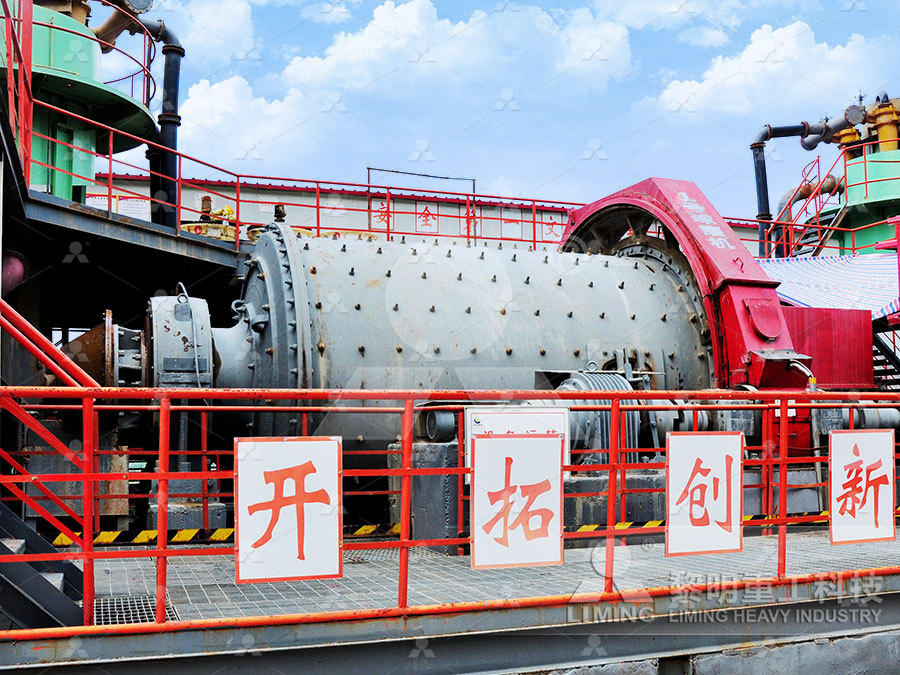

Ore limestone deep processing equipment

.jpg)

How to choose a limestone grinding mill SANDMINE

2024年1月18日 Limestone powder production is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder deep processing (400 mesh1250 mesh), and micro Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Limestone Quarrying and Processing: A LifeCycle InventoryWith decades of expertise, we specialize in providing solutions for the crushing of coal, iron ore, limestone, and stone aggregates—essential materials for infrastructure projects such as road construction, building development, and Mechtech Inframine Home of Superior Crushing and These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, storage, and drying equipmentLimestone Mills Williams Crusher

Limestone Grinding Mill Plant TAYMACHINERY

A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium Whether your mineral processing operation works with salt, sand, soil, fertilizer, coal, or any other materials beyond aggregates, Kemper Equipment can help We create specialized systems for the processing of minerals and other material Mineral Processing Equipment Solutions Kemper 2019年11月4日 The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performanceLimestone Rock Crushing Flow Price JXSC MachineTurnkey washing plant processing 6mm crushed limestone with high fines content and producing aggregates and manufactured sands We help wash previously discarded lowgrade by Limestone Processing Limestone Wash Plant CDE CDE

.jpg)

Limestone Quarrying and Processing: A LifeCycle Inventory

2 LIMESTONE QUARRYING AND PROCESSING OPERATIONS 1 1 2 3 21 LIMESTONE 22 LIMESTONE QUARRYING OPERATIONS 23 LIMESTONE PROCESSING OPERATIONS 3 LCI Once the bench is cut or split loose from the deposit, heavy equipment is used to lift the limestone bench and transfer it to an inspection area for grading, temporary storage, occasional2020年10月19日 This mine produces approximately 81 million tons of limestone annually The mine measures roughly 2 km long, 700 m wide and 50 m deep The openpit includes two oreprocessing shafts The produced limestone ore is dumped into the shafts and is then crushed and transferred to the cement plant via a conveyor beltEstimating Ore Production in Openpit Mines Using Various Limestone is a sedimentary rock comprising about 15% of the earth's sedimentary crust Limestones are generally mined using the methods of openpit mining and underground mining based on economic and environmental conditions Limestone extraction – underground mining 2016年1月7日 PGM Ore Processing The concept of project value tracking and its application in project planning at Anglo Platinum Flotation process optimization through frequent inline grade measurement as an alternative to sampling surveys that deliver outdated resultsPGM Ore Processing 911Metallurgist

