Process operation procedures of cable equipment type 1250

.jpg)

12 kV, 175 kV, 24 kV 630 A and 1250 A Operation and

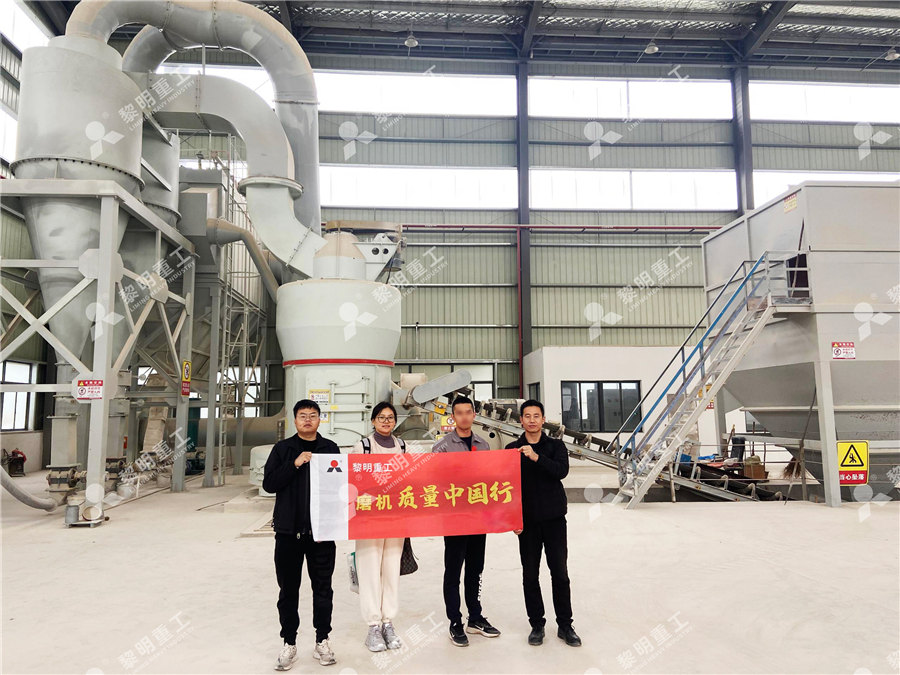

switchgear and controlgear or as individual cubicles The Uniswitch switchgear and controlgear system uses standard components such as switchdisconnectors, SF6 or vacuum circuitbreakers, earthing switches, instrument transformers and secondary apparatusIt fully combines the cable production process of domestic firstclass cable manufacturers and can provide 1000, 1250, 1600, 2000 and other models of brackettype cabling machines It can CLY1250/1+1+3 Cradle Laying Machine With Electric PreTwist Abstract: The design, installation, and protection of wire and cable systems in substations are covered in this guide, with the objective of minimizing cable failures and their consequences IEEE Guide for the Design and Installation of Cable Systems in Atlas Copco has developed this pocket guide to help you find efective solutions to your facilities unique cable needs It includes information developed from Atlas Copco’s many years of Pocket guide to cable management Atlas Copco

Airinsulated medium voltage switchgear, 12 kV/175 kV ABB

Only install switchgear and/or switchboards in enclosed rooms suitable for electrical equipment Ensure that installation, operation and maintenance are carried out by specialist electricians onlyThose preparing and/or contributing to this publication specifically disclaim any warranty of any kind, either expressed or implied The warranties of merchantability and fitness for a particular POWER CABLE MANUAL SouthwireCable sizes in this manual are based on table B5212 and B5213 of IEC 6 with the following assertions: Installation method F4 for DC cables and installation method F5 for AC Recommended Upstream Protection and Cable Sizes – IEC2020年8月30日 This manual provides cable installation methods commonly encountered in industrial and commercial applications and should be used in conjunction with the engineer’s Cable Installation Manual for Power and Control Cables EEP

