Windswept steel ball coal mill drawing

kolkata technical manuals of coal mill design

Industrial Ball Mills: Steel Ball Mills and Lined BallThe Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 LOESCHEMILLSCoal mill is an important component of the thermal power plant It is used to grind and dry the moisturized raw coal and transport the pulverized coal – air mixture to the boiler Poor dynamic (PDF) Modeling and Control of Coal Mill AcademiaThis document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals Ball Mill Grinding Process Handbook

.jpg)

Grinding in Ball Mills: Modeling and Process Control ResearchGate

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy BALL TUBE MILL The Ball Tube Mill is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter The inside of the Cylinder shell is BHARAT HEAVY ELECTRICALS LIMITED2008年6月1日 In this study, performance evaluation, modelling and simulation of airswept coal ball mill grinding circuit is presented Ball mill in the circuit was modelled based on the Whiten'sPerformance analysis, modelling and simulation of dry airswept A Simulation Model for An AirSwept Ball Mill Grinding Coal Free download as PDF File (pdf), Text File (txt) or read online for freeA Simulation Model For An AirSwept Ball Mill Grinding Coal Scribd

AUTOMATION AND OPTIMIZATION OF COAL GRINDING BY

Structural diagram of the ball mill automation and optimization system: 1 – raw coal feeder; 2 – back from separator; 3 – drying agent; 4 – ball mill; 5 – air mixtureThe ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ Coal Mill in Cement Plant Vertical Roller Mill Air Efficient Grinding of Additives and Coal in Iron and Steel Plants Laszlo Ivan, Rajnish Chandra, Rajesh Sharma and Dhananjay Koul Raymond Bartlett Snow Division (Arvos Group) (Vertical Roller Mill and Ball Race Mill)” specialized for Coal grinding in PCI application proven for highest standards on reliablility, Raymond Bartlett Snow Milling Technologies Specialized2019年11月7日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before modificationTransform the Optimization and transformation of 300MV units steel ball coal mill

What is a Coal Grinding Mill

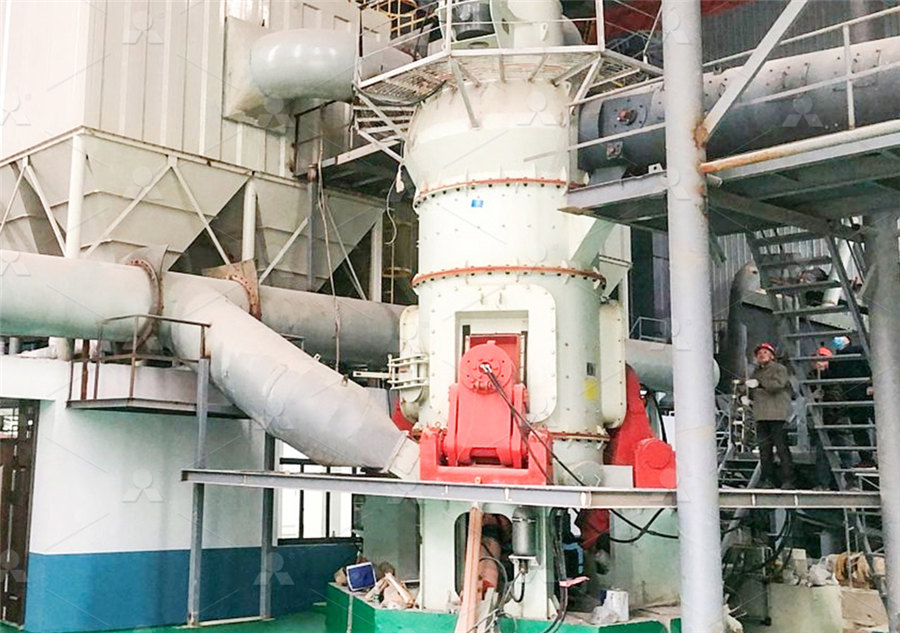

Mill liners can be made of various materials, including rubber, steel, and composite materials, and can be designed to match the specific grinding requirements of the coal material 20tph Coal Ball Mill For Clean Coal Powder Production Line In Vietnam Read More 85tph Cement Ball Mill Put Into Operation In Indian Cement Plant Read MoreThe air swept coal mill is also called coal ball mill This coal mill is a kind of ball mill Steel ball coal mill is one of the auxiliary machines of the thermal power station and an important equipment for the pulverized coal preparation system This series of coal mills are mainly used to grind coals of various hardnessAirSwept Coal Mill Hongji Mine MachineryCoal Ball Mill; Limestone Ball Mill; Ball Mill Grinder Menu Toggle Overflow Ball Mill; We have a strong production capacity and can customize various ball mill accessories according to the PDF or CAD drawings provided by AGICO trunnion bearing is made of ZG35 and ZG45 cast steel, which has high hardness, excellent wear resistance Ball Mill Trunnion Bearing – Cast Steel 1150 Tons AGICOProject achievements of wind swept coal mill Tel:+86513 Email: Home ; Project achievements of ball mill; Achievement of exporting cement equipment; Sidebar ` Jiangsu Pengfei Group Co, Attractive Butterfly Racing Fiberglass Water Slides Galvanized Carbon Steel Frame For Aqua ParkProject achievements of wind swept coal mill