How to mine lithium ore, mineral processing, crushing, grinding

2022年12月13日 Lithium ore processing equipment recommended After secondary crushing, cone crusher can be evenly sent to the grinding machine for deep grinding treatment under the action of belt One of our Mexico customers bought a mobile crushing plant of 120tph for limestone processing The mobile station is flexible and convenient, and HLMX superfine limestone grinding equipment is a preferred powder making equipment for processing superfine limestone powders, it can process the fineness between 45um7um, if used a secondary classification system, Applicable materials: raw cement, clinker, lime powder, slag powder, manganese ore, gypsum, coal, barite, calcite , etcLimestone Processing Equipment Using Superfine Grinding Mill2024年8月15日 It is suitable for processes requiring fine grinding as it more effectively releases valuable minerals from the ore 3 Mineral processing equipment Mineral processing equipment is the core of mineral processing and is used to separate valuable minerals from gangue or Mineral Processing Plants: What You Need to KnowThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

.jpg)

Iron Ore Processing, General

Iron ores are rocks and minerals from which metallic iron can be economically extracted The ores are usually rich in iron oxides and vary in color from dark gray, bright yellow, deep purple, to rusty red Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most areOnce the analysis determines a given ore body is worth recovering, development begins to create access to the ore body The mine buildings and processing plants are built, and any necessary equipment is obtained The operation of the mine to recover the ore begins and continues as long as the company operating the mine finds it economical to do so129: Mining Geosciences LibreTexts2024年1月18日 Limestone powder production is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder deep processing (400 mesh1250 mesh), and micro How to choose a limestone grinding mill SANDMINEFEECO has been helping some of the world’s top limestone and soil amendment producers through our custom equipment and process solutions since 1951 Whatever your limestone processing or handling needs, we’ve got you Limestone Processing Equipment FEECO

Mining and Mineral Processing Equipment FEECO

Mining and Mineral Processing Capabilities Brochures MinExpo 2016 Activated Carbon in Gold Cyanidation Recovery FEECO Mining Capabilities Mining Minerals Industry Mineral Processing Mineral Processing Equipment, Rotary 2024年10月14日 A double toothed roll crusher is often used as secondary or tertiary stone crushing equipment Its versatility spans applications like coal, pebble, perlite, limestone, and dolomite processing Notable features include high crushing capacity, hydraulic pressure for roller distance adjustment, and centralized lubrication on bearingsWhat Machines Do Stone Crushing Plants Need? Fote MachineryComminution (ie, the breaking of rock to facilitate the separation of ore minerals from waste) combines blasting (a unit process of mining) with crushing and grinding (processing steps) Insitu mining, which is treated under a separate heading in this chapter, is a special case that combines aspects of mining and processing but does not require the excavation, comminution, and Technologies in Exploration, Mining, and Processing2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral Processing

Copper Mining and Processing: Processing Copper Ores

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, 2020年11月1日 In this paper method for ore segmentation was developed based on deep learning algorithm and digital image processing that was trained on manually labelled images for final segmentation The feed size distribution of AG/SAG mills has a big impact on the efficiency of the whole beneficiation process In this situation is very useful instrument could be a system Ore particles segmentation using deep learning methods2019年11月4日 The compressive strength of limestone is generally around 150 MPa, which belongs to soft rock The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performanceLimestone Rock Crushing Flow Price JXSC Machine2024年6月11日 Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3)The processing of limestone typically involves several stages, including crushing, screening, and grinding Design Manufacture of Crushing Screening, and Limestone Processing Crushing Operations and Equipment

.jpg)

