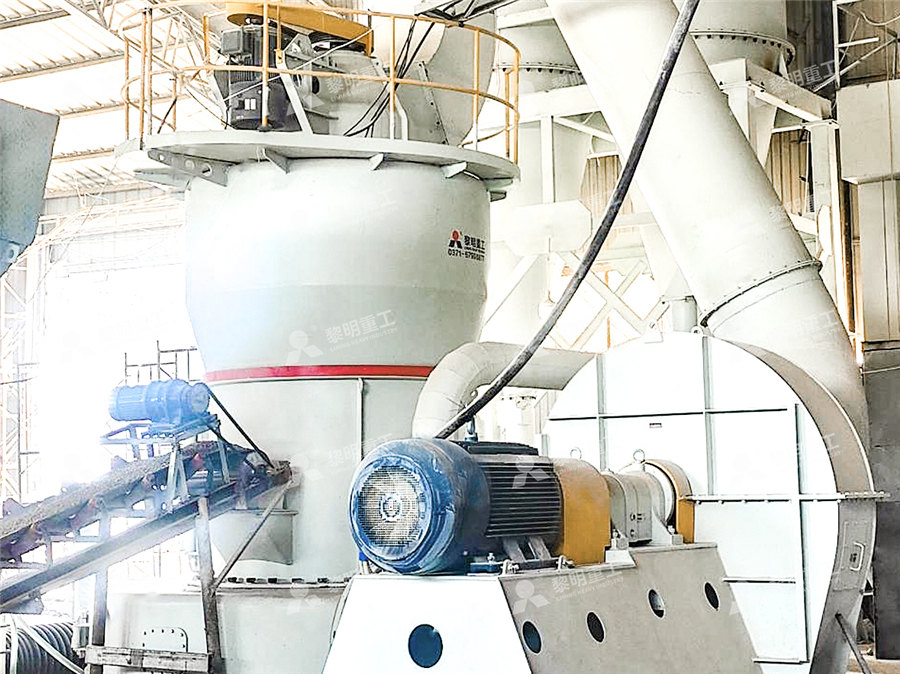

HOME→Gallbase grinding and powder production line, those without cracks can be used as stone raw materials

Gallbase grinding and powder production line, those without cracks can be used as stone raw materials

.jpg)

A comprehensive review on the grinding process: Advancements,

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and2013年1月1日 Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials These operations can be implemented separately, in combination Grinding for food powder production ScienceDirectPowder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituentsPowder metallurgy – basics applications IIT Guwahati2021年9月20日 However, in recent years they are shown to have great potential as sustainable raw materials for powder technologies Powder production from metal chips, through the From Machining Chips to Raw Material for Powder Metallurgy—A

.jpg)

Comparative study of the grinding aid effects for dry fine grinding

2019年12月1日 The grinding tests of this study revealed that powderflowassisting grinding aids are beneficial regarding the grinding efficiency, at least in the used labscale vibration mill, 2022年6月23日 Comminution is the process of breaking solid materials to a smaller size by crushing, grinding, or other mechanical processes Atomization uses gas, water, plasma, or Influence of powder characteristics on properties of parts 2022年10月4日 There are several preconcentration technologies that can be applied at each stage of mineral processing and one of the most recent methods is Bulk Ore Sorting (BOS) Reduction of Fragment Size from Mining to Mineral Processing: A 2017年9月1日 This paper aims to explore these observations further, focusing on the two fine grinding devices and the breakage mechanisms therein, size by size shape characteristics Fine grinding: How mill type affects particle shape characteristics

Size Reduction SpringerLink

2012年1月1日 “Comminution” is the generic term used for size reduction and includes different operations such as crushing, grinding, milling, mincing, and dicing Most of these terms are 2023年6月27日 This review found that ball milling is the best tool for reducing the particle size of recycled metal chips and creating new metal powders to enhance mechanical properties and Producing Metal Powder from Machining Chips Using Ball Milling 2017年12月31日 Various types of cracks exist in metals and can be categorised as cooling, solidification, centreline, crater, grinding, pickling, heat treatment, machining tears, plating, fatigue, creep, stress (PDF) Repair of Cracks in Metals: A Review2017年1月1日 The aim of the present paper is to review the commonly used crack repair techniques in metals Holes are then drilled along the crack line They are then tapped and filled with 675 Tawanda Marazani et al / Procedia 673 – 679 27 Grinding Grinding can be used to totally remove portions of a detail containing Repair of Cracks in Metals: A Review ScienceDirect

.jpg)

Limestone crushing and grinding production line

2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical Limestone crushing and grinding production line 20/04/2022 Production advantages: high Grinding for food powder production ED Baudelaire, in Handbook of Food Powders, 2013 61 Introduction Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials to give a usable form or to separate their components In developing countries, it is the common method for food powder processing In general, grinding is part of Grinding an overview ScienceDirect Topics2018年4月28日 Grinding is a staple sizereduction process to produce food powders in which the powdered form is chemically and microbiologically stable and convenient to use as end products or intermediate products The moisture content of food materials before grinding is a particularly important factor, since it determines the materials’ physical properties and the Effect of Moisture Content on the Grinding Process and Powder Gallstones can cause sudden, severe abdominal pain that usually lasts 1 to 5 hours, although it can sometimes last just a few minutes The pain can be felt: in the centre of your abdomen (tummy) just under the ribs on your righthand side – it may spread from here to your side or shoulder blade;Gallstones NHS