AirSwept Coal Mill of High Quality Fote Machinery

Lowspeed coal mill: Its rotating speed range is 15–25 r/min The lowspeed coal mills include cylindrical steel ball mill, steel ball mill with two symmetrical grinding circuits, etc Mediumspeed coal mill: Its rotating speed range is 50–300 r/min Flat plate mills, bowl mills, and MPS mills are common mediumspeed coal millsFigure 1 Typical Arrangement of the Riley Ball Tube Mill System DESCRIPTION OF PULVERIZERS AND FUEL SYSTEMS Ball Tube Mill The Ball Tube Mill (BTM) is a cylindrical lowspeed grinding mill It consists of a steel barrel, lined with cast abrasionresistant liners and partially filled with hardened steel balls Coal and preheated primary airA Comparison of Three Types of Coal Pulverizers Babcock PowerPowder Technology 192 (2009) 260–267 Contents lists available at ScienceDirect Powder Technology j o u r n a l h o m e p a g e : w w w e l s ev i e r c o m / l o c a t e / p ow t e c Steady state inferential modeling of temperature and pressure in an airswept coal pulverizing ball mill Augustine B Makokha a,⁎, Michael H Moys a, Costa Couvas a, Alex M Muumbo b a b (PDF) Steady state inferential modeling of temperature and Vertical Roller Mill Steel Slag Vertical Mill Ball Mill Raw material mill Coal Mill Slag Mill Cement Mill Rod Mill Ball Mill Rotary Kiln Cement Rotary Kiln Lime Φ38×95m wind swept coal mill 4 Riverside Group Co,LTD 3000t/d Coal Mill Great Wall

.jpg)

Performance analysis, modelling and simulation of dry

2008年6月1日 In this study, performance evaluation, modelling and simulation of airswept coal ball mill grinding circuit is presented Ball mill in the circuit was modelled based on the Whiten's (1972 2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a (PDF) Effects of Ball Size Distribution and Mill Speed and Their Coal Mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online This dissertation examines technologies to enhance the maintenance performance of coal pulverizers through new technologies It presents the results of testing modifications to rotating throat assemblies, spider and guide wear plates, ball loading cylinders, classifier cones, and Coal Mill PDF Mill (Grinding) IndustriesAnalysis of Coal Mill Operation Free download as PDF File (pdf), Text File (txt) or read online for free This document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties Analysis of Coal Mill Operation PDF Mill (Grinding) Scribd

.jpg)

Air Swept Coal Mill / Coal Grinding Ball Mill Supplier China

This type coal ball mill is widely used in black, nonferrous metal mining, building materials, chemicals, electricity, coal, transportation, light industry and other industrial sectors Our highefficiency and savingenergy ball mill adopts rolling bearing substituting for sliding bearing, which can save energy 1020% compared with sliding bearingFinally, the temperature equation is based on heat balance equation of the coal millThe significant heat contribution comes from the primary air flow , moisture of the incoming coal particles, coal flow into the mill (1) and from grinding the moisture coal particles and temperature depends on the The mass of pulverised coal on the table grinding rate and the amount of coal (PDF) Modeling and Control of Coal Mill AcademiaQuality Ball Mill Grinder from Chinahttps://zkkiln/chinahighefficiencyballmillgrinderwindsweptcoalballmilleasymaintenancehtmlHigh Efficiency Ball Mill Grinder , Wind Swept Coal Ball Mill Easy 2015年11月30日 Ball Mill Download as a PDF coal, cement, fertilizers and other materials Read less Read more 1 of 16 Download now More Related Content Ball Mill 2 PRESENTATION: PREPARED BY: RAFI ULLAH M13CE54 3 BALL MILL 4 stainless steel or rubber The inner surface of the hollow cylinder is lined with a resistant material Ball Mill PPT SlideShare

-2.jpg)

Modular HO Steel Mill Coal Mine layout Model Train Forum

2016年1月25日 This layout is based on the steel mill and coal mine operations of the Union Railroad in Pittsburgh Pennsylvania The layout is 140" by 80" or about 115 ft by 65 feet Or if you prefer metric about 35 meters by 2 meters This next drawing shows the Optimization and transformation of 300MV units steel ball coal mill Pulverizing System To cite this article: Wenlan Wang et al 2019 IOP Conf Ser: Mater SciOptimization and transformation of 300MV units steel ball coal mill 2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the Ball mill PPT Free Download SlideShareCoal Mill; Preheat Calcination can provide grinding media of various specifications according to your requirements or customize them according to your drawings Need High their diameters can range from 20mm to 150mm Ball Mill Grinding Media Steel Balls for Ball Mills

.jpg)

