Hubei cement vertical mill

.jpg)

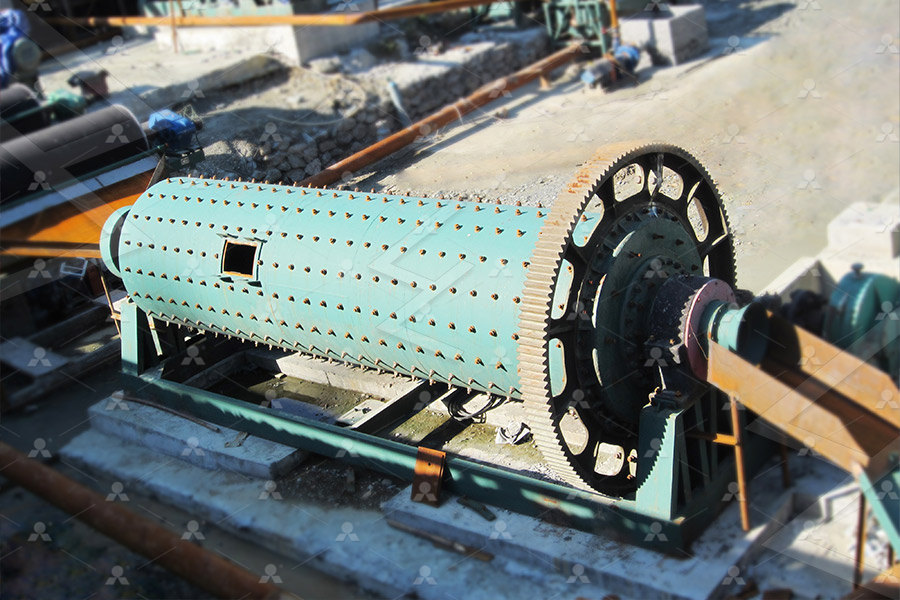

5000t/d Cement Production Line of Hubei Century Xinfeng

2015年9月14日 Project company: Hubei Century Xinfeng Leishan Cement Co, Ltd Project address: Jiangbi Road, E’cheng District, E’zhou City, Hubei Province Contracting mode: UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your equipment performance Further UBE Vertical Mill UBE Machinery Corporation, Ltd2020年5月1日 Vertical roller mill (VRM) is a type of heavyduty and energyintensive grinding equipment for many industries, such as cement, steel and chemical industries It is used to A datadriven decisionmaking framework for online control of UBE Vertical Mill We meet our customers' needs with our powder and grinding technology based on long term experience As for limestone, cement, metals, chemicals, biomass, ceramics, and UBE Vertical Mill UBE Machinery Corporation, Ltd

.jpg)

UBE Vertical Mill|SERVICES|UBE Machinery

Utilizing our knowhow as vertical mill manufacturer and the largescale processing equipment at our own workshop, we respond to every request, from product production to maintenance of various parts, technical support, and on Hubei Yadong Cement Vertical Mill China Manufacturers, Factory, Suppliers We rely upon strategic thinking, constant modernisation in all segments, technological advances and of China Hubei Yadong Cement Vertical Mill Manufacturers and 2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the Review on vertical roller mill in cement industry its performance UBE Machinery Corporation Ltd, Japan to manufacture supply stateoftheart UBE Vertical Roller Mills for grinding applications related to Raw material, Coal, Clinker and Slag The mill VERTICAL ROLLER MILLS AMCL

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient Understanding Our Proprietary Vertical Cement Mill Technology Magotteaux’s proprietary vertical cement mill technology has been developed through decades of innovation and expertise in grinding processesOur vertical cement mill Vertical Cement Mill MagotteauxGreenhouse gas (GHG) benchmarking for allocation serves as rewards for early actions in mitigating GHG emissions by using more advanced technologies China Hubei launched the carbon emission trading pilot in 2014, with the How to Set the Allowance Benchmarking for At Magotteaux, our vertical cement mill grinding parts will improve the operational prowess of any mill they are fitted to All Vertical Cement Mill Designs Covered Thanks to the smart engineering and highquality manufacturing methods that lie behind our cement milling grinding part, we can recommend a solution that your production and maintenance managers will both agree uponVertical Cement Mill Magotteaux

.jpg)

