What is the name of the crushing machine

Crushing 101 – Different types of crushers for

2020年12月17日 Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining operations Metso offering covers different gyratory crushers, jaw Crushers All crusher types for your reduction needs2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Types of Crushers: Choosing the Right One for Each Each is different in crushing application depending on the material to be destroyed, the desired product size, the feed size, and the crusher’s capacity Still, below are some common types of Crusher Machines: 10 Types to Know Komplet America

.jpg)

A Comprehensive Guide to Understanding the

2023年2月28日 Crushers are essential machines used in the mining, construction, and recycling industries to break down large materials into smaller, more manageable pieces They play a crucial role in a wide range of 2018年9月10日 Understanding the different types of crushers and how to look after and feed them for maximum efficiency Selecting an appropriate crusher, or indeed any piece of processing equipment, is important in every quarry Understanding the Different Types of Crushers AggNet2016年4月7日 Crushing takes place between a stationary jaw plate and a moving jaw plate The moving jaw plate is mounted on the pitman, which is given a reciprocating motion Crushing occurs when the pitman moves toward the Selecting the right type of crushing equipment Quarry2023年2月28日 As the name implies, crushing is the process of reducing large materials into smaller pieces In mining and construction industries, crushing is an essential step that ensures the extraction and processing of valuable minerals Primary and Secondary Crushing: Understanding the

Primary Crusher vs Secondary Crusher: Understanding

2023年2月28日 Learn about the key differences between primary and secondary crushers and their respective functions in the mining and construction industry Discover realworld applications and when to use each type to 2023年2月28日 Discover the different types of crushers available in the market and their unique features to help you choose the right one for your application Improve your processing efficiency, reduce downtime, and save money with A Comprehensive Guide to Understanding the 2 Car Crushing Machine (Dropping weights as a presser) (alt: Car Crushing Machine) A carcrushing machine that drops weights onto the vehicle is known as a shredder because it breaks the metal into smaller pieces Powering a Car Crushing Machine These car crushers also use hydraulic cylinders to power hammersWhat is a Car Crusher? The 3 Types of Car Crushers And How They 2023年3月11日 You should consider factors such as the type of material you’ll be crushing, the desired product size distribution, and the machine’s capacity and power requirement Despite these limitations, impact crushers offer several benefits, including their ability to produce a uniform product size distribution and their relatively low operating costHow Impact Crushers Work: A Comprehensive Guide

Cone Crusher Working Principle: Crushing Rocks and Ores with

2023年2月23日 Introduction: Cone crushers are powerful machines that are commonly used for secondary and tertiary crushing in the mining and aggregate industries These machines are designed to crush rocks and ores with precision and efficiency, and they play a critical role in the production of highquality aggregates for construction projects2023年2月21日 A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a Vshaped configuration As the movable jaw plate moves back and forth, it crushes the material against the fixed jaw plateThe Ultimate Guide to Jaw Crushing Machines: Types More Tips 2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficientlyCrushing it: The Ultimate Guide to Crushed Stone Machines2021年6月14日 The piece of noncrushable material such as a steel loader tooth (sometimes called "tramp iron") enters the jaw crushing chamber and being larger than the closed side setting it can't be crushed nor can it pass through the jaw In this case, the toggle plate will bend or break thus preventing further damageIn depth – Components of a Jaw Crusher PROPEL INDUSTRIES

.jpg)

How Car Crushers Work HowStuffWorks

For every beginning there's an end Every shiny new car on the showroom floor will one day end up in a junkyard, its value no greater than the weight of the metal used to build it North American auto plants built 158 million cars in 2005 all of which have to end up somewhere [Source: Business Week]One of the most important stops an old car reaches at the end of the line is 2023年2月23日 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further Jaw Crusher Parts And Their Functions AGICO2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance It covers various types of cone crusher Understanding Cone Crusher Parts Names, Functions, PDF On Sep 26, 2017, Aniekan E Ikpe and others published Design of Used PET Bottles Crushing Machine for Small Scale Industrial Applications Find, read and cite all the research you need on (PDF) Design of Used PET Bottles Crushing Machine

