bentonite highefficiency energysaving grinding mill

.jpg)

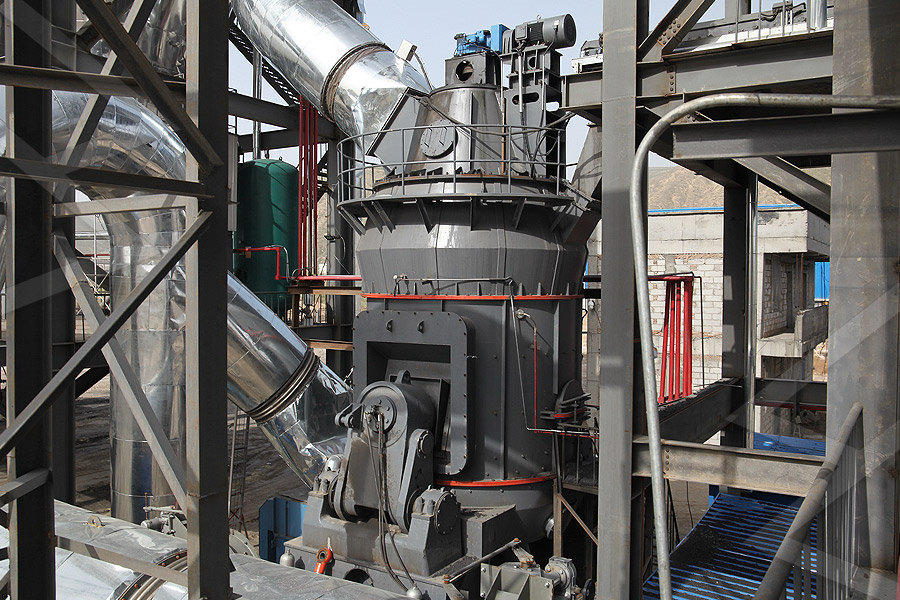

Bentonite Powder Processing Machine – HC Super Large Grinding

HC super large bentonite powder grinding mill is designed for largescale mineral powder production, Its technical parameter is at the domestic leading level and is particularly suitable 2021年12月30日 In this study, a pintype vertical stirred media mill was used to perform the dry grinding of bentonite Grinding time and stirring speed were investigated for effect on the particle sizeDry Grinding of Bentonite by Stirred Media Mill2021年9月1日 Bentonite ultrafine powder grinding mill is a kind of highefficiency, energysaving, and environmentally friendly industrial grinding equipment, which is widely usedBentonite Ultrafine Powder Grinding Mill2022年1月1日 The chemical composition, phase, mineral composition, and liberation characteristics of ground and magnetic separation products were investigated to evaluate the Highefficiency and energyconservation grinding technology

.jpg)

HIGmill high intensity grinding mill Metso

The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain HPGRs (high pressure grinding rolls) have been developed within the last decades for energy efficient processing of a wide variety of ores Special interest has been raised by projects Quantification of HPGR energy efficiency effects on downstream 2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power Roller Mill SpringerLinkMaterial transport plays a significant role on efficiency of horizontal grinding mills The magnitude of benefits that can be achieved with efficient material transport in AG/SAG mills has been BrazilAchievement of High Energy Efficiency in Grinding Mills at Santa Rita

.jpg)

Highefficiency and energyconservation grinding technology

2021年11月1日 Ceramic grinding, which in this paper is defined as a method of using ceramic materials as grinding media, is favored by many processing plants as an emerging high Hefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 HomeVertical Roller Mills Bentonite Grinding Mill With High Energy Efficiency2022年1月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 07, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%, Highefficiency and energyconservation grinding technology using 2021年9月23日 The barite industrial ultrafine grinding mill is a lowenergy, highefficiency nonmetallic ore milling equipment It can process ultrafine powder of 1503000 mesh It is often used for grinding more than 100 kinds of non Barite Industrial Ultrafine Grinding Mill SBM

What are the types of industrial grinding mills?

