Tin powder grinding equipment process flow

.jpg)

Tin Processing Equipment, Process Flow, Cases JXSC

2019年9月25日 Tin processing description from tin geology mineral property to how to extract tin from rock and placer deposit, related tin processing plant flow chart and layout designThe Process The process consists of the following: Mixing : Mixing consists of blending of various powders, like graphite powder, Copper powder, Tin powder, Specialty lubricants, chemicals and additives etc into a uniform non Process Flow Chart – Universal Sintered ProductsMethods for making powders – Atomization : Produces powders of both ferrous and nonferrous powders like stainless steel, superalloys, Ti alloy powders; Reduction of compounds : Powder metallurgy – basics applications IIT Guwahati2022年5月12日 Generally, equipment such as washing machine, crossflow belt chute, and smalldiameter cyclone are used as cassiterite desliming equipment The commonly used gravity separation equipment for tin ore mainly includes Tin Ore Beneficiation Process and Equipment JXSC

Zambia 10TPH Rock Tin Ore Process Plant JXSC Mineral

JXSC has provided a successful 10TPH rock tin process plant in Zambia We design the tin process plant flowchart plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese 2024年11月7日 In this article, we will explore the main methods of tin ore extraction, including recent advancements in processing technology, and discuss the critical role of equipment in A Comprehensive Guide to Tin Ore Processing: Techniques and Below are some tin ores which may be described as “Complex” or “Simple” based on grain size of the cassiterite and dissemination through the mineral suite, ease of liberation through the TIN ORES SOME ASPECTS OF PROCESS METALLURGY AusIMM2023年7月25日 Understanding gravity separation is vital for efficient alluvial tin ore processing DASEN MINING MACHINERY utilizes specialized equipment to achieve precise separation and highquality tin concentrate productionGravity Separation for Alluvial Tin Ore: Equipment and

.jpg)

Tin Ore Processing Plant JXSC Machinery

The specific process and equipment need to be determined according to the nature and characteristics of the ore 1 Crushing and grinding: The original tin ore is crushed and ground to refine it into an appropriate particle size for alumina, zirconia During rolling of vessel, the grinding media powder particles roll from some height This process grinds the powder materials by impact/collision attrition • Milling can be dry milling or wet milling In dry milling, about 25 vol% of powder is added along with about 1 wt% of a lubricant such as stearic or oleic acidPowder metallurgy – basics applications IIT Guwahati2022年5月12日 Tin ore is one of the important strategic mineral resources, and tin and tin alloys have been widely used in modern national defense, industry, cuttingedge science and technology and human life At present, common tin Tin Ore Beneficiation Process and Equipment JXSC 5 天之前 Grinding process The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing Here also need to use an auxiliary equipment – classifier It can classify and screen copper ore and release copper ore powder that meets the requirements 3Copper Ore Processing Plants, Flow And Equipment

.jpg)

Feldspar Powder Crushing Grinding Production Line Equipment

2023年12月14日 Jaw Crusher( feldspar production line equipment) It is necessary to crush big feldspar stones into small pieces before the grinding process The crushing equipment usually uses a jaw crusherIt has advantages such as a high crushing ratio, large feed particle size, high output, and less susceptibility to damageThe customer requires that the impurities on the surface of the ore be washed first to remove iron impurities, and the final concentrate recovery rate must reach 95% JXSC has developed a complete set of tin ore process plant equipment lines based on customer needs The following is the specific process flow: 1 Washing stage: trommel scrubber20TPH Alluvial Rock Tin Ore Process Plant In ZimbabweJXSC grinding classification equipment is the key equipment for crushing materials after they are crushed The ball mill can process various grinding minerals, nonferrous metal beneficiation, and new building materials It is often combined with a spiral classifier to form a closedcircuit ring mill, which has higher fine powder and grinding powerGrinding Classification Equipment JXSC Machineryform –not much The Tin oxide converts to Tin sulphide which rises out of the molten mass, add oxygen via blowing in air, the reaction reverses to Tin Oxide Fume and Sulphurdioxide The tin fume which looks like talcum powder is caught in Bag filters, the sulphur dioxide gas is wet scrubbed and neutralised with limeTIN ORES SOME ASPECTS OF PROCESS METALLURGY AusIMM

.jpg)

