Ceramic waste processing process

Sustainable ceramics derived from solid wastes: a review

2020年9月8日 The present review is aimed to provide an uptodate overview of the recent wastederived ceramics including refractories, glasses, whitewares, 2016年9月1日 The recycling of waste in ceramic manufacturing is theoretically beneficial because it is possible to absorb great amount of waste, also hazardous, that would otherwise Recycling of industrial wastes in ceramic manufacturing: State of 2021年5月1日 First, an overall examination of technical constraints that waste recycling must comply to be transferable to ceramic tile manufacturing Second, a detailed critical review of Waste recycling in ceramic tiles: a technological outlook2020年12月1日 Available information on the behavior of ceramic tile bodies containing wastes from various sources was critically reviewed for every manufacturing stage The main outcome is an outlook aboutWaste recycling in ceramic tiles: a technological outlook

Glasses, Frits and GlassCeramics: Processes and Uses

2024年3月14日 The review reveals that considerable knowledge and experience have been accumulated in the process of transforming silicatebased waste into useful glass and glassceramic products with properties similar to, and even 2023年7月5日 In this context, this study addresses the implementation of a Life Cycle Assessment (LCA) on the production of ceramic sanitaryware, based on a cradletograve Life Cycle Assessment (LCA) of ceramic sanitaryware: focus on the 2024年4月1日 In ceramic tile manufactories, CTW is divided into unfired and fired wastes according to whether or not it experiences a sintering process Currently, the simplest method Recycling of ceramic tile waste into construction materials2021年2月25日 In this work, we propose a “designer waste form” prepared via spark plasma sintering to limit interaction between phases and grain growth during consolidation, leading to Preparation and characterization of multiphase ceramic designer

Industrial Ceramics: From Waste to New Resources for

2023年6月15日 Reusing ceramic industrial waste as precursors for building blocks/binders, exploiting their aluminosilicate composition for an alkaline activation process, could solve the problem This chemical process facilitates 2022年1月11日 The incorporation of marble and ceramic waste not only as cementitious materials but also as aggregate replacement helped concretes to develop enhanced Recycling of ceramic tiles waste and marble waste in sustainable 2022年6月1日 Waste ceramic materials replaced with CA various percentages (0–100%, 25% interval) It was investigated the various properties for hardened concrete It was observed that porcelain waste ceramic tile increased of compressive strength till 41% and red WC increased the compressive strength till 29% for a 100% replacement for gravelUse of waste ceramics to produce sustainable concrete: A reviewIn the past, processing of the ceramic waste form has been accomplished at high temperatures (up to 850OC) and high pressures (up to 25,000 psi) using a hot isostatic press Process flow diagram for ceramic waste process at ANLW distribution, it is dried under 100 Torr vacuum at 550OC for 6 hours in a Mechanically Fluidized Drier (MFD)CERAMIC WASTE FORM PRODUCTION AND DEVELOPMENT AT

Ceramic Processing: Slip Casting American Ceramic Society

TEACHER INSTRUCTIONS Ceramic Processing: Slip Casting Objective: Students will learn the fundamentals of slip casting and be able to think critically about why slip casting is used Background Information: Historically, ceramic materials in the form of clay figurines and pots were the first manmade materials over 10,000 years ago, and maybe even as long as 25,000 yearsSimplifying Ceramic Waste Form Processing The glassbonded sodalite ceramic waste form (CWF) was developed in the 1990s to immobilize chloride saltbearing waste streams generated during treatment of spent sodiumbonded nuclear fuel This was necessary because chloride salts are essentially insoluble in borosilicate glasses(on the order of 1%)Simplifying Ceramic Waste Form Processing Argonne National 2023年7月4日 Unfired waste is fed directly back into the production cycle, while fired waste is crushed to reduce its size and then reintroduced into the body preparation process More than 100% of unfired and fired waste is reused The Italian ceramic tile industry’s production process has always been geared towards environmental sustainabilityRecycling waste, reusing water, reducing consumption ceramica2021年5月1日 Waste recycling in ceramic tiles can be traced back to the pioneering study of Kats and Kvyatkovskaya (1972) and a few others issued in the 1980s and early 1990s (Higgins et al, 1979; Brown and Mackenzie, 1982; Abdrakhimov et al, 1990; Dondi et al, 1990, 1992)In the same period, the ceramic industry began to recycle its own processing residues and a Waste recycling in ceramic tiles: a technological outlook

