Working principle of atox vertical mill roller oil station

Hydraulic system vertical roller mill operation PDF

2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of This document is an instruction manual for operating and maintaining an Atox mill for raw meal It provides general information about the construction and Operation and Maint A4P 20 en PDFThe document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular cleaning, lubrication and visual inspectionsAtox Vertical Roller Mill, Maintenance and Repairworks were performed to investigate the influences of the design and operating parameters on vertical roller mill grinding performance In this context, systematic test plans have been INVESTIGATION OF EFFECT OF OPERATIONAL PARAMETERS ON

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table 2023年8月20日 Here's how it works: The mill's motor powers the rotation of the grinding table, causing materials to descend towards the millstone's center from the feeding inlet How Does a Vertical Roller Mill Work? YouTubeVertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in Vertical Roller Mills used for the comminution of mineral oresVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy Vertical roller mill Wikipedia

.jpg)

Roller Mill Springer

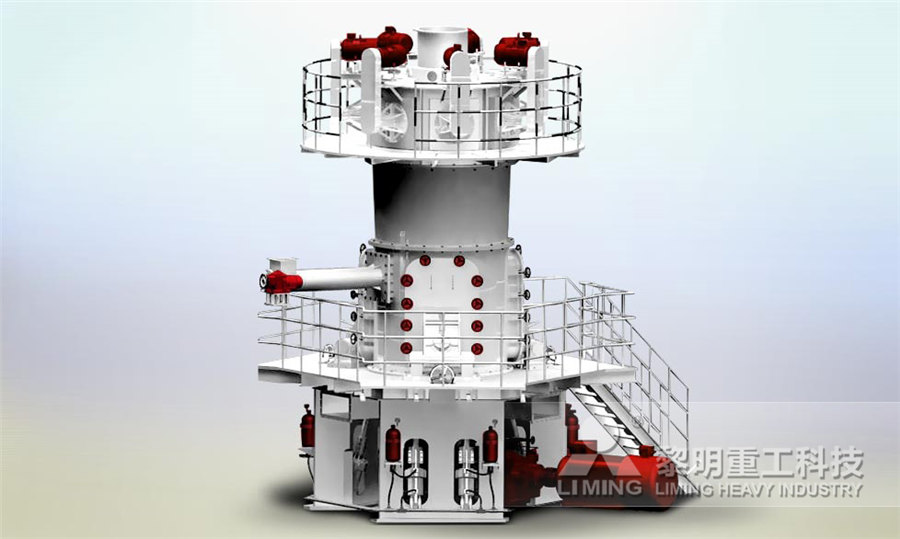

Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the air lock feeder, and the This paper proposes a performance reliability assessment method based on autoregressive integrated moving average (ARIMA) model and hidden Markov model (HMM) using the real Full article: Reliability assessment of the vertical roller mill based 2022年11月5日 This video is about the Vertical Roller Mill (VRM) In this video FLSmidth design ATOX mill has been shown Different parts of vertical roller mill shown in Vertical Roller Mill Atox Mill FLSmidth Mill tableA vertical roller mill is a type of industrial equipment used to crush or grind materials into small particles These machines consist of a large, heavyduty steel drum that relies on both hydraulic and pneumatic forces to pulverize rock or stone How Does a Vertical Roller Mill Work? The working principle of vertical roller mills is relatively How does Vertical Roller Mill Work? ball mills supplier

.jpg)

(PDF) Drives for large vertical roller mills ResearchGate

2017年1月1日 Schmitz, T: Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers Presentation 7 th International VDZ Congress 2013, 2527 September 2013, Düsseldorf/Germany2023年12月4日 When higher rolling resistance is applied due to particle shape complexity at less mill speed, more vertical force is exerted on the roller, and the roller speed is insensitive to rolling resistance This study provides the basis for further experimental investigations on industrialscale VRM and supports the design optimization of the VRMNumerical Investigation of Vertical Roller Mill Operation Using 2023年7月19日 Principle: Principle of the Triple Roller Mill Operating on the principle of shear force, the threeroll mill contains three horizontally positioned rolls These rolls rotate in opposite directions and at varying speeds relative to each other This movement allows the mill to mix, refine, disperse, or homogenize viscous materialsTriple Roller Mill: Principle, Construction, Diagram, Working, and 2024年3月13日 The working principle of the roller mill is mainly divided into two steps: 1 The material first enters the center of the grinding wheel through the feeding hopper, and is then ground into fine powder by the grinding wheel"Working principle and application of roller mill"

.jpg)

Roller Mill Springer

divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill Vertical Roller Mill The basic structure of the vertical roller mill with vertical arrangements comprises the engine body, the grinding table device, and the driving device A centering structure for determining the rotationThis document is an instruction manual for operating and maintaining an Atox mill for raw meal It provides general information about the construction and operation of the mill, including the drive station and grinding machinery The manual describes procedures for erecting, starting up, shutting down and operating the mill It also provides detailed instructions for preventative Operation and Maint A4P 20 en PDF Mill 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic Vertical roller mills ATOX® Coal Mill HiChrome Wear Segments OK™ Pro+ Ceramic Wear Segments OK™ Raw and Cement Mill Alternative fuels storage Feedex® Overhead Reclaimer OK™ Mill Working Principle FLSmidth's OK™ OK™ Mill Working Principle FLSmidth Cement

