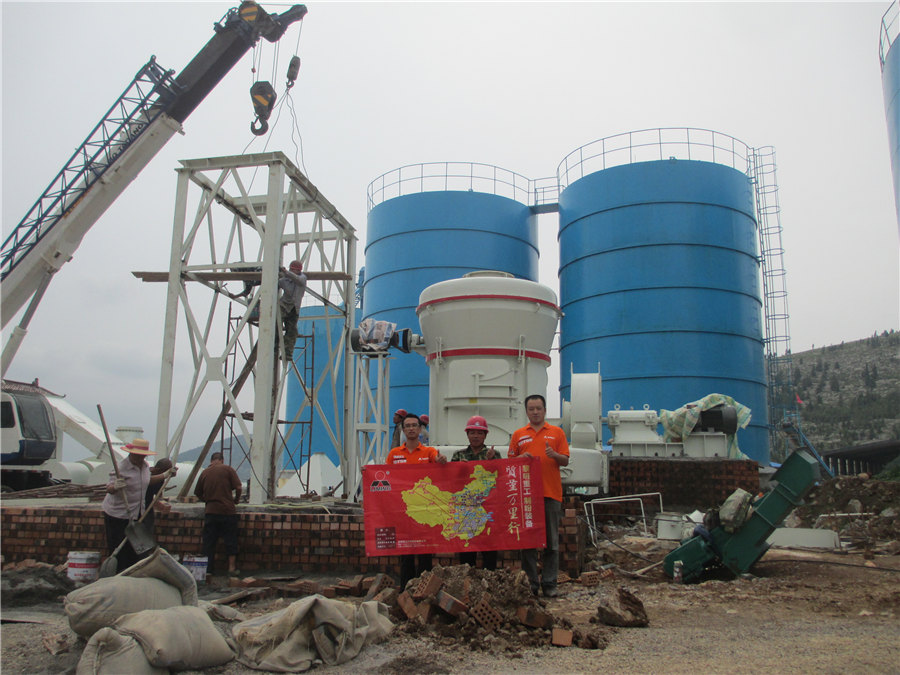

Introduction to the process of calcite ore powder processing equipment

.jpg)

Calcite powder production process flow/Calcite powder

The production of calcite powder involves several steps, starting from the raw calcite ore, through crushing, grinding, classification, and finally drying Here is a general process flow and the equipment involved:Calcite processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designCalcite Processing Equipment, Process Flow, Cases2024年8月3日 Selecting highquality calcite ore as raw material is the first step in preparing ultrafine powder The quality of raw materials is directly related to the purity and performance Calcite ultrafine powder preparation process flowCalcite processing mainly includes three steps: crushing, sand making and grinding It has a Mohs hardness of only 3 and is relatively easy to break Calcite feedstock with a size of less than Calcite Mastery: From Hardness to Powder Processing Techniques

.jpg)

Calcite Processing SBM Mill Crusher

2023年4月21日 Calcite processing involves various steps such as crushing, grinding, and classification The process is used to produce highquality calcite powder that is used in various industries such as construction, agriculture, and 2022年7月6日 So how is calcite processed? What equipment is needed for processing? Calcite crushing process There are three main technologies in calcite processing: crushing, sand Calcite Processing: 3 Incredible Technologies You Should TryCalcite mining and processing involve several steps to transform raw calcite into usable materials Here’s an overview of the typical process: Geologists conduct surveys to locate calcite How calcite is mined and processedThe innovative production process of the calcite grinding mill represents a significant advancement in the mineral processing industry Its ability to produce highquality calcite Innovative production process of calcite grinding mill

.jpg)

Calcium Carbonate Manufacturing Process and

2021年12月20日 Manufacturing processes used to fabricate this concentrated powder allow numerous industries to utilize it to fabricate a wide array of products Beyond being used as a standalone building material, the 2023年11月25日 Introduction to solids and powder feeders the engineer must retrofit an existing system, or figure out ways to make an existing process Beverage Technology HVAC Hydraulics Pneumatics Industrial IoT Industrial Introduction to solids and powder feeders for 2021年12月3日 of wollastonitecalcite ore was subjected to selfaerated Denver flotation equipment with a 15 L cell volume and a 1200 rpm mixing rate The conditions of the flotation tests are given(PDF) Extraction of Potassium from Feldspar by 2021年7月6日 Ore deposit is the gathering of ore where ore is defined as a rock or sediment which contains sufficiently high levels of minerals that can be profitably minution a Heart of Mineral Processing