.jpg)

The Use of Ceramic Waste in the Construction Materials

2022年2月2日 By using ceramic waste as a partial substitute for aggregates in the proposed the generation of construction and demolition waste as well as waste from the processing of various construction materials is a major problem in environmental The process of burning ceramic products results in pollutants of the type: total 2024年10月10日 Ceramic factories that prioritize quality control are more likely to produce highquality products that meet the needs of their customers Environmental Impact Of Ceramic Production The production process at a ceramic factory involves selecting clays or inorganic materials, processing, drying, and firingCeramic Factory And It’s Complete Manufacturing Process2023年7月22日 Large amounts of ceramic products, such as bricks, roof tiles, sanitary ware or wall and floor tiles, are manufactured worldwide, which produces significant amounts of ceramic waste (CW) because products are discarded for commercial reasons or are landfilled at the end of their useful life []As observed in [2, 3], approximately 3–7% of ceramic products are rejected Ceramic Waste: Reuse as a Recycled Aggregate SpringerLinkThe Ceramic Waste Form Process at Idaho National Laboratory Stephen Priebe Idaho National Laboratory (INL) PO Box 1625 Idaho Falls, ID 83402 ABSTRACT The treatment of spent nuclear fuel for disposition using an electrometallurgical technique results in two highlevel waste forms: a ceramic waste form (CWF) and a metal waste formThe Ceramic Waste Form Process at Idaho National Laboratory

.jpg)

Reusing Ceramic Waste as a Precursor in Alkali

2023年12月4日 Concrete and ceramic products are among the most widely used materials in the construction sector The production of ceramic materials has significantly grown in recent years Concrete is one of the most widely used 2024年4月1日 However, this inevitably leads to the generation of a large amount of ceramic tile waste (CTW) during the production process of ceramic tiles and demolition waste (Fig 1) (Zimbili et al, 2014) According to Manufacturing Economic Studies (MECS), global ceramic tile production reached 18,339 million sqm in 2021, which was a 72% increase compared with Recycling of ceramic tile waste into construction materialsMaterials List: 1 – 8pound container of plaster of paris powder (1 container makes 68 small molds)Can be found at amazon, Walmart, or your local craft store 1 – 1 gal premade porcelain slipCan be found on amazon (brand is Amaco) Plastic or aluminum trays – should have the same number as the number of molds you want to make, and should be just slightly larger Ceramic Processing: Slip Casting2013年8月13日 Crystalline Ceramic Waste Forms: Comparison of Reference Process for Ceramic Waste Form Fabrication Prepared for US Department of Energy Separations and Waste Forms KS Brinkman, J Amoroso and JC Marra Savannah River National Laboratory M Tang Los Alamos National Laboratory August 13, 2013 FCRDSWF2013 SRNLSTI Crystalline Ceramic Waste Forms: Comparison of Reference Process

.jpg)

