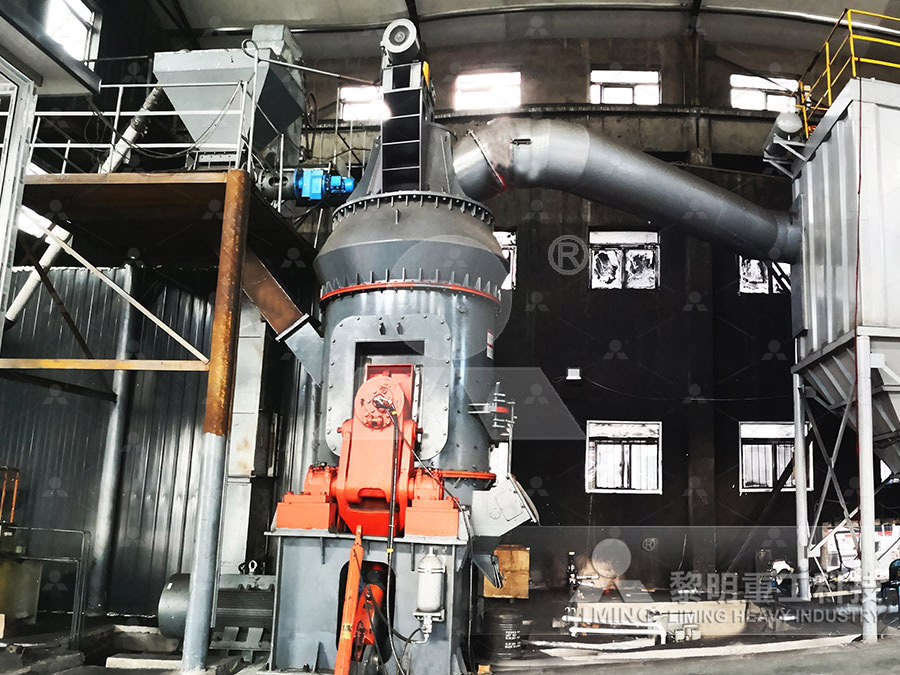

Coalbased kaolin calcining equipment

Preparation of Calcined Kaolin by Efficient

2022年8月29日 The reaction process, mechanism, and kinetics of the decarbonation of coalseries kaolinite (CSK) were investigated using the thermal analysis (TG)–infrared spectrum analysis (IR) coupling method A pilot test 2024年4月5日 In this study, coal series kaolinite (coal gangue with a kaolinite content of more than 80%) from Inner Mongolia was calcined by Fe 3 O 4assisted microwave calcination craft Cementitious properties of coalbased metakaolin prepared from 2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be Research and Design of Suspension Calcining Technology and 2023年6月1日 The kaolin sample was ground to achieve a particle size distribution on a microscale (≤90 µm) Then, the kaolin sample was calcined in an electric furnace at various firing Optimization of kaolin into Metakaolin: Calcination Conditions, mix

.jpg)

The properties and hydration of a calcined coal series metakaolin

2024年4月29日 To enhance the application of coal series kaolinite clay in the cement industry, the properties and hydration of ternary system based on calcined coal series metakaolin 2022年10月11日 We established a systematic method and production process for the use of coal series kaolin for the preparation of highquality calcined kaolin based on a new kinetic Preparation of Calcined Kaolin by Efficient Decarburization of Coal To improve the whiteness of coalseries kaolin products, calcination associated with chlorination and some chemical whitening agents has been proposed (González Ruiz, 2006; Chen et al, Sintering inhibition and oilabsorption properties of calcined coal Since the 1980s, found that a large number of coalbased kaolin (allegedly prospective reserves of over 10 billion tons), and due to the high quality of kaolin, and rarely harmful impurities, Technology for producing calcined kaolin from coalseries kaolinite

.jpg)

