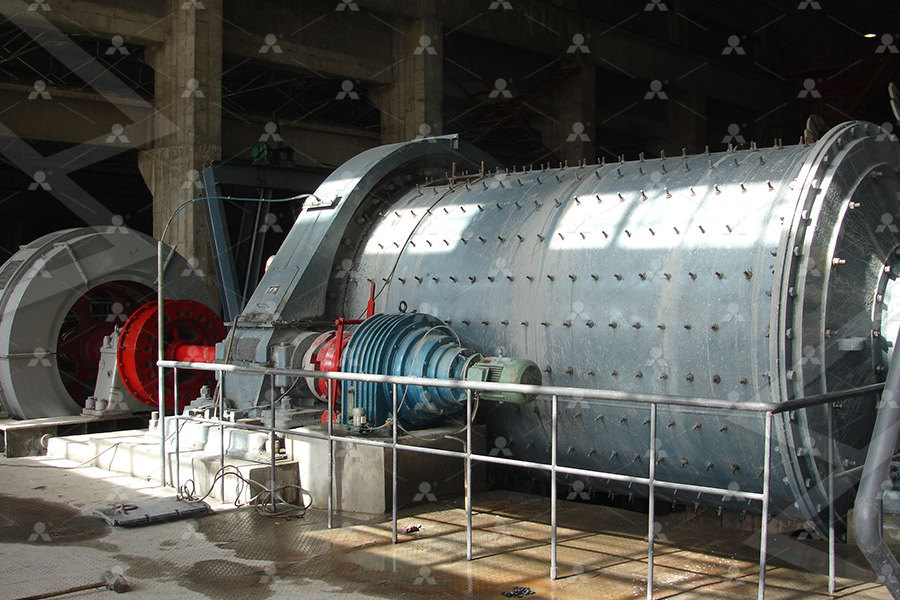

Large ore grinding machine used in power plants

.jpg)

Grinding Metso

Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for The use of highpressure grinding machines in minerals processing plants requires special attention to the following issues: » Evaluation of ore performance and assessment of process HighPressure Grinding Roller Presses for Minerals Processing2024年8月15日 Widely used for fine grinding; can operate in dry or wet modes based on process requirements High Rod mill: Largersized ores Ideal for coarse ore grinding, preventing overgrinding Low Autogenous mill: Very hard, highly Mineral Processing Plants: What You Need to KnowBall mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale ore beneficiation plant Dry grinding: suitable for materials that react with water, such as building stones such as Ball Mill Mining Grinding Mill JXSC Machinery

.jpg)

Grinding mills for mining and minerals processing

Horizontal Mill Plant Units offer complete support in grinding circuit selection, as well as execution, service and operation Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and Our Enduron® HPGR portfolio ranges from pilot machines to large format production machines including the world’s largest operational roller surface, capable of processing over 118,000 tons of ore per day For high availability Our Dynamic HPGR Technology for Mineral GrindingThe use of HPGR machines in minerals processing plants requires special attention to these issues: » Pilot plant HPGR tests are necessary to evaluate the ore performance and to assess HighPressure GrindingGearless motors up to 22 MW are in service in many of these ore processing plants Gearless motor drives are also known as “ring motors” or “wrap around motors” The motor consists of a Advantages of Gearless Motor Drives in Large Ore Grinding Mills