Tin Mining, Processing Solutions and Equipment

Tin mining equipment Our factory JXSC professional in tin mining equipment We built a complete 10TPH Hard Rock Tin Processing Plants for one of our Zambia client The process flow is Crushing > Screening > Grinding > Concentration Description:SOME FEATURES OF THE GRINDING PROCESS IN THE PRODUCTION OF POWDER MATERIALS Yunusov Bakhtiar1, Normuminov Jakhongir1 1The Tashkent state technical university, after I Karimov, Tashkent city, Uzbekistan Annotation The article sets out some of the features of the grinding process in the production of powdery materialsSome features of the grinding process in the production of powder 2023年11月26日 The stepbystep guide provided in this article highlights the equipment, chemical reactions, and methodologies employed in each stage of the chrome plant process flow By grasping the intricacies of the chrome plant StepbyStep Guide: Chrome Plant Process Flow Take a look at this powder metallurgy process flow chart to learn more about the starttofinish of powder metal creation Here’s Your Powder Metallurgy Process Flow Chart The process of creating a successful powder metal component is Breaking Down the Powder Metallurgy Process

.jpg)

Mineral Processing Equipment for Mining Industry

2024年8月7日 Key types include Jaw Crushers, which handle large rocks and ores through compressive force; Cone Crushers, which provide finer output for hard materials; and Impact Crushers, which use highspeed impacts to flowing over a refractory spout into the tin bath This mixture is constantly fed, or “floated”, onto a molten tin bath While on the tin bath, the molten glass “floats” and spreads out evenly over the surface of a liquid tin Due to the inherent surface tension of the liquid tin, and the fact that glass has less density than tin, theManufacturing Process for Float Glass2019年8月23日 Tantalum processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppTantalum Processing Equipment, Process Flow, Cases JXSC Bepex has the fine grinding and micronizing equipment, ultrafine powder and particle sizes on average from a D(50) of 3µm to a D(50) your exact system begins to take shape, including auxiliary equipment, process flow diagrams, process and instrumentation diagrams, safety provisions, and moreFine Grinding Machines and Micronizing Equipment Bepex

Grinding and Polishing Guide Buehler Metallography Equipment

2021年11月15日 During the lapping process, the disc is charged with small amounts of a hard abrasive such as diamond or silicon carbide Lapping discs can be made of many different materials; cast iron and plastic are used most commonly Lapping produces a flatter specimen surface than grinding, but it does not remove metal in the same manner as grinding2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles(PDF) A comprehensive review on the grinding process: 2004年7月16日 Li et al [95] performed numerical investigation on the pressure swirl gas atomization process (Fig 22) from Lagutkin et al [91], for metal powder production using Volume of Fluid (VOF) and Atomization process for metal powder Request PDF2024年8月17日 Defect name: features: Main causes: Stoma : There are smooth holes of different sizes inside or on the surface of the casting ① The furnace charge is not dry or contains many oxides and impurities; ② Pouring tools or additives in front of the furnace are not dried; ③ Too much water is contained in the molding sand or too much water is brushed during mold Casting Production: Process Flow, Equipment, Principle and

.jpg)

Cement Manufacturing Process INFINITY FOR

The process is called a drying /grinding process, Air slide pneumatic conveying equipment used to convey dry and powder material In DMC it is used to convey fine material and cement powder (greater amounts of exhaust gases must 2024年1月20日 Common equipment for powder milling includes ball mills, rod mills, impact mills, and disc mills, each chosen based on the specific needs of the milling process This intricate yet essential art and science of material A Complete Range Powder Milling Processing 2018年6月1日 Pectin powder, on the other hand, adsorbed water up to 12% (w/w), modifying its flowability from freeflow, to easyflow, to cohesive powder Powders flow factor changed as water content increased Effect of Moisture Content on the Grinding Process JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh We provide ore process design, mining equipment production, and Ball Mill JXSC Mineral

Characterization and flowability methods for metal powders

2020年12月3日 Curve A presents the frequentlyoccurring case of a powder where a slow growth of the unconfined yield strength σ c increases with the growing major consolidation stress σ 1Depending on load, a Sharretts Plating Can Handle All of Your Tinning Needs Sharretts Plating Company has been in business since 1925 Over the course of nine decades, we have developed and perfected an effective and affordable tin plating process that can be customized to your specific operating requirements In addition to pure tin plating, we also offer an innovative tinlead plating The Tin Plating Process: A StepByStep GuideProcess Flow Diagram In general, the following information is shown on a PFD • Process piping above a certain size, such as 2 inches • Process flow directions • Major equipment • Bypass and circulation lines • Control valves and processcritical block valves • Connections between systems located on other PFDsINTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN Powder collection: The classified powder is collected and stored Auxiliary systems: Conveyors and other equipment ensure the smooth flow of materials throughout the process The grinding powder production line is a complex system that requires careful planning and execution to ensure the production of highquality powdersGrinding powder production line: Process configuration and flow

