Crushing belt limestone description

.jpg)

Limestone Rock Crushing Flow Price JXSC Machine

2019年11月4日 The crushed limestone is uniformly conveyed to the cone crusher or impact crusher by the conveyor belt for medium and fine crushing After crushing, it is screened by a circular vibrating screen The largergrained The limestone crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening The first stage: coarse crushing The limestone stone blasted from the Limestone Aggregates Processing SHANGHAI SANME MINING The limestone crushing process involves several stages, each with specific machinery and equipment The typical limestone crushing process is Primary Crushing > Secondary Crushing > Screening > Conveying > StorageLimestone Crushing Process JXSC MineralIntroduce how to crush limestone, whole limestone crushing plant flow layout (with photo), and related rock crusher machine Contact us to do free flow designLimestone Crushing Solution Eastman Rock Crusher

Limestone crushing process sbmchina

Design the limestone crushing process, and briefly introduce the process designed by SBM experts Second, limestone crushing processing equipment SBM's equipment for this process 2023年2月14日 Proper crushing of limestone is essential to ensure that the final product meets the necessary specifications and standards A wellexecuted crushing process also reduces energy consumption and costs and minimizes Optimized Limestone Crushing Process for Increased The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of Limestone Crushing Equipment and Production Line2024年7月15日 A limestone crusher crushes bulky limestone rocks into crushed limestone easily Popular limestone crushers are hammer crushers, impact crushers, jaw crushers, and mobile crushers Choose the right crusher based Limestone Crusher: An Edge Tool for Making Crushed

.jpg)

