Aluminum ore processing white material

.jpg)

The aluminium industry: A review on stateoftheart technologies

2020年2月1日 This paper outlines the entire production process of aluminium from ore to the finished metallic alloy product In addition, the article looks at the current state of the art 2024年10月11日 Alumina, synthetically produced aluminum oxide, Al2O3, a white or nearly colourless crystalline substance that is used as a starting material for the smelting of aluminum metal It also serves as the raw material for a Alumina Properties, Uses Production ProcessWhen refined from bauxite, alumina generally looks like a white powder similar to table salt or granular sugar Aluminum oxide is typically referred to as alumina, but may also be called Alumina Refining 101 The Aluminum AssociationThe starting material for electrolytic smelting of aluminum is pure, anhydrous aluminum oxide (Al 2 O 3) called alumina In the Western World, the Bayer 1 process, invented in the 19th Chapter 2 Production and Processing of Aluminum The Minerals,

How is Aluminum Made: Full Guide to Aluminum Production

2024年5月19日 Bauxite is the primary raw material for aluminum production It’s a reddishbrown ore that contains high concentrations of aluminum hydroxides like gibbsite, boehmite, and 2024年4月19日 Extraction of aluminium metal takes place in three main stages: mining of bauxite ore, refining the ore to recover alumina and smelting alumina to produce aluminium Bauxite is mined by surface methods (opencut mining) in Aluminium Geoscience AustraliaIn this overview of an alumina refinery notice the predominant colours: white in the foreground and red behind This reflects what is happening in the unit operations: the “white” side involves THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE BAYER 2023年4月3日 Bauxite is a sedimentary rock mineral that is the primary source of aluminum It is formed through the weathering of aluminumrich rocks in tropical and subtropical regions The name bauxite is derived from the French Bauxite Properties, Formation, Uses » geologyscience

Aluminium Ore, Bauxite, Uses, Properties, Distribution

2024年10月11日 Established to boost aluminum production and ensure raw material availability for industries Read about: Energy Resources Aluminium Ore UPSC Aluminium, a lightweight silverywhite metal, is the most abundant and 2024年10月30日 Aluminum hydroxide, Al(OH) 3, is used to waterproof fabrics and to produce a number of other aluminum compounds, including salts called aluminates that contain the AlO − 2 group With hydrogen, aluminum forms aluminum hydride, AlH 3, a polymeric solid from which are derived the tetrohydroaluminates (important reducing agents) Lithium aluminum hydride Aluminum Uses, Properties, Compounds BritannicaPrimary production involves mining bauxite deposits from the earth, chemically refining it into pure aluminum oxide and performing electrometallurgical processing to ultimately form aluminum Secondary production makes new aluminum from recycled scrap that for many products, like cans, is completely suitable for the same high qualityAluminum Production and ProcessingExtraction of Aluminium (Aluminium Ore) To generate aluminium oxide from aluminium ore called bauxite is purified, a white powder form which aluminium can be extracted Visit BYJU’S for all Chemistry related queries and study materials Your result is as below 0 out of 0 arewrongExtraction of Aluminium (Aluminium Ore) HallHeroults

Aluminium Geoscience Australia

2024年4月19日 Aluminium can be extracted (uneconomically) from some clays but the most common aluminium ore is a material called bauxite or hollow, twiglike material (tubules) Its colours may be buff, pink, yellow, red, or white, or any combination of these Aluminium is also present in many precious gemstones such as turquoise 2022年1月23日 Beside the processing behaviour of the main constituents of bauxite such as hydrated alumina and silica minerals, the Chapter covers the impact of other constituents, such as titania, iron (PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals production, via the aluminium oxide (alumina) intermediate, and aided by the extensive deposits of aluminium ores 2 Bauxite Ores Aluminium is a reactive metal and is not found in its elemental form in nature There are a wide range of minerals containing aluminium almost exclusively as the oxide and often inTHE ALUMINIUM STORY BAUXITE TO ALUMINA: THE BAYER The color of bauxite is related primarily to iron oxide content If low in iron, bauxite is white, gray, Or cream; with moderate iron content, it is pink, yellow, light brown, or light red; if high in iron, it is dark red or brown In orefield processing of bauxite, crushing, washing, drying, pulverizing, and calcining may be involvedhistorical development aluminum production Total Materia