Preparation of Calcined Kaolin by Efficient

2022年10月11日 The reaction process, mechanism, and kinetics of the decarbonation of coalseries kaolinite (CSK) were investigated using the thermal analysis (TG)–infrared spectrum analysis (IR) couplingTable 1 Chemical composition of the coalseries kaolin sample (wt%) Sample SiO 2 Al 2O 3 TiO 2 Fe 2O 3 CaO MgO Na 2OK 2O Others LOI Coalseries kaolin 4376 3781 081 025 011 010 026 009 110 1571 LOI=loss on ignition Figure 1 XRD traces of (a) coalseries kaolin and (b) AlF 3⋅3H 2O and (c) cumulative particlesize distribution of Sintering inhibition and oilabsorption properties of calcined coal 2024年4月5日 The coal gangue with a kaolinite content of more than 80% is called coal series kaolinite (CSK) (Gao et al, 2010)CSK resources in China are abundant, with a prospective reserve of more than 20 billion tons, but highquality ores are in short supply (Shen and Ma, 2016; Shen et al, 2009)Highquality CSK is usually used to prepare calcined kaolin at high Cementitious properties of coalbased metakaolin prepared from coal 2022年3月16日 This paper analyzed the activity of coalbased metakaolin and noncoalbased metakaolin (ordinary metakaolin) commonly used in the Chinese market The content of kaolin was detected by XPF The phases of kaolin, Study on the Activity of Metakaolin Produced by

Assessment of pozzolanic activity of calcined coalseries kaolin

2017年7月1日 Coalseries kaolin (from the Yichang region of China) was tested as a potential pozzolanic material to be used in the cement and concrete industryPreparation of Calcined Kaolin by Efficient Decarburization of CoalSeries Kaolinite in a Suspended Bed Reactor Processes 2022, 10, 2048 kinetics based on gas products was proposedCoalSeries Kaolinite in a Suspended Bed Reactor ResearchGate2022年10月11日 The calcined kaolin product with a whiteness of 893% and an oilabsorbed value of 761 g/100 g was obtained via suspension calcination process, which meets the requirements of calcined kaolin for Preparation of Calcined Kaolin by Efficient Decarburization of Coal 2021年6月21日 Request PDF Pozzolanic activity of mechanochemically and thermally activated coalseries kaolin in cementbased materials The shortage of good quality supplementary cementitious materials Pozzolanic activity of mechanochemically and thermally activated coal

Analysis of Five Factors Affecting Calcination of Kaolin

2019年11月16日 Coalbased calcined kaolin has a loss of amount of hydroxyl and carbon, Calcining equipment Calcination equipment is also critical to the production of kaolinDOI: 101007/978981152806421 Corpus ID: ; Research and Design of Suspension Calcining Technology and Equipment for Kaolin @inproceedings{Shengliang2020ResearchAD, title={Research and Design of Suspension Calcining Technology and Equipment for Kaolin}, author={Tang Shengliang and Wu Jianjun Research and Design of Suspension Calcining Technology and Equipment 2021年9月13日 Pozzolanic activity of mechanochemically and thermally activated coalseries kaolin in cementbased materials Author links open overlay panel Shukai Cheng a b, Keyu Ge c, Tao Sun b, Zhonghe Shui b, Xuyong Chen a Structure and property analysis of Maoming kaolin at different calcining temperatures China Pulp Paper Industry, 31 Pozzolanic activity of mechanochemically and thermally activated coal Table 1 Chemical composition of the coalseries kaolin sample (wt%) Sample SiO 2 Al 2O 3 TiO 2 Fe 2O 3 CaO MgO Na 2OK 2O Others LOI Coalseries kaolin 4376 3781 081 025 011 010 026 009 110 1571 LOI=loss on ignition Figure 1 XRD traces of (a) coalseries kaolin and (b) AlF 3⋅3H 2O and (c) cumulative particlesize distribution of Sintering inhibition and oilabsorption properties of calcined coal

Effects of carbonaceous matter additives on kinetics, phase and

2018年12月1日 Recently, China's highquality kaolin clay has been facing depletion after a long history of consumption and largescale mining However, China has the world's richest coalseries kaolinite (CSK Gypsum calcining method and equipment thereof The present invention is low in order to overcome in the existing gypsum production technology productivity, the shortcoming that labor condition difference or facility investment are big, change traditional " Po Sui Fen Sui oven dry " technical process, provide a kind of method (its technical process is: " Po Sui Hong Gan Ypsum Calcining Equipment2021年1月20日 Metakaolinbased auxiliary cementitious materials fabricated by coal gangue were achieved The temperature and time required for the preparation of metakaolin materials from the calcination of coal gangue were optimized based on the analysis of the reaction characteristics and kinetics during the calcination of coal gangue The phase, microstructures, Reaction mechanism of metakaolin materials prepared by calcining coal 2021年1月20日 Results showed that after calcining with mineral powders, the crushing rate of coal gangue decreased from 168 % to 161–132 %, and water absorption decreased from 529 % to 274–390 % Reaction mechanism of metakaolin materials prepared by calcining coal

