slag micro powder process equipment table

.jpg)

Powder Processing Equipment Systems Qlar

most versatile size reduction machines in the powder processing industry Its ability to process a wide range of feed material and produce an equally wide range of product make it ideal for Grinding options for slag and pozzolan While the use of supplementary cementitious materials is increasingly popular, the use of granulated blastfurnace slag and pozzolans presents extra GRINDING Grinding options for slag and pozzolan PEC 2024年10月25日 Slag processing technology converts slag into high valueadded products such as slag powder and new slag silicate cement through highfine grinding This process not only Slag Ultrafine Powder Processing Technology Mining machinery 2024年1月2日 This solution is included in the national catalog of advanced and applicable technology and equipment for comprehensive utilization of industrial resources, and is suitable Slag micron powder process technology solution

Slag micro powder processing environmental protection

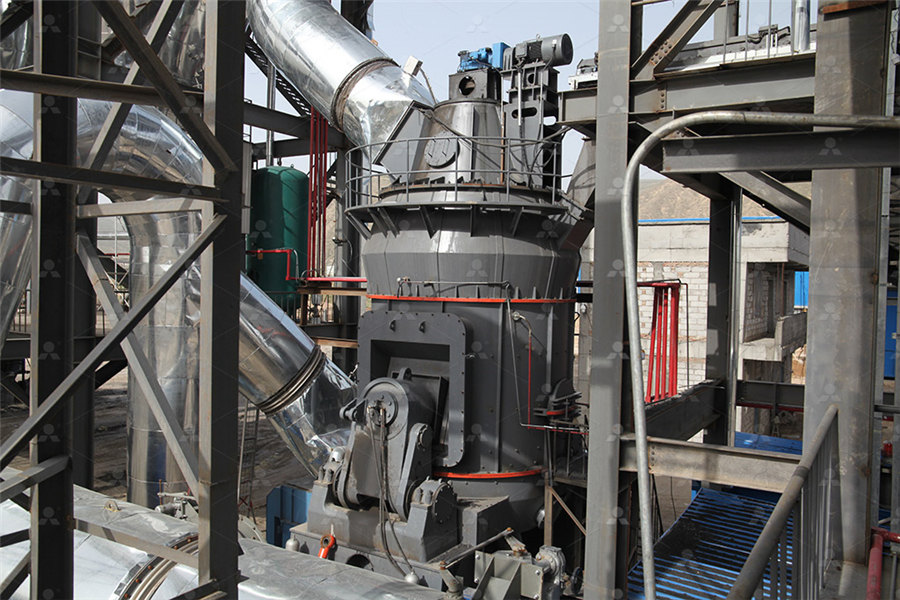

The production line adopts HLM2800 vertical mill and environmental protection equipment produced by Hongcheng, and uses advanced vertical mill grinding technology to start the 2023年5月15日 In this process, steel slag and slag were mixed in a certain proportion into the feed bin The mixed materials were treated by vselector, highpressure roller, powder Comprehensive utilization of steel slag: A review ScienceDirect2020年11月1日 Optimal solution for slag powder production process is determined by proposed CTNSGAII algorithm Slag powder is a process with characters of multivariables, strongly Analysis and multiobjective optimization of slag powder processSuperfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non Superfine Slag Powder Production Line FTM Machinery

Slag mill, slag powder mill, slag uZhengzhou Vanguard Machinery

Slag grinder (also called slag micropowder mill and slag superfine mill) is a largescale grinding machine, which Vanguard absorbs advanced European technology and designs and 2011年3月17日 The invention relates to a production process of steel slag micropowder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and Production process of steel slag micropowder Semantic Scholar2024年2月3日 Slag micro powder is a kind of ultrafine powder material with a particle size of less than 45μm It is made by grinding slag, a byproduct of steelmaking, into a fine powderSlag micro powder has a wide range of Slag Micro Powder Processing Grinding Equipment2021年8月1日 Steel slag micro powder is steel slag after special process grinding, is a byproduct in the process of steel production This paper studied the basic mechanical properties and crack control (PDF) Effect of Polyvinyl FiberSteel Slag Powder on Mechanical

.jpg)

Development of slagbased filling cementitious materials and their

2024年11月2日 The quality variation of slag micropowder is also a significant factor; the incorporation of untested admixtures and activators into the slag micropowder can lead to significant strength fluctuations, particularly a reduction in strength at later stages accompanied by cracking, posing a significant risk to the safety and durability of the structure2018年1月1日 In this experiment, ultrafine iron phosphate micropowder was prepared by hydrothermal method which used phosphate slag as an iron source The effects of reaction temperature, surfactants type and Preparation of ultrafine iron phosphate micropowder from phosphate slagThe main nickel slag vertical mill, also known as vertical roller mill, used in the nickel slag grinding micro powder process is a mechanical equipment device that grinds nickel slag through the relative movement between the grinding roller and the grinding disc based on the principle of material bed grindingNickel slag powder processing solutionLIMING HEAVY 2022年2月26日 Therefore, China, the United States, Canada, France, Britain and other countries pay attention to increasing this process equipment when building or Blast furnace slag powder of 0325 mesh generally adopts European plate mill The 1000 mesh blast furnace slag powder is suitable for three ring medium speed micro powder What is Blast Furnace Slag and How to Process It?

