How to process heavy calcium powder

.jpg)

Production and modification process of heavy calcium carbonate

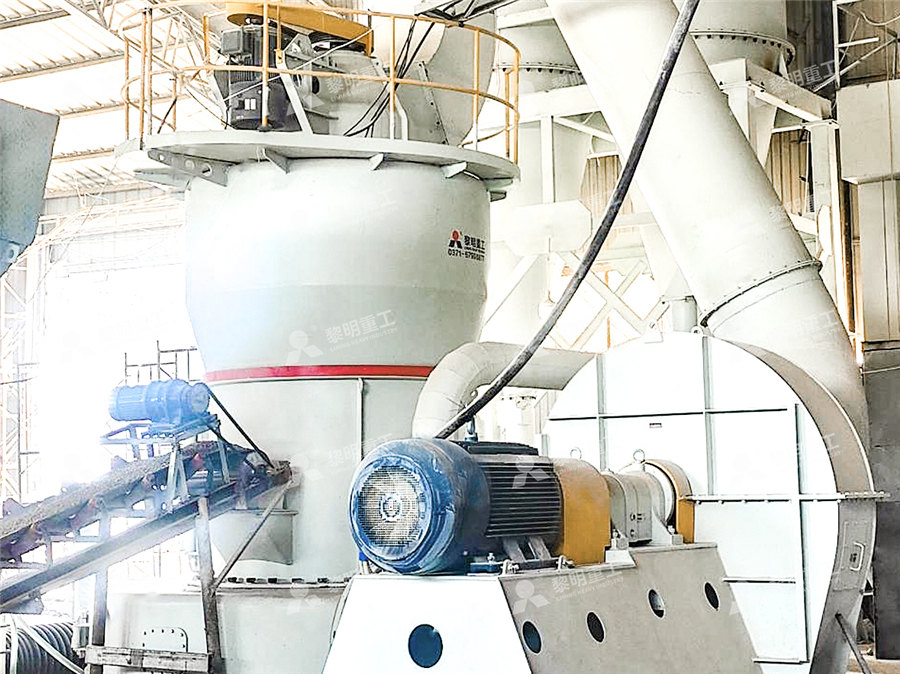

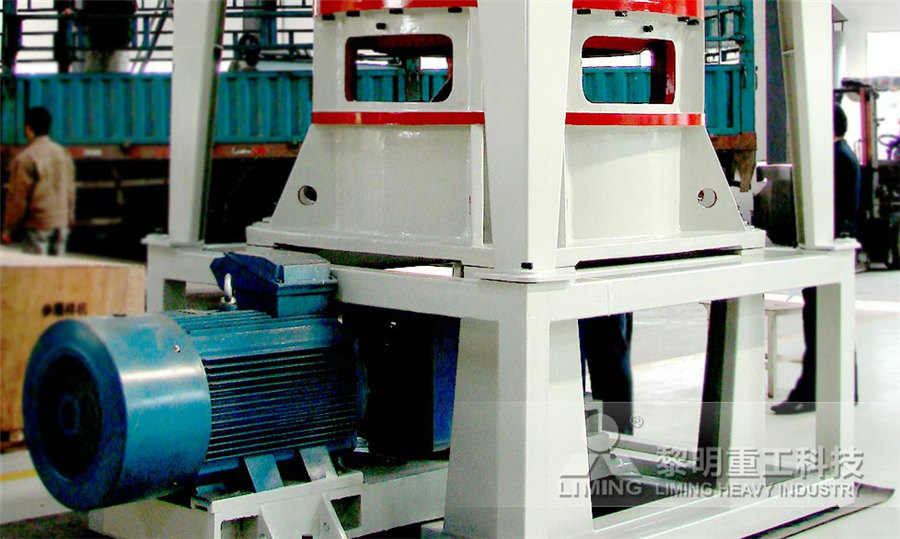

2021年8月24日 The wet method is used to process refined and functional heavy calcium powder, the mesh number is above 3000, and the equipment mostly uses stirring mills Adding pulverizing aids in the fine media mill can prepare submicron or even nano ultrafine powderHeavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the characteristics of wide source of raw materials, high News Calcium powder processing machinery and 2024年8月23日 Among them, the dry process is generally used to produce heavy calcium carbonate products with d97≥35μm The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, Heavy calcium carbonate dry production process and The ultrafine grinding of heavy calcium powder plays a crucial role in improving its application performance Choosing an appropriate grinding method and optimizing the grinding process UltraFine grinding processing method and flow of heavy calcium