How to extraction tin from tin ores JXSC Machinery

2024年11月21日 Tin ore extraction process flow Rock Tin ore Grinding: Optimizing Manganese Ore Process Flow and Equipment Configuration Challenges Process Flow of Chromium Ore Dressing Technology Would you be a confirmed Engineer, a new graduate looking for information on the process he has 1st to work on, or a student, please access below articles on unit operations and equipment that, we hope, will be useful for you PowderProcess also hosts Process Engineer's Tools, a new online ressource for Process Engineers, not limited to Powder Processing This powderprocess Engineering resources for powder PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGateIron Ore Pelletizing Process: An OverviewThe industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic Process

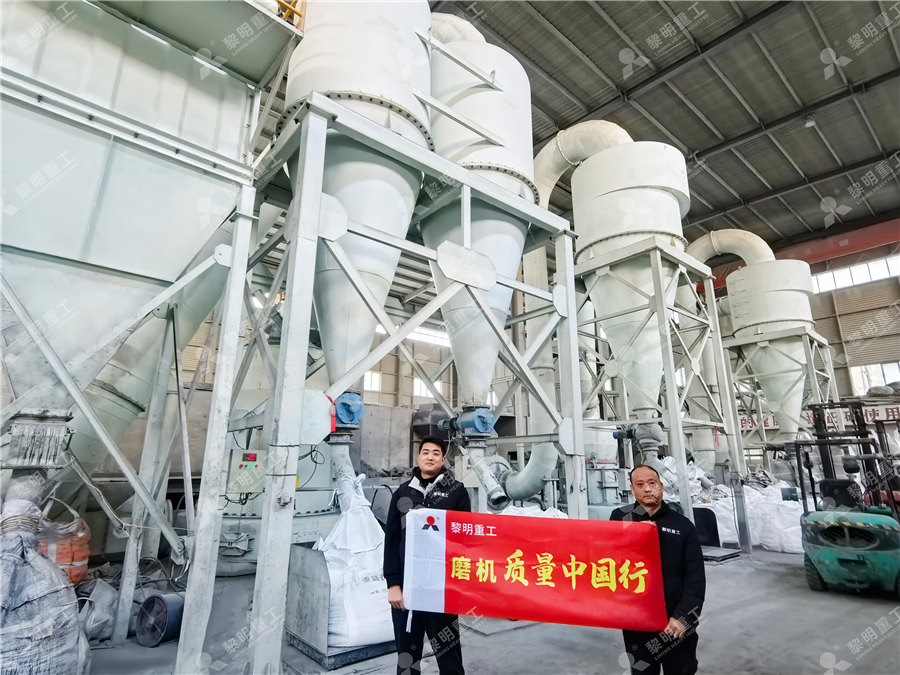

CFB石灰石脱硫剂制备64.jpg)

50TPH Alluvial Tin Process Plant In Nigeria JXSC

50TPH Alluvial Tin Process Plant in Nigeria process flow 1 Ore washing: trommel scrubber This step is aimed at the raw materials with large mud content and strong cementation, We provide mineral processing equipment and The copper powder recovery equipment can recycle and treat the metallic dust pollution generated by the grinding and brushing process in PCB production, reduce the cost of wastewater treatment, save water and electricity, and eliminate the cost of cleaning clogged drainsThe copper powder recycling equipment is suitable for the following occasions: Copper Powder Recovery Equipment JXSC MineralManufacturing Process: Grinding: for packaging Packaging: The finished product is next packaged and stored for supply 18 PROCESS MACHINERY REQUIREMENT Flow Chart: Machine and Equipments Description Machine Image Silos These Equipments are class of The powder grinding machine is primarily used For food, herbs, cumin powder, resin PROCESSING OF CUMIN POWDER NIFTEM2016年2月29日 Small miners employ this process due to alluvial deposits contain free gold, the process is fast and efficient, the final product has a high gold grade and recoveries are between 80 to 95%, commercialization is fast and simple without brokers, the process is simple and is not necessary a big investment or very special technical knowledge, the mercury can be reused Gold Extraction Recovery Processes 911Metallurgist

.jpg)

Zircon Processing Equipment, Process Flow, Cases JXSC

2019年8月26日 What is Zircon Sand? Zirconium sand, also known as zircon sand, is a mineral composed mainly of zirconium silicate Pure zircon sands are colorless transparent crystals, often dyed yellow, orange, red, and brown due to different origins and impuritiesWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stageThe six main steps of iron ore processing MultotecSpecifically, it is necessary to refer to the particle size of the raw ore and equip a reasonable lithium ore crushing process Grinding Classifying: In order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and classifying process can be adopted, using ball mill + classifying machineLithium Processing Plant, Equipment JXSC MachinerySilica sand mining process equipment flow process Crushing processing sandstone sandstone crushing processing technology at present mainly has the following kinds 1, crushing process directlyIts technological process is: the run of mine ore – grizzly – jaw crusher crushing and screening to cone crushing and screening, more paragraphs to tin ore mining process Sebocom Construction