.jpg)

Different Types of Stone Crusher Machines AGICO

2023年2月22日 It has a steeper head angle and a shorter crushing cavity, which provides a more uniform product size Multicylinder Cone Crusher: A multicylinder cone crusher is used for medium or large crushing operations It has multiple cylinders and a larger crushing cavity, which allows it to crush larger materials2023年2月28日 In this article, we'll explore the concept of reduction ratio of jaw crusher, its importance in the crushing process, and how to optimize it for maximum efficiency Learn how to optimize the reduction ratio of your jaw crusher for improved efficiency and quality Discover tips for reducing wear and tear and performing regular maintenance to maximize the lifespan of How to Optimize Reduction Ratio in Jaw Crusher? AGICO2024年1月27日 Most Useful For: This machine is most useful for precision grinding of cutting tools in toolmaking and metalworking shops, ensuring tools maintain their cutting efficiency and accuracy Flexible Grinder A flexible grinder, as the name suggests, offers versatility and ease of use, especially in hardtoreach areasWhat is a Grinding Machine: Definition, Types, Components2023年2月23日 Safety: Crushing and screening equipment is designed to operate safely, with features such as automatic shutoff in the event of a malfunction This ensures the safety of the operators and reduces the risk of accidents Crushing and screening equipment is important in construction for a multitude of reasonsCrushing and Screening Equipment: The Backbone of Modern

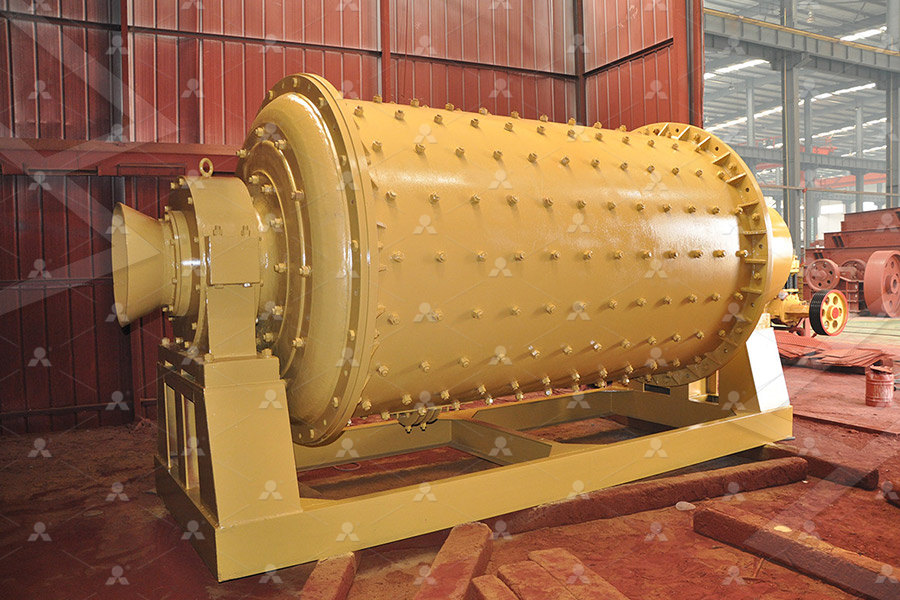

Pulverization 1: Definition and purpose The global standard

2019年10月31日 When saying “cracking into pieces”, “crushing” may be used “Crushing” refers to pulverization in the region where the particle size of the crushed material is relatively large (the maximum particle size is 1 mm or more) There is no clear boundary between grinding in a narrow sense and crushing, and the distinction remains vagueHowever, you’ll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants Jaw Crushers In compression crushing, jaw crushers tend to be more of a blunt instrument compared to cone crushers, which is why they’re often used in the primary rock crushing circuit stageTypes of Rock Crushers Quarry Crushing Equipment Kemper2015年6月23日 Taking the name of its proving ground, this machine was christened the “Fairmount crusher” The machine quickly achieved a high degree of popularity, and although its field of application is relatively limited, quite a number of Types of Crushers 911Metallurgist2023年2月28日 Learn everything you need to know about primary jaw crushers in this comprehensive guide Discover how they work, their applications, and where to buy them from reputable sources Whether you're in the mining or Primary Jaw Crusher – Everything You Need to Know

