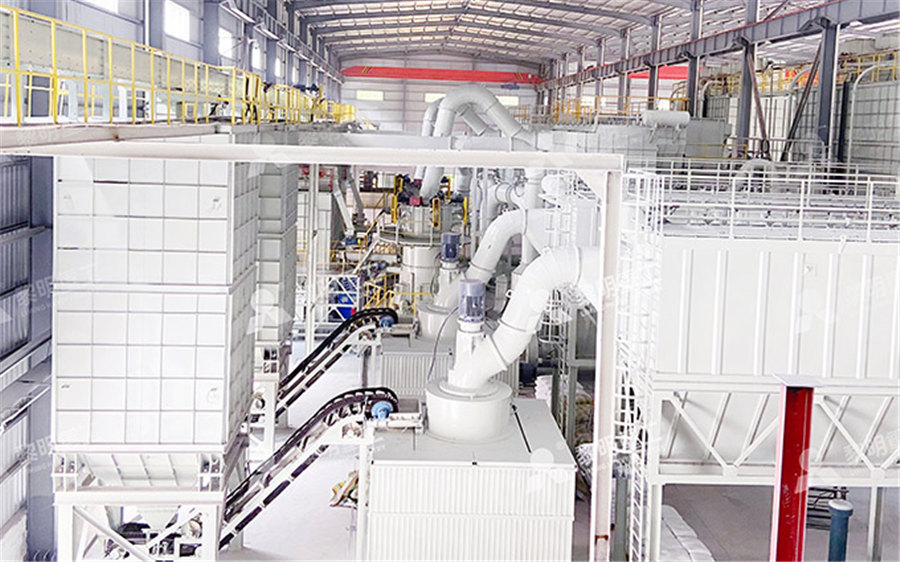

Silica fume barite mill

.jpg)

Radiation Shielding Concrete with alternate ScienceDirect

2021年2月15日 Mineral admixtures such as the silica fume and pulverized fly ash were incorporated into the barite RSC It was found that though mechanical parameters are 2014年12月1日 The effects of highenergy ball milling and subsequent calcination on the formation of barium aluminate cementing phases using mixtures of Al2O3 and BaCO3 were Effect of High‐Energy Ball Milling and Silica Fume Addition in 2013年12月19日 Silica fume was also added in the mixtures up to 10 wt % of mixture to study its role on phase kinetics Results showed that the (PDF) The Effect of Silica Fume Additions on Silica fume particles viewed in a transmission electron microscope Silica fume, also known as microsilica, (CAS number 6, EINECS number 2737611) is an amorphous (noncrystalline) polymorph of silicon dioxide, silicaIt is an ultrafine powder collected as a byproduct of the silicon and ferrosilicon alloy production and consists of spherical particles with an average Silica fume Wikipedia

Investigation of mechanical properties of concrete with

2024年2月28日 To approach the goals, several dosages of clinoptilolite (0–20%) with and without silica fume (0–10%) contributed to the design of 567 concrete mixes, at three waterto the process of grinding powder continued for two hours in a rotary ball mill to extend the surface area, producing particles with less than 2 µm in 2023, IRJET In the present world, concrete has become a vital part of our lives Barite is a soft crystalline mineral form of barium sulphate Barite powder mostly used in oil well drilling industry and paint industry Silica fume is a by product obtained from an electric arc furnace used in manufacture of silicon metalStudy of partial replacement of cement by barite powder and silica fume 2023年6月13日 Silica fume also be added to the concrete as admixture Silica fume increases compressive strength and abrasion resistance of concrete It reduces bleeding because the free water is consumed wetting of large surface area of silica fume Silica fume also blocks the pores in concrete and water holding capacity of concrete is increasedStudy of partial replacement of cement by barite powder and silica fume 14 Silica Fume Silica fume is a byproduct in the production of silicon and ferrosilicon alloys It is ultrafine material with spherical particles less than 1 micro meter in diameter, the average being about 015 micro meterwhich protects the reinforcing steel of concrete from corrosion, especially in COMPRESSIVE STRENGTH AND ANTI RADIATION SHIELDING OF

Radiation Shielding Concrete with alternate ScienceDirect

2021年2月15日 It was found that though mechanical parameters are strengthened more by silica fume compared to fly ash, attenuation coefficients are reduced more by silica fume Sakr (2006) argued that the incorporation of silica fume into the RSC made with ilmenite and barite enhances the mechanical parameters and does not affect the linear attenuation coefficientPDF On Jan 1, 2024, Maikon Moreira de Pires and others published Exploring Radiation Shielding Efficiency of EcoFriendly Portland Cement Pastes Made with Barium Sulfate, Silica Fume and Fly Ash Exploring Radiation Shielding Efficiency of EcoFriendly Portland 2012年7月1日 In the study, high consistency heavyweight concrete mixtures containing barite aggregate were produced by using some common mineral admixtures (viscosity modifier, silica fume and fly ash) at Shielding and strength tests of silica fume concrete2020年7月1日 Similar results were observed by Deb et al [24] and Mijarsh [27] In a study examining the effect of the NS/NH ratio (05, 15, 25) on the compressive strength of silica fume (SF) and BFSbased Investigation of the strength of ground granulated blast furnace

