Vertical mill blade grinding video

How Vertical Grinding Mills Work (Coal Pulverizer

Want to continue learning about engineering with videos like this one? Then visit:https://coursessavree/ Want to teach/instruct with the 3D models shown2022年3月28日 The VXPmill is an established vertical ceramic media regrind mill used in energy efficient gold, copper, lead and zinc plants worldwide All slurrycontacting components of the VXP are polyurethanelined and the FLSmidth VXPmill Operation2019年7月6日 This is Mill Skills, a multipart series to help you learn basic machine shop work Exclusive videos, drawings, models plans available on Patreon!https://wVertical Mill Tutorial 1 : The Basics YouTube2023年8月20日 Here's how it works: The mill's motor powers the rotation of the grinding table, causing materials to descend towards the millstone's center from the feeding inlet Concurrently, hot air isHow Does a Vertical Roller Mill Work? YouTube

VMT750 Vertical Mill/Turn Cutting Demo Haas Automation Inc

VMT750 Vertical Mill/Turn Cutting Demo We shot this quick VMT750 cutting demo about a week before our HaasTec Live event in September This demo shows all of the operations we UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your equipment performance Further UBE Vertical Mill UBE Machinery Corporation, LtdThe LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized Vertical Mill Shanghai Zenith CompanyThe VR5 brings 2axis spindle head capabilities to our midsize VMC platform to create a compact 5axis machine for profiling and contouring midsize parts The machine’s smaller VR5 5Axis Mill 30Taper Vertical Mills – Haas CNC Machines

.jpg)

