Calcium carbide mud grinding and Namibia ore grinding machine installation plan

Preparation and curing method of red mudcalcium carbide slag

2023年5月1日 A low carbon geopolymer (RCFG) was developed from the 100% solid wastes including red mud (RM), calcium carbide slag (CS), GGBS and FA in this study The effect of The process equipment optimization comprises the following modules, known as optimization of wet calcium carbide slag feeding system and drying system, improvement of batching and Application technology of calcium carbide slag: a case study ZKG2022年10月24日 Preparation of calcium carbide slagactivated wetground fly ash based ecofriendly geopolymers The wet grinding process is helpful for the refinement and pre Lowcarbon wetground fly ash geopolymer activated by single 2022年11月21日 Red mud (RM) and calcium carbide residue (CCR) are waste generated from alumina refining and acetylene gas producing, respectively This study utilized alkaliactivated Strength development and microstructure of sustainable

.jpg)

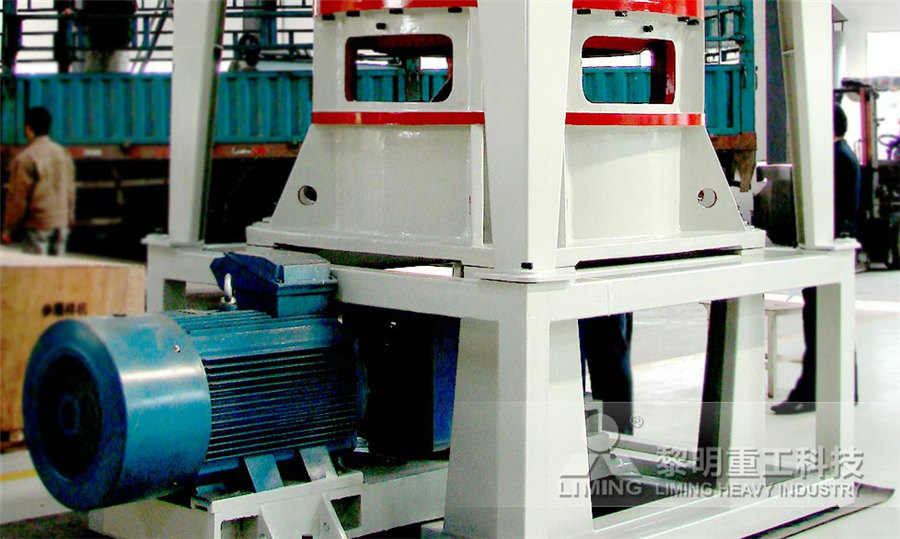

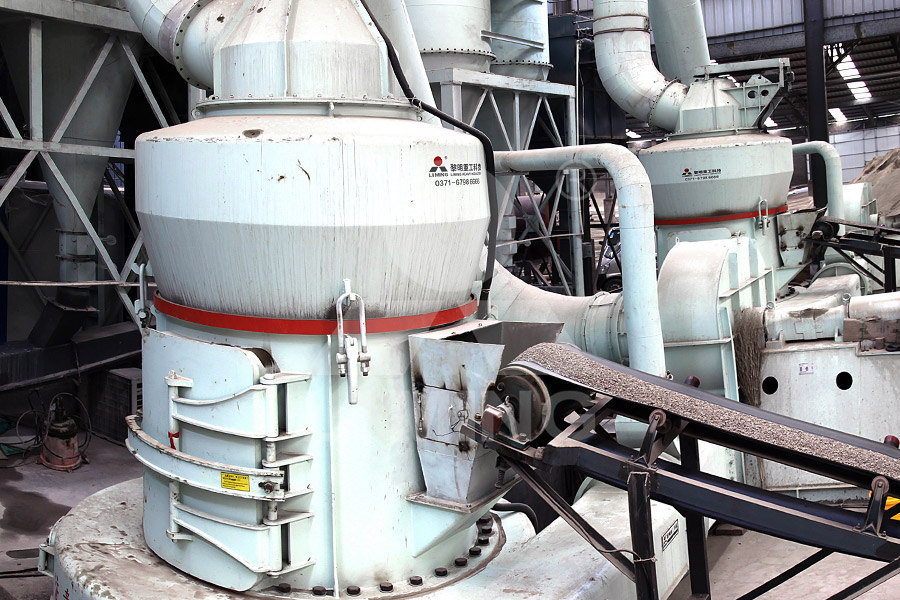

Industrial Ore, Mineral, Slag Crusher Stedman Machine

Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application Whether you are processing iron ore, coal, rock, salt, wood chips, or clay – to 2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle Mineral Processing Equipment for Mining IndustryEvery mining operation has a unique grinding process Metso has experience of over 8,000 grinding mills globally Reliable, energyefficient technology and solutions across wet, dry, Grinding Metso2020年10月30日 The flowsheet includes a primary gyratory crusher, crushed ore stockpile, and an SABC grinding circuit with a ball mill in closed circuit with cyclones to achieve the final Design of the Otjikoto Gold Mill, Namibia Mining, Metallurgy

An Innovative Approach to Prepare Calcium Oxide from Calcium

ABSTRACT: Calcium carbide slag (CS) is an industrial solid waste produced via the coalbased poly(vinyl chloride) process, and its main component is calcium hydroxide (Ca(OH) 2) (85−95 2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, (PDF) A comprehensive review on the grinding process: 2024年11月8日 In this study, a CO 2 sequestration material was obtained by all components solid wastes, ie, carbide slag and copper tailing based on red mud (RM) as crystal regulator after a sintering and carbonation process With the increasing dosage of RM, the mineral compositions of generated RMmodified clinkers were mainly γC 2 S (ie, around 80 %) at low dosage RM An all solid waste CO2 sequestration material consist of multiple 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy EnergyEfficient Advanced Ultrafine Grinding of