.jpg)

Optimization of grinding process for hard and brittle materials

2024年3月1日 The main influencing factors for grinding damage include abrasive grit size, grinding depth, workpiece feed speed, and wheel speed According to the research of Sabia et al [13], the grinding subsurface damage depth (SSD) of glass ceramics is proportional to 5 times the average abrasive grit sizeMa et al [14] found that the SSD of fused silica is 4–6 times the 2022年8月1日 Waste glass has great potential as a raw material of building materials, in view of its physicochemical characteristics (eg, higher hardness and potential pozzolanic activity) To date, the application of waste glass in cementbased materials mainly focuses on two aspects: as aggregate [3] , [4] , [5] and as supplementary cementitious materials (SCMs) in mortar or Preparation of waste glass powder by different grinding methods 2024年1月1日 The constant K d (Djantou’s grinding ability constant) is specific to the material and represents its grinding ability Equation [66] shows that for a specific time, a better grinding ability is related to a higher value of K dIn order to follow the grinding kinetics with the model, experiments were conducted and grinding yield was measured for each timeGrinding for food powder production ScienceDirect2021年11月19日 An endoscopic ultrasound can detect even small stones in the bile duct and gallbladder The presence of stones can be a reason to be evaluated by a gastroenterologist or surgeon for treatment This may include removal of stones from the bile duct, placement of a stent or removal of the gallbladder ― called a cholecystectomy Common questions about gallstones Mayo Clinic Health System

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Blending and homogenization process defined as: a creating of required specific physical and chemical properties of raw materials by mixing and integrating certain quantities of those materials Number of problems can occur and arise Cement Manufacturing Process INFINITY FOR 2023年11月6日 This is in view to tapping the maximum benefits of using GAs in cement production and use This review work established that GAs have a positive influence on mill performance when properly applied(PDF) Review of the Effect of Grinding Aids and Admixtures on the 2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Quartz Processing Mastering the Art of Stone to Powder

.jpg)

Synthesis and application of several sol–gelderived materials

2016年1月6日 Sol–gel process is a very unique wet chemical method for producing advanced materials in various areas of research An increasingly evolution trend of this process is to combine with other technologies, such as surface modification, hybridization, templating induction, selfassembly, and phase separation, for preparing new materials possessing controllable 2023年10月6日 Grinding technology is extensively applied in manufacturing industries, eg, composites, aerospace alloys, and wind turbine blades (as depicted in Fig 1), and its machining accuracy directly affects the working performance and surface integrity of workpieces [1]To fulfil the efficiency and accuracy requirements of the grinding surface, it is crucial to understand its Material removal mechanism and corresponding models in the grinding 2014年3月22日 Millstones were water powered, horizontal or vertical wheeled, since the 1st century BC, according to written documents The raw materials used in ancient Greece for manufacturing millstones since (PDF) Raw materials used for the millstones production in 2021年12月24日 In general, the term aerogel refers more to the internal structure of a substance than to its constituent materials; therefore, it is possible to synthesize aerogels by a wide range of raw materials with different chemical compositions [124 – 127] The raw materials used to synthesize aerogels include minerals, organic, and compositeNanomaterial by SolGel Method: Synthesis and Application

.jpg)

Manufacturing Processes for Permanent Magnets: Part

2022年2月2日 History of Permanent Magnet Development Several comprehensive reviews exist which extensively cover the development of rare earth (RE) magnets and the factors determining their coercivity 3,4,5,6,7,8,9 Figure 3 shows the historical development and commercialization of permanent magnets based on their (BH) max 10 It is noteworthy that the main discoveries of The production process of garlic powder manufacturing process steps such as garlic cloves, peeling, cleaning, slicing, airdrying, drying, and grinding Garlic powder manufacturing plants can choose a garlic powder production line to process garlic according to the above processing stepsGarlic Powder Manufacturing Plant Process Of Making Garlic Powder2023年2月16日 There’s no specific gallbladder removal diet, but you’ll probably want to make a few adjustments after having your gallbladder removed to avoid digestive issues We’ll tell you which foods Gallbladder Removal Diet: What to Eat and What to 2014年1月1日 Powder grinding for comminution This can be carried out at the powder production facility for online correction of the particle size and distribution, during the processing stage Powder blending and mixing (in wet or dry conditions) to prepare homogeneous powder mixtures for the compaction stage Heat TreatmentsPowder Processing of Bulk Components in Manufacturing

43.jpg)