Evaluation of mechanical strength, gammaray shielding

2024年3月15日 To achieve this goal, several concrete mixes containing normal coarse aggregate (NC), barite aggregate (BC), and nanosilica/barite aggregates (NSBC) were fabricated Several properties such as workability, mechanical strength, electrical resistivity (ER), ultrasonic pulse velocity (UPV), chloride migration (RCPT), and gamma shielding were 2014年4月1日 This paper presents a review of silica fume utilization in concrete production and its effect on the concrete Silica fume ariation of compacting factor at different replacement level of Silica (PDF) Effect of Silica Fume in Concrete ResearchGate2020年12月8日 Thus, silica fume has a specific surface and an amorphous silica content, according to XRD, higher than that of quartz powder, which directly affects the chemical and physical reactivity of these Influence of quartz powder and silica fume on the performance 2019年11月4日 Silica fume concrete incorporated with 12 mass% nano Janković K, Stanković S, Bojović D, Stojanović M, Antić L The influence of nanosilica and barite aggregate on properties of ultra high Malaiškienė J, Banevičienė V, Boris R, Antonovič V The effect of dried papermill sludge on cement hydration Synergistic effect of nanosilica and silica fume on hydration

.jpg)

Effect of Silica Fume as a Waste Material for Sustainable MDPI

2021年4月13日 The use of silica fume (SF) In their research, they stated that adding 10% SF to the cement mill during the grinding stage decreases the grinding time by 20–25%, and thus, 20–25% electrical energy savings can be achievedP S Utama et al / Songklanakarin J Sci Technol 40 (1), 121126, 2018 123 confirm that the product is silica gel The SEM EDS (JEOL JSM5800LV) was used to identify the chemical compositionSilica gel derived from palm oil mill fly ash ResearchGateSilica fume concrete is composed of cement, silica fume, fine aggregate, coarse aggregate, and water Fresh and hardened properties of silica fume concrete is superior to conventional concrete For instance, it has higher compressive and flexural Silica Fume Concrete [PDF]: Properties, Advantages, and Applications2023年12月21日 Rice husk valorization to produce silica is believed to involve an ecofriendly process rather than silica production from conventional and fume routes Nevertheless, the quantitative point of view regarding this is still not widely disclosed In this study, a simple material and energy input–output analysis (ME I/O) is employed to compare the environmental impact Silica Production from Conventional, Fume, and Biomass

.jpg)

The influence of nanosilica and barite aggregate on properties of

2016年11月15日 While silica fume, which is a byproduct of the ferrosilicon industry, can be produced with a specific surface area (SSA) of 20 m 2 /g and 90% purity (Bolhassani and Samani 2015;Li et al 2017 2016年11月15日 Chemical composition was measured by X ray flourescence spectroscopy on pressed pellets in vacuum (see in Table 1)Specific density values were for cement 3100 kg/m 3, silica fume 2200 kg/m 3, quartz sand 2695 kg/m 3 and barite sand 3770 kg/m 3Specific surface area for cement is 3500 m 2 /g (Blaine method) and for nanosilica 26931 m 2 /g (BET method)The influence of nanosilica and barite aggregate on properties 2024年10月22日 微硅粉也叫硅灰或称凝聚硅灰,英文为Microsilica or Silica fume。是铁合金在冶炼硅铁和工业硅(金属硅)时,矿热电炉内产生出大量挥发性很强的SiO2和Si气体,气体排放后与空气迅速氧化冷凝沉淀而成。它是大工业冶炼中的副产物,整个过程需要用除尘环保设备进行回收,因为质量比较轻,还需要用 硅灰 搜狗百科Our major products includes magnesium hydroxide, magnesium oxide, ceramsite, foundry sand, barite, bentonite, cenosphere, silica fume, pac, cmc and so on Our Factory Our magnesium hydroxide plant has 4 production lines with the newest production equipment and more than 400 employees, which can guarantee our annual supply of about 60000 tonsAbout Us Zhengzhou Top Trading Co, Ltd

.jpg)

Effect of Silica Fume on Workability and Compressive Strength

Effect of Silica Fume on Workability and Compressive Strength of OPC Concrete Vikas Srivastava 1*, Rakesh Kumar2, V C Agarwal3 and P K Mehta4 1 2006 reported that at 15% silica fume content gravel concrete, barite concrete and ilmenite concrete showed increased compressive strength by 2333%, 2307% and 2352% respectively at 7 days, test, lbox test, and vfunnel test Silica fume with a grade of 8% gives the best results which meet all the requirements of each method The higher the level of silica fume the lower the concrete KAJIAN PENGARUH VARIASI KOMPOSISI SILICA FUME Silica fume, also known as Microsilica, (CAS number 6, EINECS number 2737611) is an amorphous (noncrystalline) polymorph of silicon dioxide, silica It is an ultrafine powder collected as a byproduct of the silicon and ferrosilicon alloy production and consists of spherical particles with an average particle diameter of 150 nmMicrosilica, Microsilica, Micro Silica from stock or special order Silica fume was used to produce 397 highstrength concrete girders Each girder was 536 m long, 11 m wide, and weighed 100 metric tons Second Edition ii The original edition of the Silica Fume User’s Manual was produced under CooperativeSilica Fume User's Manual

