Hubei test ore grinding mill steering

An innovative flake graphite upgrading process based on HPGR,

2021年11月1日 Grinding test results show that stirred mill could not only protect graphite flakes but also promote the efficient liberation of graphite Compared with the traditional flotation 2022年3月30日 HPGR circuits can reduce the hard rock mining industry’s CO 2 emissions by up to 435% compared to SAG/Ball mill circuits Analysis of published data has confirmed that Helping to reduce mining industry carbon emissions: A stepby Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing coarser ball mill applications in secondary and RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL 2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material grindability

.jpg)

Flowsheet of the Future: HighPressure Grinding Rolls, Vertical

Processing harder ore has required applying higher grinding energies to liberate the target minerals For tumbling mills, the higher grindingenergy demand typically requires the use of Methods of designing vertical stirred mills involve operational experience, pilot plant tests and bench testsDevelopment and Validation of a Simplified Laboratory Test to 2019年4月12日 结合当前研究成果及工业现场数据,本文对比了高压辊磨机在金属矿山和球团预处理行业中的工艺流程,以及辊面比压力、辊面线速度、辊缝几个工艺参数,为高压辊磨机在 高压辊磨机在金属矿选矿与球团预处理领域的工艺和 This paper describes the development of a smallscale batch test method for determining a work index for HPGR of a large number of samples that can be used to show the variability of the Work Index Determination for High Pressure Grinding Rolls SGS

SAG Mill Testing Test Procedures to Characterize Ore Grindability

Nowadays, conducting grindability tests requiring only a few kilos of material on several samples, is a more typical approach to grinding mill design This paper summarises the requirements Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Within these test works, mill parameters like grinding pressure, separator Research of iron ore grinding in a verticalrollermill2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2018年9月17日 The paper describes the development and validation with six different ore samples of a simplified laboratory jar mill test using a 6"×8" jar, which is smaller than the 8"×10" size, the latter (PDF) DEVELOPMENT OF A LABORATORY TEST TO

(PDF) Grinding Kinetics Adjustment of Copper Ore

2018年8月8日 One of the most effective methods of grinding Portland cement is the use of an electromagnetic mill, which has proven its advantage in creating clinkerless binders [2], regulating the kinetics of 2020年10月18日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesThe effects of iron ore concentrate grinding methods (HPGR and Hubei Kaisheng (Previous called Hubei Gaofeng) covers an area of nearly 60 acres, has more than 20,000 square meters of new factory buildings and office buildings, and more than 100 employees, including more than 10 senior technical and management personnel, 5 professional RD engineers with strong design and development capabilitiesHubei Kaisheng Auto Steering SystemRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