Heavy calcium carbonate grinding, surface modification

2024年7月10日 At present, the production technology of heavy calcium carbonate is mainly based on grinding and surface modification, in order to process products that meet the 2023年6月25日 Ftmmachinery can design and optimize the grinding process for calcium carbonate plants based on raw materials, output, required particle size distribution, and equip crushers, grinders, air classifiers, dust collectors and Guide to Calcium Carbonate Grinding: Mills, Tips, and In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh For processing 4 Steps to Build a Calcium Carbonate Processing Plant2021年8月27日 Heavy calcium ultrafine processing equipment is divided into grinding equipment and grading equipment The grinding equipment includes Raymond mill, vibration Heavy calcium + superfine processing equipment ALPA Powder

.jpg)

CALCIUM CARBONATE (GCC) Hosokawa Alpine

coated GCC powder are steadily increasing The result: significantly improved properties (fracture strength, brilliance) of polymers at greatly reduced costs In practice, continuous coating 2022年5月10日 This dehydration process dramatically extends the heavy cream’s shelflife, which is a big difference compared to traditional, refrigerated cream As long as your heavy cream powder is not mixed with Vitamin D, Heavy cream powder vs heavy cream (The difference) 2019年7月22日 Recommend Calcium Carbonate Grinding Mill Capacity: 0430 T/H Feeding size: ≤20mm Output Size: 1503000mesh Calcium Carbonate Grinding Mill is the equipment specializing in producing fine and superfine calcium carbonate powderHow to make the calcium carbonate powder?Heavy calcium powder is not equal to talc powder Both heavy calcium powder and talc powder have similar uses But, they are completely different And, there are some differences in their properties and uses Heavy calcium powder Heavy calcium powder is the short form of heavy calcium carbonate It has a molecular formula of CaCO3Differences in uses and properties between heavy calcium powder

How To Make High Quality Calcium Carbonate Powder

As an important inorganic nonmetallic industrial raw material, heavy calcium carbonate powder/ground calcium carbonate is widely used in papermaking, For the crushing and cleaning process, it can be seen from the above figure 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses2021年8月24日 Among them, the use of 25006500 mesh heavy calcium powder in highend papermaking has also increased Production of heavy calcium carbonate The raw materials are carbonate minerals such as shells, calcite, marble, limestone, chalk and dolomite Common heavy calcium processing methods include dry, wet, and drywet process combination methodsProduction and modification process of heavy calcium carbonateUltrafine heavy calcium carbonate with d97≥5μm generally adopts dry production process, and some use wet grinding + drying process The ball mill + classifier production line is mainly used to produce heavy calcium carbonate fine powder and ultrafine powder with d97=5~43μm It is characterized by continuous closedcircuit production, News Calcium powder processing machinery and equipment process

How to Remove Calcium Buildup in Water Pipes 10 Easy Ways

2024年3月2日 Things to Consider When Removing Calcium Buildup in Water Pipes When it comes to removing calcium buildup in water pipes, there are a few things that you need to consider before starting the process This is because each situation may vary and require different methods of removal2023年12月15日 The sourcing of Coral Calcium Powder is a process deeply rooted in environmental sustainability, reflecting a growing consciousness towards preserving our planet’s natural resources The harvesting of this supplement is meticulously managed to ensure that living coral reefs, vital to marine ecosystems, remain undisturbedBeneath the Waves: The Transformative Power of Coral Calcium PowderHomemade Toothpaste: Combine eggshell calcium powder with coconut oil, baking soda, and peppermint essential oil to create a natural toothpaste that promotes healthy teeth and gums Making Eggshell Calcium Powder: Now, let’s guide you through the simple process of creating calcium powder from freerange pastureraised eggshells Ingredients How to Make Calcium Powder from Eggshells and Why It’s a 1、 Production of wet grinding heavy calcium carbonate: first, the suspension of dry grinding heavy calcium powder is put into the heavy calcium grinding mill for further crushing, and then the ultrafine heavy calcium carbonate is prepared after dehydration and drying The production process of wet grinding heavy calcium is as follows:News Apply The Heavy Calcium Grinding Mill Machine To The