Extraction of Aluminium Materials UK

After mining the bauxite, the next step in making aluminum is processing the raw material into alumina, a white powder, also known as aluminum oxide Depending on the quality of the bauxite, about 45 tons of it can yield about 2 tons of alumina, which will produce one ton of aluminumAluminum ore refers to the minerals such as gibbsite, boehmite, Materials such as gravel and aggregates, glass sand, clay, and aluminum, magnesium, and iron ores may occur at the surface as endproducts of weathering Red mud is produced from bauxite/ aluminum ore processing Due to its physical and chemical properties, Aluminum Ore an overview ScienceDirect TopicsThe main ore of aluminum is bauxite, the source of over 99% of metallic aluminum Most bauxite is first processed to make alumina, or aluminum oxide, a white granular material Sometimes, raw bauxite is shipped overseas for processing to alumina, Aluminum and Bauxite ScienceViewsPrior to processing, Bauxite ore is red sedimentary rock We mine bauxite at our Australian Worsley Alumina mine as well Alumina is the key raw material used to produce primary aluminium from bauxite through crushing, dissolving it Aluminium, Alumina and Bauxite South32

.jpg)

Aluminum Mining and Processing: Everything you Need to Know

2014年6月26日 Using the Bayer Process, which involves the use of heat, pressure and sodium hydroxide, the aluminum oxide is separated from impurities, as well as iron ore The white crystals of aluminum oxide are washed and heated to extract water, resulting in the white powdery aluminum oxide that’s used during smelting to produce aluminumKeywords: aluminium, red mud, Bayers process, fluoride , calcium 1 Introduction Aluminium or aluminum is a chemical element with symbol Al and atomic number 13 It is a silvery white, soft, nonmagnetic and ductile metal in the boron group By mass, aluminium makes up about 8% of the Earth’s crust; it is the thirdProcess for the Extraction of Aluminum from Aluminum OresAlumina is the name given to aluminum oxide, which is a white, odorless powder Alumina is used in many different industries For example, it’s applied in metallic paint manufacturing as well as the production of spark plug insulations Professionals use alumina as a starting material for producing aluminum metalAluminum Processing Production Explained HARBOR2015年12月1日 Production of primary aluminum involves two independent processes to transform the ore to the metal It starts with the mineral bauxite, which has the highest grade of commercially mined metal (PDF) Occurrence and Production of Aluminum ResearchGate

Electrolysis and extraction of aluminium Extracting aluminium

Aluminium ore close ore A rock containing enough quantities of a mineral for extraction to be possible is called bauxite (Al 2 O 3)The bauxite is purified close purified A substance that has Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, Copper Mining and Processing: Processing Copper OresHow Aluminum is Produced Aluminum manufacture is accomplished in two phases: the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the HallHeroult process of smelting the aluminum oxide to release pure aluminum Bauxite is the mineral form of aluminium Aluminum compounds have proven useful for thousands of yearsHow Aluminum is Produced Metallurgy for Dummies2024年4月19日 Aluminium can be extracted (uneconomically) from some clays but the most common aluminium ore is a material called bauxite or hollow, twiglike material (tubules) Its colours may be buff, pink, yellow, red, or white, Aluminium Geoscience Australia

.jpg)