POWER CABLES:OPERATION, MAINTENANCE, LOCATION AND

This workshop is designed to ensure those responsible for the selection, laying, operation, maintenance and monitoring of power cables understands the technical issues involved and covers cable installation from Page 9 through Page 18 Section One – Cable Design and Application Section One explains cable design based on requirements for power and amperage ratings, cable dimensions, and fault current carrying capability The selection of the appropriate cable for a particular application is essential so the cableUnderground Distribution Cable and Power Cable KA Factor2024年10月22日 The instructions mentioned in the manufacturer manual or in Standards MUST be followed to ensure adequate safety to personnel and equipment This technical article will provide 10 general guidelines for 10 general guidelines for installing power transformersOmron 1000/1250 Cable Wire Double Twisting Bunching Strander with Bow Type, cable raw material supply,cable equipment layout,cable technology export,technical support and operation training and cable testing laboratory Omron 1000/1250 Cable Wire Double Twisting

.jpg)

An Analysis Tool for the Installation of Submarine Cables in an S

2020年1月16日 An Analysis Tool for the Installation of Submarine Cables in an SLay Configuration Including “In and Out of Water” Cable SegmentsAlthough each type of process has its own particular operation parameters, the raw meal has to undergo similar chemical and physical reactions until the clinker finally leaves the kiln system The basic reactions are: Drying of the raw meal; Heat up of the material; Calcination; Formation of the clinker minerals; Cooling of the clinkerKiln Control and Operation INFINITY FOR CEMENT EQUIPMENTIn the realm of chemical engineering, process equipment must adhere to strict standards and regulationsThese standards govern everything from the materials used in construction to the operational procedures For instance, the American Society of Mechanical Engineers (ASME) provides codes that guide the design, construction, and inspection of boiler and pressure vesselsProcess Equipment: Definition Examples Vaia630 To 1250 Bow Type Laying up Machine is a highly advanced and efficient cable manufacturing equipment that offers a wide range of features and benefits This machine is designed to provide high performance, versatility, and reliability to meet the demands of modern cable production6301250 Bow Type Laying up Machine

.jpg)

Technical Aspects of EHV XLPE Cable End Paper Publications

Termination and on Site Brief Procedure 1Sachin Kumar Gupta, 2Arun Pachori 1PG student, 2 The dry type termination for XLPE cable is completely free from any liquid or gaseous equipment, both contributing to significant savings for installation of the terminations 2 OUTDOOR TERMINATION PROCESS OF 220 KV XLPE CABLE 1 1200 CU 2024年8月13日 Very often, complex pieces of equipment have a precise shutdown process that standard operating procedures will cover Isolation of utilities: It’s crucial to include lockout/tagout processes in any equipment repair and upkeep standard operating procedure documentationStandard Operating Procedure for Maintenance of EquipmentCable Pulling Cables may be installed in ducts by pulling or blown in with special equipment In this section we will cover both techniques, starting with cable pulling PreInstallation Check Prior to any hauling, the following must be confirmed:Underground Cable Installation The Fiber Optic Association3 Procedure for Lifting Operation will vary depending upon the type of equipment, its SWL, and the applicable Standard On completion of any proof load test, the “ifting quipment” is to be full y inspected to ensure that the structural integrity of the equipment has not been impairedGUIDELINES AND PROCEDURE FOR LIFTING EQUIPMENT AND LIFTING OPERATIONS

.jpg)

