Vertical ore mill model 200

.jpg)

Jet mill MC DecJet® 200 Dec Group vertical / for

The MC 200 is the next step up the scale from the MC 150 laboratory unit, suitable for micronizing up to 40kg/hr High grade materials – AISI type 316L stainless steel mirror polished to Ra 025 microns or Hastelloy Rapid cleaning LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, LM Series Vertical Mill LIMING(Shanghai)Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine 2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsVertical Agitated Media Mill scaleup and simulation

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, The Vibratory Disc Mill RS 200 is engineered for size reduction, The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed2021年7月1日 Vertical stirred mills may be classified according to the speed of the stirrer in two groups: gravityinduced or fluidized mills [[1], [2], [3]]In the gravityinduced mills, the stirrer, generally of the screw type, turns so that the grinding charge exhibits an ascending convective motion at the center, descending from the edges of the screw and close to the mill shell, owing Predicting the effect of operating and design variables in Vertical roller mill is an efficient industrial milling equipment, suitable for mass production, 180200: 250280: 325355: Feed size (mm Uses of vertical roller mill – in ore field Montmorillonite powder ultrafine grinding millVertical Roller Mill SBM Ultrafine Powder TechnologyUltrafine vertical roller mill is mainly composed of motor, reducer, grinding wheel device, roller device, Model : CLUM1425: CLUM1632 covering 200+ mining equipment SBM’s ore grinding equipment sells well all over the world with high quality and highcost performanceUltrafine vertical roller mill SBM Ultrafine Powder Technology

CLUM Ultrafine Vertical Grinding Mill

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding Superfine vertical grinding mill main machine and multirotor powder separator: Finished product 180200: 250280: 325410: Feed size (mm) <10mm <10mm <10mm: Moisture of feeding 2020年9月1日 The present work takes advantage of a mechanistic mill model originally developed for ball mills and the discrete element method (DEM) to simulate breakage in a vertical stirred mill Data from a batch mill, in which two materials were tested (copper ore and limestone), served as the basis for fitting selected material parameters, whereas the remainder were used Mechanistic modeling and simulation of a batch vertical stirred mill of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population 2014年11月1日 The model previously implemented in Modsim™ has been successfully applied to represent the vertical mill operated with different oresVertical mill simulation applied to iron ores

.jpg)

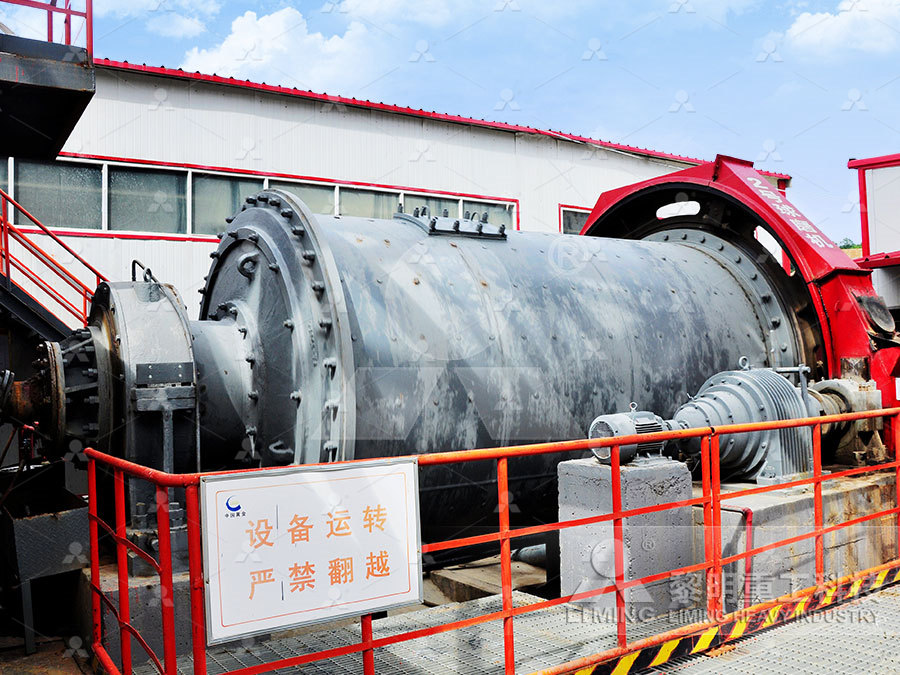

LM Vertical Roller Mill, Vertical Mill Manufacturer

Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this mill Model: 2022年10月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the (PDF) A cement Vertical Roller Mill modeling based on 2017年5月26日 ball mill model using Excel spread sheet, for an applied pressure of 200 Mpa iron ore grinding in a verticalrollermill Minerais Eng 73: 109115 [2](PDF) Application of perfect mixing model for simulation of vertical The cement raw materials (lime, silica and iron ore) enter the circuit through two apron feeders The raw materials are crushed in a hammer crusher to D95 of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D85 of 90µmModeling and simulation of vertical roller mill using population

.jpg)

News What Is Vertical Grinding Mill?