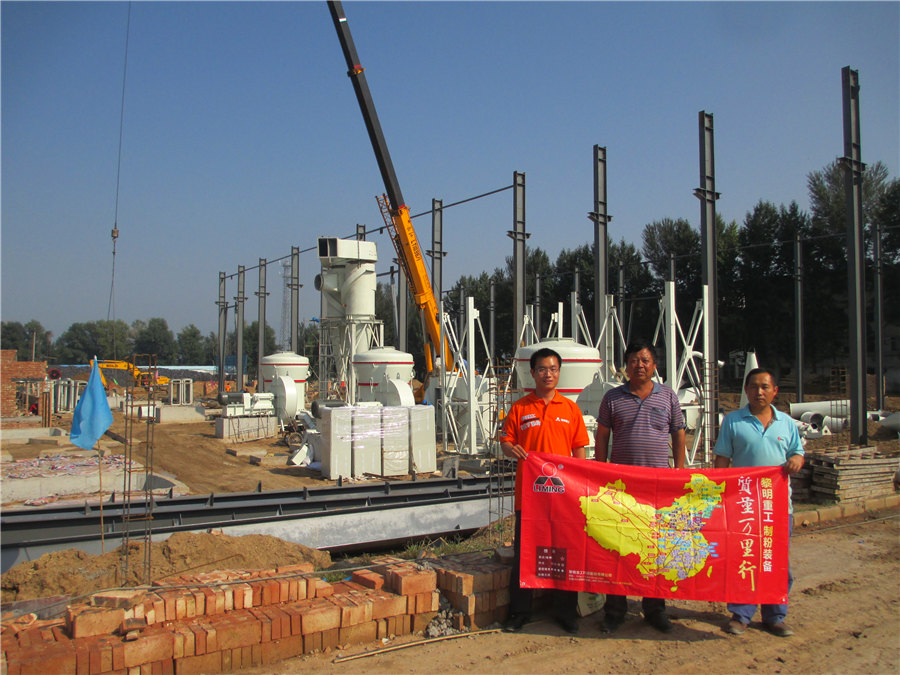

Gold Processing Plant Ball Mill Ore Grinding Machine

Gold Processing Plant Ball Mill Ore Grinding Machine, silicate and chemical industries In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the grinding machine for metal ores of gold, silver, copper, lead Power (kW) Effective Volume (m 3) Max Ball Load (t) MQ2122: 2100: 2200 The mill shell with the fixed magnets is the rotor The large numbers of magnets produce a multipole machine that by itself reduces the rotational speed of the rotor Cycloconverters, which are high power rectifier inverters, convert the incoming three phase 50 Hz power supply to a lower frequency power supplyAdvantages of Gearless Motor Drives in Large Ore Grinding MillsWe dispose with three grinding machines with range up to DN800 Steam Turbines For Biomass Power Plants; Energy From Waste; Nuclear Power Plants; Turbines For Concentrated Solar Power Plants modernization and retrofits when machining large turbine components directly in power plants successfully for several years nowGrinding Machine Doosan Škoda PowerThe Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's lawUnderstanding the SAG Mill in Copper Ore Mining Process

Dolomite Sand Making Plant And Grinding Machine

2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before discharge Step 2: Grind small stones into 2012年11月17日 2 1Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form Pulverized coal achieved its first commercial success in the cement industry At Wisconsin Electric Power Company, the use of pulverized coal was also shown to be a viable fuel for Coal mill pulverizer in thermal power plants PPT SlideShare2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022 EasternEuropean Journal of Enterprise Technologies 1(1 (115)):93105Improving the efficiency of the coal grinding process in ball drum When designing mining and processing plants, ore grinding can be developed as an but it is technically difficult to perform and therefore is used relatively rarely at mining and processing plants Machines with movable individual and longterm investments for the construction of large solar power plants around the world Mining and processing plant design ESFC Investment Group

.png)

Advanced control of gold ore grinding plants in South Africa

In of Cultural Identities in West and Central Asia: A Festschrift for Prudence Oliver Harper, 2023 me for the complete paper! In 1942 Sir Aurel Stein acquired a copperandbronze rhyton in the form of a centaur in the Gilgit Agency of the British Raj; his estate later bequeathed it to the Ashmolean Museum (acc no EA196328)2023年7月14日 Tool and Cutter Grinding Machines: Tool and cutter grinding machines are widely used to sharpen and recondition different cutting tools like drills, milling cutters, and tool bits Jig Grinding Machines: These advanced Top 10 Grinding Machine Manufacturers Suppliers 2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more Crushing Plant Flowsheet DesignLayoutBall mill is widely used in mineral processing plants for wet or dry grinding materials and equipped with spiral classifier, high efficiency and are most widely used in small or largescale ore beneficiation plant Dry grinding: Ball Mill Mining Grinding Mill JXSC Machinery

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 It consumes most of the energy used in mineral processing plants with grinding using up to 50% of the provided energy Tumbling mills are an old technology that is still commonly used for grindingAGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 Cement Grinding Plant Overview Cement Grinding Unit AGICO Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill2024年8月2日 The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient lowquality iron ore beneficiation to meet steelmaking quality requirements This comprehensive review explores Exploring LowGrade Iron Ore Beneficiation Techniques: A MDPI

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangue2024年5月22日 Grinding balls, also known as grinding media, are spherical components used in various industrial applications to grind materials into fine powders or smaller particles They play a crucial role in the efficiency and quality of the grinding process in industries such as mining, cement production, chemical processing, and power generationWhat Are Grinding Balls Used For?2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod millsGrinding Machines: Types and Selection Principles Mining classification, as well as the use of inert media in a high energy intensive environment This paper will examine the use of IsaMill™ technology in fine grinding (P80 below 15 micron), and examine the use of the technology in conventional grinding applications (P80 20 150 µm)IsaMill Technology Used in Effecient Grinding Circuits

