenerate CaO from CaCO 3 by reburning The CaO is used to regenerate the cooking chemicals for the digester A lime kiln is around 70100 meters long and around 24 meters in diameter The kiln is typically equipped with product coolers at theDusting in a lime kiln Chalmers2018年3月1日 The lime kiln is responsible for most of the fossil fuel consumption in a kraft pulp mill Fossil fuel prices, and the obligation to reduce CO2 emissions, are strong incentives to replace fossil Replacement of fossil fuel with biomass in pulp mill lime kilns

.jpg)

Impact of cofiring biofuels and fossil fuels on lime kiln operation

pulp mills Several new biofuels will become available, together with traditional mill derived fuels such as tall oil In considering use of biofuels for replacement of fossil fuels in the lime kiln, each fuel has a different impact on kiln performance An assessment on kiln performance can be achieved and compared to either heavy fuel oil or biomass to produce syngas as fuel in lime kiln has impact to global warming 425E+01 kqCO 2 /ton CaO Its lower than if used MFO that impact to global warming 691E+01 kqCO 2 / ton CaO For increased environmental quality, using 100% biomass as primary fuel in lime kiln is recommended Keywords: Biomass, bark gasifier, lime kiln, pulp and paper Life Cycle Assessment (LCA) in Pulp Paper Mills: Comparison 2019年4月11日 Fredrik Lind and Charles BrooksWind inspecting the lime kiln at SCA Munksund mill “Our lime kiln was 50 years old and had seen better days To match our strategy of being fossil fuel free, we decided to build a new kiln utilizing biofuel The new kiln was ready and in operation in January 2015Pulp mill lime kilns go fossil free Valmet2015年7月1日 The forest industry is a significant emitter of CO 2 and thus it needs to transform toward a more sustainable operation in order to contribute to tackling climate changeImpact of cofiring biofuels and fossil fuels on lime kiln operation

.jpg)

A Lime Rotary Kiln To Build Your Lime Calcinating Plant

4 Lime Rotary Kiln’s cooling method better be forced air cooling 5 There has to be a step to detect the temperature of lime Rotary Kiln’s burning belt 6 Better adopt stepless variable speed motor as lime Rotary Kiln’s main motor Set up a series of auxiliary drive and backup power Lime Rotary Kiln Outstanding AdvantagesEnergy balance is: qg cpg @T g @ðqg hg v g Þ 000 ¼ q 000 þ conv þ qrad þ Sg @x @t ð5Þ where q 000 conv represents the energy transfer by convection with load and coal phases, q 000 rad represents the energy transfer by radiation with coal particles, lime and kiln walls 213 Coal particles A Lagrangian framework selected for (PDF) Oxyfuel combustion as an alternative for increasing lime 2020年5月30日 This paper is the second of a twopart series on “green” lime kiln fuels The first part of this work reviews the use of pulp mill and recovery byproducts as either full or partial Alternative “Green” Lime Kiln Fuels: Part II Woody Biomass, Bio This study evaluated the technoeconomic feasibility of integrating renewable lime kiln fuel production into the kraft pulp production process The lime kiln in a kraft pulp mill converts lime mud, which is largely composed of calcium carbonate (CaCO 3), into burnt lime, ie, calcium oxide (CaO), and carbon dioxide (CO 2PEERREVIEWED ARTICLE bioresources North Carolina State

Lime Shaft Kiln for Sale, Energyefficient Vertical Lime Kiln Plant

New type TTHN vertical shaft kiln for lime production Output 100500t/d, particle size 3060/4080mm Lime shaft kiln with reasonable design and excellent performance for sale