The 8 Steps of Ceramics Processing

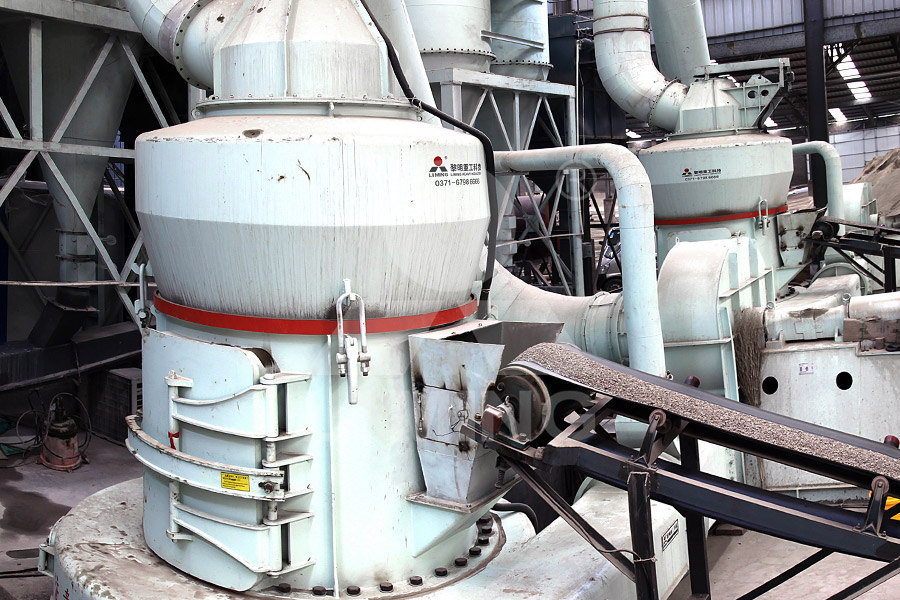

In order to create these end products, the ceramic matter needs to go through the traditional manufacturing process which goes as following: Step #1: Milling Raw Material Procurement – The raw materials used in the process are milled materials typically found in mining sites that have been reduced from a large size to smaller sizes or even in some cases, pulverized 2023年2月13日 Therefore, the basics of ceramic processing (ie, powders, slurries or pastes to an increasing environmental awareness are the production of powders from natural sources (Cestari et al, 2021) or waste Cold sintering is another very new and intriguing consolidation process for ceramics It was introduced Grand challenges in ceramics processing FrontiersDefense Waste Processing Facility obtains samples of highlevel waste glass by inserting a small cup into the molten glass pour stream (probing), four types of potential sampling activities were defined for the ceramic waste form production process as shown in Table I Table I Potential sampling activities defined in terms of the waste formDEVELOPMENT OF A SAMPLING METHOD FOR QUALIFICATION OF A CERAMIC “The composition of the new material closely matches the relative proportions in which the different ceramic waste products [scraps, sludges, and dusts] No processing changes at manufacturing plants means no added costs And because the process uses entirely waste materials, it saves material costs, tooClay Culture: Zero Waste

The Use of Waste Ceramic in Concrete: A Review MDPI

2024年5月20日 Waste ceramic is produced from different sources and, if not reused, is often disposed of in landfills, contributing to the pressure on landfill capacity and potentially releasing toxins into the surrounding environment as ceramics break down over time The waste can easily be crushed to the required sizes, which has interested many researchers It has been used as 2022年1月11日 Currently, recycling of waste materials in construction is being considered very important because waste generation is posing serious threats to our living environment Hence, to induce sustainability in the ongoing urban development, researchers around the globe are using numerous wastes in concrete as partial substitutes of binders (cement, lime, etc) and fillers Recycling of ceramic tiles waste and marble waste in sustainable 2020年12月1日 The ceramic industry is going to be deeply involved in the transition to a circular economy However, the main obstacle to a widespread recourse to waste recycling is the lack of knowledge about Waste recycling in ceramic tiles: a technological 2024年3月14日 These processes can also be performed using powdered glass or crushed frits thanks to a sintering–crystallisation process (glassceramic processing by sintering) The petrurgical route is the most commonly used to manufacture glassceramic materials from natural raw materials (rocks and minerals) and all types of industrial waste Glasses, Frits and GlassCeramics: Processes and Uses in the

MulliteBased Ceramics from Mining Waste: A Review

2021年3月23日 Mullite (3Al2O32SiO2) is an aluminosilicate characterized by excellent physical properties, which makes it an important ceramic material In this way, ceramics based on mullite find applications 2021年8月10日 The preparation methods of glass ceramic foams mainly include powder sintering method, organic slurry impregnation method, solgel method, etc However, the most commonly used methods for preparing glass ceramic foams from industrial solid waste are powder sintering processA review of glass ceramic foams prepared from solid wastes: Processing Explore sustainable ceramic solutions with our waste stream minerals services, focusing on waste recycling and efficient mineral recovery processes 4063708923 / info@intoceramics MenuWaste Stream Minerals Recycling IntoCeramics2021年1月26日 Sensor‐based ore sorting applies at various points in the process flow diagram and is suitable for waste elimination, for material diversion into different process lines, for the production of Recovery of Raw Materials from Ceramic Waste Materials for the

Reducing Environmental Footprint: Investigation of Waste Ceramic

2024年7月1日 Changing from traditional materials like clay, sand, aggregates, and Portland cement to more sustainable options is a challenge for the construction material sector This study aims to find out the viability of using ceramic waste in bricks as a partial replacement for cement The utilization of ceramic waste was employed as a substitute for cement in varying The Stages of Ceramics Processing While each stage in the ceramic manufacturing process can look different depending on the desired shape and raw materials being used, in technical ceramics, the process follows a very similar pattern 1 Milling The raw materials are prepared for ceramics processing through a number of different techniquesAll About The Ceramics Manufacturing Process Sentro Tech2024年3月12日 Abstract The applicability of bentonite claybased ceramics for immobilization of waste from pyrochemical reprocessing of spent nuclear fuel–spent electrolyte, which consists of alkali metal chlorides, was studied Main matrix characteristics such as the phase composition, mechanical durability, leaching rate and microstructure were studied The results obtained Assessment of Applicability of Bentonite ClayBased Ceramics for 2019年10月1日 In this paper, phosphate based glassceramic waste forms containing monazite CePO4 as crystalline phase were prepared by a meltquenching process using NH4H2PO4, H3BO3, Fe2O3 and CeO2 as the feed Synthesis of phosphate based glassceramic waste forms by a

Ceramic Manufacturing Consulting Services

Expert ceramic manufacturing consulting, toll manufacturing, and advanced ceramics services for process optimization and innovation 4063708923 / info@intoceramics Menu2023年5月18日 Ceramic 3D printing is a promising technology that overcomes the limitations of traditional ceramic molding It offers advantages such as refined models, reduced mold manufacturing costs, simplified processes, and automatic operation, which have attracted a growing number of researchers However, current research tends to focus more on the ThreeDimensional Printing of Large Ceramic Products and Process 2021年1月26日 Products of the refractory industry are key for the production of heavy industry goods such as steel and iron, cement, aluminum and glass Corresponding industries are dependent on thermal processes to manufacture their products, which in turn would not be possible if there were no refractory materials, such as refractory bricks or refractory mixes For Recovery of Raw Materials from Ceramic Waste Materials for Supporting: 1, Mentioning: 16 SUMMARYThe research conducted in this work package is aimed at taking advantage of the long term thermodynamic stability of crystalline ceramics to create more durable waste forms (as compared to high level waste glass) in order to reduce the reliance on engineered and natural barrier systems Durable ceramic waste forms that incorporate a Crystalline Ceramic Waste Forms: Reference Formulation Report

.jpg)

Zero waste: European project revamps ceramic tile manufacturing

2016年7月11日 A European project called LIFECERAM—coordinated by the Instituto de Tecnología Cerámica of the Universitat Jaime I of Castellón in Spain and including Spanish Association of Ceramic Tile and Paving Manufacturers and several commercial partners—has reached an important milestone towards its goal of achieving absolutely zero waste in ceramic 2017年4月10日 The treatment of spent nuclear fuel for disposition using an electrometallurgical technique results in two highlevel waste forms: a ceramic waste form (CWF) and a metal waste form Reactive metal fuel constituents, including all of the transuranic metals and the majority of the fission products, remain in the salt as chlorides and are processed into the CWFThe Ceramic Waste Form Process at Idaho National Laboratory2024年8月16日 Types of glass and ceramic nuclear waste forms Vitrification, or the transformation of a substance into a glass, is the most common approach to immobilizing highlevel radioactive wastesIn this process, nuclear waste is mixed with glassforming materials, commonly borosilicates and aluminophosphates, and then melted at high temperaturesImmobilizing nuclear waste: Status and future developments in 2013年11月1日 Sanitary ceramic ware waste is classified as belonging to group of nonbiodegradable industrial waste The paper presents the studies on possible reuse ceramic sanitary wastes as the aggregate Using ceramic sanitary ware waste as concrete aggregate