.jpg)

Calcium Carbonate Powder HuberCal Calcium

HuberCal ® Calcium Carbonate Powder HuberCal ® calcium carbonate powder is a naturally pure source of calcium It is the ideal ingredient for use in dietary supplementation for food fortification, granulations, antacids and other various Content from this work may be used under the terms of the CreativeCommonsAttribution 30 licence Any further distribution of this work must maintain attribution to the author(s) and the title of Dry surface modification of heavy calcium carbonate powder 2022年9月1日 Calcium carbonate serves as both a skeleton and a white pigment in coatings making Paint Industry a huge market for Calcium Carbonate Powder Supplier in India Calcium carbonate can be used as an extender pigment in paint because it is a white colour, costs less than latex and solvent, and has finer, more evenly dispersed particlesWhat are the uses of calcium carbonate powder? Zillion Sawa 2024年4月18日 The best calcium supplement for a person will depend on their age and health needs This article lists seven high quality options to consider7 Best Calcium Supplements for 2024 Medical News Today

How to Choose a Calcium Carbonate Grinding Mill DASWELL

In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, storage bins, grinding mill, dust collectors, classifiers and other equipment2023年12月11日 It has a higher density than light calcium carbonate due to its larger particle size and higher purity Heavy calcium carbonate particles typically range from 5 to 20 microns Heavy Calcium Carbonate Production Process: Heavy calcium carbonate production involves mining and extracting highquality limestone or marble depositsThe Difference Between Heavy Calcium Carbonate and Light Calcium 13 Production process First, Add the raw heavy calcium carbonate powder to the reaction tank, and add an appropriate amount of mother liquor, then start stirring Added dropwise concentrated formic acid to the reaction tank to a pH of 4 to 45 at room temperature, and the reaction is further continued for 15 minutesCalcium Formate Production Process Cellulose Ether2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry Calcium carbonate milling process SBM Ultrafine Powder

Manufacturing Process Flowchart Calcium Carbonate, Heavy Powder

Manufacturing Process Flowchart Calcium Carbonate, Heavy Powder, USP CA131 Raw material analysis Mining Start Raw material storage Cleaning Boring at instructed area Coarse crushing Intermediate pulverizing Packaging Product inspection Storage Shipment Intermediate inspection Product tank Fine grinding Air separation2018年2月25日 I’ve been taking eggshell calcium for about six months now (since August 2016) the way i take it is i process the eggshells by collecting a sufficient amount and then boiling it and then drying it out in the oven then i How to Make Eggshell Calcium (and Why You’d Want Heavy calcium carbonate, also known as heavy calcium carbonate, is the most commonly used product in the calcium carbonate industry The production process of heavy calcium is simpleHow much is the heavy calcium grinding Introduction to Downstream Application Fields of UltraFine Grinding Process of Heavy Calcium Powder The ultrafine grinding process of heavy calcium powder mainly includes the following steps: Crushing and Grinding The raw material is first crushed to a suitable size by a jaw crusher or impact crusher, and UltraFine grinding processing method and flow of heavy calcium powder

Calcium Carbonate – What Is It And How To Make It

Calcium Carbonate Production Process Ground calcium carbonate is also called known as heavy calcium carbonate,it is made by mechanical methods (using grinding mills such as roller mill or other highpressure grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc Ground calcium carbonate can be made into different b Milk powder c Fruits d Meat e US FDA methods 33 Beverage samples 9 a Juice Carbonated Nonalcoholic Beveragesb Part 3 Industrial samples 10 etal samplesM 10 l sami esplO 1 0 efinery productsR 10 ectronic wasteEl 11 Part 4 Clinical research and pharmaceutical samples 12 loodB 12 erumS 12 ineUr 12 Pharmaceutical 12Sample preparation techniques for AAS, ICPOES and ICPMS for 2023年9月6日 To clean calcium buildup from your shower floor, you’ll need some rubber gloves, a cleaning brush, a sponge or cloth, a bucket, and some lemon juice Step 2 Prep the Shower Floor: Clear the area of any clutter or debris before beginning the cleaning processHow To Clean Calcium Buildup on Shower Floor 5 DIY Methods2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a review

