VSI centrifugal asphalt coke petroleum coke mill belt model

Cemco® Vertical Shaft Impactor (VSI) Superior Industries

How Does the Cemco VSI Work? Feed material drops onto the impeller table or enclosed rotor which, through centrifugal force, throws the material against stationary anvils made up of The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI crushers are available in Vertical Shaft Impactors AstecVSlam™ VSI Models from Stedman are vertical shaft impactors for all your coarsetofine crushing needs VSI crushers offer significant savings over higherpriced competitive crushers Vertical Shaft Impactors VSI Crushers Stedman MachineIMPACT CRUSHERS (VSI) CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact crushers are designed for higher capacity, reduced power SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

.jpg)

PORTABLE VERTICAL IMPACT (VSI) CRUSHERS WITH FEEDER

Portable Vertical Shaft Impact Crushers are wheelmounted rock crushing machines, engineered for tertiary or quarternary crushing applications Equipped with a vertical shaft impact crusher Sandvik CV217 VSI can be used for a variety of applications, from quality aggregate production for concrete products, road construction and Dam production, to Mining industries where is's CV217 VSI crusher SRPVertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the VERTICAL SHAFT IMPACT CRUSHERSBarmac® VSI crushers produce cubical aggregate that performs well in concrete, asphalt and base mixtures It can also be considered for fine crushing, particularly for abrasive materials, Barmac® B Series™ impact crushers Metso

Stationary VSI crushers precision shaping SRP

Sandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption The autogenous "rock on rock" crushing technique results in several major 3 PILOT PLANT TRIAL Properties of HFO and asphaltite relevant to combustion Natural asphalt, or asphaltite, was extracted from the Cerrejón Mine, northwest of ColombiaColloidal Fuel Dispersions using Coal, Petroleum Coke2020年4月16日 The BET surface area of the raw needlecoke was only 30 m 2 /g, but it was drastically enlarged after activation, especially when it was activated at 750 • C (80769 m 2 /g)(PDF) Preparation of activated petroleum coke for 2014年3月1日 The production of petroleum coke (petcoke) in the refineries is progressively peaking up because of the trend of processing heavy crudes and in turn, a renewed interest in delayed coking process(PDF) Petroleum coke gasification: A review

.jpg)

Colloidal Fuel Dispersions using Coal, Petroleum Coke and

2012年10月14日 shows CO (a) and NO x emissions (b) as a function of A/F mass ratio for CAW; fuel combustion efficiency is included in the figure In similar combustion conditions, CO and NOx emissions for HFO HCMilling(Guilin Hongcheng) provides exclusive Petroleum Coke Vertical Roller Mill equipment with customers for grinding Petroleum Coke powder It is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying Its fineness can achieve 200325 mesh (7544μm) The production capacity is 5200T/HPetroleum Coke HLM Vertical Roller MillPDF On Jan 1, 2014, Aliasghar Rohani and others published Calcinations of Petroleum coke Find, read and cite all the research you need on ResearchGate(PDF) Calcinations of Petroleum coke ResearchGatePetroleum Coke: The sulfur content of petcoke can vary widely, with some grades having low sulfur content and others having high sulfur content Coal: Coal can also have varying sulfur content, with some types of coal containing higher sulfur levels, leading to potential environmental issues when burned 4What is Petroleum Coke or Petcoke? Its Types, Applications, and

Changing the Fineness of Calcined Petroleum Coke with Ball Race

New developments of Anode Coke Grinding using a vertical Mill Technology, TMS 2015 3 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany 42014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used The History and Future Challenges of Calcined Petroleum Coke Production 2011年1月1日 Moreover, because petroleum coke is the byproduct in the process of refining and commercializing crude oils [7][8][9] [10] [11], refineries can provide longterm stable supplies of petroleum coke (PDF) Optimizing Utilization of Petroleum Coke in Nigerian Petroleum coke is a solid byproduct of petroleum refining and is used in the production of carbon electrodes for the aluminum industry, graphite electrodes for steel making, as fuel in power generation, and as fuel for cement kilns In the United States, more than 15 million tonnes (168 × 10 6 tons) of petroleum coke are used by major utilities, as shown for 2000 in Table 57Petroleum Coke an overview ScienceDirect Topics

Grinding Characteristics of Coal and Petroleum Coke/Coal

2015年8月7日 The pyrolysis process of blends of petroleum coke and coal accords with mechanism model (1−α)15 well, and the combustion process accords with mechanism model w15 wellPetroleum coke is, essentially, the "bottom of the crude barrel" the carbon in the crude charge that cannot be recovered in normal refining processes comprising about 57Calcinations of Petroleum coke ResearchGate2018年3月22日 All content in this area was uploaded by Walid Alalayah on May 16, 2018Analysis of petroleum coke from low grade oily sludge of refineryProduce Uniform, RoadBuilding Material Compared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of material at higher tonnages and allow for more customization of rock shape and size Our Valor VSI offers significant application flexibility because of options like adjustable chamber configurations and Valor® Vertical Shaft Impactor (VSI) Superior Industries