How grinding wheel is made material, history, used, parts,

Quality bearings could not be produced without them, and new materials such as ceramic or material composites would be impossible without grinding wheels to shape and finish parts Sandstone, an organic abrasive made of quartz grains held together in a natural cement, was probably the earliest abrasive; it was used to smooth and sharpen the flint on axes2020年10月1日 The current study investigates the type of ratio for ball mill jars listed in Table 3 and [63,80,168,181,183] Different balltojar ratios can affect the milling kinetics, the size, and Silicon Powder Properties Produced in a Planetary Ball Mill as a Through quantitative injection of grinding additives by metering pump, the accurate ratio is ensured, and the grinding efficiency and stability of product performance are improved; The silo adopts high quality level indicator to ensure the automatic control of the production process;Ball Mill and Air Classifier Production Line ALPA Powder2019年4月8日 Cutting tools and machine tools are the two main factors to achieve removal Based on the needs of processing technology in the movement requirement of the tool, the machine tool can achieve the tool’s trajectory and then achieve removal, and the cutting tools in contact with the workpiece can remove the workpiece material directly (Altintas 2012)Design of Tools, Grinding Wheels, and Precision Spindles

Raw Material DryingGrinding Cement Plant Optimization

Wet Grinding: Open circuit Ball mill or closed circuit Ball mill Dry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill However, it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are:Kidney stones can vary in size from a few mm to a few centimeters They typically leave the body by passage through the urine stream, and many stones are formed and passed without causing symptoms (Rao et al 2011) Stones having a size more than 3 mm in diameter before passage can cause obstruction of the ureterAnalysis of stones formed in the human gall bladder and kidney 2020年6月14日 Double disk grinding can be used with a wide range of materials, including stainless steel, tool steels, sintered metals, and highstrength alloys The resulting surface finish is often better than the finish produced by many other grinding techniquesPrecision Metal Grinding Metal Cutting CorporationCritical raw materials list for 2011–2020 overlaid on the periodic table of elements (adapted from [])European initiatives were broadened, and in 2011, the EU started a trilateral dialogue with Japan and the United States to promote cooperation in the field of critical materials; identify the main areas of cooperation in collecting raw materials data; and analyze trade, waste recycling, Powder Bed Fusion Additive Manufacturing Using Critical Raw Materials

An investigation on machined surface quality and tool wear

2020年4月30日 In this study, the machined surface quality of powder metallurgy nickelbased superalloy FGH96 (similar to Rene88DT) and the grinding characteristics of brown alumina (BA) and microcrystalline alumina (MA) abrasive wheels were comparatively analyzed during creep feed grinding The influences of the grinding parameters (abrasive wheel speed, workpiece 2013年1月1日 Bond, 1952, Bond, 1960 formulated the earliest scaleup model for prediction and design of the performance of an industrialscale ball mill This procedure evolved from the classical energysize reduction principle (Austin, 1973)Although the Bond model has since been used to characterize the grinding of carrots (Chakkaravarthi et al, 1993), Gum karaya (Walde Grinding for food powder production ScienceDirect2020年9月29日 Raw materials chemistry Cement manufacture requires a source of calcium, such as CaCO 3 or CaMg (CO 3) 2, which comprises almost 80–90% of the total and the rest is iron oxide (Fe 2 O 3, Fe 3 O 4), quartz (SiO An overview of alternative raw materials used in 2015年10月23日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production EnergyEfficient Technologies in Cement Grinding IntechOpen

Effect of FreezeDrying on Quality and Grinding Process of Food

2020年3月20日 Freezedrying is an important processing unit operation in food powder production It offers dehydrated products with extended shelf life and high quality Unfortunately, food quality attributes and grinding characteristics are affected significantly during the drying process due to the glass transition temperature (during drying operation) and stress generated 2019年12月1日 The production of fine particles in the lower micron range by dry grinding processes demands large amounts of energy For instance, the cement industry alone consumes approximately 12–15% of the world’s total industrial energy, whereby the fine finish grinding of the cementitious products accounts for about 30% of the overall energy consumption (Madlool, Comparative study of the grinding aid effects for dry fine grinding 2024年1月23日 The lack of coolant in dry grinding can lead to increased wear on the grinding wheel, but it can be beneficial for certain materials that may oxidize or react with liquids Wet Grinding In contrast to dry grinding, wet grinding introduces What is Grinding: Definition, Process, Types Specifications2022年12月10日 The name GP0H describes granite powder without any grinding (natural powder), for other granite powders (GP1H, GP3H, and GP5H) we used a grinding technique to achieve more fine grains of powder—we ground GP 1, 3 or 5 h (those numbers are the names of each sample of GP) Detailed compositions of each research series are presented in Table 2Effect of Granite Powder Grain Size and Grinding Time of the

.jpg)

Producing Metal Powder from Machining Chips Using Ball Milling

2023年6月27日 In the pursuit of achieving zero emissions, exploring the concept of recycling metal waste from industries and workshops (ie, wastefree) is essential This is because metal recycling not only helps conserve natural resources but also requires less energy as compared to the production of new products from virgin raw materials The use of metal scrap in rapid 2021年11月15日 The grinding abrasives commonly used in materials preparation are silicon carbide (SiC), aluminum oxide (Al2O3), emery (Al2O3 – Fe3O4), composite ceramics and diamond Emery paper is rarely used today in materials preparation due to its low cutting efficiency SiC is more readily available as waterproof paper than aluminum oxideGrinding and Polishing Guide Buehler Metallography