Mechanical Properties of SlagBased Geopolymer Grouting

2023年7月19日 Homogenized microcrack crushing can fully retain the bearing capacity of concrete pavement, but local weak road base needs to be reinforced before being directly overlaid with hotmixed asphalt Therefore, indoor tests were conducted to study the mechanical properties of slagbased geopolymer as a grouting material for weak road base, and the morphology and 2022年3月7日 The main components of the three tailings slag are CaO, SiO 2, and Al 2 O 3 (Table 2), which are consistent with the main chemical components of limestone powder and red clay, it can be used as a mineralizer, especially the content of Fe 2 O 3And Fe 2 O 3 in lead–zinc tailings accounts for 1392% Nickel tailings contain relatively high MgO When they are Preparation of composite microslag based on the application of 2024年1月31日 Wang K, Li X, Jia C, et al Tracking control of slag powder production process based on adaptive dynamic programming Acta Automatica Sinica 2016; 24: 1542–1551 Google ScholarIntelligent process control system for predicting operating of phosphate slag and the synthetic process of recycling and reuse It has a deep understanding of it and has mastered the technology of phosphate slag to purify iron phosphate[5,8,2526] I have adopted a new method to purify and prepare iron phosphate micropowder with smaller particle size The purified and modified iron phosphatePreparation of ultrafine iron phosphate micropowder from phosphate slag

Effect of grinding method on properties of steel slag powder

Effect of grinding method on properties of steel slag powder: DUAN Siyu 1, LI Xi 2, MA Zhuohui 1, LIAO Hongqiang 1, CHENG Fangqin 1: 1 State Environment Protection Key Laboratory of Efficient Utilization Technology of Coal Waste Resources, Institute of Resources and Environmental Engineering, Shanxi University, Taiyuan , China; 2 Shanxi Architectural 2016年2月29日 In general, slag from smelting process arises from extraneous materials such as rust and oxides; oxidation of elements in the charge (eg iron, copper, zinc); residues from fuels; fluxes employed in the process (silica, Gold Smelting Refining Process 911Metallurgist2024年11月1日 Based on the above analysis, the following improvement suggestions were put forward: (1) In terms of electrode research, the use of inexpensive graphite electrodes had a good effect on steel slag treatment, and hightemperature ceramic electrodes and iron erosionresistant electrodes (ZrB 2) were gradually being exploited; (2) In terms of equipment, the existing Recent research progress on recycling metallurgical waste slag 2023年7月1日 Although the CaO content of limestone powder is higher than that of steel slag powder, the main mineral phase of limestone powder is CaCO 3, and the adhesion between CaCO 3 and asphalt is weak [28] The research shows that the adhesion between SiO 2 and SBS modified asphalt is slightly higher than that of Al 2 O 3 , and both are significantly higher than Creep and fatigue properties of asphalt mastic with steel slag powder

(PDF) Hot metal dephosphorization process using calcium ferrite slag

2022年2月20日 To solve environmental pollution caused by using fluorite slagging in the process of hot metal dephosphorization, this paper applies premelted calcium ferrite slag in the production of stainless 2022年11月11日 By calculation from Equation (1) [22], the alkalinity coefficient of the steel slag is 222, which is higher than 18 lower than 25 This means that this kind of steel slag belongs to the Laboratory Preparation and Performance Characterization of Steel Slag 2019年5月23日 Table 62 Output of steel and steel slag in the main provinces and municipalities in 2012 Generally, steel slag fine powder that is of over 80mesh standard sieve is taken as the standard, The advantages of this technique are that has a short process and small equipment volume and that it requires less occupied prehensive Utilization Technology of Steel Slag2023年5月15日 In this process, steel slag and slag were mixed in a certain proportion into the feed bin The mixed materials were treated by vselector, highpressure roller, powder separator, and ball mill to produce steel slag and slag composite micro powder Table 3 illustrates the equipment types for SSCMComprehensive utilization of steel slag: A review ScienceDirect

Comprehensive utilization of steel slag: A review Request PDF

2023年3月1日 Request PDF Comprehensive utilization of steel slag: A review Steel slag, the main solid waste in the steelmaking process, is produced more than 120 million tons annually in China Most of 2023年10月15日 CCS is placed in the air, and during the cyclone separation of impurities, part of the calcium hydroxide on the surface will be converted to calcium carbonate (Fig 6 b); 2) Impurities are wrapped: Impurities are coated with calcium hydroxide powder, as shown in Fig 6 b, the presence of carboncalcium mineral phase was found in the calcium hydroxide and Carbon emission free preparation of calcium hydroxide with 2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing Research on the Flexural Performance of Steel Pipe 2023年6月14日 To investigate the toughening effect and stress–strain relationship of steel fibrereinforced steel slag micropowder ultrahighperformance concrete (UHPC), nine sets of specimens with coarse aggregate Experimental Study on Axial Stress–Strain Behaviour of