(PDF) How to Set the Allowance Benchmarking for Cement Industry

2017年2月22日 35 Hubei cement factories because all 40 BAT s are industrial wide technologies Raw material vertical mill technology 37 Low pressure drop cyclones for suspension preheater 38The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement PlantUBE Vertical Mill We meet our customers' needs with our powder and grinding technology based on long term experience As for limestone, cement, metals, chemicals, biomass, ceramics, and fiber materials, various fields needs pulverization technology for UBE Vertical Mill UBE Machinery Corporation, LtdUBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Information about UBE Vertical Mill services Repair Service Restoring your equipment to its original performance Consulting ServiceUBE Vertical Mill UBE Machinery Corporation, Ltd

.jpg)

Vertical roller mill services FLSmidth Cement

The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioningTherefore, when the vertical mill is operated, the control of the inlet and outlet dampers should be balanced by the kiln mill When the vertical mill inlet and outlet dampers are balanced, the system's wind will be balanced and will not affect the pressure at the kiln end Precautions for Starting and StoppingImportant Operation Tips For Cement Vertical Mill2022年1月10日 Vertical Cement Mill is the main tool used in the final process of making cement at PT Semen Baturaja (Persero) Tbk Vertical Cement Mill is used to mix and grind clinker and corrective materialsAnalisa Kinerja Alat Vertical Cement Mill di Pabrik II PT Semen 2020年5月1日 The authors would like to thank Hubei Gucheng Longtai Cement Products Co, Ltd and Jiangyin Xingcheng Special Steel Co, Ltd for providing the real data of equipment operation status Fault diagnosis expert system for large vertical mill with alarming judgement based on measured data Mining Processing Equipment (2017)A datadriven decisionmaking framework for online control of vertical

Vertical Roller Mill in Cement Manufacturing Plant

2023年7月4日 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding It is an energyefficient alternative to traditional ball mills, as it utilizes rollers to Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMAUBE Vertical Roller Mill performs drying, grinding, UBE has designed the Six Roller Mill for large capacity Cement Plants UM436 SR Hubei, China UM564 SN Hebei, China UM series mills for the Coal/ Pet Coke grinding Ensure efficient grinding and safetyVRM – AMCL Machinery Limited2022年10月3日 Raw materials grinding process is a first step of cement production which is has an important role in the first grinding step Vertical Raw Mill is a main equipment that is used in grinding or (PDF) ANALISA KINERJA ALAT VERTICAL RAW MILL PABRIK II PT

.jpg)

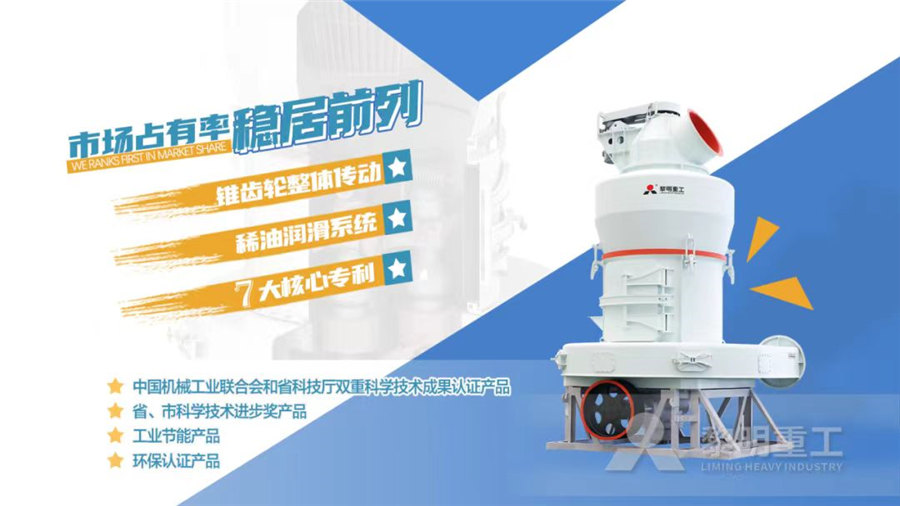

Why Choose Cement Vertical Mill?

2020年3月13日 There are some kinds of cement grinding mill on the market, such as cement ball mill, cement vertical mill, cement roller press, etc Why choose cement vertical mill? AGICO CEMENT helps to find answer now! Skip to content +86 s about blog contact EN ES Menu Menu2022年10月3日 Vertical Cement Mill is the main tool used in the process of grinding and drying the main raw material for making cement, namely clinker plus additional materials in the form of limestone, gypsum (PDF) EFISIENSI THERMAL ALAT VERTICAL CEMENT MILL PABRIK 2022年10月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the (PDF) A cement Vertical Roller Mill modeling based on the Cement vertical mill is also called a vertical milling machine AGICO customizes any sizes of AG series vertical mills for customers Our vertical grinding mill applies for limestone, clinker, clay, gypsum, etc Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment CALL US +86 Cement Vertical Mill Vertical Grinding Mill Vertical Mill

