Mineral powder grinding soft connection

Energy Use of Fine Grinding in Mineral Processing

Fine grinding is usually performed in highintensity stirred mills; several manufacturers of these stirred mills exist Two frequently used stirred mills include the Isamill, produced by Xstrata Technology, and the SMD, produced by Metso (Figure 1) A third mill, the Knelson–Deswik mill (now the FLS stirred mill), is a relative 展开Mechanicalimpact mills are ideal for easy to grind (“soft”) materials requiring “medium” fineness (see Table 1) Harder materials (typically defined as solids with a harness of the Mohs scale of ADVANCES IN POWDER PROCESSING TECHNOLOGIES FOR 2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a Fine grinding: How mill type affects particle shape characteristics 2023年6月8日 The difference in the properties of component minerals in ores leads to the interaction between component minerals during the grinding process This is the negative Study on Grinding Behavior Characteristics under LowSpeed

.jpg)

Mineral Powders: Activity and Specific Surface Area

2024年5月23日 To characterize the reactivity of powder materials obtained by the method of mechanical grinding, the thermodynamic criterion—the surface activity (k s) —is proposed, 2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the Ore Grinding SpringerLinkproduction technology of new materials based on mineral supplements Automation of technological processes of production of mineral powder, allows to obtain a building material AUTOMATION OF THE DRYING AND MILLING UNIT FOR THE 2024年3月11日 The main theoretical prerequisites for the thermodynamic analysis of the process of grinding rocks are given The structuralenergetic relationships between the Thermodynamic analysis of mineral powder grinding processes

.jpg)

Robotic Powder Grinding with a Soft Jig for Laboratory

We developed a soft jig consisting of offtheshelf gel materials and 3Dprinted parts, which can be used with any robot arm to perform powder grinding The jig's physical softness allows for 2023年11月22日 Bonded abrasives are materials used in grinding, polishing, and cutting operations They are usually composed of some form of aggregate material that is connected to a matrix or binder, which holds the abrasive Understanding Abrasive Materials: Types, Applications, Mill for grinding and drying soft to medium minerals The Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying minerals such as bentonite, clay, limestone, and others It combines grinding, de Grinding and drying of bentonite Makingrequirement Most types of readily available hammer mills for agricultural grinding are not suitable for grinding most types of minerals Hardness of minerals is expressed on Mohs scale a numerical index ranging from 1 for talc (the softest mineral) to 10 for diamond (the hardest known material) Table 2 below shows Mohs’ scale of hardnessMINERAL PROCESSING MILLING United Diversity

Mineral Powders: Activity and Specific Surface Area

2024年5月23日 Abstract A thermodynamic criterion—surface activity—has been proposed to characterize the reactivity of powder materials obtained by the method of mechanical grinding The work shows that, between the surface activity calculated taking into account values of the specific surface area of powder materials determined by the method of gas sorption and this 2017年10月3日 Stage 3 – Grinding Following the first controlled size reduction stage of crushing, we want to further reduce our ore to obtain a mineral powder There could be various reasons for reducing the size – we might want to free the individual minerals trapped in ores or simply expose the mineral to a leach solution Grinding can be either Dry Grinding Mill Types, Working Principle ApplicationsJXSC grinding classification equipment is the key equipment for crushing materials after they are crushed The ball mill can process various grinding minerals, nonferrous metal beneficiation, and new building materials It is often combined with a spiral classifier to form a closedcircuit ring mill, which has higher fine powder and grinding powerGrinding Classification Equipment JXSC Machinery2021年7月6日 dimension, and ends with grinding the reduced materials into powder Be it minetomill reduction or crushing and grinding of ore particles, comminution improves the surface area ofComminution a Heart of Mineral Processing ResearchGate

.jpg)

Trusted Industrial mineral powders manufacturer in India

HighQuality Industrial Mineral Powder Manufacturer in India Access topquality industrial mineral powders manufactured in India Quality products that meet your industrial needs and standards Connect with Us G297, MIA Alwar, Rajasthan () (+91) The material to be ground is subjected to compressive stress between the grinding table and the grinding rollers, and is comminuted in the process They are suitable for brittle/elastic grinding materials; the fineness level of the end product is between 20 µm and 100 µm Popular applications include soft to mediumhard mineral raw materialsGrinding Hosokawa AlpineFree of: Cruelty Free, Vegan, Paraben Free, Gluten Free, Talc Free, Synthetic Fragrance Free, PEG Free, Tree Nut Free, SLS Free What it is: A weightless and talcfree translucent loose setting powder with mineral SPF 25 that sets makeup and extends wear—all while blurring the look of pores and fine lines for a soft matte finish Made with only 7 ingredientsbareMinerals Mineral Veil Setting Powder with SPF 年4月2日 Powder Grinding Crystal Hollows not only included a new type of powder, it also introduced a new powder grinding strategy This guide includes everything you need to know about grinding powder, and it prioritizes powder The Ultimate Guide to Powder Grinding Hypixel