Loesche Vertical Roller Mill for efficient processing

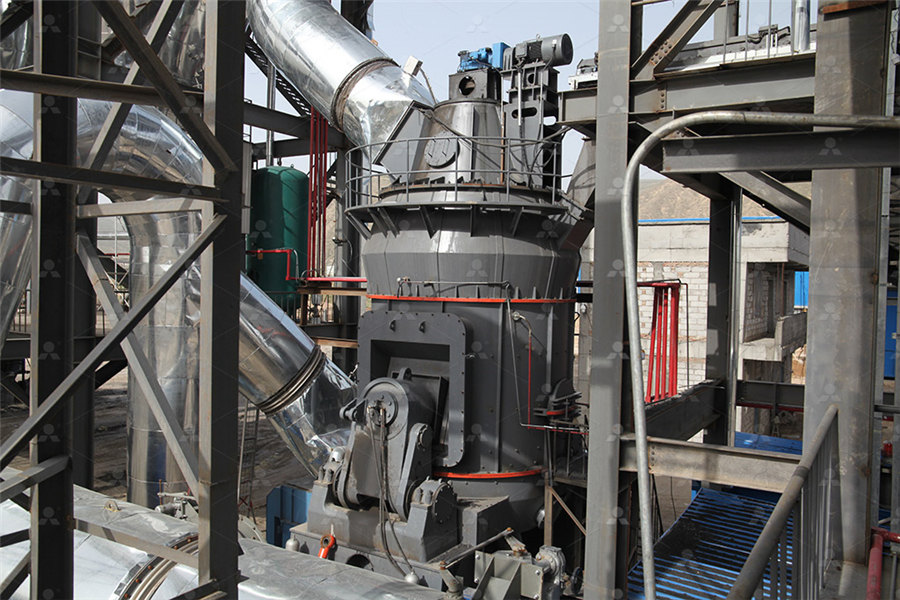

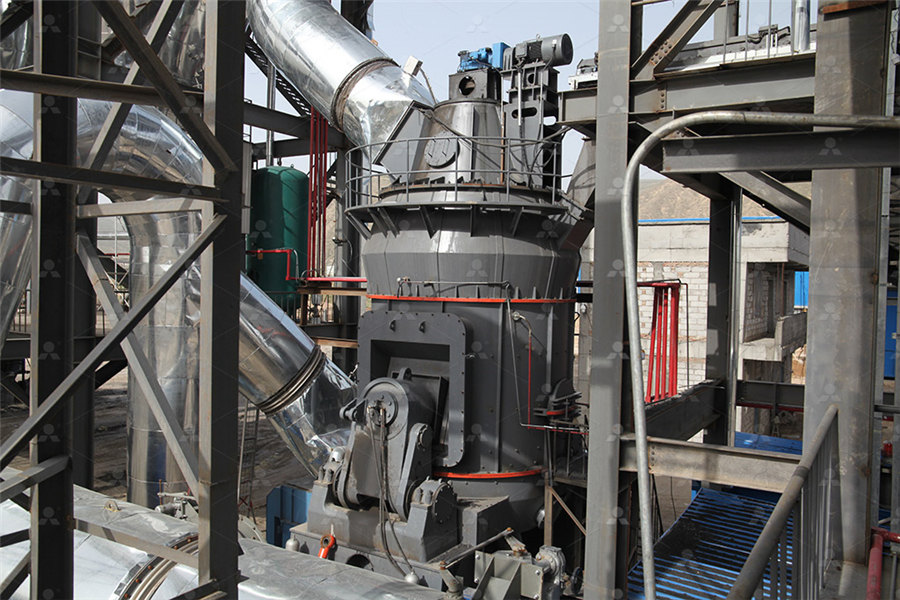

2024年11月4日 Loesche Vertical Roller Mill (VRM) is a revolutionary mineral processing tool that operates without water, capable of grinding rocks and minerals up to 50mm in a single pass Under special circumstances, compared with the traditional tube mill wet grinding process, the product recovery rate and product quality can be improved As a manufacturer of HLM vertical Detailed explanation of vertical mill grinding technologyThis vertical mill machine is applied in electric power, metallurgy, chemical and nonmetallic industries, such as portland cement and blended cements, limestone, slag, manganese, gypsum, coal, barite, calcite etc HLM vertical grinding mill has proven to be a versatile grinding tool that exhibits many advantages over traditional ball milling, it is also faster to install than a traditional Best HLM Vertical Roller Mill Manufacturer and FactoryVertical mill consists of main mill, classifier, fan, finished product cyclone separator, and air duct Among them, the main mill consists of frame, air inlet volute, shovel blade, grinding roller, grinding ring and housing HLM vertical roller mill Max feeding size: 50mm Capacity: 5200t/h Fineness: 200325 mesh (7544μm)News What Is Vertical Grinding Mill?

CLUM Ultrafine Vertical Grinding Mill

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17The Vertical Grinding Mill is now CEapproved For very fine grinded coffee on our Diamant Vertical mills, we can supply the mills with special coffee stones in the size 400 mm and 500 mm Our mill in size 400 mm is available in a special version for milling oily products for example mustard – it must be dry and not wetDiamant Vertical Grinding Mill EngskoVideos; BlogNews; 8556708777 +44 1322559106 About; Products Pendulum Roller Mills spinning the passing air and throwing coarse particles out to the sides of the mill, where they fall back into the grinding zone Uses of Bradley Vertical Blade Classifiers Vertical Blade Classifiers (VBC) Bradley Pulverizer CompanyVertimill® is a unique product offered exclusively by Metso Grinding efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner wear make Vertimill® the lowest total cost of ownership in many applications, substantially improving the profitability of concentratorsVertimill® Metso

Vertical Grinding Mill: How it Works, Application And Advantages

Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 sales@macawberindia 130131, Hindustan Kohinoor Complex, LBS Road, Vikhroli, Mumbai Home; blade, grinding roller, and liner, need to be checked for wear tear and replaced accordingly 3The Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to efficiently produce finely ground materials The mill is available in 18inch and 35inch sizes and can process a variety of materials including minerals, chemicals, and manufactured products It Raymond Vertical Mill Technical Datasheet PDF Mill (Grinding With years of technical innovation experience in cement and slag grinding, Shanghai Yingyong Machinery Co, Ltd has successfully developed various models of vertical roller mills Our team of specialists is dedicated to assisting customers worldwide in creating dependable, energyefficient, and highperforming solutions for vertical roller mill grindingOptimize Your Grinding Process with Our Vertical Roller MillsUBE Vertical Mill Video Strong Points Energy Saving (Less than 30% compared to Ball Mill) Possible to carry out simultaneously with grinding, UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Information about UBE Vertical Mill servicesUBE Vertical Mill UBE Machinery Corporation, Ltd