.jpg)

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 2023年5月27日 Step 1: Dry the calciumbased bentonite raw ore in the sun, and control the moisture content to 22% Step 2: Crush the calciumbased bentonite ore to a particle size of 25mm with a roller crusher Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodiumbased bentoniteHow to Dry, Grind and Granulate Your Bentonite Clay?A wide range of grinding and polishing machines and equipment from Struers, the world’s leading materialographic and metallographic equipment supplier, for quick and reproducible sample preparation in the laboratory and production environments, or on siteGrinding and polishing equipment Struers2017年4月1日 In preparing geopolymer based on red mud (RM), preactivation processes that are generally energyintensive are employed, including two indispensable steps, namely, calcination and fine grindingPreparation of blended geopolymer from red mud and coal

.jpg)

(PDF) Environmental Hazards of Limestone Mining and

2020年2月18日 Explore the environmental hazards of limestone mining and learn about adaptive practices for effective environment managementThe process equipment optimization comprises the following modules, known as optimization of wet calcium carbide slag feeding system and drying system, improvement of batching and grinding system for calcium carbide slag, and the optimization of clinker calcination system A detailed description for the three modules will be shown as the followingApplication technology of calcium carbide slag: a case studyCARBIDE GRINDING MACHINES FOR ULTRAPRECISE ROTARY TOOLS For significantly higher productivity during grinding without compromising on quality, VOLLMER's VGrind grinding machine has provided a solution which immediately set new standards VGrind VGrind special models Model VGrind Carbide tool grinding machines from VOLLMER for best tool 2020年7月1日 The residual calcium carbide in CCS can release a large number of hazardous gas C 2 H 2 (0125 L/(kg CCS)) [17,18], which brings the risk of C 2 H 2 deflagration and the environmental pollution Utilization of carbide slaggranulated blast furnace slag system by