.jpg)

Calcining Vulcan® Drying Systems

Some examples of calcining applications include: The removal of water from alumina at temperatures ranging well above 2,000°F Removing water from alumina makes it possible to manufacture catalysts The removal of water from kaolin, from which calcined kaolin can be used in the production of paper and other similar processes2014年6月14日 Precursors for the preparation of onepart geopolymers were synthesized by calcining lowquality kaolin, which containing a lot of quartz, with NaOH or Na2CO3, then the cement pastes of ground precursor powders were synthesized by only adding water and cured at 80 °C for 3 days followed by curing at ambient environment for 25 days The geopolymeric Synthesis, characterization and mechanisms of onepart 2024年9月1日 Kaolin ore is more abundant than bentonite in China and has a lower impurity content, of which the reserve of coalassociated kaolin leads the world The participation of coalassociated kaolin in the coal pyrolysis process can promote the comprehensive utilization of resources and mitigate the environmental pollution and land waste caused by coalbased solid Catalytic upgrading of Hami coal pyrolysis volatiles over 2022年3月30日 Pozzolanic activity of mechanochemically and thermally activated coalseries kaolin in cementbased materials Construction and Building Materials, 299 (6), DOI 101016/j Li, H, Chen, Y, Xu, D (2005) Preparing kaolin from coal waste by suspension calcining process Fourth International Conference on Geopolymers JRM Free FullText Properties and Hydration Mechanism of

Catalytic upgrading of Hami coal pyrolysis volatiles over

2024年9月1日 Kaolin ore is more abundant than bentonite in China and has a lower impurity content, of which the reserve of coalassociated kaolin leads the world The participation of coalassociated kaolin in the coal pyrolysis process can promote the comprehensive utilization of resources and mitigate the environmental pollution and land waste caused by coalbased solid 2024年11月21日 Coalseries kaolin (also known as a claytype coal gangue) is a mineral resource associated with coal (Liu et al, 2024), and it is often discarded as useless gangue in coal mining and sorting industry, which results in resource waste and environmental pollution (Yuan et al, 2018)Therefore, the comprehensive and efficient utilization of coalseries kaolin An effective strategy for coalseries kaolin utilization: Preparation 2022年8月17日 synthesized by calcining the coal gangue at 750 ° C – 850 ° C for approximately 5s via suspension calcination The prepared cementitious material showed 28(PDF) Synthesis and characterization of lowcarbon Influence of calcined coalseries kaolin fineness on properties of cement paste and mortar Yuanyuan Liua,⇑, Shaomin Leia, Min Lina, Zhangjie Xiaa, Zhenyu Peia,BoLib a School of Resource and Environmental Engineering, Wuhan University of Technology, Wuhan , China bYichang Huilong Science and Technology Co, Ltd, Yichang , China highlightsInfluence of calcined coalseries kaolin fineness on properties of

Influence of calcined coalseries kaolin fineness on properties

2018年5月20日 Coalseries kaolin, a byproduct in the coal mining and dressing procedure with large reserves (about 38 billion tons in China), is rich in chemical constituents of SiO 2 and Al 2 O 3 and hence can be used as pozzolan into cement mortar and concrete after calcination [1] The partial replacement of calcined coalseries kaolin (CCK) into mortar and concrete will slowly With CO (Coal Based) 3Fe2O3 + CO →2Fe3O4 + CO Fe3O4 + CO → 3 FeO + CO2 FeO + CO → Fe + CO2 With Solid Carbon in reaction CO2 + C → 2CO 4Direct reduction processes There are several processes for direct reduction of iron ore: gasbased rotary kiln furnace processes coal based rotary kiln furnacesSponge Iron (DRI) Rotary KilnCalcining EquipmentHenan BALANCE OF PLANT FOR COAL/ LIGNITE BASED THERMAL POWER STATIONS ON EPC BASIS 1(i) The bidder should have executed contracts on engineering, procurement and construction (EPC) basis for at least one (1) no coal based/lignite based/power plant of installed capacity not less than 250 MW which has been commissioned during the lastREVISED GUIDELINES FOR QUALIFYING REQUIREMENTS FOR 2024年1月28日 Calcining Equipment and Technology The evolution of calcining technology has introduced advanced equipment that enhances efficiency and precision in the process 1 Rotary Kilns Rotary kilns are commonly used for calcining bulk materials These cylindrical vessels rotate slowly, ensuring a uniform distribution of heatHow Calcining Works Vulcan® Drying Systems