Vertical mill is an industrial mineral powder production equipment integrating five functions of heavy spar, gypsum, alunite, graphite, fluorite, phosphate rock, potassium ore, etc We are a reputable vertical mill manufacturer, please tell us your raw material, required fineness and 200325 mesh (7544μm) Vertical mill machine CLUM series ultrafine vertical roller mill is independently designed by SBM on the basis of years of experience in grinding mill production narrow particle size distribution, good fluidity, and strong product adaptability It is an ideal nonmetallic ores powder making equipment 86 180200: 250280: 325355: Feed CLUM Series Ultrafine Vertical Roller MillLM series vertical mill is an efficient grinding equipment which combines crushing ,drying, ORE MILL Model: Disc Dia (mm) Capacity (t/h) Output Fineness: Final Product Moisture: Input Size (mm) Best Input Moisture: Input Model: Disc Dia (mm) Capacity (t/h) Input Size (mm) Fineness (R008) Original Moisture of Coal: Coal Powder Moisture:LM Vertical MillGreat Wall CompanyA vertical stirred mill model, based on the Population Balance Model (PBM) technique, has recently been developed and validated using extensive data from pilot scale vertical stirred milling tests This model is the subject of this investigationVertical stirred mill scaleup and simulation: Model validation by

Regrind of metallic ores with vertical mills: An overview of the

2014年10月20日 It is important to note here that the ore that feeds the Vertical Mill has a composed of a VTM200 Vertical Mill, The sizeenergy relationships in comminution are useful models that 2017年4月1日 A vertical stirred mill model, based on the Population Balance Model (PBM) technique, several representative samples of 100 g of each stream were sieved until 200 the ore breakage parameters determined from the batch mill test results, classification parameters from a mass balance around the hydrocyclones, Vertical stirred mill scaleup and simulation: Model validation Vertical stirred mill is a fine grinding equipment that covers advantages of low rotation speed, The above table is based on that 60 percent of feed particles are in minus 200mesh size, the grind fineness of 80 percent is minus 400 Vertical Stirred Mill Mineral Processing EquipmentAs the vertical roller mill works, We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results 3Required capacity (t/h)? Maximum feeding size: 50mm; Capacity: 10150t/h; Fineness: Best HLM Vertical Roller Mill Manufacturer and

Analysis and Optimization of Grinding Performance of Vertical

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersMain reducer for MLX280 cement vertical mill used for 4,000T/d cement production lines of Lafarge Yunnan Dongjun Cement Plant, supporting FL Smith OK334 vertical mill Main reducer for MLX200 cement pregrinding vertical mill used for Zhejiang Jinshou Cement Co, Ltd, supporting CKP vertical mill of KawasakiMLX Vertical Mill Gearbox China TAILONG DECELERATOR2020年9月1日 A vertical stirred mill model, based on the Population Balance Model (PBM) technique, has recently been developed and validated using extensive data from pilot scale vertical stirred milling testsMechanistic modeling and simulation of a batch vertical stirred mill 2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

.jpg)

(PDF) Performance Comparison of the Vertical and ResearchGate

2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16Limestone ultrafine vertical mill is a high quality ores material powder grinding mill Limestone ultrafine vertical mill are suitable for huge capacity producing, 180200: 250280: 325410: Feed size (mm) <10mm <10mm <10mm: Moisture of feeding material <3% <3%Limestone Ultrafine Vertical MillSBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 [ protected] copper and other minerals These powders are then used in various applications such as ore processing and metallurgy Model: CLUM Payment methods: Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Calcium Carbonate Ultrafine Powder Vertical Millof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population

.jpg)

LM Vertical MillGreat Wall Company

LM Vertical Mill LM series vertical mill is an efficient equipment which combines crushing ,drying, milling , separating and transporting together It is wildly used in field of cement, metallurgy, electricity, chemical,ceramics, glass, nonmetal Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill 2015年3月10日 Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchers Investigating the firstorder flotation kinetics models for Sarcheshmeh copper sulfide ore International Journal of Mining Science and Technology, Volume 25, Issue 5, 2015, pp 849854Copper ore grinding in a mobile vertical roller mill pilot plantUltrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, 180200: 250280: 325355: Uses of ultrafine vertical mill – in ore fieldUltrafine Vertical Mill

Calculating breakage parameters of a batch vertical stirred mill

2017年9月1日 The present work takes advantage of a mechanistic mill model originally developed for ball mills and the discrete element method (DEM) to simulate breakage in a vertical stirred mill Data from a batch mill, in which two materials were tested (copper ore and limestone), served as the basis for fitting selected material parameters, whereas the remainder were used The vertical roller mill integrates crushing, drying, grinding, Machinable materials: nonmetallic ore with Mohs hardness less than 6 Such as limestone, calcium carbonate, marble, carbon black, dolomite, diatomaceous earth, and so on 180200: 250280: 325355:Dolomite Ultrafine Vertical Roller MillVertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden The Boliden area concentrator processes approximately 18 Mt/yr ore and 200 kt/yr slag The Boliden Area concentrator has three processing Vertical Roller Mills used for the comminution of mineral oresThe model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treated(PDF) Operational parameters affecting the vertical roller mill