.jpg)

Energy Use of Fine Grinding in Mineral Processing

2013年3月1日 Request PDF Energy Use of Fine Grinding in Mineral Processing Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizesSemantic Scholar extracted view of "Mineral Crushing and Grinding Circuits: Their Simulation, Optimisation, the effects of powder filling were investigated on natural amorphous silica at batch grinding conditions based on a kinetic model Mineral Crushing and Grinding Circuits: Their Simulation, 2024年1月17日 For nonmetallic mineral grinding, the choice of processing equipment is very important Different types of grinding equipment are suitable for minerals of different attributes, and have specific correspondences to hardness, raw material size, humidity, output, etc, and understanding the working principle, performance characteristics and scope of application of 11 types of grinding equipment commonly used in the nonMineral powder grinding machinery is a type of equipment used to grind various minerals into fine powder Skip to content : [ protected] Tel: +86 ; HOME used in metallurgy; Phosphates, nitrates and potash are essential in fertilizer manufacturing; various other industrial minerals are used in ceramics, grinding, Mineral ultrafine grinding equipment EPIC powder

R)8OC`6F[ZIB.jpg)

6 different milling technologies for powders Palamatic Process

Particle size reduction can be achieved through different types of fragmentation: Cutting: reduction of very large blocks of material from quarries or mines into pieces with dimensions greater than 100 mm; Crushing: reduction to sizes ranging from 25 to 100 mm; Granulation: reduction to sizes from 63 to 25 mm; Grinding: reduction to sizes between 04 and 63 mm2024年3月11日 The main theoretical prerequisites for the thermodynamic analysis of the process of grinding rocks are given The structuralenergetic relationships between the regularities of plastic deformation with energy characteristics that occur during the crushing of mineral substances are describedThermodynamic analysis of mineral powder grinding processes2024年1月16日 Mineral change and micropore development are important deterioration features of soft rock during water–rock interaction, but ignoring the differences and contributions of potential physical and chemical processes in existing laboratory studies This paper carried out multiple micromeasurements on mudstone and sandstone after powder immersion and Clay minerals separation in soft rock driven by the liquidCONTINUE TO MineralSoft Login Now Discover MineralSoft CONTINUE TO Enverus Visit Website Discover our full suite of mineral solutions CONTINUE TO Our Solutions Visit Website Skip to content Solutions Close Solutions Open Enverus puts the oilfield on display, connecting mineral investors, managers and owners with insights they need to Mineralsoft Enverus

.jpg)

Ultrafine Mineral Powder SpringerLink

2024年1月1日 The particle size of ultrafine mineral powder is generally expressed by the cumulative percentage content d y = X microns, which is less than a certain particle size (where d represents the particle size and y represents the percentage content of materials with particle size less than X microns in ultrafine powder material; d 97 = 10 μm means that materials with When I was told I’d been selected to try Elizabeth Arden’s new foundation, Pure Finish Mineral Powder Foundation SPF 20 (833 g/S$58), I was hesitant at first because not only do I seldom use minerals, I’m also not really a foundation Elizabeth Arden Pure Finish Mineral Powder 2021年10月26日 HGM superfine powder grinding mill The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency The production capacity is 40% higher than that of jet mills and stirring mills, and Graphite Grinding Machine Powder Mill Equipment2015年11月1日 Request PDF Hardwareintheloop simulation platform for supervisory control of mineral grinding process Supervisory control technology is widely used to improve product quality in mineral Hardwareintheloop simulation platform for supervisory control

.jpg)

Practical Action/Mineral processing Appropedia, the

Most types of readily available hammer mills for agricultural grinding are not suitable for grinding most types of minerals Hardness of minerals is expressed on Mohs scale a numerical index ranging from 1 for talc (the softest mineral) to 10 for diamond (the hardest known material) Table 2 below shows Mohs’ scale of hardness2022年10月23日 Grinding materials into a fine powder is a timeconsuming task in material science that is generally performed by hand, as current automated grinding machines might not be suitable for preparing smallsized samples This study presents a robotic powder grinding system for laboratory automation in material science applications that observe the powder's Robotic Powder Grinding with a Soft Jig for Laboratory 2024年8月8日 In this process, a powder mixture is placed in a rotating drum, along with grinding media such as balls The kinetic energy imparted by the balls' motion breaks the powder into smaller pieces, making it a critical technique in various industries In mining, it's used for ore processing, enabling the extraction of valuable mineralsBall Mill Success: A StepbyStep Guide to Choosing the Right Grinding 2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the Grinding SpringerLink