Ball Tube Mill PDF Manufactured Goods Equipment

The document provides details about a Ball Tube Mill model BBD 4772, including its components, construction, operation, and specifications Some key points: 1) The BBD 4772 is a low speed tube ball mill that operates at 15 rpm It has a 47 meter diameter shell and is 72 meters long 2) It is designed to pulverize coal for boiler combustion Each mill has a capacity of 90 tons per 1 Air swept ball mill is an efficient tool for grinding many materials into fine powder 2The Air swept ball mill is used to grind many kinds of mine and other materials, or to select the mine 3Air swept ball mill is widely used in building material, and chemical industry 4 There are two ways of grinding: The dry way and the wet way 5Air Swept Ball Mill2017年5月25日 In an airswept mill, the body of which does not differ significantly in general design from a trunnion overflow mill, a powerful stream of air is passed through the mill and removes the finer particles produced by the grinding processAir Swept Mill 911Metallurgist2017年2月13日 As for Rod Mills, the image above best expresses what is going on inside As rocks is feed into the mill, they are crushed (pinched) by the weight of its 35” x 16’ rods at one end while the smaller particles migrate towards the discharge end and get slightly abraded (as in a Ball Mill) on the way there How much steel enters a ball millBall Mills 911Metallurgist

.jpg)

AirSwept Coal MillFTM Machinery

The special steel ball coal mill for power plants is a new type of equipment, which is widely used in thermal power plant equipment Working Principle The raw coal enters the feeding device of the mill from the feeder equipment, and the hot air having a temperature of about 300 °C also enters the feeding device through the air inlet pipe1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS2023年4月23日 of cement clinkers was higher with cylpebs grinding media than with steel balls in a ball mill 492 mm and a mixture of the grinding media on a coal It was found that the mill power draw (PDF) Grinding Media in Ball MillsA Review ResearchGateIn bowl mill pulveriser raw coal coming from feeder gets ground between the grinding rolls and bull ring segments installed on the revolving Bowl The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on Pulveriser in Thermal Power Plant Bowl Mill Ball

Swept Coal Mill,Coal Mill

Ball Mill Rod Mill Autogenous Mill SemiAutogenous Mill Lining Plate, Support Dish Electric Control Large Gear Pinion And Pinion Shaft DoubleGeared Roller Crusher Mining Hoist SingleRope Winding Mining Hoist Electric Control Engineering Plastic Reducer Hydraulic Station Brake Depth Indicator Head Sheave,Guide Pulley MultiRope Friction Mining Hoist Sinking Hoist1984年7月1日 Circuit capacity versus air flow rate for Belie Ayre coal ground in the pilotscale mill Appendix A2 gives a method of scaling the internal classification to larger mills At the moment, however, it is not possible to scaleup the total model to larger mills because the variation of 77 with mill diameter is not known CONCLUSIONS If it is assumed that the A simulation model for an airswept ball mill grinding coalThe pulverized coal mill mathematical model for EType vertical spindle mills has been analysed and refined which was developed through a previous research project A multisegment mathematical model for TubeBall mill is developed and the unknown parameters were identified using onsite measurement data fromDevelopment of a tube ball mill mathematical model for mill What is the difference between a ball mill and a coal pulverizer? A ball mill is a machine that grinds materials up to a consistent size using steel balls as the grinding medium A coal pulverizer is a machine that pulverizes coal to a fine powder for combustion in power generation, cement production, and other industries How does the ball How Is Coal Pulverized in a Ball Mill?

ATOX COAL MILL

The ATOX mill will grind and dry coal containing more than 20% moisture in one operation The possibility of customersupplied parts, along with the low civil costs that accompany compact mill installation, add to the excellent economy of the ATOX coal mill Working principles The raw coal enters the mill via a rotary sluice and feed chuteBoilers Pulverized coal boilers fire finely powdered coal,typically with an average particle size of about 25 µm (0001 in)Coal burns in suspension,like the combustion in an oil or gas fired boilerCoal is pulverized in some type of large mill Pulverized coal is fired out into the furnace volume using burners that lESSENTIAL TECHNICAL DATA ON STEEL kolkata technical manuals of coal mill design2015年4月1日 There are three basic structures among the coal grinding, t: AirSwept or Wet Tumbling Ball Mill, RollerRace or BallRace Mill and Hammer or Impact Mill [7–10] The type of the mill and its efficiency depend on the type of coal, its moisture, input and output fraction of the material and the grinding susceptibility of the coalOptimization of a fully airswept dry grinding cement raw meal ball Swept Coal Ball Mill and Grinding Machines for Cement Plant, Find Details and Price about Coal Ball Mill Ball Mill from Swept Coal Ball Mill and Grinding Machines for Cement Plant LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES 3 HUGE MACHINE SHOP CAPABILITIES 4 TRAINING PROGRAMMES 5 PREVENTATIVE MAINTENANCE Swept Coal Ball Mill and Grinding Machines for Cement Plant

Coal Grinding Cement Plant Optimization

Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(>25mm) Conveying to Hoppers: To economize grinding media consumption, presently grinding media used are high chrome steel balls Mill shell is