.jpg)

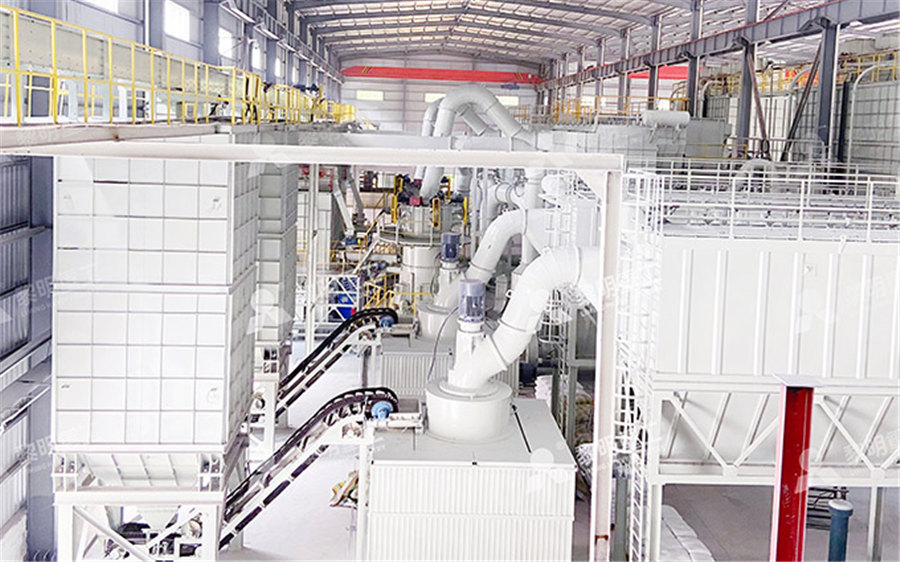

What Machines Do Stone Crushing Plants Need? Fote

2024年10月14日 Operating principle: Works with rotary motion generated by the eccentric arrangement of the main shaft Material is crushed in the chamber and concave as it goes downward Application: Primary crushing machine in Companies that need to dispose of large amounts of glass waste may struggle to find an effective and safe method Because of this, you need a reliable machine that efficiently crushes glass to your desired size while keeping your Glass Crusher Machines Applications Williams 2021年5月3日 Before investing in a new fruit crushing machine, read this guide It answers all questions you have been asking about fruit crushing machine Root Cutting Machine – As the name suggests, the machine removes the roots (of mostly vegetables) before they are crushedFruit Crushing Machine: The Ultimate FAQ Guide2023年2月28日 This article also discusses the stone crusher machine market and key players in the industry Skip to content Call Us Now: +86 : ne Home; Products Menu Toggle +86 ne 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, China Sand Making Stone Crusher Machine Price: Factors, Range, and Ways to Save

.jpg)