Thrufeed Centerless OD Grinding: Parameters and

2017年2月15日 The abrasive types used in the grinding wheel are determined by the part material to be ground Aluminum oxide, ceramic aluminum oxide and CBN grains are typically used to grind ferrous materials Silicon carbide and 2019年5月23日 714 Basic Performance of Dry Acetylene Carbide Slag Dry acetylene technique is compared to the traditional “wet” acetylene preparation technique It uses water a little more than the theoretical amount, which is sprayed on calcium carbide powder in a foggy state to hydrolyze prehensive Utilization of Carbide Slag SpringerLink2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect2016年7月14日 A case study illustrating the optimization of a conventional gold ore grinding circuit is shown in the attached Table 3 Operating Modes of the Polycom HPGR in a Gold Plant The grinding circuit applications of Polycom HPGR units for mining applications have been described previously by Patzelt (1987), Otte (1988), and Otte Patzelt (1991)HPGR 911Metallurgist

.jpg)

Ore Crushing, Sand Making, Grinding Machinery Bellian Mining

At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where technology and excellence converge 2024年1月5日 A mixture of calcium carbide residue and coal fly ash with a Ca/(SiO2 + Al2O3) ratio of 15 resulted in the highest compressive strength at long curing periods in both pastes and mortarsEvaluation of calcium carbide residue and fly ash as sustainable 2024年7月1日 In order to reduce carbon emissions and consume a large amount of lowquality solid waste, CFBFARMCS has been developed by utilising the synergistic effect of circulating fluidised bed fly ash (CFBFA), red mud (RM) and calcium carbide slag (CS)The solidification mechanism of the ternary paste was studied from both macroscopic mechanical properties Optimization of proportions and solidification mechanism of all 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

.jpg)

Preparation and curing method of red mudcalcium carbide slag

Request PDF On Feb 1, 2023, Yuxuan Shi and others published Preparation and curing method of red mudcalcium carbide slag synergistically activated fly ashground granulated blast furnace slag 2016年6月29日 Nowadays, the modeling and simulation of grinding have become powerful tools in predicting the process performance and work results However, common simulations focus on material removal process of abrasive grains and neglect deformations of machine structure The grinding quality can be influenced by various factors, of which the processmachine interaction Simulation of grinding process for cemented carbide based on an 2021年5月31日 The nature of the ore blending problem is due to uncertainty and the uneven distribution of minerals in geology The benefits of ore blending are extending the ore reserve base by utilization of (PDF) A Method of Ore Blending Based on the Quality 27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM Mining Machinery

Preparation and Performance Assessment of Calcium Carbide

2024年10月29日 The production of one ton of calcium carbide results in the generation of about 12 tons of calcium carbide slag (CCS) [23] CCS can be utilised as a raw material for the production of cement, modified for use as a waterproofing material, 2022年6月24日 Singh A, Sinha MK MultiResponse Optimization During Dry Turning of BioImplant Steel (AISI 316L) Using Coated Carbide Inserts Arab J Sci Eng 2020; 45(11): 9397 An experimental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication—MQL grinding Int J Machine Tools Manufacture 2009 A comprehensive review on the grinding process: Advancements 2024年8月7日 Key types include Jaw Crushers, which handle large rocks and ores through compressive force; Cone Crushers, which provide finer output for hard materials; and Impact Crushers, which use highspeed impacts to process softer ores Grinding Equipment: After crushing, grinding refines ore into a fine powder to liberate valuable mineralsMineral Processing Equipment for Mining IndustryToday the EWAG product range includes manual machines for grinding and regrinding tools as well as the production of small precision parts, CNC tool grinding machines for grinding as well as laser machines for indexable cutting inserts and rotationally symmetrical tools made from carbide Ewag AG is part of the UNITED GRINDING GroupINSERT LINE UNITED GRINDING

.jpg)