2021年7月7日 Industrial grinding mills generally include vertical roller mills, ultrafine grinding mills, highpressure suspension roller brittle materials with medium and low hardness, Mohs hardness ≤6, such as calcite, limestone, carbon black, kaolin, bentonite, etc For a variety High production efficiency, energy saving and 2022年1月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 07, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%, Highefficiency and energyconservation grinding technology using Hefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 HomeVertical Roller Mills Bentonite Grinding Mill With High Energy Efficiency2021年9月6日 Application: Suitable for grinding nonmetallic ores with Mohs hardness less than 6, such as gypsum, mica, marble, dolomite, limestone, bentonite, etc Features: The equipment occupies a small area, is easy to operate, and easy to maintain High grinding efficiency, energysaving, and environmental protectionMarble Ultrafine Powder Grinding Mill

FYEFEPS2HDZ49G5Z0[B.jpg)

Calcium Carbonate Ultrafine Grinding Mill

Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling stable operation, long service life, strong complete set, environmental protection and energy saving, safe and reliable, etc 86 and impact It has important application value in the processing of calcium carbonate, calcite, limestone, bentonite, 2021年12月30日 The depletion of highgrade ores has forced the utilization of lowgrade ores The small liberation sizes in the lowgrade ores require fine grinding which is an energy intensive operationDry Grinding of Bentonite by Stirred Media Mill ResearchGateThe MTW EuropeanType Grinding Mill boasts high grinding efficiency, thanks to its unique roller design and advanced classifier technology The mill can handle a wide range of materials, including calcite, dolomite, limestone, and bentonite, with a fineness of 80325 meshEnvironmental friendly energysaving MTW europeantype grinding millHigh pressure grinding mill, which greatly improves the milling efficiency 2 The grinding area is large, the grinding force of the grinding roller on the material is increased by 8001200 Kg under the action of the highpressure YGM High Pressure Grinding Mill

Types of Grinding Mills for Bentonite Processing Plant

Ultrafine Vertical Mill is a highperformance grinding mill that can produce bentonite powder with a fineness of 3252500 mesh It has the advantages of low energy consumption, high efficiency, and large capacity Ball Mill Ball Mill is a traditional grinding mill that can grind bentonite into powder with a wide range of particle sizes2021年11月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were Highefficiency and energyconservation grinding technology 2021年9月29日 Sepiolite superfine powder grinding mill is a highefficiency, energysaving, lowconsumption, and environmentally friendly industrial nonmetallic ore mill The equipment is independently developed and produced by SBM, and mainly includes HGM series ultrafine grinding mills and CLUM series vertical millsSepiolite Superfine Powder Grinding Mill SBM Ultrafine Features of High Pressure Roller Mill The HPRM boasts the following remarkable features: High Efficiency and Energy Saving: It crushes materials through highpressure force, consuming less energy while maintaining high efficiency; High Crushing Ratio: Capable of significantly increasing the crushing ratio, it is suitable for materials of varying hardnessHigh Pressure Roller Mill huashengming

.jpg)

Rethinking Grinding Efficiency in Ball Mills

Kolev et al (2021) –In press Improving the energy efficiency in tumbling mills with the use of Relo grinding media (MDPI) • Lab trials conducted using a standard Bond ball mill (@ Wardell Armstrong) • Standard Bond ball mill procedures were followed –only the RELO media PSD and mass of charge adjusted to match spherical mediaHigh grinding efficiency and energy saving The capacity of one unit can reach 40t/h Using single and multihead classifiers, no need to using secondary air separation and classification, and it can save 30% 50% energy consumption than ordinary millsHLMX 2500 Mesh Superfine Powder Grinding Mill2013年7月15日 Minerals processing engineers and grinding experts agree that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit ball mills(PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing DOI: 101016/jpowtec202110056 Corpus ID: ; Highefficiency and energyconservation grinding technology using a special ceramicmedium stirred mill: A pilotscale studyHighefficiency and energyconservation grinding technology

.jpg)

EFFICIENCY IN GRINDING AND ENERGY MANAGEMENT IN THE MILLS

2019年11月11日 14 November 2024 2 min reading CESCO validates highperformance bagging system for UFC's grain facility in Saudi Arabia CESCO, a global leader in grain handling, storage, and processing solutions, has announced the successful completion of the Factory Acceptance Test (FAT) for a highcapacity bagging line system as part of its extensive project with United 2021年11月3日 Choosing a highefficiency, intelligent, energysaving, and environmentally friendly phosphate rock powder mill can greatly enhance the market competitiveness of phosphate rock powders and create more great Phosphate Mineral Powder Grinding Mill SBM 2009年6月1日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and Comparison of energy efficiency between ball mills and stirred mills 2021年4月29日 Ball mills have a low efficiency rate partially due to the lack of a proper method to monitor the mill filling level, which makes it difficult to control the grinding process(PDF) A Comparative Study of Energy Efficiency in

.jpg)