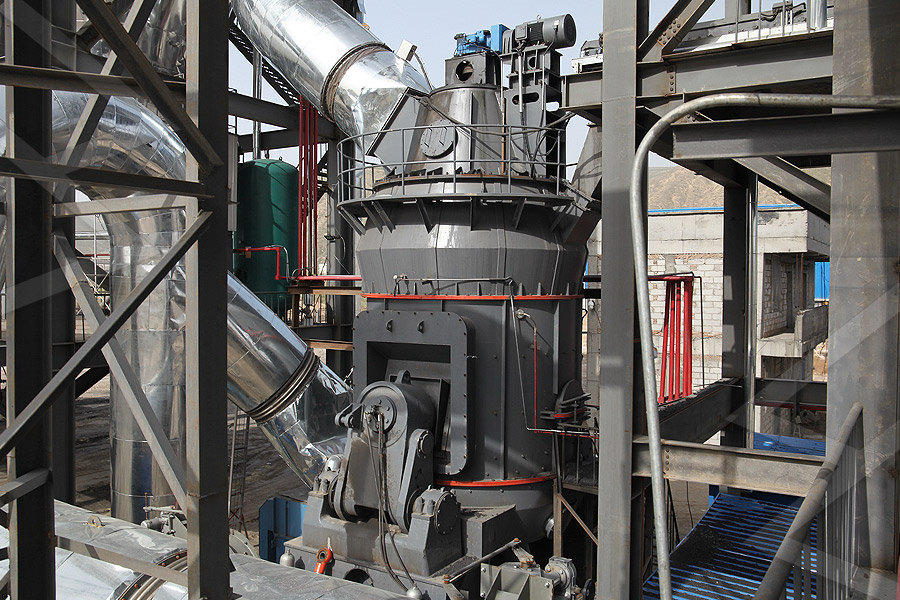

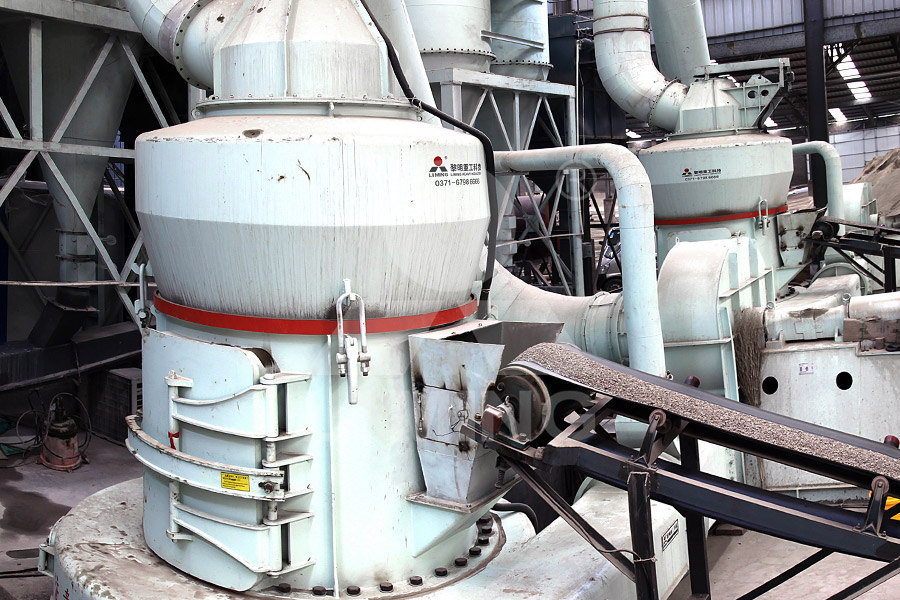

Limestone crushing and screening production line introduction

2024年1月23日 If a powder form is needed, limestone particles are transported to a limestone grinding mill via a conveyor belt system for the final fine grinding This step aims to obtain the There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 MetallurgistThe Limestone sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and screening The first stage: coarse crushing The pebbles blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing The second stage: medium brokenLimestone Aggregates Processing SHANGHAI SANME MINING crushing plant and belt conveyor is not optimal because the work efficiency of limestone crusher II is 26,20%, crusher IIIA is 21,54%, and crusher IIIB is 28,33% Second, the minimum production capacity of the belt conveyor is 1,4097 tons/hour Third, the ideal crusher working hours is 672 hours in a month so that the productionEVALUASI KINERJA CRUSHING PLANT DAN BELT CONVEYOR

Selecting Conveyor Belt for Stone Crusher Systems

2024年5月25日 Conveyor Belt for Stone Crusher: Scaling Up with 1:14 Scale Conveyor Design and Specifications Scale Model Design The design of the stone crusher conveyor belt, particularly the 1:14 scale model, is meticulously The crusher operator job description involve various duties that go beyond feeding a crushing plant Crushing is a violent process and requires more maintenance and having a close eye on critical components See below a summary of the most common responsibilities and requirements Responsibilities Setup and Material ManagementCrusher Operator Job Description Template RUBBLE MASTER1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC Machine2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing,

.jpg)

800tph Stone Crushing Plant TAYMACHINERY

800tph Stone Crushing Plant: A pinnacle in stone crushing technology This highcapacity plant is meticulously engineered to crush and process large stones into essential aggregates or sand, vital for mining, quarrying, and construction industries Equipped with powerful jaw crushers, efficient cone crushers, advanced sand making machines, dependable vibrating screens, and robust 2023年2月14日 The limestone crushing process is a crucial step in the production of cement, as well as in other industries that utilize limestone as a raw material The process of crushing limestone involves several stages, each of which plays a critical role in ensuring that the final product meets the necessary specifications and standardsOptimized Limestone Crushing Process for Increased EfficiencyA Cone Crusher is used for secondary crushing, followed by material distribution via belt conveyers to either proceed to the tertiary plant or cycle back for reprocessing Tertiary Crushing Plant: The tertiary stage involves additional reduction by a second Cone Crusher, after which the material is allocated to various stockpiles (4, 5, and 6) through a series of belt conveyersThreeStage Limestone Crushing Plant Optimization NIAflowWhat is the crushed limestone conveyor system project like ? This project is a typical limestone production line project It forms a closedloop circulation system from exploration Primary crushingsecondary crushingsand making sievingconveyingmixing plantfinished mixer truck, which implements a threeshift 24hour continuous production, its conveyor system covers the Limestone Belt Conveyor System used in Crushing Plant in China

.jpg)