.jpg)

Sustainable and Clean Utilization of Coal Gangue: Activation and

2021年9月20日 In this study, we produced highefficiency coalgangue based silicon fertilizer by calcining a mixture of coal gangue, calcium carbonate (CaCO 3 ) and corn stalk powder at hightemperature (ie 2017年7月1日 Semantic Scholar extracted view of "Assessment of pozzolanic activity of calcined coalseries kaolin" by Pozzolanic activity of mechanochemically and thermally activated coalseries kaolin in cementbased Materials Science, Engineering 2021; 28 Save Reaction mechanism of metakaolin materials prepared by calcining coal gangueAssessment of pozzolanic activity of calcined coalseries kaolinFramework for monitoring and control of the production of calcined kaolinproduction of calcined kaolin ResearchGateIn this study, aluminium fluoride trihydrate (AlF 3 ⋅3H 2 O) was used to inhibit the sintering of calcined coalseries kaolin (CCSK) In addition, the oil absorption properties of CCSK were studied The particlesize distribution, specific surface area and porosity of the samples were investigated as a function of calcination temperature and the addition of AlF 3 ⋅3H 2 OSintering inhibition and oilabsorption properties of calcined coal

Assessment of pozzolanic activity of calcined coalseries kaolin

2017年7月1日 Calcined coalseries kaolin (CCK) was prepared by calcining 200 g RCK in a crucible at different temperatures in the range 500–900 °C with 2 h holding time using a muffle furnace The CCK was then cooled to room temperature at ambient conditions to avoid crystallization of amorphousactivated coal gangue increased with an increase in the replacement of activated coal gangue The total porosity and median pore diameter of the blended cement mortar containing higher kaolin contents of coal gangue was slightly lower than that with lower kaolin contents of coal gangue 34 Strength and porosity relationshipEffect of coal gangue with different kaolin contents on 2023年10月1日 Therefore, the effective decarbonization of seriescoal kaolin with different particle sizes was achieved via rotary triboelectric separation, in which the decarbonization efficiencies for 025–050 mm, 0125–025 mm, and 0074–0125 mm coalseries kaolin were 4186%, 4538%, and 4266%, respectivelyEffective decarbonization of coalseries kaolin by triboelectric DDFT is a professional leader China Calciner, Calcination equipment, Calcining furnace manufacturer with high quality and reasonable price Welcome to contact us +86Calciner, Calcination equipment, Calcining furnace, Calcination

Performance of microwaveactivated coal gangue powder as

2021年8月1日 The coalbased kaolin, This requires the use of fine crushing equipment such as ball mills to achieve the transition of were synthesized by calcining the coal gangue at 750°C–850°C In this study, aluminium fluoride trihydrate (AlF 3 ⋅3H 2 O) was used to inhibit the sintering of calcined coalseries kaolin (CCSK) In addition, the oil absorption properties of CCSK were studied The particlesize distribution, specific surface area and porosity of the samples were investigated as a function of calcination temperature and the addition of AlF 3 ⋅3H 2 OSintering inhibition and oilabsorption properties of calcined coal 2017年8月14日 A novel radarbased system for longwall coal mine machine localisation is described The system, based on a radarranging sensor and designed to localise mining equipment with respect to the mine Infrastructurebased localisation of automated coal mining equipmentCalcined kaolin has high whiteness, softness, easy dispersion and suspension in water, good plasticity, high cohesiveness, etc Therefore, calcined kaolin has become a popular choice in more than a dozen industries such as papermaking, ceramics, rubber, chemicals, coatings, medicine, and national defense—necessary mineral raw materialsKaolin Rotary Kiln Kaolin Calciner for Sale

Insitu Synthesis of NaY Zeolite with CoalBased Kaolin

2003年3月1日 NaY zeolites were insitu synthesized from coalbased kaolin via the hydrothermal method The eects of various factors on the structure of the samples were extensively investigated