.jpg)

Petroleum Coke an overview ScienceDirect Topics

The effect of pressure on the measured value for resistivity of different coke samples has also been reported elsewhere 66 The resistivity of bulk metallurgical coke is given as 0024 Ω m with a slightly lower value of 0020 Ω m at a pressure of 043 Pa, while for calcined fluid petroleum coke at zero applied pressure the resistivity was 002 Ω m, which decreased to 0002 Ω m Petroleum coke Petroleum coke, abbreviated coke, pet coke or petcoke, is a final carbonrich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokesPetcoke is the coke that, in particular, derives from a final cracking process—a thermobased chemical engineering process that splits long chain hydrocarbons of petroleum into Petroleum coke WikipediaThe activation energies of coal, petroleum coke and coal/petroleum coke mixture were calculated by using both a shrinking core model and a modified volumetric model The results showed that the activation energies for the anthracite and petroleum coke used in this study were 956 and 1192 kcal/mol and reaction times were 158 and 270 minPetroleum Coke Gasification Based Ammonia Plant DocsLib1 Raw material preparation: select highquality petroleum coke as raw material Petroleum coke is usually a byproduct of the oil refining process and is a solid material obtained by calcination 2 Crushing: The raw material lump petroleum coke is roughly broken through a crusher to break it into smaller particles 3Petroleum Coke Ultrafine Pulverizer

.jpg)

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

The Sandvik VSI crushers are delivered with a fixed rotor speed depending of the crusher model It is possible to order different pulleys and taper locks that will change the rotor speed However, the fixed rotor speed is chosen with many years’ experience in mind and the benefits of changing to other rotor speed can only be seen in few casesPetroleum Coke Grinding Mill Supplier Shanghai Clirik Machinery Supply Petroleum Coke ultrafine Grinding Mill,Petroleum Coke Ball Mill,Petroleum Coke Raymond mill,Petroleum Coke Hammer Mill,Petroleum The high pressure centrifugal blower will inhale air from outside and blow the Parameters of HGM Series Ultrafine Grinding Mill: Model:Petroleum Coke Grinding Mill Clirik2024年6月2日 Petroleum coke, or pet coke, is a carbonaceous solid derived from oil refinery coker units or other cracking processes It serves as a valuable fuel source in various industries, including cement, power generation, and Petroleum Coke Crusher: Choosing the Right Equipment2019年11月3日 Shen et al 17 proposed introducing a (1 − α) 3 model to predict the pyrolysis process of petroleum coke and estimated the kinetic parameters of four kinds of petroleum cokeA Modified Model for Kinetic Analysis of Petroleum

R)8OC`6F[ZIB.jpg)

Changing the Fineness of Calcined Petroleum Coke with Ball

2019年2月16日 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany Google Scholar NN; Presentation documents, Claudius Peters Technologies GmbH, Buxtehude, Germany, 20012016年2月25日 A realtime mathematical model for the twodimensional temperature field of petroleum coke calcination in vertical shaft calciner was developed based on computational fluid dynamics In the modeling process, the petroleum coke discharging process was described by the solid viscous flow, the dynamic heat flux boundary condition was adopted to specify the heat A RealTime Mathematical Model for the TwoDimensional PDF On Jul 1, 2021, Yu V Sharikov and others published Mathematical Model of Optimum Control for Petroleum Coke Production in a Rotary Tube Kiln Find, read and cite all the research you need (PDF) Mathematical Model of Optimum Control for Petroleum Coke Petroleum Coke is a fuel item distilled from Heavy Oil Residue As the AWESOME Sink does not accept fluids, converting Heavy Oil Residue into Coke is one way to sink it, solving the fluid deadlock problem in the early petrochemical setup It was formerly used in the production of Aluminum Scrap without alternate recipes It can be burned in the Coal Generator, which Petroleum Coke Official Satisfactory Wiki

coke crusher in centrifugal pumps

API 610 11th Edition / ISO 13709 2nd Goulds Pumps ITT Goulds Pumps is a proven leader in API Pumps • More than 20,000 units installed More than 17,000 OH2/OH3s More than 3,000 BB1/BB2/BB3 pumps 2016年10月31日 In this work, the effectiveness of using briquettes made from chromite ore, mill scale, and petroleum coke for direct chromium alloying is tested by induction furnace trials carried out in three (PDF) Direct Alloying Steel with Chromium by Briquettes Made The chromite ore, mill scale, and petroleum coke were dried in an oven at around 473K for 24h Then the materials were ground by a ball mill into various particle sizes (chromite ore: DDirect Alloying Steel with Chromium by Briquettes Made from The ground petroleum coke can be used as an important fuel in the chemical and metallurgical sectors instead of petroleum The recycling and reuse of petroleum resources can be realized after the petroleum coke is superfine pulverized by Petroleum Coke Ball Mill