Complete Quarry Crushing Plants Mobile Granite Limestone

Complete Quarry Crushing Plants Mobile Granite Limestone Gravel Jaw Crusher Factory Price Aggregate Rock Stone Crushing Plant, Product Description Company Info Basic Info Model NO 100t Materials Limestone Condition New 2High capacity integral crushingscreening 3Belt conveyor selfloadedcrushing plant and belt conveyor is not optimal because the work efficiency of limestone crusher II is 26,20%, crusher IIIA is 21,54%, and crusher IIIB is 28,33% Second, the minimum production capacity of the belt conveyor is 1,4097 tons/hour Third, the ideal crusher working hours is 672 hours in a month so that the productionEVALUASI KINERJA CRUSHING PLANT DAN BELT CONVEYOR Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that direction of the arrows Crushing Wheel Create Wiki FandomLimestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production Line

Limestone Conveying System KWS Manufacturing

General Description Duluth Minerals provides ground or pulverized limestone to the roofing industry Ground or pulverized limestone is used extensively in asphalt roofing shingles, both fiberglassreinforced and organicmatbased, as well as in rolled roofing Ground limestone has two primary functionsApplication Limestone Crushing in cement plants Elecon Impactors are powered by electric motors that utilize Vbelt drives for smooth and reliable operation Contact the nearest Elecon sales office to learn more about the Elecon Impactor, or request a call back Description Application Limestone Crushing in cement plants Features Rigid Elecon Impactors: HighCapacity Crushing Solutions2024年1月23日 Limestone crushing and screening production line introduction Limestone is a common sedimentary rock, primarily composed of calcium carbonate If a powder form is needed, limestone particles are transported to a limestone grinding mill via a conveyor belt system for the final fine grindingLimestone crushing and screening production line introductionZambia 200TPH Limestone Crushing Plant Yield: 120 Applications: Construction aggregate Onsite Photo Project Description: Address: Ndola city, Zambia Time Starting Production: June, 2014 PE Series Jaw Crusher, Pan Feeder, PF Series Impact Crusher, Vibrating Screen, Belt Conveyor, Control Box Related cases More Other cases Zambia 200TPH Limestone Crushing Plant sbmchina

Portable Impact Crushing Plants MEKA Concrete Plants

soft and mediumhard materials such as limestone, low abrasive rocks, for quarrying, between production sites and often utilized in aggregates production and recycling applications WHY MEKA PORTABLE IMPACT CRUSHING PLANTS? Belt Width Belt Width: 800 mm 31" 1200 mm 47" Length Length: 14 000 mm 45' 11" 14 000 mm 45' 11"2023年2月24日 Limestone crusher machines play a crucial role in the construction industry by crushing limestone into the right size for construction projects The choice of the machine depends on several factors, including the type of material being crushed, the capacity required, and the machine’s maintenance requirementsLimestone Crusher Machine: The Key to Construction EfficiencyPDF On Aug 7, 2018, Ocheri c published Design and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use Find, read and cite all the research you need on (PDF) Design and Construction of Rock Crushing 2023年3月2日 Introduction For the 100tph stone crushing plant, the truck transfers the original stone with input size under 500mm into vibrating feeder 380*96, and it transfers the stones to jaw crusher PE 600*900, after first Getting To Know The Complete Set Stone Crushing Plant

.jpg)

cement manufacturing Cement Plant Optimization

Process description: 1: Raw Material of mine (ROM) Limestone/sandstone to size (1030mm) suitable for grinding operation in ball mill, VRM or roller press Crushing of limestone can be accomplished stored in individual feed bins are proportionally delivered through weigh feeders at the discharge of the bins to a belt conveyor or a Draft solution of primary crushing at limestone and stone aggregates processing plant from deposit 'Suvodo' AD – Jelen Do January 2006 Journal of Mining and Metallurgy A Mining 42(1)(PDF) Draft solution of primary crushing at limestone and stone Customizable configured limestone crushing plant meets the different requirements of output, finished size, and shape Skip to content Call Us Now: +86 : ne It is sent to the impact crusher through the belt conveyor for the second stage of crushing ScreeningLimestone Crushing Plant Supplier – Limestone Crusher For SaleDescriptions: Fixed stone crusher plant including stone crusher, vibrating screen, such as gypsum, limestone, and chalk, the stone crushing production line can be configured as: pile through the belt conveyor while material more than 315mm is delivered into the secondstage cone crusher by the belt conveyor for recrushingStone Crushing PlantStone Crusher MachineMobile Crushing

Limestone Crusher LIMING (Shanghai)

