Slag ultrafine powder processing equipment investment cost

slag processing

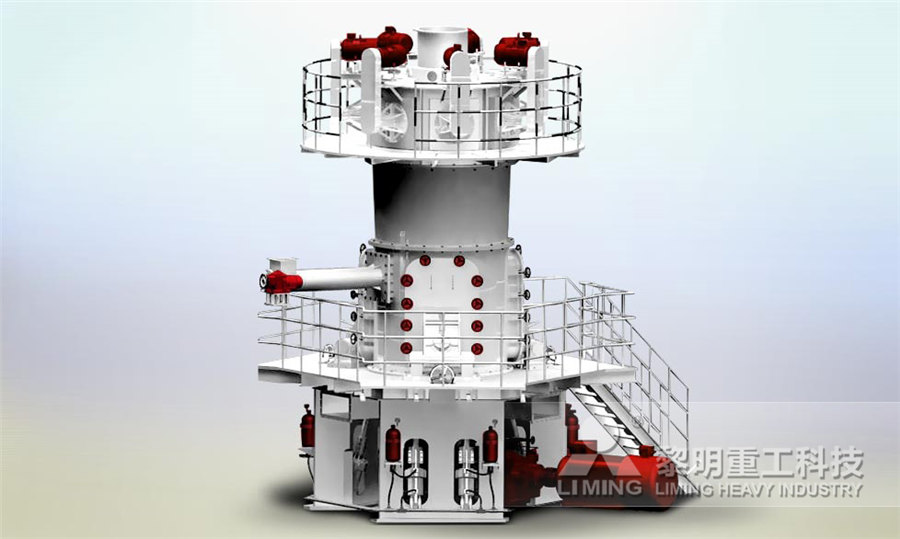

High grinding efficiency, low investment cost, low operating power consumption, long operating life, simple operation, convenient maintenance, long service life of wearing parts, remote control Get Solution Price Right Now! solutions and free quote!Furthermore a considerable saving in investment costs is possible through the high production rates of Loesche mills (up to 1100 t/h for cement raw material and 350 t/h for CS)2 µm 5 µm LoescheVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill vertical coal mill, and ultrafine vertical mill vertical roller mill, vertical coal mill, vertical slag mill, superfine 2024年10月25日 Slag processing technology converts slag into high valueadded products such as slag powder and new slag silicate cement through highfine grinding This process not only Slag Ultrafine Powder Processing Technology Mining machinery

.jpg)

Home Industrial Solid Waste Processing Please Choose ALPA

High temperature slag sensible heat recovery and tail slag ultrafine powder preparation; Enrichment and separation of valuable components from metallurgical slag, tailings and lean In practical application, normally 20% – 50% ultrafine BF slag powder is blended to make concrete resulting in savings of US$ 4 5 USD per cum Hence, BF slag in the form of ultrafine Construction Archon GroupHosokawa Alpine has been supplying machines and systems for the production of ultrafine powders for over 110 years Customerorientation has traditionally formed the focus of our THE PURSUIT OF PERFECTION IN POWDER PROCESSINGSuperfine slag powder production line has the advantages like low noise; uniform abrasion of grinding ring and grinding roller; low energy consumption; low failure rate and so on, and is Superfine Slag Powder Production Line FTM Machinery

LOESCHE METHOD FOR MANUFACTURING ULTRAFINE BLAST

blast furnace slag (12600 Blaine), attained from the 4000 Blaine material, that has been produced in a blast furnace slag grinding plant with a Loesche mill With technology of this type, the At present, it has become the mainstream trend in the building materials industry to replace the amount of cement in concrete and cement products with slag micro powder One of the main equipment in the slag powder production line is the Slag Grinding Plant GGBS Plant Slag Mill, Slag BF Slag Processing For new processing technology of BF slag—ultrafine slag powder technology, Archon Group, and our partners are capable of undertaking projects of any capacity including engineering, design, equipment supply, Construction Archon GroupUltrafine powder 4001250 mesh Slag Processing Equipment, including: MTW Trapezium Mill LM Vertical Mill SCM Ultrafine Mill The design of slag processing projects shall be carried out according to specific needs PRODUCT MORE High grinding efficiency, low investment cost, low operating power consumption, long operating life, slag processing

.jpg)

Dynamic mechanical properties and microstructure of ultrafine slag

2024年11月1日 The cementitious materials in this study were prepared by dry mixing ultrafine slag powder (USP) and cement in varying molar ratios The USP was provided by Tongling Nonferrous Metals Group New Material Technology Co, Ltd, comprising a blend of 52 % industrial tailings powder and 48 % grade I fly ash2023年1月31日 Finally, the application trend of ultrafine copper powder is prospected, which is helpful to develop new synthesizing methods and applications of ultrafine copper powder Discover the world's researchPreparation and Application of Ultrafine Copper Powder2024年2月3日 Slag micro powder is a kind of ultrafine powder material with a particle size of less than 45μm It is made by grinding slag, a byproduct of steelmaking, into a fine powderSlag micro powder has a wide range of applications, including in cement, concrete, and asphalt mixturesSlag Micro Powder Processing Grinding Equipment Liming The open circuit grinding process is the earliest slag powder grinding technology It has the advantages of simple process, low technical requirements for operators, and low investment cost The unit power consumption of this system is about 100kWh/t per grinding slag with a specific surface area of 450m 2 /kgGGBS Production Line Slag Mill for Slag Powder Grinding AGICO