VSI Rotor Centrifugal Crusher BHS Sonthofen Process

Consult BHS Sonthofen Process Technology's entire VSI Rotor Centrifugal Crusher catalogue on DirectIndustry Page: 1/16 Exhibit with us {{>currencyLabel}} 45 mm steel mill slag 100% 90% 80% Input material Final product Sieve fraction BF Indexing Belt Filter 16 Pages CF Candle Filter 16 Pages LCS Liquid Clarification Systems 24 Pages2024年2月27日 Petroleum coke grinding machines play a pivotal role in unlocking the full potential of petroleum coke, enabling industries to achieve precise particle size distributions, enhance product quality, and optimize process efficiencyWith their advanced technology, versatility, and environmental benefits, these machines are driving innovation and progress Petroleum Coke Grinding Machines2013年10月29日 Source: US Environmental Protection Agency, ScreeningLevel Hazard Characterization, Petroleum Coke Category, June 2011; and HW Nelson, Petroleum Coke Handling Problems, 1970 Notes: The process of “calcining” converts green coke to almost pure carbon, with a defined structure to produce carbon anodes for the aluminum industryPetroleum Coke: Industry and Environmental Issues CRS ReportsPetroleum Coke Petroleum coke is a carbonaceous product obtained in the oil refining process It is abbreviated as Coke or Petcoke, and is a carbonrich solid material derived from final cracking process — a thermobased chemical engineering process that splits long chain hydrocarbons of petroleum into shorter chains— that takes place in coker unitsPetroleum Coke IndianOil

Brief review on petroleum coke and biomass/coal cogasification:

2021年11月15日 Petroleum coke (PC) is a critical byproduct derived from delayed coking of residual oil [1]PC is characterized by high carbon content, high calorific value, low ash content and low cost [2]Therefore, it is generally used as (i) an electrode material (lowsulfur PC) for aluminum smelting and steel making, or (ii) industrial fuel (mid/highsulfur PC) for power Identification of the substance Petroleum coke (Greencoke) Registration number (REACH) this information is not available EC number 2650803 CAS number 6 Product number RDG7806 12 Relevant identified uses of the substance or mixture and uses advised against Relevant identified uses industrial usesSafety Data Sheet: Petroleum coke (Greencoke) Rosneft 2016年12月12日 1 Application Material: Petroleum Coke 2 Feed size: ≤200mm Moisture ≤5% 3 out size: 325mesh(D97), particle size can be adjusted 4 Output: shot coke 3t/h4t/h ; sponge coke 4t/h5t/h 5 Crushing Equipment for Petroleum Coke Plant by feng li Medium2021年8月23日 Here, we demonstrate the use of petroleum coke as a feedstock for carbon nanomaterial production Graphene, in particular, is an exciting target because of its ongoing deployment into a range of Sustainable production of graphene from petroleum coke

.jpg)

Technology for separating powdered materials from petroleum coke

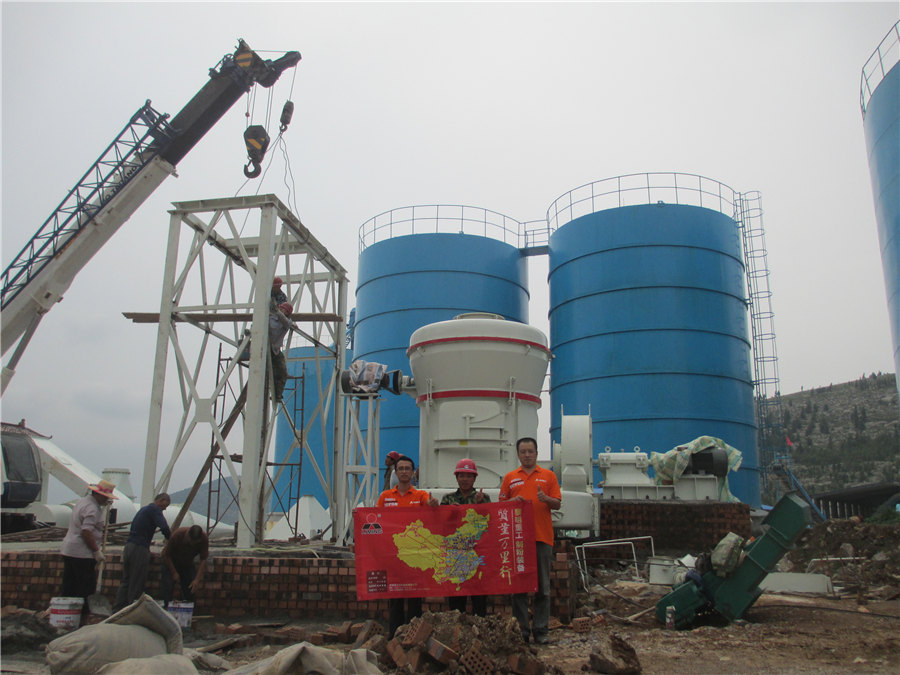

2024年2月7日 Centrifugal mill with stratified flow classifier for use in the production of powdered petroleum coke in Uzbekistan (Universum, technical sciences Z N Mamadjanov I T Rustamov