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Manufacturing: Used in the production of glass, paper, plastics, and paint Environmental: Used for flue gas desulfurization in power plants to reduce sulfur emissions By processing limestone into fine powder, the grinding mill plant supports various industries by providing a versatile and essential material for manufacturing processesLimestone Grinding Mill Plant TAYMACHINERYFor Cat wheel loaders, the compact models work best with light materials and have a bucket capacity of 2 cubic yards However, large models can handle iron ore or rock and can hold up to 38 cubic yards of rock in the bucket Typically found at surface mines, large wheel loaders can take on many tasks, such as:Common Types Of Mining Equipment Empire Cat2021年5月5日 Once the grinding operation starts the wheel can not rotates in the reverse direction and The wheel is constantly degrading and it requires much spindle power Grinding Machine Application: The following application of Grinding Machine are: The Grinding Machine is used in various industries for grindingGrinding Machine: Definition, Parts, Working Principle, Operation

.jpg)

10 Profitable Mineral Grinding Plants for Sale (Costs and Cases)

Coarse powder machine, grinding various metal and nonmetal ores Raymond mill Fine powder machine, necessary for grinding nonmetallic ores HGM ultrafine mill Ultrafine powder machine, a new type of milling processing equipment Threering mediumspeed micropowder mill Suitable for micropowder processing of brittle materialsThe crushing process of iron ore washing plant generally uses feeders, first crushing, second crushing, screening, and fine crushing In the production of chromite ore, jaw crushers are generally used for head crushing, and largescale production units (especially largescale foreign mines) use gyratory crushersIron ore washing process and equipment LZZGThe coal input to the boiler of the power plant passes through three different phases before combustion in the boiler Receiving, storing, and transporting the coal to the boiler This is bulk storage and bulk handling Preparing the coal for firing or pulverizing This is what is special in a coal fired power plant, especially large thermal Why Pulverized Coal is Used in a Power Plant Bright Hub 2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials Ore crushing provides suitable particle size of material for subsequent ore grinding, beneficiation or smelting, which is the preparation process before beneficiation or smeltingOre Crushing SpringerLink

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports that 15% 2024年4月26日 These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding Iron Ore Processing: From Extraction to ManufacturingChina Ore Grinder Machine wholesale Copper Ore Processing Plant Equipment Gear Driven Small Scale Rock Grinder Ball Mill Grinding Machine US$ 980016900 / Set 1 Set (MOQ) Jiangxi Hengchang Mining Machinery Manufacturing Co, grinding mill, Ore Grinder Machine MadeinChina2019年4月19日 At new ore locations, power system stiffness doesn’t seem to be growing as fast as large mill sizes High starting current (usually of low power factor) drawn through the utility system,ant transformers, and plant distribution networks causes voltage dips A utility often limits that dip at the point of purchase to 3% or lessElectric Drives for Large Ore Grinding Mills 911Metallurgist

.jpg)

How do power plants work? How do we make electricity?

2023年9月19日 The magical science of power plants A single large power plant can generate enough electricity (about 2 gigawatts, 2,000 megawatts, or 2,000,000,000 watts) to supply a couple of hundred thousand homes, and that's the same amount of power you could make with about 1000 large wind turbines working flat out But the splendid science behind this amazing 2024年1月12日 The type of drilling machine used is determined by the material’s hardness, the hole’s size, and the required precision In manufacturing plants, drilling machines are used for a wide range of applications, from creating small holes in electronic components to large holes in construction materialsMachines Used in Manufacturing: Full List of TechniWaterjet2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately 50 mm (2 in) and Grinding Mills — Types, Working Principle ApplicationsThis machine can be can grind all kinds of ores and other materials, which Compare this product Remove from comparison tool ball grinding Ф2200×5500 Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 10 t/h 20 t/h Ball mill is common used grinding plant in the Motor power: 75 kW 3,300 kW Machine length Ore mill, Ore grinding mill All industrial manufacturers

.jpg)

The copper ore dressing plant adopts semiautogenous grinding

2024年9月21日 The SAG grinding process uses the ore's own fragments as the grinding medium, with a small amount of steel balls, and realizes the initial grinding of the ore through a large mill The advantage of the SAG process is that it can handle larger ore blocks, reduce the crushing process, and reduce overall energy consumptionCement roller press is a kind of pregrinding equipment commonly used in cement grinding plants It has advanced working principles and reasonable structure, features high reliability, less mechanical failure, large crushing ratio, high efficiency, and low power consumptionMaking Your Cement Grinding Plant Energy Saving Cement Grinding 2017年1月17日 Furthermore, dilution of ore by waste rock, through the use of largescale and nonselective mining methods for example, can result in lowgrade material being processed by comminution circuits Breaking down energy consumption in industrial grinding mills