(PDF) Effect of Iron Tailings and Slag Powders on

2021年7月1日 The addition of tailings powder improves the working performance of concrete and slightly improves the strength Due to the large amount of cement used in ultrahighperformance concrete, physical 2024年11月1日 Steel slag displays good reactivity, and its high calcium oxide and magnesium oxide content can be further enhanced using alkaliactivation technology, enabling its application as a geopolymer material [33], [34]The addition of micropowder materials can effectively fill the voids between the coarse and fine aggregates in concrete, enhancing the continuity of particle Effect of electric furnace steel slag powder on the strength of 2020年5月15日 Micro surfacing (MS) is a type of bituminous coating frequently applied in the surface of pavement structures in order to prevent the occurrence of common distress and/or as a maintenance procedureEvaluation of the use of steel slag in micro surfacing ResearchGateSteel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can provide an effective way for the recycling of steel slag HCMilling(Guilin Hongcheng) provides customers with professional micropowder Introduction To The Way Of Steel Slag Recycling The Micropowder

.jpg)

Laboratory Preparation and Performance Characterization of Steel Slag

Steel Slag Ultrafine Powder Used in CementBased Materials Yuanhang Sun 1 , Meizhu Chen 1,2, *, Dongyu Chen 1 , Shaoyan Liu 3 , Xintao Zhang 1 and Shaopeng Wu 12024年10月24日 The objectives of this research are: (1) to examine the influence of using steel slag micropowder UHPC on the performance of steel tube UHPC composite members; (2) to analyze the failure mechanisms and load–deformation characteristics of the short column specimens; and (3) to develop a calculation method for predicting the axial compressive load Experimental Performance Study on Axial Compressive Load xxx Metall Mater Eng Vol xx (x) 202x p xxxxxx Fig 2 Xray analysis of crystalline phases, slags of Lúčka, Jakubany, and HenckovceTable 1 Analysed slags: (locality, geographical THE LOAD DEPENDENCE OF THE MICROHARDNESS OF THE BLAST FURNACE SLAGDownload Table Chemical composition of slag powder (wt %) from publication: Effect of alkali dosage on alkalisilica reaction in sodium hydroxide activated slag mortars Alkalisilica Chemical composition of slag powder (wt %) ResearchGate

Efficient separation of iron elements from steel slag based on

2023年3月1日 Steel slag is a byproduct of the steelmaking process In fact, each ton of steel produces 110–150 kg of steel slag China's steel slag reserves are more than 300 million tons, and the annual hoard continues to increase [1]Due to the different steel composition, scattered varieties of converter slag and complex composition exist, which seriously limits the Chinese 2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder Characteristics of Recycled Micro Powder Produced Using Construction 2021年7月25日 When the ratio of iron tailings powder and slag powder is not more than 5:5, the flexural strength and splitting tensile strength of concrete are similar to those of concrete with slag powder alone For example, when the Effect of Iron Tailings and Slag Powders on Workability 2024年7月28日 The cement industry is known for being highly energyintensive and a significant contributor to global CO2 emissions To address this environmental challenge, this study explores the potential of using the waste materials of steel slag (SS) and eggshell powder (ESP) as partial replacements for cement in alkaliactivated mortars (AAMs) production, activated by NaOH Optimizing AlkaliActivated Mortars with Steel Slag and Eggshell Powder

.jpg)

Research on the Properties of Steel Slag with Different MDPI

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water 2012年7月1日 In order to determine the effect of slag composition during the RH process on refractory wear, magnesia–carbon and magnesia–chromite refractories were immersed for 10 min at 1600 °C in a Investigation of SlagRefractory Interactions for the2011年8月17日 To improve the properties of steel slag blended cements, a chemical activator was added into blended cements, the mechanical properties and durability of steel slag blended cements were investigated The results show that steel slag in blended cement pastes presents low hydraulic activity and makes practically no contribution to strength development After the Investigation on mechanical properties, durability and microstructural Download Table Physical Properties of Steel Slag from publication: Steel slag to improve the high strength of concrete Steel slag is an industrial byproduct of steel industry It possesses Physical Properties of Steel Slag Download Table ResearchGate

.jpg)

Review Accelerated carbonation of steel slag: A review of methods

2024年1月12日 Steel slag is a byproduct of the steel production process, accounting for approximately 15% of the whole crude steel output [1]The accumulation of untreated steel slag not only occupies a significant amount of land but also leads to the leaching of heavy metal ions (such as vanadium, chromium, arsenic, lead, cadmium), polluting surrounding water sources 2023年11月8日 This article presents an original study into the feasibility of using blast furnace slag and stainless steel pickling sludge to produce solidified/stabilized Cr slag micropowder and its (PDF) Effect of Crsolidified/stabilized Waterquenched Slag on