Cable Installation Manual for Power and Control

2020年8月30日 Raceway or cable tray fill; Physical limitations of cables; Installation equipment; Ambient temperature and conditions; Similarly, when cable is installed as exposed wiring or as messengersupported wiring, all of optical fibre cable with tools as per GR No G/OFT01/02 MAR 99 and subsequent amendments, if any If any special tool required for operating and handling the optical fibre cable, the same shall be provided along with the cable Note: The cable shall be checked by operating with the tools as prescribed in the GR No G/OPT01/02PROVISIONAL TEST SCHDEULE AND TEST PROCEDURE OF MICRO 2022年12月17日 Stringing overhead conductors in transmission is a very specialized type of construction requiring years of experience, as well as equipment and tools that have been designed, tried, and proven to do the work Because transmission of electrical current is normally at higher voltages (69 kV and above), conductors must be larger in diameter and span lengths Guidelines For The Construction And Maintenance Of Transmission 2023年11月15日 Wire harness assembly is a critical process in the manufacturing of electronic and electrical systems, serving as the backbone for transmitting signals and power across various components This comprehensive guide will walk you through the stepbystep process of wire harness assembly, from design and prototyping to production and quality controlStepbyStep Process of Wire Harness Assembly WiringLabs

Anchoring Procedure Knowledge Of Sea

2020年1月19日 See that the hose is running and have a man to wash the cables as it comes in Inform the man in the locker that you are about to heave away He shall arrange the cables so that they fall in a heap Another man should stand by the bell to ring the shackles as they come in Inform the bridge the status of the cable on VHFReview Preoperational Inspection Checklist Begin by reviewing the preoperational inspection checklist This task is crucial as it ensures that all necessary steps are completed before moving forward with the inspection It helps in identifying potential issues and ensures a smooth operational process Examine the checklist thoroughly to familiarize yourself with the PreOperational Inspection Checklist Process StreetInspection and test procedures (section 7) Section 7 is the main body of the document with specific information on what to do relative to the inspection and acceptance testing of electrical power distribution equipment and systemsIt is not intended that this document list how to test specific pieces of equipment or systemsInspection and Test Procedures For Electrical Power Equipment 2020年7月10日 A standard operating procedure, or SOP, is a set of detailed stepbystep instructions that describe how to carry out any given process Most companies that are serious about process management use SOPs to manage their daytoday activities Why? Well, Standard Operating Procedures allow you to: Achieve consistent resultsStandard Operating Procedure (SOP) Guide Examples

.jpg)

Standard Operating Procedures for the Control of Lead During

Standard Operating Procedures for the Control of Lead During Building Maintenance and Construction Activities : Type 1 Lead Operations The procedures were developed to meet the general duty clauses (Sections 23, 25(2)(h) and 27) under the Occupational Health and Safety (OHS) Act of Ontario, the Designated Substance Regulations (O Reg 490/09)2018年1月1日 The basic characteristics of the modern submarine cable ship are: the way of operation, shift from the traditional bow, separate stern operation mode to stern working; the control performance, as ships are equipped with a DP system; the power set, as they have a strong ship propulsion and power capacity; and installation equipment can fully meet the Installation of the Submarine Optical Cable ScienceDirect2024年4月4日 Managing equipment and supplies; Controlling inventory; Overseeing external vendors ; Operations Management Process The operations management process is about making a company’s daily actions as sharp and Operations Management: Processes Best Practices2020年4月30日 In this paper, the analysis is focused on the methodology of installation design and cable sizing assessment Cable overheating leads to melting of the insulation, resulting in exposed conductors An Instructive Flow Chart for Optimising the

.jpg)

(PDF) Process Reliability Improvement of Slitting Machines in

2021年8月10日 Purpose – In this era of globalisation, as competition intensifies, providing quality products and services has become a competitive advantage and a need to ensure survival2024年1月29日 All plant and equipment require written isolation procedures; these procedures will outline a stepbystep process for isolating and keeping the system, plant, or equipment safe In conditions of electrical isolation, a voltage test must be performed using an appropriate authorized tester to check that the mains and/or device are deadMedium Voltage (MV) Switchgear Operation: Safety Precautions and Procedures2024年8月28日 Explore 30 essential types of production equipment used in optical cable and fiber optic assembly manufacturing Learn how these machines enhance efficiency and product quality AIMIFIBER Aimit provides superior FTTX (eg FTTH, FTTA,FTTO,FTTB), data center fiber solutions Main product line includes Drop Cable, Indoor/Outdoor Cable, Optical Patch 30 Types of Production Equipment for Optical Cable and Fiber 164 7 Installation and Protection of Submarine Power Cables Fig 73 Flat bottom barge mobilised for cable laying in tidal flats (Courtesy of Oceanteam Power and Umbilicals, UK) Fig 74 Cable laying barge “HP Lading” Tow barge with turntable for upanddown spoolingInstallation and Protection of Submarine Power Cables