Aluminium Ore: Extraction of Aluminium Vedantu

Most common Aluminium Ores are Bauxite, corundum, cryolite and alunite In India, most of the Aluminium metal is extracted from its Bauxite ore India has large deposits of Bauxite Aluminium Ore in Gujarat, Madhya Pradesh, Jharkhand, Uttar Pradesh, and Karnataka Here we have given a list of common Aluminium Ores with their chemical formulae Bauxite is formed over millions of years by chemical weathering of rocks containing aluminum silicates, producing an ore rich in aluminum oxide Today, bauxite is mined primarily in Africa, Australia and the Caribbean Step 2: Production of Aluminum: The HallHéroult ProcessAlumina is a white granular material, a little finer than table salt, and is properly called aluminium oxide Aluminium does not occur as a metal but must first be refined from bauxite into alumina Approximately two tonnes of alumina are required to produce one tonne of aluminiumAlumina Refining The Australian Aluminium Council2023年12月15日 Introduction Ore extraction and processing remain highly relevant today, pivotal in the global economy and technological advancement As the backbone of the manufacturing and construction industries, titanium mining techniques and subsequent processing are crucial for producing a wide array of essential materials, from steel and aluminum to rare Titanium Ore Plant: Efficient Mining and Processing Methods

.jpg)

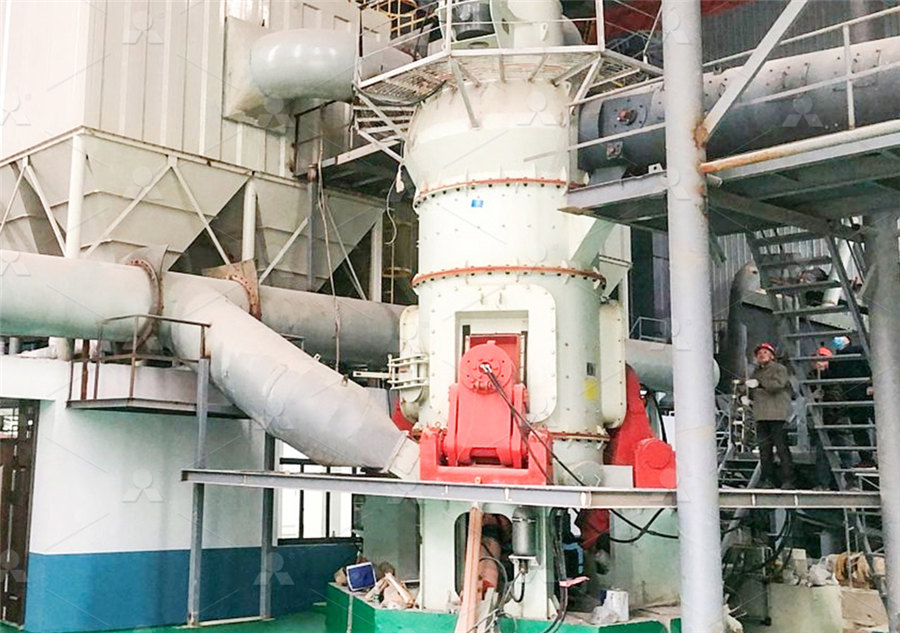

Aluminium ORE Processing Aluminium Ore Processing Aluminium

Aluminium Ore Processing Aluminium, or aluminium (Al), is a silvery white metal with a melting point of 660 0 C (1,220 0 F) and a density of 2 grams per cubic centimetre The most abundant metallic element, it constitutes 8 percent of the Earth's crust Alloys of aluminum are light, strong, and formable by almost all known metalworking processesBauxite ore is the main source of aluminum and contains the aluminum minerals gibbsite, boehmite, and diaspore Aluminum is used in the United States in packaging, transportation, and building Because it contains several minerals, bauxite itself is a rock, not a mineral Bauxite is reddishbrown, white, tan, and tanyellowAluminum Minerals Education Coalition2022年8月12日 The above infographics use data from the USGS, Aluminium aluminum typically goes from ore to metal in heated in calciners to form pure aluminum oxide—a sandy white material known Graphic: How is aluminum made? 2023年11月7日 The production of primary aluminum metal begins with bauxite ore, which is composed of hydrated aluminum oxide (40% to 60%) Imports of bauxite concentrate and alumina for processing into aluminum accounted for $22 billion or 21% of Canada’s aluminum imports in 2022 Most imports came from the United States (41%), Brazil (20% Aluminum facts Canada

.jpg)

Cost Effective Technology of Alunite Ore Processing ResearchGate

Alunite ore is a raw material for the chemical and aluminum industries Industrial deposits of alunite ores are widespread in the USA, China, Azerbaijan, Mexico, Iran, Kazakhstan, Uzbekistan Bauxite, the main ore for aluminium, is another bulk material that may contain trace but significant quantities of REE Extraction of REE, Daoping Peng, in Managing Mining and Minerals Processing Wastes, 2023 721 Bauxite ore Bauxite is the primary aluminum ore composed of one or more aluminum hydroxide minerals, including gibbsite (Al Bauxite an overview ScienceDirect Topics2018年11月5日 3 Ironrich bauxite processing and metallurgy Ironrich bauxite ore usually contains over 40 wt% iron oxide [11, 12], huge reserves are found in Australia, Guinea, Brazil, Laos, Vietnam and China, but they have not yet Aluminum Mineral Processing and Metallurgy: Iron 2019年8月1日 Find Aluminum Ore Processing stock images in HD and millions of other To transport, sorting and carry raw material from quarry ie ore, coal, rock to factory plant 64x64 pixel Floating Crane Transhippers in the process Black and white photography Horizontal frame Alumina processing plant, aerial view aluminum cast house Aluminum Ore Processing royaltyfree images Shutterstock

.jpg)

Facts: Raw Materials The Aluminium Story

Refining and smelting both require a series of raw materials that help turn bauxite into pure aluminium From caustic soda to water, here’s how it happens Aluminium refining The Bayer Process is the most commonly used method of obtaining alumina from bauxite, and is explored in detail here The key input materials are the ores []An overview of this conversion process and the materials along the way are described here Bauxite Aluminum starts out as bauxite ore – an aluminum ore formed from laterite soil Bauxite is the world’s primary source of aluminum Before it can become aluminum, however, bauxite destined for use as aluminum must first be processed into aluminaThe Transformation of Bauxite to Aluminum (and the Products Aluminum processing Smelting, Refining, Alloying: Although there are several methods of producing aluminum, only one is used commercially The Deville process, which involves direct reaction of metallic sodium with aluminum chloride, was the basis of aluminum production in the late 19th century, but it has been abandoned in favour of the more economical electrolytic Aluminum processing Smelting, Refining, Alloying BritannicaThe first step in producing aluminium is mining this ore Bauxite occurs mainly in tropical and subtropical areas, like Africa, the Caribbean, South America and Australia Australia is one of the world’s largest producers of bauxite, with five large mines supplying around 30 per cent of Bauxite Mining The Australian Aluminium Council

Aluminum processing History, Mining, Refining, Facts

2024年9月14日 Aluminum processing, preparation of the ore for use in various products aluminum typically goes from ore to metal in three stages Stage 1: The aluminum hydroxide crystals are washed and heated in calciners to form pure aluminum oxide—a sandy white material known as aluminaProduction and Processing of Aluminum 21 Extraction of Aluminum The extraction of aluminum from its ore water Calcination in rotary kilns or in fluidized beds at 1100°C to 1300°C finally converts the hydroxide to a dry, white factors other than the type of bauxite ore to be used as feed material and the form of alumina to be Chapter 2 Production and Processing of Aluminum 21 Extraction of AluminumThe Hall–Héroult process is the major industrial process for smelting aluminiumIt involves dissolving aluminium oxide (alumina) (obtained most often from bauxite, aluminium's chief ore, through the Bayer process) in molten cryolite and electrolyzing the molten salt bath, typically in a purposebuilt cell The Hall–Héroult process applied at industrial scale happens at 940–980 °C Hall–Héroult process Wikipedia