How to Soften Hard Water (Advice From a Water Treatment Expert)

2024年7月5日 Ion Exchange Water Softener The Evidence A 2005 study on water softeners for hardness removal concluded that a hardness concentration of up to 1000 mg/L could be removed by at least 8168% by these systems; Water softeners are also recommended by the EPA for homes in “areas of substantial hardness” thanks to their ability to remove the calcium and Generally according to the type of application machine classification, calcium carbonate processing into coarse powder (03mm), fine powder (80425 mesh), ultrafine powder (4001250 mesh), micro powder (12503250 mesh), etc The 400 mesh calcium carbonate mill is between fine powder and ultrafine powderWhat is the process flow of calcium carbonate milling? How to 1、 Production of wet grinding heavy calcium carbonate: first, the suspension of dry grinding heavy calcium powder is put into the heavy calcium grinding mill for further crushing, and then the ultrafine heavy calcium carbonate is prepared after dehydration and drying The production process of wet grinding heavy calcium is as follows:News Apply The Heavy Calcium Grinding Mill Machine To The 2024年1月3日 During this process, calcium and magnesium are replaced with sodium and occasionally potassium Calcium Hydroxide Calcium hydroxide is a powder used to treat and prepare water, food, filters use activated carbon to How to Remove Calcium from Water: 4 Simple

How To Use And Buy Food Grade Calcium Carbonate

2022年7月28日 Food Grade Calcium Carbonate Powder is an extremely healthy, nutritious and safe all natural ingredient This white crystalline compound is very popular with gardeners, culinarians and painters It increases the pH of 4253000mesh heavy calcium powder grinding mill The heavy calcium powder in this fineness range can be processed by ultrafine mediumspeed ring roller mill The system is dry production, which can realize selfgrinding and self 4 Steps to Build a Calcium Carbonate Processing Plant2022年3月7日 What is the shelf life of eggshell powder? As long as the powder is allowed to fully dry, it should last a year long time (multiple years) I recommend keeping it in an air tight container, away from any moisture, heat or light If stored well, it should keep for 3+ years How much should I add to my plants?Homemade Eggshell Powder (Calcium Carbonate The Harvest 2021年11月1日 Calcium carbonate (CaCO3) particles represent an appealing choice as a drug delivery system due to their biocompatibility, biodegradability, simplicity and costeffectiveness of manufacturing, and Structure and phase analysis of calcium carbonate powder

Significantly improved sintering shrinkage of heavy calcium

2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Standard Process Calcium Lactate Powder Immune Support and Bone Strength Bone Health and Muscle Supplement with Magnesium and Calcium 12 Ounces Unflavored 12 Ounce (Pack of 1) Options: 4 sizes 48 out of 5 stars 942 50+ bought in Amazon: Calcium PowderIt is also used in cement, is converted to quicklime (calcium oxide) and slaked lime (calcium hydroxide) Ground calcium carbonate is slightly basic and can be used to neutralize combustion vapors or increase the pH in water or soils Pure calcium carbonate is a relatively soft mineral/compound, with a Mohs hardness of 25 – 30Ground Calcium Carbonate / Limestone Hosokawa Micron Powder Systems2010年9月22日 Calcium deposits, or efflorescence, form when excess moisture within cement rises to the surface These white, powdery deposits are common on basement walls, floors and other cement surfaces Although efflorescence is not harmful to cement, excessive amounts of it may cause mold or insect problemsHow to Remove Heavy Concrete Calcium Deposits Hunker

Nature Fresh Calcium Magnesium Complex 300g Clicks

The average person can only assimilate 200 mg of calcium per day Extra calcium is used for alkalizing or to excrete toxins heavy metals that it binds to Calcium is best absorbed when its pH is acidified and combined with magnesium, vitamins: B6, D3 C Trace elements and tissue salts assist the process, to target weakened areas