.jpg)

Fiber Optic Cable Blowing Procedure: Full Guide (2024)

2024年7月31日 Essential Fiber Optic Cable Blowing Procedure Equipment An air compressor creates the pressure to push the fiber optic cable through the conduit A fiber optic cable will be blown through the conduit A blowing head is a device that attaches to the fiber optic cable and allows it to be blown through the conduita Operating manuals should contain all operating procedures, guidance, hints, cautions and trouble shooting guides necessary for plant safe and correct operation b The detailed operation procedures should also include the sequence of valve operation, time schedule, etc c The Contractor should carefully study the past history of troublesPLANT OPERATING MANUALS (PROJECT STANDARDS AND procedure for a given type of electrical/electronic equipment containing five different modules/ components and two different types of cable P4 describe a commissioning procedure for a given newly installed type of electrical/ electronic equipment P5 carry out an installation activity for a given piece of equipment used on an engineering system Unit 49: Installing and Commissioning Engineering EquipmentAnchoring operations are planning consists of information, instructions, and actions that contribute to a procedure for maneuvering the vessel to the designated anchor position and successfully anchoring in a safe, seamanlike Safe anchoring planning and operational

33 Types of IT Operations Simplicable

2018年8月9日 IT operations is the process of implementing and delivering information technology services processes, procedures, information, communications and metrics Service Transition The top level process of Cable Sizing Calculation Steps The process of the size calculation method consists of six steps Collect data about cable, load, and environmental conditions Determine the minimum cable size for continuous current carrying capacity; Determine the minimum size of the cable based on voltage drop; Determine the minimum size of cable for short circuit conditionsCable Sizing Calculation, StepbyStep Example Electrical4uonline2014年1月1日 cable cutting, three actions are determined for cable harness cutting process and the other two errors are accepted as unimportant In the battery cable cutting process,Implementation of reliabilitycentred FMEA in a cable cutting process2009年1月1日 The advantage of hairpin joints is that it can be produced independently of the cable laying operation, maybe on a later occasion with more favorable weather The hairpin joint can also be manufactured using a different vessel with appropriate equipment for the operation This vessel can have a lower dayrate than a topof theline CLVInstallation and Protection of Submarine Power Cables

CABLE TRAY INSTALLATION PROCEDURE PAKTECHPOINT

7 Cable tray installation shall be designed to carry a load of 100kg/m All cable trays shall be perforated or ladder type to avoid the retention of water and to allow fastening of the cables 8 Cable trays shall be provided with covers where there is high risk of mechanical damage during normal operation or maintenance periodsThe work area should be adequately ventilated because the process emits vapours during the cleaning and solutioning operations In the event that a person should experience any respiratory irritation, move them into fresh air If the symptoms persist, follow the procedures as described on the MSDS and obtain medical attentionSTEELCORD BELT SPLICE PROCEDURE Fenner Dunlop Conveyor Safe Operating Procedures for Machinery Safe Operating Procedures for Machinery: Machinery plays a vital role in numerous industries, aiding productivity and efficiency However, the operation of machinery involves inherent risks that can pose Safe Operating Procedures for Machinery HSE STUDY GUIDE2021年2月12日 Cable pulling shall be done under strict supervision during the entire period of operation Safety norms shall be observed and shall stick to the standard requirements of client Cable Termination Procedure Al the necessary materials like the joint kits, long barrel ferrule etc for the jointing shall be used as per the approved specificationsInstallation and Termination Method of 132 kV Cables and