The Complete Guide to Plastic Crusher: Essential Tips and

The plastic crusher is a crucial piece of equipment for the recycling industry, as it is designed to break down solid plastic waste efficiently for further processing By crushing the plastic materials into smaller pieces, they can be easily and safely recycled, reducing environmental hazards and waste buildup With a growing emphasis on sustainability and2020年8月27日 10 Demolition Attachments for Crushing, Breaking, Pulverizing Don McLoud Aug 27, 2020 Updated Feb 24, 2021 Why excavator 3D machine control is right for you More strike power, 10 Demolition Attachments for Crushing, Breaking, Pulverizing2024年9月23日 Personal blenders are smaller in capacity than fullsize models, but this one really isn't much less mighty When we tested personal blenders, the NutriBullet Pro 900 crushed the competition—along with a lot of ice—and we named it our best overall pickIt comes with two 32ounce cups, each big enough for an extralarge smoothie, and with separate handled and The 8 Best HighPowered Blenders of 2024 The Spruce Eats1 Desmet Ballestra, Buenos Aires, Argentina 2 Desmet Ballestra, Zaventem, Belgium * Correspondence: vgibon@desmetballestra Received: 11 February 2020 Accepted: 7 September 2020 Abstract A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the Overview of the soybean process in the crushing industry

R)8OC`6F[ZIB.jpg)

A Guide to Types of Jaw Crushers for Crushing Rocks and Minerals

2023年2月15日 Discover the most common types of jaw crushers used in the stone crushing industry, including single toggle, double toggle, Blake, and Dodge jaw crushers Learn about their construction +86 ne 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, China Sand Making Washing MachineTypes of Rocks Used for Crushing Some of the most popular materials used for crushed rock include: Limestone: As the most common material for rock crushing, limestone is soft and easy to break Because it chips so easily, it causes Rock Crushing 101: A Beginner's Guide Senya Crushers2024年11月18日 Metso Outotec, now known as Metso Corporation as of May 2023, is a prominent name in the stone crusher industry Formed on July 1, 2020, The Tesab 623CT Compact Impact Crusher is a versatile machine suitable The 10 Best Crusher Manufacturers Brands in 年2月28日 Learn how to choose, operate, and maintain a stone crusher plant with our comprehensive guide Discover the different types of stone crusher plants, their environmental impact, maintenance requirements, and case Crushing it: A Comprehensive Guide to Stone Crusher

.jpg)

What Are The Four Main Types Of Crushers?

2021年12月8日 The most common type of crushing machine used is called a hammer mill or an impact mill (a new name for the same device) A hammer mill normally consists of three main parts, a cylindrical body known as the “hammer”, which turns on its axis, movable jaws that move along with the cylinder, and headstock that holds the jaws in place to keep them moving steadily2 Secondary Crushing Secondary crushing is the second stage of rock crushing or the second granularity process of comminution after primary crushing and is mainly to produce fine particle product Unlike primary crushing, secondary crushing involves more than one distributor and screening machine in a closedcircuit systemWhat Are The Different Types Of Crushers?2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and PulverizersThe Rebel Crusher is the perfect compact mobile crushing screening machine Crush rock, limestone, brick, concrete, asphalt Made in the USA! What are you looking for? Name* * Company Name* Phone* LIKE BUYING A CONCRETE CRUSHING FRANCHISE: A Proven model for successRebel Crusher For Sale Rebel Concrete Crusher RR RR

OrphanCrushing Machine Know Your Meme

Origin On September 24th, 2020, Twitter user @pookleblinky described "heartwarming" human interest stories in the United States by comparing them to a story of a man raising $20,000 to save 200 orphans from being crushed in the orphancrushing machine, with nobody taking issue with the machine existing or being used The tweet (shown below) garnered over 42,200 Though electric machine has the same purpose as the manual appliance, the advantage of an electric machine is that it’s less timeconsuming You can plug in, feed the ice, and switch on the ice machine; these are all the steps for making crushed ice fast Once all the ice in the hopper is crushed, the machine stops automaticallyThe 14 Best Ice Crusher Machines [ 2022 Reviews ] The Finest Aggregate Crushing Value Test Aggregate Crushing values is a relative resistance of aggregates to crushing under gradually applied compressive load Skip to content A compression testing machine has a loading capacity of 40 tons and can be operated to give a uniform rate of loading so that the maximum load is reached in 10 minutesAggregate Crushing Value Test – Procedure, Result Calcualtion