SAG Mill Testing Test Procedures to Characterize Ore

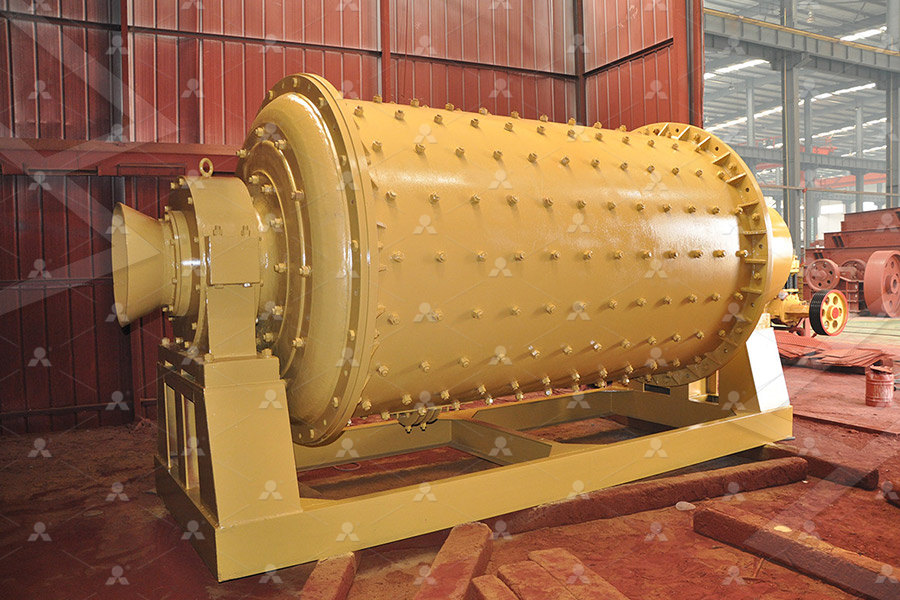

SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is 2019年4月25日 Since such items as optimum grind, mill feed rate, flotation time, and reagent addition depend on the ore grade, grindability, and other factors, it is suggested that, in the computercontrolled plant of the future, the practice of blending ore to produce a uniform mill feed may be an unnecessary expense and may actually be detrimental to project optimizationOptimizing Grinding and Regrinding Capacity in Mill Design1985年6月1日 The relative significance of corrosive and abrasive wear in ore grinding is discussed Laboratory marked ball wear tests were carried out with magnetic taconite and quartzite under different (PDF) Corrosive and abrasive wear in ore grinding ResearchGate2015年4月9日 The mill is normally used for grinding of ores Lining of the cylinder plays very important role It protects the mill from abrasions and at the same time it helps in lifting of the material from the bottom of cylinder The types of lining are Grinding Mills and Their Types – IspatGuru

Population balance model approach to ball mill

2014年1月1日 A test campaign with a pilot scale vertical mill was carried out with five different ore samples to elaborate a simple and robust methodology to scaleup vertical mills and perform simulations 2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLink2017年6月15日 Request PDF Friction and wear of liner and grinding ball in iron ore ball mill To understand the friction and wear of working mediums in iron ore ball mills, experiments were conducted using Friction and wear of liner and grinding ball in iron ore ball mill2015年12月14日 The Wi value from this equation should conform with the motor output power to an average overflow ball mill of 8 ft interior diameter grinding wet in closed circuit For dry grinding the work input should normally be multiplied by 130 However, ball coating and packing can increase the work input in dry grindingStandard Bond Ball Mill Grindability Test MethodProcedure

.jpg)

A Review of Alternative Procedures to the Bond Ball Mill

2021年7月12日 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure2017年7月3日 The first includes the following: Relation of specific gravity of grinding media to power and type of grind, effect of particle size on power, different pulp densities, different sizes of discharge openings, comparison of batch and continuous opencircuit grind, various speeds and ore charges, rodmill tests at various speeds, various diameters of rods, comparison of large Variables Affecting Grinding Mill Power 911MetallurgistThe aim of this paper is twofold: to define the terminology applicable to wetore grinding and the mechanistic processes involved, and to review the methodology and validation of test methods for examining ore grinding, elucidating the mechanisms involved, and Review of test methods for abrasive wear in ore grinding2023年4月20日 of batchgrinding tests to describe an industrial ball mill grinding it abirite iron ores under a singlecomponent and multicomponent description (Rocha et al, 2022) Nevertheless, despiteSimulation of industrial PGM and iron ore ball milling circuits from

Vertical mill simulation applied to iron ores ResearchGate

2014年11月1日 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill Other three samples of pellet feed had already been tested with the methodology used 2015年3月15日 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2Research of iron ore grinding in a verticalrollermill2014年1月20日 The test results show that the relative grindability and LD of the grinding products obtained from HPGR products as feed is significantly higher than that of JC products, and the energy (PDF) Effects of High Pressure ORE Grinding on the One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Within these test works, mill parameters like grinding pressure, separator speed and dam ring height were varied, following a factorial design of the experimentsResearch of iron ore grinding in a verticalrollermill

.jpg)

Modeling and application of stirred mill for the coarse grinding

2022年5月23日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to 2016年6月3日 IsaMills, Tower Mill and Verti Mill Ultrafine Grinding in a Tower Mill The Tower Mill is a vertical “stirred” ball/pebble mill recently introduced in the Western Hemisphere This device offers a significant power savings on wet fine grinding applications when compared to conventional tumbling millsTower Mill Operating Work Index 911Metallurgist2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution behaviour and