.jpg)

Mechanical properties of silica fume based concrete: A review

2024年5月11日 Humanity has been facing an everincreasing danger of climate change due to increased greenhouse gas emission The CO 2 gas is one of the most important greenhouse gases [1]The manufacturing of cement produces around 5–7 % of the total CO 2 emissions [2]The production of 1 ton of cement generates about 08–09 ton of CO 2 [3] Fumed silica serves as a universal thickening agent and an anticaking agent (freeflow agent) in powders Like silica gel, it serves as a desiccantIt is used in cosmetics for its lightdiffusing properties It is used as a light abrasive, in products like toothpasteOther uses include filler in silicone elastomer and viscosity adjustment in paints, coatings, printing inks, adhesives and Fumed silica Wikipedia2024年4月29日 This blog delves into “How is fumed silica made,” highlighting the intricate steps from silicon tetrachloride to the versatile, ultrafine powder used to improve products from cosmetics to coatings Discover the science behind its manufacture and its broad applications, underscoring fumed silica’s essential role in modern material scienceHow is fumed silica made Rawsource2024年1月2日 Utilizing silica fume as a substitute for cement in pervious concrete offers a viable approach to achieve sustainability within the realm of construction industry The mechanical characteristics of pervious concrete are influenced by several factors, such as quantity of silica fume utilized as a replacement for cement, the cement content, coarse aggregate, sand, Silica fume as a supplementary cementitious material in pervious

.jpg)

Fumed Silica ‐ Production, Properties, and Applications

2008年6月10日 Consequently, the surface of the virgin SiO 2 nanoparticles was highly reactive to water molecules Together with the high surface energy from oxide nature, the virgin fume silicas therefore are with the words “silica fume” every time that they appear in the text 732 All samples, whether grab or composite, shall have a mass of at least 1 kg (2 lb) 733 When compliance verification tests of silica fume are required to be made at a laboratory other than that of the silicafume manufacturer or marketer, coordinate the silica Silica Fume Used in Cementitious Mixtures133 Densitied Silica Fume — Silica fume that has been treated to increase the bulk density by particle agglomeration The bulk density typically being above 500 kg/m3 34 Silica Fume Slurry — A homogeneous, liquid suspension of silica fume particles in water, typically with a dry content of 50 percent by mass,IS 15388 (2003): Specification for Silica Fume Law2008年4月1日 According to a recent study, the SBE consists of fume silica within the range of 50% to 8305% (Dermawan Ashari, 2018), making it an excellent thickening agent (Barthel et al, 2005) with no Fumed Silica ‐ Production, Properties, and Applications

.jpg)

(PDF) MECHANISMS OF RADIUM ADSORPTION ON SILICA AND BARITE

2022年8月3日 The goal of this dissertation is to develop a multiscale model to study radium removal mechanisms onto silica and barite, and the effect of water quality parameters on radium removalMicronized is a South Africanbased mining and minerals processing group supplying feldspar, silica, mica, talc, kaolin and barytes to a range of industries Home; About Operations; Documents; Products Microbrite Data Sheets; We mine mill Feldspar, Silica and Mica to your specifications at our Limpopo operationsMicronized Industrial Minerals South Africa2023年1月15日 Several types of amorphous silica generate pozzolanic reactions at micro and nanoscale, which can improve concrete macrostructural characteristic However, their addition can raise the viscosity of the mixture, thus decreasing its workability In the present work is proposed an experimental setup to determine concrete compression and manageability Combined effect of nanosilica and silica fume to improve Washington Mills is a supplier of Silica Fume produced in the reduction process of fusing high purity zirconia from zircon sand Skip to main content Utility Navigation Main navigation Products Core Technologies Fused Minerals + Silicon Carbide + All Products Alumina Bubble Silica Fume Washington Mills

(PDF) Effect of Silica Fume on Strength Parameters of Concrete As

2017年5月1日 (Chouhan et al, 2017) investigate the effect of silica fume on strength parameters of concrete as a partial substitution of cement by replacing 0%, 5%, 750%, 1250%, 15%, 20%, 25% with silica Continental Star Impex Gen Trading Llc is a leading Exporter, Manufacturer, Supplier of Barite Powder , Bentonite Powder, Microsilica Silica Fume from Ajman, Ajman, United Arab EmiratesContinental Star Impex Gen Trading Llc in Ajman, Ajman, United 2020年10月22日 Synergistic effect of nanosilica and silica fume on hydration properties was studied in cementbased materials In the present study, various tests were used to characterize hydration properties Synergistic effect of nano‑silica and silica fume on hydration