UMC400SS 5Axis Mill 40Taper Super Speed Vertical Mills

Rotary Burrs / Die Grinding Bits; Keyseat Cutters; Corner Rounding End Mills; Slot Mill Bodies; Boring Systems Indexable End Mill Kits; CutOff Tool Block Blade Kits; Drill Tap Kits; Indexable Drilling Kits; Shell Mill Kits; SuperSpeed 5Axis CNC Vertical Machining Center with 17" x 11" x 13" travelsAs the HLMX 2500 Mesh Superfine Powder Grinding Mill works, the motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder The material moves to the edge of the dial due to the effect of HLMX 2500 Mesh Superfine Powder Grinding MillIn addition, the raw material grinding process will be supported by a QMR² 48/24 For the 4,000 tons per day kiln line Shiva Cement Ltd contracted a quadropol® vertical roller mill for grinding pet coke with a QMK² 32/16 The same mill size quadropol® Vertical Roller Mill myPolysiusService2019年7月6日 This is Mill Skills, a multipart series to help you learn basic machine shop work Exclusive videos, drawings, models plans available on Patreon!https://wVertical Mill Tutorial 1 : The Basics YouTube

.jpg)

Campbell Grinder Creep Feed Grinders, Vertical Grinding

Campbell Grinder Company solves manufacturers’ most challenging grinding problems by designing and manufacturing the best vertical, creep feed, and 5axis grinding machines available This allows our OEM and Tier 1 customers to produce the highest quality parts, at the lowest overall costperpartWant to continue learning about engineering with videos like this one? Then visit:https://coursessavree/ Want to teach/instruct with the 3D models shownHow Vertical Grinding Mills Work (Coal Pulverizer Example)Compared with the ultrafine vertical grinding mill in the same industry, HCMilling(Guilin Hongcheng) HLMX nonmetallic ore ultrafine vertical grinding mill equipment has the following advantages: lower cutting point of the classifier; The median diameter is smaller; The content of fine powder is higher; Higher yield; Lower energy consumption; The floorstation structure is News Application of HLMX Ultrafine Vertical Roller Mill for Non Vertical type,so it only need a small space for installation The grain of powder uniform and easy to select the grain from mesh Treatment Grinder Material Properties Oily NonOily Fineness 3mm ~ 30mesh Capacity 20kg ~ 300kg Production Methods Single MachineBlade mill VM series Mill Powder Tech Co, Ltd vertical / grain

.jpg)

Grinding Mills Manufacturers, Factory, Suppliers from China

Getting started; Grinding Mills; Grinding Mills Manufacturers, Factory, Suppliers from China Our purpose is to fulfill our clients by offering golden company, great price and premium quality for Grinding Mills, Quick Lime Manufacturer, Which Desulfurization Equipment Is Good, Rock+Crush,Calcium Carbonte MicronizerOur concept is to help presenting the confidence of HLMX ultrafine vertical mill is a highend ultrafine grinding mill equipment developed by the HCM research and development team on the basis of coarse powder vertical mills and a series of optimization and upgrades for ultrafine powder grinding and screening Advantages and characteristics of HLMX series ultrafine vertical mill 1News [Conference News] HCM’s Vertical Mill Injects Green And MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsBradken customises the design of the Vertical Grinding Mill flights to further increase performance to suit your operating conditions and manufacture the liners from superior wear materials to extend your wear life and maximise mill Vertical Mill Liner Solutions Bradken

VMX Superfine Vertical Mill Grinding Mill Fertilizer production

We offer complete industry grinding mill production line for designs, VMX series ultrafine vertical mill is suitable for nonmetallic mineral industry, such as limestone, calcite, marble, other coarse powder will be brought down to the millstone by the For ball mills grinding OPC to a fineness of up to around 3600 cm2/g (Blaine) grinding aid is usually not required; it may not even be feasible considering the cost of grinding aid However, a vertical roller mill for cement grinding generally requires the use of grinding aid to achieve the most efficient operation with a stable grinding bed Cement grinding Vertical roller mills VS ball millsWe welcome all slag grinding mill manufacturers to come for detailed consultation If you have the equipment purchase demand for Slag Grinding Mill Machine, please contact mkt@hcmilling or call at +86773, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check hcmillingNews Application Of Slag Grinding Mill Introduction To Product Application Of Limestone Ultrafine Vertical Mill Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as gypsum, calcium carbonate, limestone, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement Limestone Ultrafine Vertical Mill

Vertical Bead Mill Tipco Engineering

Vertical Bead Mill is a small laboratory as well as an industrial machine that is perfect for grinding and dispersing materials into small particles The mill uses batchtype grinding method, so it is best suited for wet grinding with three corresponding sentences of premixing Grinding and dispersing can be done simultaneously on this machineCan construction waste be treated with a vertical mill? The manufacturer of Vertical Mill HCMilling(Guilin Hongcheng) utilizes the advantages of largescale and efficient energy conservation of vertical mills, using construction waste as raw material After grinding, two types of recycled building materials can be produced simultaneouslyCan Construction Waste Be Treated By Vertical Mill? Details of 2024年11月4日 Loesche Vertical Roller Mill (VRM) is a revolutionary mineral processing tool that operates without water, capable of grinding rocks and minerals up to 50mm in a single pass With over 117 years of experience and Digital 40 software integration, it sets the standard for efficiency and sustainabilityLoesche Vertical Roller Mill for efficient processingLM vertical mill adopts new milling devic and automatic electric control system, integrating drying, Under the action of the blade, The collected powder is the product of the ultrafine vertical grinding RELATED CASE 30tph LM170K Vertic LM190K Vertical RolLM Vertical Roller MillGrinding mill machine, mineral mill,

Blade mill SHARP PRO KUBAN COFFEE ROASTERS

quot;The Ultimate Solution for Mass Production: KUBAN SHARP PROquot; Experience industrial coffee grinding with KUBAN SHARP PRO Our quot;Proquot; series stands for cuttingedge technology and toptier quality, The major design features of the tower mill are (1) a central agitator screw, the only moving machine component in contact with the slurry and steel media, and (2) the vertical grinding chamber which minimizes overgrinding of the product This arrangement reduces energy consumption in fine grinding of minerals by 25% to 50% when compared to traditional Vertical mills for fine grinding – FLS2017年1月27日 Grinding, one of the “Shaping” functions of Technology Cycles, enables grinding on 5axis machines and machining centers Conversational programming software for grinding embedded in 5axis machines and Grinding Products DMG MORIlink of the main components of vertical mill, carried out the antijamming analysis, and solved the problems in the assembly, overall design of vertical mill was completed well and achieved the expect of design Fig 6 Vertical roll grinding explosion Fig 7 Vertical grinding structure Solid Edge’s Application in Vertical Mill Design 1101Solid Edge’s Application in Vertical Mill Design Springer

.jpg)

FLSmidth VXPmill Operation

2022年3月28日 The VXPmill is an established vertical ceramic media regrind mill used in energy efficient gold, copper, lead and zinc plants worldwide All slurrycontacting components of the VXP are polyurethanelined and the grinding discs are solid polyurethane, making the VXP the only vertical stirred mill providing ironfree grinding worldwideVertimillreg; is globally recognized as an energy efficient grinding machine Through a low total cost of ownership, they bring substantial improvement to the profitability of concentrators During the years, Vertimillreg; technology has proven to be efficient especially in Vertical mill Vertimill® 7000 Metso Corporation DirectIndustry2023年8月20日 A vertical mill operates on the principle of material bed grinding, where raw materials undergo a precise grinding process Here's how it works:The mill's moHow Does a Vertical Roller Mill Work? YouTubeThe mill consists of the lower casing, upper casing, table mounted on the vertical planetary gear reducer and grinding rollers supported by the swing levers The separator is installed at the upper parts of the mill The raw material fed through the air lock gate is ground between the rollers and table with the grinding force added byVERTICAL ROLLER MILLS AMCL

The functions of the vertical roller mill separator Great Wall

2021年8月16日 If largescale grinding mills want to control the fineness of the finished product, the powder separator is a very critical component The separator of the vertical roller mill is mainly composed of shell, cage rotor, wind guide blade, transmission device, and other components The existence of this device not only affects the quality of the finished product, but also can greatly Haas CNC Grinding Multigrind CB (Turbine Blade) Thanks to its enormous capability, the CB is the ideal machine for the highly demanding serial production of complex tools and components Gear cutting tools made of tool steel with a total weight of 600 kilograms can be machined on the CB with the same precision as knee implants made of CoCrHaas CNC Grinding Multigrind® CB (Turbine Blade) Kingsbury