Zinc concentrate powder processing cost

The Extractive Metallurgy of Zinc AusIMM

Chapter 21 – Costs and Economics of the Electrolytic Zinc Process 265 Purpose and Basis 265 Capital Costs 265 Direct Operating Costs 268 Metal Pricing 270 ByProducts 271 Smelter Economics 272 Capacity Limitations and Incremental Expansion 年11月5日 China Zinc Smelters Purchasing Team (CZSPT) has set domestic processing fees for zinc concentrate at between 2,000 yuan ($28157) a metric ton and 2,500 a ton for the China zinc smelter group sets processing fees for Q1 年4月9日 The processing fee that Canadian miner Teck Resources will pay smelter Korea Zinc to convert its concentrate from Red Dog mine in Alaska, the US, into finished metal is Zinc benchmark TCs settled at $165/t; down nearly 40% yoy on 2024年11月7日 China's Zinc Smelter Purchasing Team (CZSPT) has set the domestic processing fees for zinc concentrate at between 2,000 yuan ($28157) and 2,500 yuan per China's Zinc Smelter Purchasing Team Sets Processing Fees Amid

woodmac Zinc Lead Mines Cost Service

Zinc Concentrates Service woodmac Obtain a complete picture on zinc concentrate supply, from mine to smelter production Use it to: Develop detailed zinc concentrates supply and Metso Outotec has a proprietary leaching method for zinc concentrate This highly costefective and environmentally friendly process has been proven on an industrial scale at several zinc Hydrometallurgical Zinc Plants and Processes2023年4月13日 This year's benchmark treatment charge, the fee a smelter earns for converting mined concentrates into metal, has been set at $274 per tonne, up from $230 in 2022 and $159 in 2021Zinc treatment charges jump after 2022 smelter Monitor monthly Zinc price assessments covering 4 locations: United States, Europe, Southeast Asia and China Also check Zinc 10year price history and forecasts The chart below is a sample of Intratec Primary Commodity Prices Zinc Prices Current and Forecast Intratecus

Zinc Concentrate and Processing Trends

Within a few years, such fine concentrates will account for up to 1 000 000 t/y of contained zinc New processing technologies including novel transport methods, siliceous leach circuits, content, demand long process duration, high cost, and other problems; (3) the reverberatory furnace roasting labor intensive and energy inefficient The zinc concentrate powder wasMicrowave absorption and roasting characteristics of zinc sulfide sources available, ensuring Skorpion Zinc remains a low cost zinc producer in a volatile market and economic climate Important considerations for a suitable process for Skorpion Zinc are: A process with more favorable economics will be preferred This implies low operating and capital cost with high zinc recoveryEVALUATION OF PROCESSING OPTIONS FOR THE TREATMENT OF ZINC Zinc concentrate is similar to powder in that it is made up of minute, dry particles of pure substance Concentrate is also useful in any application where high surface areas are desired such as water treatment and in fuel cell and solar Zinc Concentrate ALTech GROUP

.jpg)

Evaluation of processing options for the treatment of zinc

Although it has not been commercialized to process zinc concentrates, the Geocoat process was applied at the Agnes Mine (Barbrook, Barberton, South Africa) to leach refractory gold concentrates This mine has ceased operation Some other projects are also under evaluation but not implemented yet Harvey et al (2002) reported 95% recovery from 2016年3月12日 ZINC CONCENTRATE MARKETING As previously stated, zinc, Base charges for zinc concentrates are very high, comparatively speaking, on account of the cost of the process, particularly the item of fuel, which is usually gas Lump or powder 3c to 8c/lb Quartz:Mineral Concentrate Marketing – Treatment Charges PenaltiesZinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation methodThere are two methods of smelting zinc: the pyrometallurgical process and the hydrometallurgical process (over 90% of hydrometallurgical Zinc: smelting, producing and classificationMetalpedia2021年10月1日 The jarosite process was developed in the 1960s and is nowadays the most important way for the removal of iron from zinc leach liquor Jarosite is a basic iron sulphate with the general formula XFe 3 (SO 4) 2 (OH) 6 whereby X can be represented by monovalent cations such as K +, NH 4 +, Na +, Ag +, H 3 O + or 1/2 Pb + (Bayliss et al, 2010)Jarosite A comprehensive review of processing strategies for iron precipitation

Zinc Concentrate Efe Chartering

Zinc Concentrates – When shipped in bulk may be subject to loss in weight and liquefaction; see also Concentrate (of Minerals) The presence of chlorides reduces the value of the concentrates and contact with sea water results in the deterioration of value Zinc ores contain 515% zinc To concentrate the ore it is first crushed and then ground to enable optimal separation from the other minerals Typically, a zinc concentrate contains about 55% of zinc with some copper, lead and iron Zinc concentration is usually done at the mine site to keep transport costs to smelters as low as possibleProduction Zinc IndiaWhile challenging for zinc powder suppliers, the lower prices potentially benefited pharmaceutical manufacturers and other downstream industries relying on zinc powder as an input However, the prolonged price pressure raised questions about its longterm impact on research and development investments in the zinc processing sectorZinc Prices, News, Monitor, Analysis Demand2021年8月21日 The dielectric properties and thermal behaviors of zinc sulfide concentrate and ZnS, CaO, MgO, ZnO, FeS, and ZnFe2O4, covering a temperature range of 25 to 1000°C at 245 GHz, are systematically Microwave absorption and roasting characteristics

Critical review on secondary zinc resources and their recycling

2020年6月17日 As far the lowgrade Zn, they have much difficulty in mineral processing, high mineral processing costs, low utilization ratio (50–60%) and a serious waste of the resource (Yanbo and Xia, 2016) There is no economic and environmentally friendly technology yet to directly treat the lowgrade Zn oxide ores/wastestreatment of zinc concentrates to produce a highpurity, oxide fume and low zinc content, the high cost of autoclaves employed by this process have limited its application [4]The Outotec Direct Zinc Smelting Process ResearchGate2013年5月1日 Skorpion Zinc, an integrated zinc mine and refinery located in the south of Namibia, has a production capacity of 150 000 t/a of special high grade (SHG) zincEvaluation of processing options for the treatment of zinc process for zinc extraction [711], to a large extent for low grade and mineralogically complex concentrates [1214] Direct leaching processes can be divided into two categories, zinc pressureAtmospheric curing of zinc sulfide concentrate by ResearchGate

.jpg)

Common Basic Formulas for Mineral Processing Calculations

2016年3月21日 (1) a lead concentrate, (2) a copper concentrate, and (3) a zinc concentrate It can be readily appreciated that an accurate comparison of several tests on an ore of this nature would involve a large number of factors, and that mathematical formulas to solve such problems would be unwieldy and useless if they included all of these factorsThis research has been done to study and diagnose operational factors and conditions affecting the zinc powder specification and efficient performance of the electrochemical process The selection of the optimal conditions for the powder preparation at an average particle size up to 100 μm will be investigated with high productivity and efficiencyThe results indicated that the (PDF) Processing of Zinc Calcine AcademiaSECTION 1 IDENTIFICATION Product Name: Zinc Concentrate Product Number: All applicable American Elements product codes, eg ZNM02CONC , ZNM03CONC , ZNM04CONC , ZNM05CONC , ZNM06CONC CAS #: Relevant identified uses of the substance: Scientific research and development Supplier details: American Elements 10884 Weyburn AveZinc Concentrate American ElementsRed Dog Zinc Concentrate Revision Date: 08/21/2024 Page 1 of 10 Section 1 Identification The handling, shipment, storage and processing of this material requires appropriate controls and care to prevent spillage or gradual accumulation in the terrestrial and aquatic environments finegrained powder Odor Weak organic odour from entrainedSafety Data Sheet Red Dog Zinc Concentrate Section 1