04 Vertical Roller Mills PDF Mill (Grinding) Turbine

The document discusses vertical roller mills (VRM) which are used to grind raw meal in the cement production process It describes the three main sections of a VRM as the feeding, grinding, and discharge sections Key components of a A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between Vertical roller mill ATOX® FLSmidth MAAG® 2022年4月27日 Principle The principle of the roller mill is breaking and crushing actions are achieved mechanically with the application of pressure Stress is applied by rotating heavy corrugated wheels (mullers or rollers) The oil is Roller Mill Principle, Construction And WorkingConstruction of Triple Roller Mill Triple roller mill consists of three rollers which are made up of hard abrasionresistant material; These rollers are arranged in such a way that they come very close to each other These rollers are rotated at different rates of speedTriple Roller Mill – Principle, Construction, Diagram, Working

.jpg)

Vertical roller mill DARKO

Working principle The vertical roller mill powder separator operates as an airflow classification system Maintenance of the oil cylinder, rotation of the swing arm, and replacement of roller shells and liners are more convenient, reducing downtime lossesThe document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal Millhow hydraulic cylinders work for vertical roller mills china Vertical Roller Mill Vertical roller mill Introduction The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay loesche vertical mill working principle of the hydraulic cylinder1 Introduction The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani Mohanta, Citation 2015)The equipment always needs to work in the environment of heavy load, high temperature, high pressure, high corrosiveness, electromagnetic radiation interference, and multifield Full article: Reliability assessment of the vertical roller mill based

.jpg)

Working principle of vertical roller mill YouTube

2023年7月15日 https://oreproskd/grindingmill/lmseriesverticalrollermillhtmlGrinding roller bearings are lubricated with forced thin oil, longer bearing life;Using an independent oil station,and there is an automatic protection system for oil pressure and oil temperature, which makes the whole set of equipment safe and reliable;Use hydraulic control system to apply and control its force on materials and pressure can be adjusted automatically LUM series superfine vertical roller grinding millroller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater efficiencyVertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary

Total station in surveying– Working Principle of Total

2021年3月17日 Total station is used for computing slant distances, horizontal and vertical angles, elevations in topographic and geodetic works, tacheometric surveys, etc The total station is a preeminent contribution to modern Compared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding MillThe ATOX raw mill is a compact vertical roller mill designed for grinding raw materials with several advantages: It can grind a variety of materials efficiently using minimal space Roller segments can be reversed to maximize material usage The patented toein design eliminates axial loads on roller bearings, improving reliability Segmented wear parts allow for easy replacement It Atox Mill PDF Mill (Grinding) Bearing (Mechanical)2023年12月27日 Triple Roller Mill: Principle, Construction, Working December 27, 2023 0 Comments A triple roller mill is used to mix semisolids while preparing ointments, creams, castor oil, etc Tags: construction o fTriple Roller Mill3123principle of Triple Roller Mill3123Triple Roller Mill3123working of Triple Roller Mill Silverson Mixer Triple Roller Mill: Principle, Construction, Working

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a ATOX® Coal Mill FLSmidth Cement2015年3月25日 The working principle of Vertical roller mill Slag material grinding vertical roller mill disc is composed of two parts, a small part of the new high water into grinding slag and most are The working principle of Vertical roller mill by Smile WeiLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Limestone Powder Ultrafine Vertical Roller Mill

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Working principle Three stationary grinding rollers roll on a rotating grinding table MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, Working principle of superfine vertical roller mill Guikuang Ultrafine vertical mill is an efficient grinding equipment, that adopts a vertical structure, tWorking principle of superfine vertical roller mill YouTube2023年8月5日 High pressure roller mill is a new type of grinding equipment developed on the basis of roller press for cement in recent years Mines increase the specific surface area for fine grinding The high pressure roller mill has the characteristics of high production efficiency, large crushing ratio, low power consumption, significant energy saving and convenient maintenanceWorking principle of high pressure roller millZYmining2023年11月16日 Company Introduction: CNBM Hefei Zhongya Building Material Equipment Co, Ltd is a technologyoriented enterprise with the integration of research development, engineering design, equipment manufacture and technical service, which was established by professional scientific technical personnel engaged in research of vertical mill from Hefei Vertical Roller Mill and Vertical Grinding Mill MadeinChina

.jpg)

Vertical roller mill services FLSmidth Cement

The vertical roller mill (VRM) ATOX lubrication station (228 MB) Language: English view Download ATOX Pull Rod (008 MB) Language: English view single piece rollers with oil lubricated spherical bearings ensure premium grinding capability, topofclass availability and utmost reliabilityCLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the largescale production field of nonmetallic mineral ultrafine powder processingCalcium Carbonate Ultrafine Vertical Mill SBM Ultrafine The document describes a roller mill used in the cement industry It discusses the key components of a vertical roller mill including the grinding table, rollers, separator, and material flow It explains how the mill functions to grind materials through a combination of rolling and sliding forces The document also covers maintenance needs, wear materials, operational VRM Presentation PDF Mill (Grinding) Electric MotorLM Vertical Roller Mill LM vertical mill adopts new milling devic and automatic electric control system, longer bearing life; Using an independent oil station,and there is an automatic protection system for oil pressure and oil temperature, Working Principle The main motor drives the grinding table to rotate through the reducer, LM Vertical Roller Mill, slag vertical mill, coal vertical mill

.jpg)

Vertical roller mill CEMENTL

Vertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a