Calcite Industrial Ultrafine Powder Grinder

2021年8月5日 Calcite grinding and crushing process Calcite, widely distributed, hardness 2730, Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses Common calcite powder has 3000 They can produce 3003000 mesh ore powder, which can meet the processing of ultrafine calcite powder2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of Iron Ore Processing, General SpringerLink10 Introduction 11 Mineral Processing and Extractive Metallurgy Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for useIntroduction to Mineral Processing or Beneficiation2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen

Copper Ore powder processing

Model selection and technological process in Copper Ore powder processing Welcome to Guilin HCM Machinery Official WebSite! mkt@hcmilling English Espanol Русский язык 简体中文2023年2月15日 Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying; 3 Further crushing: After drying, talc ore is sent to a hammer crusher for medium and fine crushing;How to Process Talc (the Softest Mineral)? FTM MachineryAltogether, the articles of this Special Issue stress the importance of powder processing in pharmaceutical applications and the contribution of indepth process understanding and modelling of correlations towards the development approaches that provide predictive power to safely and reliably handle such complex systems as powder blendsPowder Processing in Pharmaceutical Applications—InDepth 2024年8月7日 Mineral processing faces several challenges, including equipment wear and tear, high energy consumption, and achieving processing efficiency with variable ore qualities Solutions to these issues include regular Mineral Processing Equipment for Mining Industry

Introduction to Powder Metallurgy

This extensive introduction to the Powder Metallurgy (PM) process provides a detailed overview of a dynamic technology The following pages guide the reader through the steps required to produce components via the Powder Metallurgy The three stages of powder metallurgy include turning the primary material into a powder, injecting the powder into a mold or compacting in a die, and finally applying pressure, heat, and long setting times to consolidate the powder into a solid form Types Many types of powder production equipment and melting equipment are used in powder Powder Production Equipment Selection Guide: Types, Features 2024年10月14日 Remark: For conversion from millimeter to mesh, please refer to mm to mesh Process 3: Calcinating dolomite rock The crushed dolomite is calcined in a rotary kiln, which is used for producing refractory materials, magnesium alloys, cement, etc Dolomite is calcined at 1500°C to obtain magnesiacalcium raw materials, such as dolomite sand, magnesiacalcium How to Process Dolomite Rock and What Is It Used for?2014年1月1日 The gelcasting process dates back to 1990s when Omatete and Janney from Oak Ridge National Laboratory, USA, came up with a new slurrybased manufacturing process for making ceramic components in which conventional wet processing techniques were combined with polymer chemistry (Janney and Omatete 1989; Omatete et al 1997; Yang et al 2011) Powder Processing of Bulk Components in Manufacturing

.jpg)

(PDF) Characterisation of Minerals and Ores: On the

2017年3月1日 The focus of the paper is on complementary nature of techniques used for mineralogical characterisation of ores, minerals and, intermediate and final products generated during processingPowder processing equipment is used to process powders into a more usable form This can include grinding, blending, and sifting the powder The importance of powder processing equipment is that it can create a more uniform product which will be easier to use in manufacturing or other applications 30Kg/Hour:Global Powder Processing Equipment Market Report Segments:2017年3月4日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing SIZE REDUCTION BY GRINDING METHODS ResearchGate2020年12月15日 The way to successfully upgrade a phosphate ore is based on the full understanding of its mineralogy, minerals surface properties, minerals distribution and liberationReview of the Main Factors Affecting the Flotation of Phosphate Ores

.jpg)

MINERAL PROCESSING MILLING United Diversity

MINERAL PROCESSING MILLING Introduction Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size Milling is used to produce a varietyThe equipment in food processing refers to processing machines, components, systems used to cook, handle, package, prepare or store food and food products Although this equipment is primarily aimed towards consumability, Types Of Food Processing Equipment Plant 2023年12月20日 Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running The Cement Manufacturing Process Thermo Fisher 2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods

Powder Process an overview ScienceDirect Topics

Powder Processes Lorraine F Francis, in Materials Processing, 2016 56 Summary Powder processes provide a means to create simple as well as complex shapes from powder starting materials The engineering of powder processing methods requires an understanding of how the characteristics of powders, including size, size distribution and shape, impact the flow and 2022年3月22日 Complex and nonsulfide lead–zinc ores are difficult to concentrate, but the growing demand for lead and zinc metals necessitated their beneficiation Froth flotation is practically the most effective method in their beneficiation when optimum flotation conditions are attained The aim of the current study is to use process mineralogy as a tool to understand the A Process Mineralogy Approach to the Flotation of Complex The continuous advancements in ore powder production process equipment are transforming the mineral processing industry With the ability to produce highquality powders efficiently and sustainably, these technologies are not only meeting the demands of various applications but also contributing to the environmental stewardship of the industryAdvancements in ore powder production process equipment: We strive to make your equipment and systems robust and efficient Our project management teams become an extension of your business with a direct line of communication to the many resources within the Schenck Process global network Your team will take command of the design/build process from the project kickoff all the way to processPowder Processing Equipment Systems Qlar

.jpg)

(PDF) Introduction to powder metallurgy ResearchGate

2017年4月27日 Introduction to powder metallurgy (PM) technology, materials, market figures and applications Main focus is pressandsinter route, but a brief overview of other processes such MIM, AM, HIP, etc 2022年8月17日 Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of Introduction of iron ore crusher: have changed the twostage grinding to threestage grinding due to the adoption of the new finescreen regrinding process The equipment used for grinding generally includes Iron ore crushing equipment and process flowCalcite is a calcium carbonate mineral, widely distributed, usually white or colorless Common shapes are granular, massive, fibrous, earthy, and so on The calcite mill can grind calcite into a fine powder of 1503000 mesh, which is widely used Generally, calcite is used as industrial raw material such as chemical industry and cementCalcite Ultrafine Grinding MillManufacturers of powder processing equipment have, in turn, developed new and improved methods for producing powder products that meet/exceed these stringent parameters This paper will review the basics of particle size reduction and classification, and describe recent developments in powder manufacturing technologies A summary of available ADVANCES IN POWDER PROCESSING TECHNOLOGIES FOR

.jpg)

Evaluation of the best suitable purification method to purity Calcite

Comparatively calcite is good economic mineral so that we have to do many researches to purify, separate, precipitate and enhance of CaCO 3 Inmine calcite (Pvt) ltd is one of the leading companies regarding calcite mining processing of Micro Calcite raw materials are crushed by a crusher, and the crushed raw materials are sent to MW series ring roller micro powder mill by a hoist for grinding The ring roller micro powder mill grinds the materials into 1000 mesh dry powder particles, The dry powder particles will enter the storage bin after being collected by the dust collectorA brief introduction to the process of calcite ultrafine powder 2015年12月25日 In Chap 2, the most important occurrences of the rare earths were describedThis chapter will deal with what happens when the rare earths have been mined It answers the question: how are the ores processed? Mineral processing (sometimes called mineral dressing or ore dressing) is the preparation of ore from the stage that the material is Mineral Processing and Extractive Metallurgy of the Rare Earths2018年10月9日 For the processing of calcite, different processing requires different production lines For the grinding process of the material, the grinding process is required, and the grinding mill cannot What are the stages of the calcite grinding process

.jpg)

Calcite Grinding Mill Calcite Powder Processing Solution

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing But the degree of largescale is relatively lower compared to vertical grinding mill 2, HLM vertical mill: largescale equipment, high capacity, to meet the largescale production 5 天之前 The main beneficiation process of copper ore is flotation, contact us to customize copper ore processing plants and equipment get a quote now! Skip to content JXSC Machinery Us +86 Home Copper ore powder flotation machine can guarantee better stability index for refractory and complex copper ore or highgrade Copper Ore Processing Plants, Flow And EquipmentStage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process2021年8月21日 62 Powder Processing Equipment Market Size Forecast by Enduser industry 621 Food Beverage 622 Mining Construction 623 Metal Extraction 624 Pharmaceutical 63 Market Attractiveness Analysis by Enduser industry Chapter 7 Global Powder Processing Equipment Market Analysis and Forecast by Technology 71 IntroductionGlobal Powder Processing Equipment Market Report Segments:

Mineral Processing Design and Operations: An Introduction: Second Edition

2016年5月17日 Mineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes