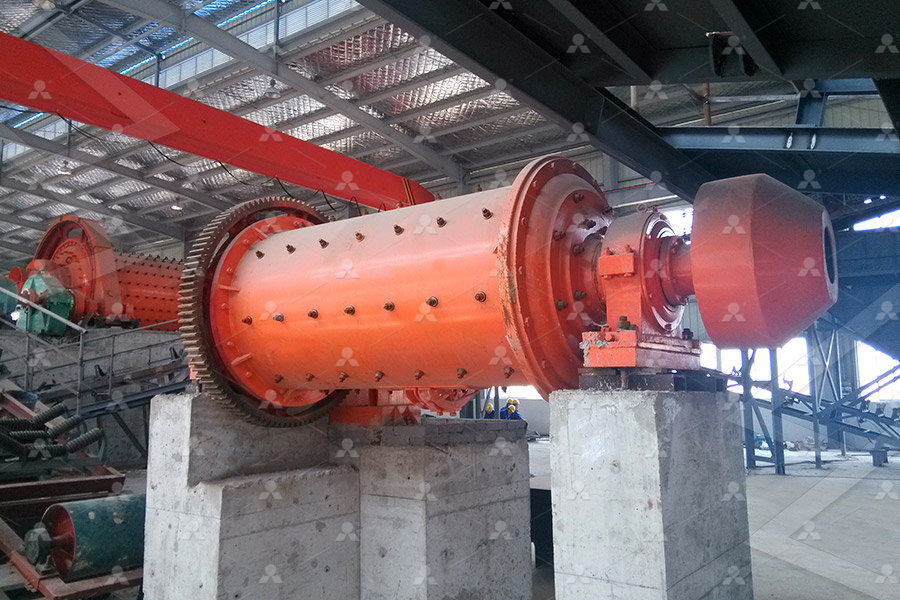

xsd3016 quicklime powder equipment installation plan

.jpg)

Sand washing plant XSD3016 Henan LIMING Heavy

This machine can be used to metallurgy, building materials and hydropower, etc industries, which is more suitable for building sand Applications: Aggregate Field, Concrete Mixing Plant, Dry quicklime, hydrated lime, soda ash, and magnesium oxide in large quantities, requires an efficient method for storing these chemicals as part of your overall storage silo and chemical YOUR LIME HANDLING EXPERTS CarmeuseLime in the form of quicklime (calcium oxide – CaO), hydrated lime (calcium hydroxide – Ca[OH]2), or lime slurry 1 can be used to treat soils Quicklime is manufactured by chemically LIMETREATED SOIL CONSTRUCTION MANUAL Graymont2023年12月8日 After calcining, limestone turns into calcium oxide CaO (commonly known as quicklime), which is generally in block form and is used in water treatment, asphalt Limestone crushing technology and equipment SBM Ultrafine

.jpg)

Quicklime preparation Gebr Pfeiffer

Calcium oxide (also called quicklime, burnt lime, or unslaked lime) is formed by burning limestone Quicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, Our standard quicklime feed system provides an integrated solution for receiving, storing, feeding, slaking and delivering up to 2,500 lb/h of quicklime from truck to the point of applicationSTANDARD QUICKLIME2024年4月16日 Quicklime, also known as calcium oxide (CaO), is a caustic alkaline substance It has been used by humans for centuries for many things such as mortar, flux, treating corn, How to Make Quicklime: 10 Steps (with Pictures) wikiHow2018年9月3日 Hydrated Lime, Quicklime, Powdered Activated Carbon (PAC), or Soda Ash in a silo, dissolve it in a tank, and pump the chemical solution to the point of application Each Bulk Chemical Storage and Feed Systems for Hydrated Lime,

.jpg)

Lime/quicklime for metallurgy – how producing and briquetting

2023年2月4日 Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime China Quick Lime Plant Equipment wholesale Select 2024 high quality Quick Lime Plant Equipment products in best price from certified Chinese Machine Equipment Control Quick Lime Plant Equipment MadeinChinaThis IQ/OQ Protocol applies to the following equipment: Items System Information URS Reference N/A Factory Acceptance Testing (FAT) Reference Project Master Validation Plan Number N/A Site Master Validation Plan Number N/A Equipment Name/Description VH 8/Powder mixer Manufacturer LFA Machines Model Number 1 Serial Number Equipment ID Number or VH 8 Powder Mixer IQ/OQ LFA Tablet Presses2015年9月1日 Exterior dimensions of the equipment need to be known so that you can plan a good shop layout Make sure you have enough room in your shop for not only the equipment, but adequate turning space for your parts or racks, Choosing Your Powder Coating Equipment Reliant

.jpg)

ColorMax Powder Coating Booth Installation Guide Nordson

Before installing any system equipment, make sure it is rated and approved for the environment in which it will be used Any approvals obtained for Nordson equipment will be voided if instructions for installation, operation, and service are not followed All phases of equipment installation must comply with all federal, state, and local codes2024年11月1日 Quicklime powder processing equipment #grindingmachine #machineQuicklime powder processing equipment #grindingmachine Learn how to plan and schedule your capital equipment installation with minimal disruption to your operations Follow these six best practices from capital equipment sales experts6 Steps to Plan and Schedule Capital Equipment InstallationWhat is the procedure for machinery installation? A successful machinery and equipment installation involves a series of welldefined steps that need to be executed meticulously Here’s a breakdown of the key stages: Step 1: Planning and Preparation Before any physical work begins, a comprehensive project plan should beKey steps for a successful machinery installation

.jpg)

02 Excel 3000 Series Powder Coating Booth Installation

Nordson equipment will be voided if instructions for installation, operation, and service are not followed All phases of equipment installation must comply with all federal, state, and local codes Refer to the National Fire Protection Association publication NFPA 33 for standards on installation and operation of powder spray systems Grounding2022年11月7日 Create a Detailed Budget: Account for equipment, installation, training, and operational costs Establish a Timeline: Set realistic milestones for each phase of the installation process 2 Equipment Selection Choosing the Right Ovens, Machines, and Equipment: Powder Coating Ovens: Select between batch or conveyor ovens based on production needsPowder Coating Plant Design Powder Coating Equipment» Low Dust Levels – No need for air filtration Keeps installation costs to a minimum » Low Noise – No costly acoustic protection Mobile units can be used in any location » Flexibility – Freestanding mobile units, standard models as part of process systems and special custom units as an integral part of other equipment and systemsPowder Processing Equipment Systems Qlar2015年3月13日 If your equipment is running smoothly, we can still help Our service staff has a number of preventative maintenance tasks that can be performed as needed or during regularly scheduled visits, including: installation of new filters and bearings; system examination and recalibration; line audits for improved performance; Datapaq recorders for powder oven Industrial Painting Powder Coating Equipment Repair Maintenance

.jpg)

Contractor Quality Control Plan For Rotary

Contractor Quality Control Plan for Rotary Equipment Installation Free download as PDF File (pdf), Text File (txt) or read online for free This document outlines the quality control plan and inspection test plan for installing rotating Quicklime powder is created by heating limestone (which is calcium carbonate or CaCO3) to high temperatures in a kiln, causing it to undergo calcination; The chemical reaction during calcination can be written as CaCO3 → CaO + CO2; When water is added or mixed into quicklime, it undergoes hydration and develops intense heatQUICKLIME CALCIUM OXIDE POWDER2019年5月6日 9 Installation Qualification (IQ)Installation Qualification (IQ) Details of the Equipment Equipment name, made by model No shall be noted down Location for the installation equipment shall be checked Utilities Validation of drypowdermixer PPT Free 2016年2月11日 A wise but costly decision made during equipment installation is almost always better than being stuck with a system that doesn’t work as well as it could Plan for BIG success Before issuing the first PO, address your potential production needs for 5+ years down the roadPlanning Success For Your Automatic Powder Coating Line

.jpg)

A Comprehensive Guide to Designing and Installing Plant Silos

2024年4月15日 The design and installation of plant silos are critical components of an efficient and effective storage system for agricultural and industrial applications By understanding the key features, design considerations, and installation processes, businesses can make informed decisions when investing in plant silo infrastructureCreate a Detailed Budget: Account for equipment, installation, training, and operational costs Establish a Timeline: Set realistic milestones for each phase of the installation process 2 Equipment Selection Choosing the Right Ovens, Machines, and Equipment: Powder Coating Ovens: Select between batch or conveyor ovens based on production needsSurface Pretreatment For Powder Coating Finishing Washing4 SART UP: T Conduct a preliminary equipment evaluation prior to production ‘Follow the Plan’ When Installing and Commissioning Compounding Lines A fully operational and documented system doesn’t happen by chance An efficient, welldesigned installation plan, prepared well in advance, will put you on the path to maintaining a‘Follow the Plan’ When Installing and Commissioning LeistritzAIS Vanguard is one of the UK’s leading providers of comprehensive machinery installation services and equipment installation, including crane installation and robot installation As one of the largest privatelyowned specialists in equipment installation within the UK, we excel in delivering machinery installation, removal, and relocation servicesMachinery Installation Industrial Plant Equipment AIS

Equipment Installation for Manufacturers Vixxo

For your larger install projects, the right outsourced installation partner adds value by creating and then executing a coordinated plan that ensures the installations will be consistent from location to location, the technicians are certified and trained on proper installation protocols, and that costs are contained and the project timeline metAn equipment installation project charter is a document that defines the scope, objectives, roles, and responsibilities of a project that involves installing new or upgraded equipment in a facilityHow to Create an Equipment Installation Project Charter LinkedInChina Quick Lime Plant Equipment wholesale Installation: Under Our Engineer's Guide After Sale Service: Supply Testing: We Offer Certificate: ISO9001,ISO14000,Ce Quicklime Powder Packing Machine Chinese Factory Automatic Granules Powder Filling Quick Lime Plant Equipment MadeinChinaQuicklime powder processing equipment #grindingmachine #machineQuicklime powder processing equipment #grindingmachine

Equipment Installation Checklist Template

2022年8月10日 With the help of a equipment installation checklist in your workflow, you can help account for any wasted time and refine your processes How It Works Fire Protection Plan execute Asset Testing and Reporting 2021年4月6日 Plan for the time other equipment in the facility will need to shut down during installation bring in a qualified tradesperson to complete it well ahead of the equipment installation date PlasticsToday MD+DI Qmed+ Design News Powder A StepbyStep Guide to Installing Packaging Machinery2024年4月18日 Implementing software is a daunting task that small businesses often struggle with Leaders and IT professionals could be aware that it's time to put a software implementation plan in place, but not how detailed that rollout plan should be You want to cover all the essentials from the software purchase to the project's golive date5 Critical Steps to a Successful Software Implementation PlanCreate a Detailed Budget: Account for equipment, installation, training, and operational costs Establish a Timeline: Set realistic milestones for each phase of the installation process 2 Equipment Selection Choosing the Right Ovens, Machines, and Equipment: Powder Coating Ovens: Select between batch or conveyor ovens based on production needsPaint Line Systems Powder Coating Equipment

How to Make Quicklime: 10 Steps (with Pictures) wikiHow

2024年4月16日 Safety is extremely important when making or dealing with quicklime Quicklime is extremely dangerous and is reactive to moisture When making or handling quicklime, you must wear safety material Specific dangers include eye hazards and skin hazards Contact with eyes or skin can cause burning and possibly permanent damageThe equipment definitely helps and improves the time spent and the final product, but how involved and how much money you want to spend on equipment is up to you Powder coating is a great hobby and if you are willing to put in the time to learn it properly and invest in the right equipment, it can be a great career as wellWelcome to Powder Coating: The Complete Guide5S is a simple way to improve your workplace productivity, safety, cleanliness, output quality, and team morale The 5S approach is rooted in lean production principles, and it is designed to be costeffectively implemented using the resources you already have in placeThe Ultimate Guide to 5S Lean ProductionAccording to the quicklime mesh and output, the following suggestions are given for the selection of quicklime powder grinding mills for reference only Quicklime Powder 1 Raymond mill is used for quicklime powder making It is recommended to use Raymond mill for the processing of quicklime with an output of 1 to 9 tons and a mesh of 80 to How to choose quicklime powder grinding mill?

Network Installation Steps: How To Set Up (2025

4 天之前 The floor plan and features of the physical space will shape how an installation is planned for, designed, and carried out Sometimes, the physical space imposes obstacles such as solid walls (instead of hollow), HVAC Create a Detailed Budget: Account for equipment, installation, training, and operational costs Establish a Timeline: Set realistic milestones for each phase of the installation process 2 Equipment Selection Choosing the Right Ovens, Powder Coating Conveyor Systems Powder Coating It helps to distribute power to various appliances and equipment through accurate operation and installation of elements Benefits of Electrical Plan A plan highlights all the potential risks to make amendments quickly before the occurrence of any substantial damage It helps to ensure that your system runs safely, efficiently, and smoothlyElectrical Plan 101: Know Basics of Electrical Plan EdrawMaxReliant powder coating ovens include free startup and calibration by our technicians Through expert tuning, our ovens reach curing temperatures faster and cost less to operate Our proprietary heat system, 6” thick insulated panels, and innovative air flow design save fuel, increase reliability, and help keep your oven at the ideal curing temperaturePowder Coating Oven Reliant Finishing Systems Electric Gas

15 ITP Installation of Static Equipment PDF Scribd

The plan lists 5 main test sections with various acceptance criteria and involvement needed from the company and subcontractors installing the equipment while checking verticality and orientation, grouting the equipment base, and completing a punch list to ensure all mechanical completion checks are doneFor over 40 years, Sodimate has supplied bulk handling equipment and systems for a vast array of clients We provide a wide range of equipment from conventional flexible screw feeders to completely automated bulk storage silos, discharge and feed systems With over 9000 successful installations throughout our worldwide subsidiaries and representative networks, we have Powder handling specialist Sodimate IncLeading the Way in Rubber Recycling Discover Rubber Powder Equipment GmbH's stateoftheart rubber recycling technology Transforming waste into valuable resources with efficiency and environmental consciousness Explore Our Technology Contact Us Customized Solutions for Your Business Our P650/S650 recycling systems are designed to meet diverse industrial RUBBER POWDER – EquipmentEquipment and Process Description RTP 10i® Process The basic mechanism of the RTP 10i® involves filling the Tooling (Die, Upper Punch, and Lower Punch) with powder, compressing the powder, and ejecting the tablet Filling the Tooling with Powder The dry materials are poured into the Hopper, which funnels the powder into the Fill Tray As theRTP 10i Tablet Press IQ/OQ

.jpg)

Home Electrical Plan Free Electric Schematic Software Kozikaza

From your house plan to your electrical network in a few clicks Overview of house electrical plan design with Kozikaza electrical software Our architects have designed for you a free, complete 2D and 3D home plan design software It allows you to create your virtual house and integrate your electrical plan directly