Limestone can be directly processed into stone and fired into the quicklime So it has a wide range of applications, such as building materials, metallurgy, chemical industry, and highway the outputs will be sent into impact crusher via belt conveyor for secondary crushingAN EXPERT IN CRUSHING NONABRASIVE MATERIALS Primary impact crushers are preferred for their high performance and high reduction ratios in crushing softer substances like gypsum and limestone Due to the different principle of crushing these materials, the reduction ratio is higher than in jaw crushers MPI1313 MPI 1515 MPI 1620CRUSHING SCREENING2024年10月30日 Limestone, sedimentary rock composed mainly of calcium carbonate, usually in the form of calcite or aragonite It may contain considerable amounts of magnesium carbonate (dolomite) as well; minor constituents also commonly present include clay, iron carbonate, feldspar, pyrite, and quartzLimestone Characteristics, Formation, Texture, Uses, FactsDescription Limestone is a sedimentary rock composed mostly of the mineral calcite and comprising about 15% of the Earth’s sedimentary crust It is a basic building block of the construction industry (dimension stone) and a chief material from which aggregate, cement, lime and building stone are made 71% of all crushed stone produced in the US is either limestone Limestone Minerals Crushing in Mining JXSX Mine JXSC Rock

Joy Crushing and Conveying Systems Continental Global

Crushing and Conveying Systems 6 Komatsu Mining Corp Group Komatsu Mining Corp Group 7 Belt turnovers Belt turnovers are designed to minimize material buildup and spillage on the return side of your conveyor system By turning your conveyor belt over and allowing the clean side of Limestone Storage yang ada di PT Semen Baturaja terdapat 3 pile, dimana terdapat 2 pile medium grade limestone dan 1 pile high grade limestone Pile yang sudah disusun membentuk layer, kemudian dilakukan proses reclaiming yang kemudian ditransportasikan lagi menggunakan belt converyor menuju limestone bin Table 3PROSES CRUSHING MATERIAL LIMESTONE UNTUK BAHAN 2024年7月15日 When crushing limestone with a mud content of less than 5% and a moisture content of less than 7%, choose a hammer crusher Hammer crushers are the first choice for crushing soft to mediumhard rocks Belt Limestone Crusher: An Edge Tool for Making Crushed When the process starts running, the limestone is uniformly fed into the jaw crusher through the vibrating feeder for primary crushing, crushed to a certain particle size, and then sent to the cone crusher through the belt conveyor for secondary crushing, and then The material enters the circular vibrating screen for screening and classificationLimestone crushing process sbmchina

.jpg)

(PDF) Evaluasi Kinerja Limestone Crushing Plant Terhadap Target

2021年10月1日 After many refinement efforts, work efficiency of the limestone crushing plant 09 unit increased 1731% to 80, 19%, masingmasing belt conveyor dan , massa 2022年5月14日 It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing Right from hard stones to delicate minerals, stone can incorporate slag, limestone, quartz, rock, iron metal, sandstone, copper metal, marble, concrete and that is just the beginningStone Crushers: A Technical Review on Significant Part of800TPH Limestone Crushing Project Background The customer is a concrete company whose products are widely used in concrete mixing plant, belt conveyor and hopper so that the investment on the whole production line decreased Basic Introduction Material: Limestone Capacity: 800TPH Application: Concrete aggregate Output Size: 05, 510 800TPH Limestone CrushingSBM Industrial Technology GroupPortable Tertiary Impact Crushers are wheelmounted rock crushing machines, engineered for tertiary crushing applications Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and mediumhard materials, such as limestone and recycled materials, and ideal for the production of high grade concrete and Portable Tertiary Impact Crushers MEKA Concrete Plants

Complete Set Quarry Limestone River Stone Stationary Crushing

The Stone Crushing Plant mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyor and Control System, etc It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, and produce sand gravels with various granularities for construction and building 2013年6月20日 1 Limestone mobile crusher is the complete crushing unit, includes feeding, crushing, screening process for example, limestone mobile jaw crusher includes vibrating feeder, vibraging screen, primary jaw crusher, vibrating screen, and belt conveyor There are other models, such as limestone mobile impact crusher, limestone mible cone crusher, crawler type Limestone crushing plant PDF SlideShare