ANALISA KINERJA ALAT VERTICAL CEMENT MILL DI PABRIK II PT

Vertical Cement Mill digunakan untuk mencampurkan dan menghaluskan clinker dan bahan – bahan korektif Selain itu, alat ini juga digunakan sebagai pengering dengan memanfaatkan udara panas daripage 05 2 vertical mills introduction page 07 3 principles of vertical grinding systems page 07 31 vertical mill components page 07 32 how does a vertical mill work? page 08 4 a new generation of grinding additives: maga/vm and mape/vm page 08 41 mill output increase page 09 42 quality and water demand optimisation page 09 5Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSThe cement industry has long been a major consumer of energy, contributing to approximately 5% of global CO2 emissions In order to address this issue, the industry has been exploring new technologies and innovations to improve energy efficiency, reduce emissions, and lower production costsVertical Roller Mill in Cement Plant ball mills supplier2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million tones per Review on vertical roller mill in cement industry its

.jpg)

Vertical Roller Mill for Sale AGICO Cement Plant

AGICO vertical roller mills can be used as cement mills, raw mills, and slag mills AGICO also supplies vertical roller mill components and parts, we can customize machines according to customers’ needs Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish []2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement CEMENTS GROUND IN THE VERTICAL ROLLER MILL FULFIL THE QUALITY REQUIREMENTS OF THE MARKET DiplIng Th Fahrland, DrIng KH Zysk, Loesche GmbH, Duesseldorf, GermanyCEMENTS GROUND IN THE VERTICAL ROLLER MILL FULFIL THE Cementos Cibao SA, cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of quadropol® thyssenkrupp Polysius Grinding Technologies

Vertical Mill In Cement Plant Cement Vertical Mill AGICO Cement

In the construction of the cement production line, vertical mill or cement vertical mill is the main cement equipment Its installation plays a vital role in the construction of the whole production line Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment CALL US +86 7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRY2015年9月14日 5000t/d Cement Production Line of Hubei Century Xinfeng Leishan Cement Co, Ltd News Date: Project Overview Project company: Hubei Century Xinfeng Leishan General contractingturnkey project Host configuration: Φ46×105+35 m raw material vertical roller mill Production capacity: Annual production of 900,000t 5000t/d Cement Production Line of Hubei Century Xinfeng Leishan Cement The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainabilityVertical roller mill vs ball mill for cement grinding: Comparison

Vertical Cement Mill Magotteaux

Given that vertical cement mills are the norm in the cement production sector, production and maintenance managers have seen very little innovation in recent years with these systems However, at Magotteaux, we have broken the mold and produced our own designs to offer numerous commercial benefits Benefit From Vertical Cement Mill Innovation2020年11月5日 We compare 3 cement milling and cement mill processes, including cement ball mill, vertical roller mill, and rod mill Find your answer here! Skip to content +86 s about blog 3 Necessary Cement Milling Comparison Ball Mill, MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, MPS 4750 BC cement mill, Holcim Val de Seine, France MPS 4750 BC cement mill, Holcim Val de Seine, France MPS 200 BK coal mill, Krimzement Bakhchisarayski, UkraineCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2022年10月5日 Cement Mill Vertical Roller Mill Operation Using Simulator English VersionIn this session I will explain about How to Operate a Vertical Roller Mill for Cement Mill Vertical Roller Mill Operation Using Simulator

.jpg)

Increase productivity of vertical roller mill using seven QC tools

2021年1月29日 Specific Power consumption of Vertical Roller Cement Mill for preimprovement phase Data of last 6 months was taken to analyze the exact nature problem and behaviour of dataVertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a Vertical roller mill CEMENTL2016年12月31日 A Vertical Roller Mill will be installed in a plant for cement grinding at Mukterpur, Bangladesh The biggest ever Vertical Roller Mill for cement grinding is under execution for Shah Cement Industries Ltd, Bangladesh, at its Char Merashar plant located at Mukterpur in Bangladesh Shah Cement Industries Ltd, a flagship company of the Abul Khair []FLSmidth to supply the world’s biggest Vertical Roller MillHighquality cement vertical roller mill manufacturer Tongli ZJTL series cement vertical mill is a very important link in cement production and is the best choice for raw material grinding and clinker grinding As an iterative product of the ball mill, the vertical mill occupies a small area, which is about 50% less than the ball millCement Vertical Roller Mill CEMENTL

Comparison Of Vertical Roller Mill And Roller Press Mill

Table 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller