Highway ore powder plus common spodumene particle size

Aspects of Spodumene Lithium Extraction Techniques

2024年9月30日 This research examined multiple parameters: concentrations of NaCl and Ca(OH) 2, temperature, pulp density, time, and ore size, to evaluate the extraction of Li The results indicated that a nearly complete extraction of Li 2022年10月31日 While there are 145 lithiumbearing minerals, only a few (such as spodumene, petalite, and lepidolite) are commonly used in the production of lithium 8, 9 Spodumene is the Lithium deportment by size of a calcined spodumene orepodumene particles with minor amounts of lithium bearing micas and beryl in the Pil1 sample, whereas in Pil2 and Pil3 spodumene is largely the lithium source In the Pil1 sample a Assessment of a spodumene ore by advanced analytical and mass 2024年3月12日 Particle size of the ore is one of the most relevant parameters in the separation of minerals using flotation, and thus, knowing in detail its impact is key to achieving a good recovery In China, how particle size affects the Molecular Design and Spodumene Flotation—A

.jpg)

Assessment of a spodumene ore by advanced analytical and mass

2018年4月1日 To liberate the spodumene in the middling class would require further particle size reduction to reject the mica, quartz and feldspar Pil 2 and 3 samples have spodumene with 2023年2月1日 DMS is the most widely accepted preconcentration technique for treating spodumene liberated at coarse particle sizes It rejects the impurities at the coarsest particle Recovery of lithium from spodumenebearing pegmatites: A 2021年12月3日 Considering the higher liberation of spodumene grains, it may be indicated that, d80 of 113 microns and particle diameter of 80 microns are good comminution parameters for processing spodumene ore, particularly PhysicoChemical Characteristics of Spodumene 2024年7月9日 The spodumene concentrate was ground and sieved to a particle size less than 75 μm The processed spodumene samples were combined with Na 2 CO 3 (SigmaAldrich, 995%) and Al 2 O 3 (SigmaAldrich, nanopowder) Direct Lithium Extraction from αSpodumene through

Lithium deportment by size of a calcined spodumene

2022年10月31日 The results showed that closedcircuit grinding resulted in 89% lithium recovery of the finest size fractions (− 06 mm) while opencircuit grinding led to 65% lithium recovery for the sameparticle size imp ortant? Particle size is critical within a vast number of industries For example, it determines: appearance and gloss of paint flavor of cocoa powder reflectivity of highway paint hydration rate strength of cement properties of die filling powder absorption rates of pharmaceuticals appearances of cosmeticsA GUIDEBOOK TO PARTICLE SIZE ANALYSIS University of Iowa2016年5月25日 The Ti48Al2Nb07Cr03Si alloy comprising of α2Ti3Al and γTiAl phases was successfully fabricated using vacuum arc melting To study its hot corrosion behaviour, the alloy was subjected to EFFECT OF PARTICLE SHAPE AND SIZE ON THE 2021年12月6日 is now obtained from ores [2] and spodumene (LiAlSi 2 O 6) stands out as the m ost signifi cant ore type due to the high lithium content ( about 4% ) in its pure state as well as its ease of PhysicoChemical Characteristics of Spodumene

Green Battery Minerals How to Get Lithium from Spodumene

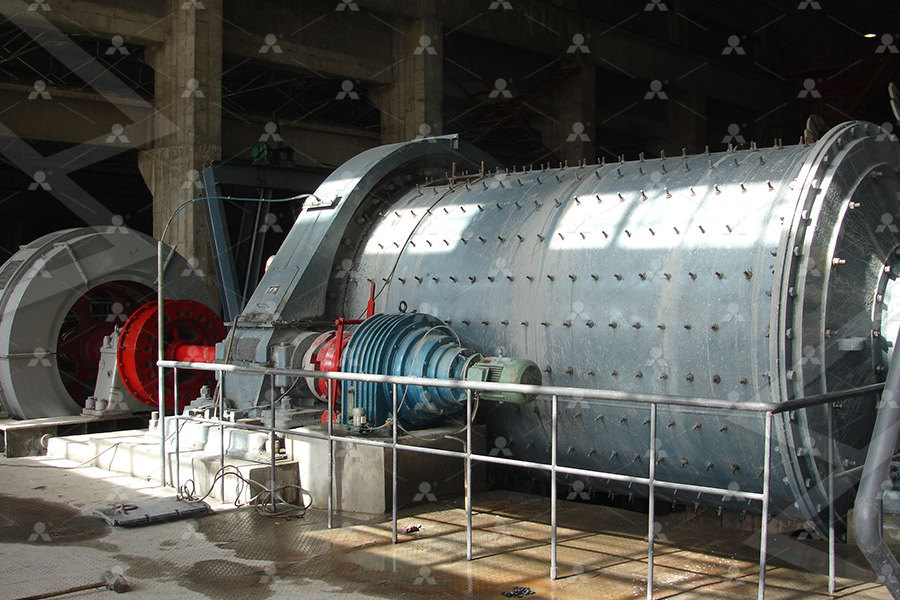

2023年4月7日 The particle size of spodumene ore is ground to less than 015 mm to obtain a better flotation effect Spodumene grinding equipment you need Wettype ball mill : The ore under the sieve is sent to the wettype grid ball mill for grinding2017年10月1日 Xu et al [58] and Tian et al [106] discussed the impact of particle size on the concentration of Testwork with real spodumene ore is rare in The most common beneficiation method for A novel approach for flotation recovery of spodumene, mica and The flotation and adsorption of sodium oleate (NaOL) on spodumene with four different particle size frac tions (45–75 l m, 38–45 l m, 19–38 l m and 0–19 l m) were investigated The Surface crystal chemistry of spodumene with different size Figure 31 Examples of particle size distributions with median particle size of lOjLm Table 31 Common Descriptors of Particle Size Distribution % less than 48 mesh % less than 60 mesh % less than 100 mesh % less than 325 mesh % less than 20 micrometers median particle size (size at 50 CPFT) size at 90 CPPT size at 10 CPFTChapter 3 Introduction to Particle Size Analysis Springer

Progress of Five Spodumene Beneficiation Methods

2024年11月21日 Satisfactory results have been obtained, the feeding particle size is 35 mesh, containing 20% spodumene, the obtained concentrate contains 92~95% spodumene, the recovery rate is 86~89%, and the recovery rate of heavy liquid is 95% above Years of practice show that as long as there is good protection, tetrabromoethane can be used on a large scale2022年7月30日 In order to show the flow characteristics of each mineral powder more intuitively, with the increase of particle size, the flow index from large to small, it was also observed that the fluidity indices of iron ore powders B, F, and G showed a polarized arrangement, while iron ore powder A showed the smallest fluidity index under each particle size of iron ore powder, Study on the Basic Characteristics of Iron Ore Powder with MDPI2024年9月30日 Zhou et al proposed a direct Li extraction process for αspodumene (particle size D 10 ~2595 μm, D 50 ~31818 μm, and D 90 30 g of spodumene concentrate powder and CaO were mixed in the required ratio and deposited in a corundum crucible leaching temperature, ore particle size, leaching time, and L / S ratio (Figure 15 Aspects of Spodumene Lithium Extraction Techniques MDPITable 1 Anthracite powder with a particle size of less than 147 μm was used as the reducing agent Its chemical compositions are shown in Table 2 Analytically pure Fe 2O 3 powder was added as a reaction accelerator and alloying agent According to the XRD analysis, the spodumene ore is mainly composed of threeComprehensive utilization of spodumene ore through

.jpg)

Transformations of Critical Lithium Ores to Battery

2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical 2022年11月1日 Particle size distribution of the grinding product was obtained from the wet sieving process and the 200 mesh (75µm) ore particles were analyzed using a laser diffraction particle size analyzerThe effects of dry grinding and chemical conditioning during Download scientific diagram The proportion of each particle size of iron ore powder from publication: Study on the Basic Characteristics of Iron Ore Powder with Different Particle Sizes In The proportion of each particle size of iron ore powder2018年4月1日 The most common industrial processes for the extraction of lithium from spodumene requires the conversion of the αspodumene form at elevated temperatures (1000–1100 °C) to the βspodumene form to generate a porous material which is more amendable to either an acid or alkaline digestion for extraction of lithium and other elements, Assessment of a spodumene ore by advanced analytical and mass