Atmospheric curing of zinc sulfide concentrate by sulfuric acid

2022年1月1日 Using 037 M EDTA at 80 °C, 1/10 solidtoliquid ratio for 180 min leaching time, more than 90% of zinc dissolved along with a substantial amount of iron, arsenic and lead codissolutions 474% 2020年1月25日 Despite the beneficiation process that usually takes place in the mine sites and aims to reduce impurities , concentrating the zinc and reducing logistics costs, the Zn concentrate contains several impurities (averaging 15% of the concentrate mass)Simulation of an Alternative Direct Leaching Process for High Imperial Smelting Furnace (ISF): Currently about 810 % of the primary zinc of the world production is through the Imperial Smelting Process This process coproduces lead bullion in addition to zinc metal using a mix of lead and zinc concentrates or complex leadzinc concentrates as raw materialZinc Refining an overview ScienceDirect Topics2012年5月15日 Recently a new application of the Outotec Zinc Concentrate Direct Leaching Process has been started up in PR ChinaThis process can case by case be combined with all the other zinc technologies Direct Leaching Alternatives for Zinc Concentrates

Atmospheric curing of zinc sulfide concentrate by sulfuric acid

process (RLE process) [3, 4] In RLE process, zinc concentrate is first roasted from zinc sulfide to zinc oxide calcine and SO 2 gas After that, twostepleaching of the calcine is carried out with sulfuric acid at room temperature and 60~80 ℃ The traditional zinc hydrometallurgy processes have always been associated with environmental pollution2019年3月1日 In the present study, the production process of zinc sulfate from the zinc oxide ore was experimentally investigated The effect of main operating condition such as weight ratio of sulfuric acid (PDF) PURIFICATION PHASES OF ZINC SULPHATE SOLUTION Lahtinen, M and Takala, H 2005 Atmospheric zinc concentrate leaching technology of Outokumpu Lead Zinc '05 Proceedings of the International Symposium on Lead and Zinc Processing, Kyoto, Japan, 1719 October 2005 pp 803816 [ Links ]Evaluation of processing options for the treatment of zinc 2021年3月1日 In order to improve the production efficiency and reduce the production cost of copper removal process (CRP), it is necessary to control the addition rate of zinc powder in CRP In this study, the control of zinc powder addition rate is modeled as a dynamic multiobjective optimization problem (DMOP)A novel hydrometallurgical treatment for the recovery of copper, zinc