(PDF) CEMENT RAW MATERIAL GRINDING ; VERTICAL ROLLER MILL OPERATION

2018 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder small grinding media perform in industrial grinding mills? The use of small grinding media in regrind mills proved that finer grinding can be achieved at lower energy consumption In ball mills, smaller grinding media versus 25 mm media generate a power saving from 10% to 44% In vertical stirred mills, the power saving increases from 20% to 60 Energy Savings and Improved Recovery with Small Grinding MediaIn this study, a pintype vertical stirred media mill was used to perform the dry grinding of bentonite Grinding time and stirring speed were investigated for effect on the particle size distribution and energy consumption (Ec), while ball charge and bentonite charge were kept constant as 60% and 40%, respectivelyDry Grinding of Bentonite by Stirred Media Mill Academia

.jpg)

New Bentonite Grinding Mill Equipment Used In Iron ore Pellet

2021年1月29日 The new Raymond mill and vertical roller mill manufactured by HCM have high grinding efficiency, large production capacity and low energy consumption If you are in need of any nonmetallic grinding mill, contact mkt@hcmilling or call at +86773, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please The high technical index equipment is a really high efficiency, easy maintenance, stable operation, energy saving grinding mill Mill Structure HC Series Grinding Mill consists of main mill, constraint turbine classifier, pipe system, high pressure blower, cyclone separator, electromagneticvibrating feeder, electronic control motor and jaw crusher, pan elevatorHC Grinding Mill, Raymond Mill, Pendulum Powder Mill, Non As a generalpurpose mill, Raymond mill is suitable for bentonite grinding, which can reach the fineness of finished powder in the range of 80325 mesh It has simple structure, high efficiency, energy saving, low carbon and high yield The Applications of Bentonite powderHigh quality Vertical Roller Grinding Mill Energy Saving And Efficient Bentonite Vertical Mill from China, China's leading Bentonite Grinding Mill product market, With strict quality control Bentonite Grinding Mill factories, Producing high quality Vertical Roller Grinding Mill Energy Saving And Efficient Bentonite Vertical Mill productsBentonite Grinding Mill, Vertical Roller Grinding Mill Energy Saving

Superfine Bentonite Grinding Mill 45 T/H Efficient Energy Saving

High quality Superfine Bentonite Grinding Mill 45 T/H Efficient Energy Saving Vertical Mill from China, China's leading Bentonite Grinding Mill product market, With strict quality control Bentonite Grinding Mill factories, Producing high quality Superfine Bentonite Grinding Mill 45 T/H Efficient Energy Saving Vertical Mill productsA research project may be worthwhile for more detailed investigations 6 Conclusions Stirred mills have been primarily used for fine and ultrafine grinding They dominate these applications because greater stress intensity can be delivered in stirred mills leading to better energy efficiency over ball mills in fine and ultrafine parison of energy efficiency between ball mills and stirred mills The FDS60 nano sand mill features a new pintype grinding component design, ensuring high efficiency, substantial output, and low energy consumption Its compact length/diameter ratio and elevated energy density set it apart The incorporation of a highflux static centrifugal separation sieve with a sizable discharge area ensures that the grinding medium doesn't contact the High efficiency super fineness sand mill FDS年9月9日 Diatomite ultrafine grinding mill is an efficient ore stone powder such as limestone, calcium carbonate, kaolin, bentonite, vermiculite, etc stable operation, long service life, high efficiency and energy saving, environmental protection, and no dust pollution The industrial ultrafine mill has a material layer Diatomite Ultrafine Grinding Mill SBM Ultrafine Powder

.jpg)

Bauxite Grinding Mill, Customized Energy Saving Bauxite Grinding Mill

Hefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 HomeStone powder making machine is an ultrafine industrial grinding mill, used to grind barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energysaving capabilities, and Stone Powder Making Machine2015年6月5日 2 1 High Efficiency Under the same finished final size and the same motor power, the capacity of the machine is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30% 2 Long lifecycle of spare parts The ring and roller are forged by special material with high utilization, the lifetime can reach 25 years for grinding Bentonite Grinding Mill PDF SlideShare2024年2月5日 Energysaving grid ball mill is a kind of grinding equipment widely used in industrial production It has the advantages of energy saving, high efficiency, and environmental protection However, inHow to Improve Working Efficiency of EnergySaving Grid Ball Mills

.jpg)

NEWS Raymond Mill

2020年8月10日 What equipment can be used to grind 300 mesh bentonite powder? The mill manufacturer Clirik is an experienced equipment manufacturer According to the needs of customers and the market, it provides new environmentally friendly Raymond mill equipment to help the bentonite grinding project save comprehensive investment costs and achieve