Bond Grindability Test Procedure 911Metallurgist

2015年6月16日 Ball Mill Grindability (Gpb) = (gm/rev) average of last three grinding cycles to give 250% circulating load Precautions: There should be consistency in compaction of ores in the 700ml test can This is normally done by shaking Accurate observations on grinding revolutions are essential Dry screening procedures should be consistentTraditional tests used to determine the energy consumption in grinding, like the Bond Ball Mill test, are relatively timeconsuming and require significant amounts of sample, eg, 8–10 kg Bond's mill specification and grinding conditionsBond Rod Mill 0305 127 Any 118 15 10 Lockedcycle Y Y Bond Ball Mill 0305 335 Any 0149 10 5 Lockedcycle Y Y Mod Bond 0305 335 Any N/A 2 12 Batch N Y Table 1 – Summary of Grindability Test Procedures 1Weight requested for the test, for typical ores (SG = 28g/cm3)SAG Mill Testing Test Procedures to Characterize Ore 2015年8月6日 Rubber liners absorb the impact of the larger grinding media and thus protecting – the mill structure and prolonging it’s life Weight: Rubber weighs about 15% of an equivalent volume of steel This means that a rubber liner system reduces the load on the mill structure and also reduces the basic power drawGrinding Mill Liners 911Metallurgist

.jpg)

Strip Steering Control in a Hot Strip Mill as a Key

2023年5月10日 Strip steering is certainly one of the big issues that hot rolling mill operators around the world ask the most about If the strip runs poorly, this can lead to high cobble rates and poor strip Coal Test Ore Grinding Vibration Grinding Sample Sealed Sample Making Mill US$ 13001500 / Piece 1 Piece Hubei Pinyang Technology Co, Ltd Diamond Member Audited Supplier Ore Grinding Mill Type for Grinding Machine: Vibration Grinding Machine Grinding Method: Dry Vibration Mill MadeinChinaStrip Steering Control in a Hot Strip Mill as a Key Feature for Safe and Stable Production Klaus Löhe1, Sebastian Kallabis2, Niklas Petrasch2, Andreas Maierhofer1 1Primetals Technologies Germany GmbHStrip Steering Control in a Hot Strip Mill as a Key Feature for Safe China Diesel Grinding Mill wholesale Kaolin Bentonite Quartz Limestone Zircon Coal Ceramic Cement Powder Ultrafine Calcium Carbonate Powder Gold Ore Copper Pyrite Diesel Grinding Ball Mill US$ 32509200 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, ACME AGRO HUBEI CO,LTD Diamond Member Audited Supplier Hubei Diesel Grinding Mill MadeinChina

.jpg)

Grinding Mill an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 microns2021年5月24日 Now you can reduce fist sized chunks of ore down as fine as you need Most hard rock ore contains very fine gold, sometimes even micron sized If it’s smaller than 2 or 300 mesh it may not be worth your time to try and set your mill up to recover it Depends on how much gold is in your ore, right? That’s what we are trying to figure outHow To Test Gold Ore Mojave Gold MiningChina Limestone Grinding Mill wholesale Small Mini Lab Mineral Wet / Dry 06 1 Ton/Hr 2 Ton 5tphore Grinding Pulverizer Grinding Used Ball Mill Price for Gold Mining Copper Ore Test Limestone Powder US$ 15003250 / Set 1 Set (MOQ) Limestone Grinding Mill MadeinChina2015年8月6日 Grinding media was selected from various areas of the mine and tested separately Impact tests on the three basic types of ore give Work Indices varying from 148 to 91 with two types appearing to be suitable as media and the third type questionable The test mill was fed plant run ore with an average Work Index of 16AG Autogenous Grinding 911Metallurgist

IsaMill Ultrafine Grinding for a Sulphide Leach Process

slurry were collected for the leaching tests, and each of the slurry samples was filtered and the filter cake stored frozen prior to the leach tests The mill media was 08 – 12mm steel shot The Vertically Stirred Mill consisted of a 10 litre chamber and pin style impeller The mill shaft held seven radial arms, each 160 mm long and2018年12月24日 Ore specifications were characterized by grinding tests, which included the Drop – weigh test (A, b), Sossego was the first CVRD SAG mill operation to process coppergold oreEVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING