How to operate when the concentration of Raymond mill is too low when selecting calcite ore

How to control the feed amount of Raymond mill LinkedIn

2018年9月7日 However, if the concentration is too small, the yield is too low The concentration of the powder in the gas stream is determined by factors such as the amount of feed, the ability to2018年9月6日 If the concentration of the powder contained in the gas stream is too large, the classification efficiency is lowered, and large particles are easily contaminated in the finished How to control the feed amount of Raymond mill2021年7月21日 Here are the reasons and solutions about 8 frequent problems of Raymond mill 1 No Powder Or Less Powder Yield Reasons: No air lock device is installed, causing the How to Solve 8 Frequent Problems Of Raymond Mill?2016年3月28日 The proposed DOBMPC method aims to effectively control the current of raymond mill and reduce the peak overshoot and settling time under strong disturbances, Composite control for raymond mill based on model predictive

Supervisory expert control for ball mill grinding circuits

2008年4月1日 On the contrary, when the mill solid concentration is very low, then the mill feed water will be decreased and the ore feed is also stopped in emergency Once the overload 2019年12月23日 When the Raymond mill is working, on the one hand, it is necessary to consider whether the equipment model can meet the daily production demand and avoid How to deal with the lower and lower powder output rate of the 2017年10月7日 In the Raymond mill grinding processes, highaccuracy control for the current of Raymond mill is vital to enhance the product quality and production efficiency as well as cut Disturbance rejection control for Raymond mill grinding system 2015年8月7日 If you make a change in the ore in the fine ore bin, that change will be reflected through the entire grinding process and beyond into the rest of the concentration system The Operating and Troubleshooting a Grinding Circuit

8 Effective Ways to Improve the Powder Yield of Raymond Mill

2023年6月8日 Here are 8 effective ways to improve the powder yield of Raymond grinding mill The grinding pressure mainly comes from the centrifugal force of the grinding roller, and the 2016年2月29日 Roughing can be considered as the upgrading of the ore to produce either a low grade, preliminary concentrate or to reject tails that contain gangue at an early stage The equipment used in this part can produce a large Gold Extraction Recovery ProcessesApplication of Raymond mill Raymond Mill is also called Raymond roller mill,raymond grinding mill,raymond pulverizerYGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive mineral materials with Moh's hardness less than 93 and humidity less than 6%Raymond Mill,Raymond Roller Mill,Raymond Grinding Mill,Raymond Mill At this point, the Raymond mill grinding work begins The simple Raymond mill operation sequence is as follows: Start: hoist → crusher → analyzer → fan → host → feeder When the Raymond mill is stopped, the machines should be Raymond Roller Grinding Mill

.jpg)

How Does a Raymond Mill Work? Zenith Crusher

2021年10月19日 Raymond Mill Working Principle The Raymond Mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts Of them, the host is made up of a frame, an inlet volute, a shovel blade, grinding rollers, a grinding ring and a shell2023年6月12日 Overview of Raymond Mill Raymond mill is one the most commonly used grinding mill in China's grinding industry It has been widely used in the milling and processing fields of more than 280 kinds of materials in the industries of nonflammable and nonexplosive minerals, chemicals, construction, etc, such as barite, calcite, potash feldspar, talc, marble, 6 Aspects For You to Understand Raymond MillC If the concentration of HI is doubled, the reaction rate will increase from k[HI] 0 2 to k(2[HI]) 0 2 = 4k[HI] 0 2 The reaction rate will therefore quadruple By selecting two experiments in which the concentration of B is the same, we were able to solve for m Conversely, 143: Effect of Concentration on Reaction Rates: The Rate Law2024年9月11日 Mill scale is something that metal workers and welders should be aware of The remaining mill scale from production can develop in all varieties of steel It must be eliminated before working with the steel because its presence can cause corrosion and impair a weld This article will define mill scale and go over a few methods for getting rid of it MILL SCALE: What is Mill Scale And How To Remove It — Benchmark Abrasives

6 Methods to Improve the Output of Raymond Mill

2020年12月29日 A highpressure Raymond mill can be used to process materials with humidity below 6% If the water content of the material is too large and too humid, the material will stick and form agglomerates during the grinding process, and some materials will even stick to the internal parts of the equipment, causing the parts to malfunction2022年3月9日 Advantages of Raymond mill 1 High fineness of finished products: The finished powder after Raymond mill treatment has uniform fineness, and the sieving rate can reach 99% 2 Strong wear resistance: The important parts of the machine are made of highquality castings and profiles, and the craftsmanship is fine, which ensures the durability of the entire grinding How to set the mesh of Raymond mill?The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2023年9月18日 If you are in the market for a Raymond grinding mill, you have come to the right place This guide, SMAT will discuss what a Raymond mill is, how it works, and why you should consider purchasing one We will also Raymond Grinding Mill: The Ultimate Guide From

.jpg)

How To Reduce The Maintenance Cost Of Raymond Mill

How To Reduce The Maintenance Cost Of Raymond Mill As you all know, Raymond mill is mainly used to grind materials, and most of the materials are ore and so on Raymond mill often deals with these ores, wear and tear of vulnerable parts is normal, and the general Raymond mill works outdoors, the working environment is relatively poor, this 1970年1月1日 1 In order to make the Raymond Mill operate normally, we should establish the "equipment maintenance and safety operation system" to ensure the longterm safe operation of Raymond mill and meanwhile to have necessary maintenance tools, grease and Raymond mill maintenance guideline2019年7月25日 Misunderstanding of Lubricating Oil Used in Raymond Mill As a common grinding plant, Raymond Mill can be used in fine powder making of barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement and phosphate rock, and other Nonflammable and explosive How to Increase the Output and Efficiency of Raymond Roller Mill?2020年6月8日 The above mainly introduces how the Raymond mill works For the analysis of this problem, the above introduction is more detailed First, the work process of the entire production process is introduced, and then the Raymond mill is analyzed The grinding principle inside the powder machine and the important parts needed in the grinding processWhat is the working principle of Raymond Mill?

.jpg)

How to choose ring roll mill and Raymond mill SBM Ultrafine

2022年10月21日 1 Difference of grinding system: Raymond mill adopts centrifugal pendulum suspension roller device for rolling, impact crushing The number of rollers is generally 37, and the number of grinding rings is one The contact surface between the grinding roller and the grinding ring is flat, and the interior is equipped with Blade feeder2015年1月4日 In all normal circumstances, open the gate for material transport silo observed amplitude again (amplitude allow open hopper drop 05mm, such as falling too shall electric vibrating feeder trough manual inspection and adjustment of the elastic ballast system ) and the current is stable, the feeding amount meets the requirementsHow to Control Raymond Mill Feeding System2023年12月22日 Baichy Machinery will introduce how to install and debug Raymond mill, hoping to help more users understand and correctly use Raymond mill equipment 1Before starting the grinding mill Check whether there are iron blocks and other debris in the working chamber, check whether the bolts and nuts are loose, and check whether all access doors are closed tightly, How to operate and debug a raymond mill?2024年2月13日 As an interesting note, in an acceptable range of feeds and speeds, increasing feed rate has the same effects as decreasing speed So, when we say you have too high of a feed rate, you can also take it to mean that you have too slow of a speed Too slow of a feed rate reduces your tool C Feeds Speeds Formula (How to Calculate Feed Rate)

Welcome to Raymond

Raymond Limited was first incorporated as the Raymond Woolen Mill in 1925 near Thane Creek Lala Kailashpat Singhania took over The Raymond Woolen Mill in the year 1944 Ever since then they have been analogous with class, The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the Ball Mills 911MetallurgistBy selecting two experiments in which the concentration of B is the same, we were able to solve for m Conversely, by selecting two experiments in which the concentration of A is the same (eg, Experiments 5 and 1), we can solve for n143: Concentration and Rates (Differential Rate Laws)

.jpg)

719: Concentrations: Dilution Chemistry LibreTexts

Because the calculated final concentration of the solution, C 2, is smaller than the initial concentration, C 1, the value of the final answer is reasonable 719: Concentrations: Dilution is shared under a CC BYNCSA 30 license and was authored, remixed, and/or curated by new Raymond mill Raymond mill profile Raymond mill model Raymond Mill Applied Materials Nonflammable and explosive ore with a Mohs hardness of 6 or less and a humidity below 6%, such as calcium carbonate, graphite, bentonite, wollastonite, coal powder, water slag, fly ash, alumina, zircon sand , quartz sand, gypsum, talc, calcite, limestone, marble, barite, dolomite, Raymond Mill Raymond Mill For Sale AGICO2023年2月15日 Main parts of Raymond roller mill Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower, reducer, base plate, shovel, Raymond mill pendulum, star stack, etc Main materials of the parts: manganese(16Mn, 65Mn), High manganese steel, high chromium(Cr13、Cr23、Cr26)Raymond Roller Mill PartsUltimate Guide Fote Machinery2018年1月23日 When choose lubricating oil, we should choose type with good stability, supreme rust protection and anticorrosion property Lubricating oil with anticorrosion property can better protect the Raymond mill when it is not working while form a layer of protective film when working At the same time, lubricating oil can reduce wearingHow to Accurately Select and Use Lubricating Oil for Raymond Mill?

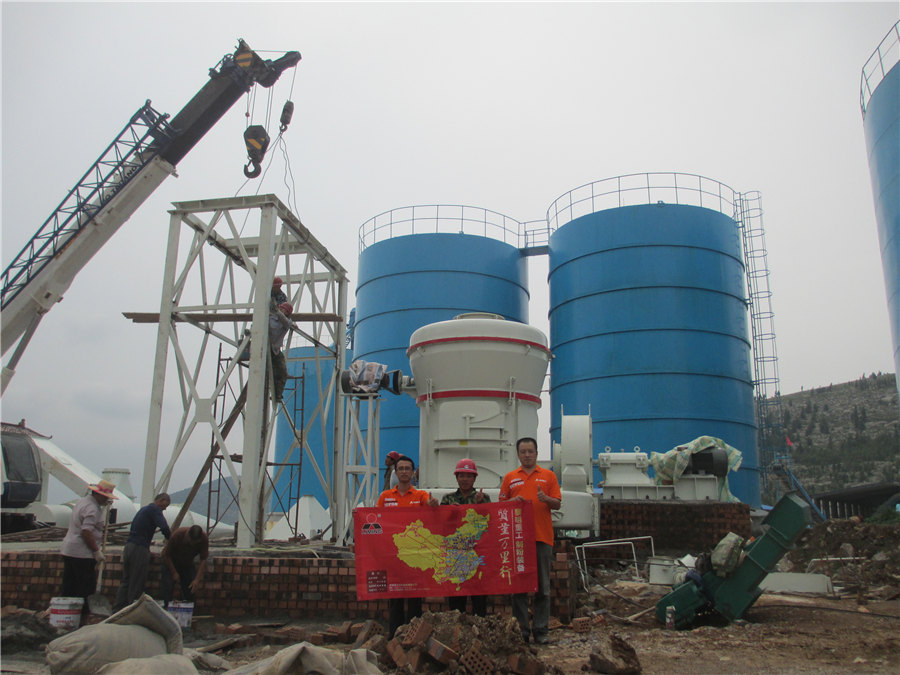

Raymond Mill Machine Manufacturing Dura Mortar

HomeDry Mortar MachineRaymond Mill Machine Raymond Mill Machine Manufacturing As a production line for grinding nonmetallic minerals, the Raymond mill machine is commonly used in coal mines, metallurgy, and mines with a Mohs hardness 2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Raymond Roller Grinding Mill Machine2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills MiningpediaFTM Raymond mill, as a kind of grinding mill which is widely used in the field of ore grinding can help users to grind the limestone, marble, calcite, feldspar, and other solid materials into the requested particle size within the range 80325 Raymond Mill FTM Mining Machine

.jpg)

Calculate and Select Ball Mill Ball Size for Optimum

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA 2020年6月8日 Misunderstanding of Lubricating Oil Used in Raymond Mill As a common grinding plant, Raymond Mill can be used in fine powder making of barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement and phosphate rock, and other Nonflammable and explosive minerals, chemicals, What is now the working principle of Raymond Mill?If the air volume of Raymond mill fan is not adjusted properly and the air volume is too large, it will cause abnormal powder discharge of the mill If the air volume is too small, the powder will be too fine If there is no abnormality in other conditions, the air volume of the fan should be adjusted to correct the powder size Failure of the How to increase powder output rate of Raymond Mill?2023年8月22日 1 Understanding Raymond Mill's Working Principle Raymond Mill has established itself as a renowned grinding equipment in various industries, revolutionizing material processing and setting new standards for efficiency and performance The Working Principle of Raymond Mill is based on the pendulum grinding principle Here is a stepbystep breakdown The Working Principle of Raymond Mill PDF Free Download

.jpg)

How to Improve Ball Mill Performance 911Metallurgist

2017年10月25日 b the classification system efficiency, which defines the fraction of the total mill power effectively applied to the grinding of coarse material; c the grindability characteristic of the ore over the size reduction range of the circuit; and, d the breakage efficiency of the ball mill environment on the coarse materialDilution is the addition of solvent, which decreases the concentration of the solute in the solution In both dilution and concentration, the amount of solute stays the same This gives us a way to calculate what the new solution volume must be for the desired concentration of solute From the definition of molarity,413: Dilutions and Concentrations Chemistry LibreTextsThe highlighted tags were those that correspond to top ten highgrade panels of their respective shafts and their low recovery rates indicate that highgrade ore does not reach surface timeously, if at all The slow arrival of highgrade ore causes a Monitoring ore loss and dilution for minetomill integration in 2015年1月12日 Before operating the Raymond mill , Then continue to turn on the machine must remove excess stock, otherwise it will affect to start it when the current is too large : info@clirik Tel: PRE The Standard Operating Procedure of Raymond mill