Sustainable Methods of Dewatering and Disposal of Processing

2024年3月13日 In the case of industrial minerals like iron ores, limestone, rock phosphate, etc, tailings may be from 20 to 50%, whereas in the case of sulfide and gold ores, tailings may be huge from 90 to 95% Mineral processing of lowgrade ores particularly, iron ores, rock phosphates, marly and kankar limestone, bentonite, coal, and talc generates tailings Metal Ore Processing After mining, crushing, mineral processing and refining, , the equipment investment in grinding operations accounts for about 65% to 70% of the total investment in the whole Vipeak will use more than 30 years of deep mining industry experience wholeheartedly to Metal OreMining Equipment Manufacturer Vipeak Mining 2023年2月15日 3 The practice has proved that a shaft furnace is best for limestone with a size of 4080mm while a rotary kiln is ideal for limestone with 1030mm Fote Company manufactures various crushing and mining equipment Lime Production Process and Required Equipment2021年5月10日 Jung et al [5] used discrete event simulation to stochastically predict ore production in an underground limestone mine by using four different probability density functions for truck travel timesStochastic Predictions of Ore Production in an Underground Limestone

.jpg)

Ore particles segmentation using deep learning methods

2020年11月1日 The size distribution of ore particles is an important basis for evaluating the crushing effect, and is also the main index for the optimal control of mineral processing equipment Image It is critical that limestone (CaCO3) is of adequate quality to permit proper raw feed formulation The presence of excessive Mg contamination in limestone often leads to inferior clinker that forms potentially less durable cements Mining of limestone requires the use of Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENTLearn more about the best mining equipment options for your worksite Skip to main content Equipment EQUIPMENT No The final step involves material processing: grinding, separating, crushing, ore, metals, or other goods located deep underground require different techniques and tools of removal depending on the mon Types Of Mining Equipment Empire CatThe rock/ore crushing processing plant requires applying different crushers, including jaw crushers, hard and abrasive materials such as granite, basalt, iron ore; limestone and river pebbles vertical shaft compound crusher Capacity: 5200t/h Application: We provide mineral processing equipment and solutions; Stone Crusher│Ore Crushing Machine JXSC Machinery

.jpg)

(PDF) Deep Neural Network for Predicting Ore Production by Truck

2020年3月1日 Predicting ore production throug h deep learning using equipmenttracking data affords produces limestone, each w ith an oreprocessing shaft Figure 1 Aerial view of investigation 2019年10月7日 Deep Neural Network for Ore Production and Crusher Utilization Prediction of Truck Haulage System in Underground MineDeep Neural Network for Ore Production and Crusher Utilization 2023年5月12日 Top 3 Chrome Ore Processing Methods that Get Higher Recovery Rate; The Most Effective Lithium Ore Processing Method You Must Know; Cobalt Extraction Process: Recover Cobalt From Copper Effectively; Graphite Ore Processing: Optimal Processes and 2016年6月20日 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Ore, Rock Aggregate Ore, Rock Aggregate Screening (Complete Guide)

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 Request PDF Processing of lithium ores: Industrial technologies and case studies – A review Recently, there has been a steady increase in demand for lithium (Li) and its compounds Blasting, drilling and scaling out limestone from the Earth requires the right equipment—and when it comes to reducing the size of that limestone material, it’s no different Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the marketLimestone Mills Williams CrusherFrom 1890 to 1920, underground mining of graphite was practiced in New York and Pennsylvania From 1942 until the end of World War II, only openpit methods were used, because working weathered rock was relatively easyGraphite Processing Equipment, Process Flow, Cases JXSC 2017年2月16日 PDF Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming Find, read and cite all the research you (PDF) Iron Ore Sintering: Process ResearchGate

.jpg)

Manganese ore crushing equipment processing technology

The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiationDuring the crushing process, the threestage closedcircuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding 2024年3月16日 In the wake of the era of big data, the techniques of deep learning have become an essential research direction in the machine learning field and are beginning to be applied in the steel industry The sintering process is an extremely complex industrial scene As the main process of the blast furnace ironmaking industry, it has great economic value and Application of deep learning in iron ore sintering process: a review2023年6月30日 Thus, the urgency of using crushers in mining and processing plants is clear, so it is relevant to find ways to optimize their operation and reduce energy consumptionModeling and Improving the Efficiency of Crushing Equipment2022年3月21日 Rareearth elements (REEs) are required for use in modern hightech applications and demand has increased significantly over the last decade 1 However, processing of REE ores poses potential hazards to human health and the environment due to challenges in the management of thorium (Th) and uranium (U) in waste products 2 If well managed, REE Processing the ores of rareearth elements MRS Bulletin