The Common Uses And Applications Of Sepiolite Powder

2024年4月2日 Sepiolite powder, also known as meerschaum or hydrous magnesium silicate, is a naturally occurring mineral that has a variety of uses in the construction and other industriesIts unique physical and chemical properties make it a versatile material for numerous applications Here are some of the common uses and applications of sepiolite powder:21 Ore preparations Spodumene ore samples (15 mm) were obtained from the Bald Hill Mine Eastern Goldfields, Western Australia Table 1 shows the mineralogy of the sample used in this work As seen in Table 1, the ore contains spodumene as a valuable mineral with the presence of feldspar, quartz and mica as associated gangue mineralsThe ores samples were collected Lithium deportment by size of a calcined spodumene ore2020年1月3日 Based on the total retention time of each ore, the optimum grinding time for each ore was identified to obtain the desired P 80 passing particle size with acceptable hematite liberation The results obtained after considering the standard reference retention time to the LBM were improved with respect to the desired P 80 passing percentage of 150 μm and hematite Estimation of Grinding Time for Desired Particle Size Distribution 2020年9月16日 There are three types of spodumene that can occur including phenocrystic spodumene in unzoned pegmatite with a Fe 2 O 3 content of 06–09% (Fe substitutes for Al in the spodumene crystal structure), zonal spodumene with a Fe 2 O 3 content of 001–003%, and spodumene plus quartz aggregates pseudomorphs after petalite with and Fe 2 O 3 content of Mineralogical Characterization and Preliminary Beneficiation

.jpg)

Molecular Design and Spodumene Flotation—A Review MDPI

2024年3月12日 Particle size of the ore is one of the most relevant parameters in the separation of minerals using flotation, XPS analysis revealed that collector adsorption occurred at Al and Si sites However, given that the most common spodumene surface is Powder Technol 2023, 415, [Google Scholar]2019年6月21日 pegmatite ore) with di ff erent particle sizes was studied to determine the optimum flotation particle size range This provides a theoretical basis for the selective grinding of spodumene(PDF) Spodumene Flotation Mechanism ResearchGate2022年10月31日 Ore preparations Spodumene ore samples (− 15 mm) were obtained from the Bald Hill Mine Eastern Goldfields, Western Australia Table Table1 1 shows the mineralogy of the sample determined using XRD As seen in Table Table1, 1, the ore contains spodumene as a valuable mineral with the presence of feldspar, quartz and mica as associated gangue mineralsLithium deportment by size of a calcined spodumene oreThe MASTERSIZER 3000 particle size analyzer was applied in this investigation to obtain a high accuracy for the size distribution of the studied finegrained materials depending on the laser Particle size distribution of raw materials including

.jpg)

Surface crystal chemistry of spodumene with different size

Spodumene Particle size Anisotropic adsorption Flotation Molecular dynamics due to the minerals’ common active Al site that interacts with anionic collectors [6] ratory porcelain mill Then, the powder samples were screened to four different size fractions (45–75 lm, 38–45 lm, 19–38 lm and 0–19 lm)Keywords Particle size distribution (PSD) Retention time Comminution Characterization studies 1 Introduction Ball mills are progressively used to grind the ores for particle size reduction and to liberate valuable minerals from the ores The (PDF) Estimation of Grinding Time for Desired Particle Size 2023年2月7日 Experimental Process Figure 1 is the experimental process for the production of highpurity silicon, hydrogen and lithium metal from spodumene Spodumene ore powder was taken from Sichuan Daofu Mining Co, Ltd, the size was smaller than 05 mm The main minerals in the spodumene ore are 95 mass% spodumene, and with a small amount of quartz and A New Method for Producing Hydrogen, Lithium Metal, and High 2023年9月8日 The average grade of lithium ore is 086%, making it a lowgrade ore with 841% of Li derived from spodumene The Li grade decreases with increasing depth, and the samples from shallower depths Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene

Dry deep screening of spodumene and its mineral ScienceDirect

2022年3月30日 The spodumene ore used in the screening tests came from a spodumene mine The curves of the particlesize composition and cumulative particlesize characteristics of spodumene are shown in Fig 1 The material was mainly composed of four particlesize classes, 0–08 mm, 08–1 mm, 1–3 mm, and 3–6 mm, and the proportion of each particle 2021年1月1日 Anthracite powder, with a particle size below 100 mesh, the spodumene ore and anthracite powder were crushed to a particle size of less than 0015 mm (HITACHI TM3030 Plus) Experimental and mechanism research on carbothermal reduction Mineralogy of the spodumene ore Mineral % mass Spodumene 106 Feldspar 702 Quartz 134 Mica 55 Others 03 Figure 1Estimation of particle properties ( a) before calcination and (b) a˙er Lithium deportment by size of a calcined spodumene ore Natureintensive process [1–4] In this process, the size of the particle obtained depends on the energy consumption of the ball mill The major challenge encountered in the process of iron ore grinding is to maintain the desired product particle size distribution (PSD) with sufficient liberation of valuable minerals The demand for desiredEstimation of Grinding Time for Desired Particle Size Distribution

.jpg)

Revisiting the Traditional Process of Spodumene Conversion

2018年8月19日 Here, the influence of initial particle size on thermal conversion and lithium extraction yield has been studied using the traditional process This study is based on the property of spodumene Spodumene undergoes a phase transition during the thermal treatment which allows its density to go down to 237 from 315 g/cm 3 [ 10 ] leading to a volume expansion of 2019年6月21日 Fine and coarse fractions of spodumene were obtained from a pegmatite ore and their flotation was investigated under different conditions In particular, the optimum pH and collector dosage were studied It was found Spodumene Flotation Mechanism MDPI2019年8月15日 Natural spodumene occurs as αphase, the lowtemperature, monoclinic polymorph of LiAlSi 2 O 6 that resists dissolution by most chemical agents (Rosales et al, 2014)In lithium refineries, the thermal treatment of αspodumene at temperatures above 1050 °C (typically around 1080 °C) transforms it into the more reactive βphase that affords ion Phase transformation mechanism of spodumene during its 2023年11月20日 Lithium recovery from βspodumene was conducted using a hydrometallurgical process consisting of water leaching and calcination Water leaching experiments were conducted using a mixture of βspodumene and CaO The effect of experimental parameters such as the particle size of βspodumene, reaction temperature, reaction time, and mass ratio of CaO to β Recovery of Lithium from BetaSpodumene Through Serial

Particle Size Distribution in Highway Runoff ResearchGate

2005年9月1日 Particles in highway runoff contain various sorbed pollutants, and many best management practices (BMPs) are selected for particle removal efficiency, which makes particle size distribution a 2022年1月1日 Extensive research works (Ohenoja et al, 2013, Kinnarinen et al, 2015, Prziwara et al, 2018a, Prziwara et al, 2018b) were carried out to investigate the operation conditions on energy consumption, particle size distributions, and breakage characteristics of minerals in the laboratory stirred millsThe PBM has been proved to be well successful in simulating the Effect of operating conditions on the particle size distribution and 2015年5月1日 The size distribution and particle shape of various iron ores are measured in this paper, then the ballability index and compression strength of green pellet of different iron ores are examinedSize distribution and particle shape of iron ore powder based on Iron ore, refined through orebeneficiation techniques, yields ironore concentrate powder, Common types of iron ores and their iron contents are shown in Table 21 Although, the iron ore particles maintained their particle size without agglomeration, the particles become more porous due to thermal stress and repeated oxidation Ore Particle an overview ScienceDirect Topics

.jpg)

Effectively enhancing recovery of fine spodumene via

2020年2月18日 Abstract The effects of shear strength on aggregation flotation processes for fine spodumene (particle size less than 19 μm) were investigated in this study Sodium oleate was used as a surfactant and collector The shear strength was controlled by varying the agitation speed of a selfmade stirring apparatus The aggregation process was studied by measuring