Phosphate Mineral Powder Grinding Mill SBM Ultrafine Powder

2021年11月3日 Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, highpressure mills, etc can grind ores into a fine powder +17 [ protected]2015年4月9日 Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grinding Milling, sometimes also known as fine grinding, pulverizing or comminution, is the process of reducing materials to a powder of fine or very fine sizeGrinding Mills and Their Types IspatGuruRegardless of whether soft, mediumhard or hard minerals – suitable wet or dry processing technologies are available for every desired particle size and capacity Besides lowcontamination and lowwear processes, the manufacture of individual particle structures is also an important factor in the processing of mineral and metal bulk materialsMinerals Metals Hosokawa Alpine2020年4月2日 I would also like to mention that powder grinding is 100% required if you want to make money gemstone mining It gives an extremely large amount of fortune and speed that you can't get anywhere else, and the longer The Fastest Way to Grind Gemstone/Mithril Powder

MINERAL PROCESSING MILLING Internet Archive

requirement Most types of readily available hammer mills for agricultural grinding are not suitable for grinding most types of minerals Hardness of minerals is expressed on Mohs scale a numerical index ranging from 1 for talc (the softest mineral) to 10 for diamond (the hardest known material) Table 2 below shows Mohs’ scale of hardnessOur iconic Original Loose Powder Foundation offers clean hypoallergenic SPF makeup solutions Powdered foundation with SPF for flawless coveragebareMinerals Original Loose Powder Foundation with Request PDF On Oct 23, 2022, Yusaku Nakajima and others published Robotic Powder Grinding with a Soft Jig for Laboratory Automation in Material Science Find, read and cite all the research you Robotic Powder Grinding with a Soft Jig for Laboratory 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral Processing

.jpg)

HGM Superfine Powder Grinding Mill FTM Mining Machine

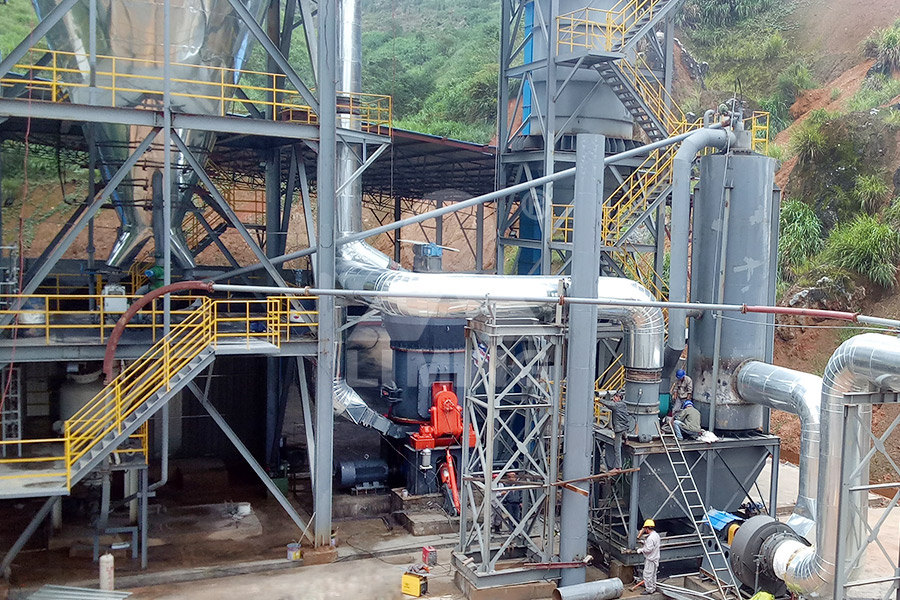

Environmental protection, clean; With soft connection, rubber pads and other measures can avoid the influence of shock, vibration of the grinding cavity analysis machine and improve the accuracy of analysis effectively At the same time, reduce noise, improve the working environment Customer Case: Belgian calcite grinding production line2021年8月13日 Talc ultra fine powder grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into fine powder +17 [ protected] Talc is a common silicate mineral, it is very soft and has a creamy feel Its Mohs hardness is 1, which is a known softer mineralTalc Ultra Fine Powder Grinding Mill2016年1月1日 As a crucial component of the beneficiation process, mineral grinding process (MGP) is used to grind the runofmine ore into suitable particle size such that the valuable mineral constituent can be exposed to be recovered in the subsequent classification process [1], [2]In the past, the process control research of the MGP was focused on the basic loop control Hardwareintheloop simulation platform for supervisory control 2014年5月15日 Soft, clayey Free feed 84120 in Normally coarse Product is discharged after a suitable dwelling time Meanwhile new feed is charged Continuous grinding is preferred in Mineral Dressing Electrostatic effects on the particles is reduced / removed by using conducting rubber in the flexible connections 175 176 4 Mineral Processing PPT SlideShare

Powder Grinding Mills Engineered by FTM Fote Machinery

Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, marble powder, barite powder, mica powder, and bentonite