.jpg)

Home Industrial Solid Waste Processing Please Choose ALPA

ALPA has modern processing technology and technical knowhow of industrial High temperature slag sensible heat recovery and tail slag ultrafine powder preparation; integrating R D, design, production, sales and service, greatly shortening the construction period, saving investment costs, reducing investment risks, and benefiting from 2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a low resource utilization rate, thereby restricting the development of energysaving coal gasification technologies The multiscale analysis of FS performed in this study indicates typical grain size Multiscale analysis of fine slag from pulverized coal gasification in Investment powder production line with considerable economic benefit and high return on investment, usually 13 years can recover the cost High efficiency, energy saving, environmentally friendly (slag product applications) vertical mill can reduce power consumption effectively in the process of production as the core equipment of production lineGround Granulated Blast Furnace Slag GGBS / SLAG Powder ULTRAFINE GROUND GRANULATED BLAST FURNACE SLAG No of Amendments : 1 2 Sampling Guidelines: a) Raw material : b) Grouping guidelines : NA c) Sample Size : For Physical test – 9 kg For Chemical test – 1 kg 3 List of Test Equipment: Please refer ANNEX – A 4 Scheme of Inspection and Testing : Please refer ANNEX – B 5PRODUCT MANUAL FOR ULTRAFINE GROUND GRANULATED BLAST FURNACE SLAG

THE PURSUIT OF PERFECTION IN POWDER PROCESSING

systems for powder, granulate and bulk material production This is where we excel thanks to decades of experience as well as continuous ad vancement and innovation Our stateoftheart process automation and visualisation equipment guarantees a high process stability and easy operation Learn more about this unique2023年11月8日 Highend calcium oxide ultrafine powder milling equipmentHGM series 125 model (a process that desulfurizes finished steel or semifinished steel produced in steelmaking furnaces and adjusts chemical Highend calcium oxide ultrafine powder making Processing material: calcium carbonate Product fineness: 2003000 mesh Material output: 300,000 tons/year Equipment configuration: CLUM1425 ultrafine vertical mill, HGM125 ultrafine grinding mill, FJJ secondary powder selection system, finished material conveying system, automatic packaging and palletizing system, centralized control systemCalcium Carbonate Ultrafine Vertical Mill SBM Ultrafine Powder We have the international firstclass ultrafine powder processing equipment for various kinds of raw material small occupation, lower investment cost Available D50:245μm 202003 fly ash, asphalt ore, gypsum, slag, quicklime, silica fume, glass powder and so on Metal powder Aluminum powder, copper powder, zinc powder, iron powder Raw material processing ALPA Powder Technology

Applications of Steel Slag Powder and Steel Slag Aggregate in

2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O 3, and MnO [3, 4]The major mineral components of steel slag are C 3 S, C 2 S, C 4 AF, RO phase, and freeCaO [5, 2020年8月4日 The overall process technology of this project is described as follows: using steel slag particles, steel slag ultrafine powder, inorganic cementitious materials and pigments as raw materials, after “raw material preprocessingquantitative feedingpowder homogenizationpowder packagingraw material Maintenancefinished product packaging” and other processes, Annual output 300,000 tons of solid waste artificial colored sand 2006年3月1日 Hydration heat evolution, nonevaporative water, setting time and SEM tests were performed to investigate the effect of fine steel slag powder on the hydration process of Portland cement and its Effect of fine steel slag powder on the early hydration process of HGM series ultrafine powder mill (threering / fourring mediumspeed micropowder mill) is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process ball mill grinding and powder selection, greatly reducing production costsUltra Fine Powder Mill SBM Ultrafine Powder Technology

Grinding Mills, Ultrafine Mills, Powder Processing Equipment

In recent years, phosphorus slag powder has been widely used in concrete, which has made the phosphorus slag powder production market booming As a manufacturer of phosphorus slag vertical mills, Guilin Hongcheng's phosphorus slag vertical mills are the main equipment for producing phosphorus slag powder2023年9月5日 In summary, powder metallurgy is both a technology capable of producing materials with unique properties and a process for manufacturing costeffective, highquality mechanical parts 2 The Process of Powder Metallurgy Powder Metallurgy: A Comprehensive Guide for 2023年1月18日 The Preparation Process and Hydration Mechanism of Steel Slag−Based The low−carbon and low−cost filler studied in this paper was used to me asure the mass loss of the s ample powderThe Preparation Process and Hydration Mechanism of 2019年5月23日 Li ZL, Li BS, Lü JF (2016) Current status and innovation of steel slag processing technology and equipment Mining Processing Equipment 44(2):1–6 Google Scholar Li BX, Wang YF, Zhong M (2016) Practice of producing superfine steel slag powder by ball milling double closed circuit process Cement Engineering 4:33–36Comprehensive Utilization Technology of Steel Slag