Lead Zinc Processing Solution JXSC Machinery

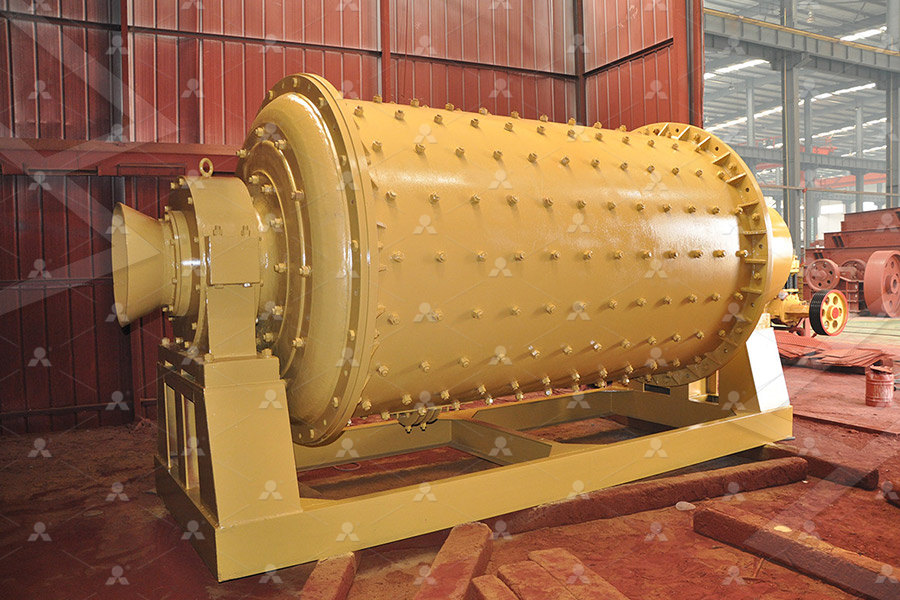

The leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, Subsequently, the flotation froth can be collected and further processed to obtain a higher lead or zinc concentrate Gravity separation: The ball mill can grind 020mm ore to 01mm powder sizeZinc concentrates /Zinc Ore Buyer Zinc smelting is the process of converting zinc concentrates (zinc ash/ore /zinc powder) into zinc ingot We request to buy Zinc concentrates and zinc Ore for Zinc smelting purpose, with Zn 20%70% or above Serious suppliers, pls send us your offerTurkish Metal :Mining company Selling Lead, Zinc, copper and 2024年10月15日 In the Lanping lead–zinc mine area, hazardous jarosite residue produced by the jarosite process seriously threatens the remaining capacity of the tailings pond and the local ecological environment Therefore, the hematite process has been recommended as an alternative to the jarosite process to overcome the challenge of the hazardous jarosite residue Hematite Process to Treat Zinc Sulfide Concentrate from22 Process Description Reduction of zinc sulfide concentrates to metallic zinc is accomplished through either electrolytic deposition from a sulfate solution or by distillation in retorts or furnaces Both of these methods begin with the elimination of most of the sulfur in the concentrate through a roasting process which is described belowBACKGROUND REPORT PRIMARY ZINC SMELTING Prepared for

NITRIC ACID ROUTE TO PROCESSING COPPER CONCENTRATES

1973年6月1日 Since 1984, the Sunshine Mining Company has used a patented nitricsulfuric acid pressure leaching system for production of silver and copper from a refractory sulfide ore bodyZINC CONCENTRATES The manufacturing process of zinc concentrate typically involves several stages, including mining, The final product is a dry powder known as zinc concentrate, which typically contains between 50% to 60% UM Zinc Concentrateoperation Three plants treat a zinc sulphide concentrate and are located in Spain (4,000 tpa zinc metal) and Germany (18,000 tpa zinc metal) and Australia (250,000 tpa zinc lead) A fourth Albion Process™ plant was operating in the Dominican Republic treating a refractory gold/silver concentrate, producing 80,000 ounces of gold annuallyThe Albion Process™ for Copper/Zinc Concentrates Glencore 2016年5月31日 Recognized in India as a metal in the fourteenth century, zinc and zinc oxides have been used for centuries for a variety of applications Currently, over 13 × 10 6 MT of refined zinc are produced annually from ores, concentrates, and recycled materials (ILZSG 2016)The predominant application for zinc is in the galvanization process to protect steel by increasing A global life cycle assessment for primary zinc production

.jpg)

EVALUATION OF PROCESSING OPTIONS FOR THE TREATMENT OF ZINC

sources available, ensuring Skorpion Zinc remains a low cost zinc producer in a volatile market and economic climate Important considerations for a suitable process for Skorpion Zinc are: A process with more favorable economics will be preferred This implies low operating and capital cost with high zinc recoveryet al, 2006) as well as direct processing of zinc concentrates, which is the topic of this paper 12 Direct zinc processing – future solutions Over the past 25 years, fundamental investigations have been conducted into the direct smelting of zinc sulphide concentrates with the objective of producing crude zinc metal directly by conTop submerged lance direct zinc smelting ETN Socratesconcentrates into zinc cathodes Especially in 1990’s big development leaps have been taken in roasting, leaching, solution purification and electrowinning areasLatest Developments in Zinc Processing ResearchGate2021年7月1日 A comprehensive review of processing strategies for iron precipitation residues from zinc hydrometallurgy July 2021 Cleaner Engineering and Technology 4(1):(PDF) A comprehensive review of processing strategies for iron

Lead and Zinc Sintering IntechOpen

2013年2月6日 Sinter is the primary feedstock for blast furnace to produce lead and zinc metals and it is obtained by the oxidation sintering of fine particulate zinc/lead sulphide concentrates in updraught sinter machines A typical flowsheet of sinter process is shown in Figure 2