Barite Ore Grinding MillCLIRIK Machinery

2021年8月2日 Barite grinding mill Barite is mainly used in petroleum, chemical, paint, filler and other industrial sectors after barite grinding machine powder, of which 80 to 90% is used as a mud weighting agent in petroleum drilling CLIRIK barite grinding mill is a2023年5月1日 Calcium carbide slag (CS) is a byproduct of the hydrolysis of calcium carbide to produce acetylene, containing more than 80% calcium hydroxide and thus presents a high alkalinity [23]Its large production volume challenges the disposal of CS, and currently CS is mainly dealt with by pilling and landfilling, which not only occupies a large amount of land Preparation and curing method of red mudcalcium carbide slag Calcium carbonate is an important building material and is widely used in industry Through ultrafine grinding machine processing, calcium carbonate ultrafine powder can be obtained, which is widely used in rubber, plastic, coating, paint, paper, and other manufacturing industries, as well as the food industry and construction industryCalcium Carbonate Ultrafine Grinding MillCalcite Calcium Carbide Powder Grinding Mill Production Line Machine Price $13,00000 Min Order: 1 set carbide calcium carburetor calcium carbide 50 80mm gas yield 295/kg nw 50kg 100 kg high quality calcium carbide machine $50000$60000 Min Order: 225 tons Previous slide Next slideSimple Ore Extraction: Choose A Wholesale calcium carbide machine

(PDF) Optimization and performance of grinding

2020年1月16日 Buzwagi Gold Mine (BGM) is operated by Acacia Mining and located in the Lake Victoria Goldfields of central Tanzania The mine commenced its operation since April 2009 and treats a sulphide copper DescriptionTungsten carbide grinding bowls and mortar is the highest density grinding tools for laboratory grinding mill, ball mill machine, power grinder,ball mill crusher etcHigh hardness and strengthness can meet the application of Miller™ Tungsten Carbide Grinding Bowls and 2019年6月27日 Cemented carbides are widely used in aerospace and mechanical processing industries due to their excellent physical and chemical properties However, cemented carbide products processed by conventional methods have such deficiencies as poor surface integrity, high surface roughness, and high consumables Given this, a method for machining blind Ultrasonic vibrationassisted grinding of blind holes and internal 2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangueGrinding Modeling and Energy Efficiency in Ore/Raw Material

Utilization of Carbide Slag by Wet Grinding as an Accelerator in

2020年10月13日 In this study, wetground carbide slag (ie, WGCS) was utilized as an accelerator in calcium sulfoaluminate cement (CSA) for obtaining considerably faster setting processes for some special 2020年11月1日 Grinding and polishing have a long history that can be dated back to the 15th century, a time when grinding was generally a manual work performed with natural sandstones (Fig 1)It was not until the 1850s that the initial concept of a grinding machine was introduced [1]Such machine still needed intensive human involvement [2], making it a semiautomated Compliant grinding and polishing: A review ScienceDirect2020年3月31日 This laboratory study investigates selective grinding and beneficiation options for a Greek bauxite ore First, a series of batch grinding tests were carried out in order to investigate the grinding behavior of the ore and the effect of the material filling volume (fc) on the distribution of aluminium and ironcontaining phases Then, the ground ore was subjected to magnetic Grinding Behavior and Potential Beneficiation Options of Bauxite Ores2024年8月15日 4 Screening equipment Screening equipment is used in a mineral processing plant to classify ore particles at different processing stages, ensuring that the size of the ore being handled is suitable for each stage, which improves processing efficiency and product qualityMineral Processing Plants: What You Need to Know Fote Machinery

.jpg)

Calcium Silicate Board Production Equipment Jiurui Machine

Among them, the production line equipment of calcium silicate plate by slurry method includes: pulp treatment system, pulp section, plate stacking and demoulding section, pressure steaming and curing section, grinding and chamfering sanding section The production process of calcium silicate board mainly includes the following:Ore Grinding Wu Caibin1 and Xu Kuangdi2 1School of Resources and Environmental Engineering, Jiangxi University of Science and latter is suitable for the ore containing more mud (washingcanbeomitted)andforrainyregionsIn order to improve the processing capacity of the autogenous mill Ore Grinding Methods and Process of Ore Grinding