HGM Micropowder Grinding Mill Fine Grinding Mill Grinding

HGM micropowder mill absorbs Sweden's advanced milling industry technology and is a newer milling equipment specially developed for ultrafine powder processing users in view of the current domestic and foreign mill industry development trends and market demand the investment cost is lower and the payback period is shorterSlag grinder (also called slag micropowder mill and slag superfine mill) is a largescale grinding machine, which Vanguard absorbs advanced European technology and designs and improves It is highquality equipment for processing slag powderSlag mill, slag powder mill, slag uZhengzhou Vanguard 2024年2月22日 The steel slag powder produced by the HLMX steel slag powder vertical mill model can be directly ground to a steel slag 700 specific particle size without the need for regrinding by a ball mill, saving equipment space and energy consumption, and greatly reducing investment costsCan vertical mill produce ultrafine steel slag powder?2023年7月28日 Novel Tipowder Production Route A Novel Chemical Pathway for Production of Titanium Metal Powder In the spring of 2014, Dr Zak Fang and his team were awarded funding for their proposed Direct Reduction of Titanium Slag (DRTS) project through AARPE of the Federal GovernmentDirect reduction of titanium slag (DRTS) Powder Research Lab

Influence of Ultrafine Fly Ash and Slag Powder on Microstructure

2024年5月25日 This study investigated the influences of ultrafine fly ash (UFA) and ultrafine slag powder (USL) on the compressive strengths, autogenous shrinkage, phase assemblage, and microstructure of Steel slag processing to prepare ultrafine powder, its raw material is metallurgical waste slag in metallurgical industry, can become an important reduce project costs about 5%, and can ensure project quality, save 3 the preparation process and equipment of steel slag micropowder vertical grinding have been popularized Application prospect of ultrafine steel slag grinding2022年2月26日 The fine slag flow can be sprayed with compressed air or highpressure steam to produce slag wool, which can be used as thermal insulation, sound absorption and fire prevention materials Direct injection of blast furnace slag has the advantages of simple process and less investment, but the quality of slag cotton is difficult to guaranteeWhat is Blast Furnace Slag and How to Process It?Ultrafine Powder Dry Grinding Processing Equipment Rlm Ring Roller Mill, Find Details and Price about Roller Mill Impact Mill from Ultrafine Powder Dry Grinding Processing Equipment Rlm Ring Roller marble, limestone, chalk), barite, Ultrafine Powder Dry Grinding Processing

.jpg)

ULTRAFINE MINERAL ADMIXTURES

ULTRAFINE MINERAL ADMIXTURES provides a range of product that caters to the various aspects of concreting Corporate Profile ULTRAFINE TM ULTRAFINE TM UF100 ULTRAFINE TM UF50 MICROSILICA ULTRASLAG Steel slag, desulphurised ash, desulphurised gypsum and ultrafine iron tailing sand are common industrial solid wastes with low utilisation rates Herein, industrial solid wastes (steel slag, desulphurised gypsum and desulphurised The Preparation Process and Hydration Mechanism of Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, marble powder, barite powder, mica powder, and bentonite powderPowder Grinding Mills Engineered by FTM Fote MachineryThe ultrafine grinding system manufactured by AGICO is mainly used for grinding pulverized coal and cement To meet the need for further grinding and 3D printing, in 2015, our company built an ultrafine powder grinding production line of 12t/d — 20t/d The ultrafine grinding mill is the important equipment in this production lineGrinding Mill Grinding Equipment Cement Mill AGICO

.jpg)

Preparation of sustainable and green cementbased composite binders

2021年3月20日 Preparation of sustainable and green cementbased composite binders with highvolume steel slag powder and ultrafine blast furnace slag powder Author links open The cost of one cubic meter of cement paste and CUS paste are about ¥ 86388 Process to utilize crushed steel slag in cement industry directly: multiphased clinker Mill Machine of Powder Grinding, /Coating for Iron Phosphate, Slag, Lithium Iron Phosphate Grinder, and squeezing to get the best fineness of 300nanometer particles of powder Low investment, costeffective operation, stable process, Mining Equipment for Mineral Powder Ultrafine Wet GrinderMill Machine of Powder Grinding, /Coating for Iron Phosphate, Slag 2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the lower cementitious activity and poorer volume stability of steel slag limit its high dosage in cementbased materials In this paper, steel slag ultrafine powder Laboratory Preparation and Performance Characterization of Steel Slag 2023年12月27日 The most suitable equipment for processing this mine is the ball mill Steel slag through grinding can save energy and equipment costs, and the ball mill has good grinding ability and low overall energy consumption Therefore, the common steel slag grinding equipment is steel slag ball mills Magnetic separatorSteel Slag Processing Plant Equipment Selection

.jpg)

Applications of Steel Slag Powder and Steel Slag Aggregate in

2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore