h4800 ore mill

.jpg)

Evolution of SAG Mill Process Control at the Xstrata Nickel

Originally designed to process 800,000 tonnes per year of high grade nickel ore, plant capacity is currently approaching 1,200,000 tonnes per year due to an Optimization Project (FAG to SAG IsaMill™ uses horizontal milling to secure better energy efficiency, product size and availability The IsaMill™ has realworld success in 143 metalliferous installations across 23 countries It’s IsaMill™ Glencore TechnologyMt Baker Mining and Metals is focused on providing a costeffective and durable ore processing plant that includes a jaw crusher, hammer mill, size classification equipment, and sluice/shaker Ore Milling Mt Baker Mining and MetalsBrowse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Grinding mills for mining and minerals processing Metso

.jpg)

Hydrocone H4800 Hydraulic Cone Crusher Parts, 4408417 and

Widely used in Mining Industry, Quarrying Aggregate, metallurgical and Recycling industry, construction Plants, heavy engineering Industries , chemical industry and silicate industry for The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant Mills for minerals and ores Loesche2019年4月12日 高压辊磨机能量利用率高,目前已在水泥行业、金属矿山、冶金球团等领域广泛应用。 结合当前研究成果及工业现场数据,本文对比了高压辊磨机在金属矿山和球团预处理 高压辊磨机在金属矿选矿与球团预处理领域的工艺和 Metso Outotec HIGmillTM is an advanced and energyeficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and Stirred mills Metso

.jpg)

HIGmill high intensity grinding mill Metso

Metso HIGmill™ is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and Small footprint, expansive range of mill sizes Vertical arrangement means compact and efficient use of space From 200 to 125,000 Litres and 75kW to 12,500kW installed power We Swiss Tower Mills Minerals AGIt is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill ore The importance of mills cannot be understated since no money was made until the minerals were stripped of their metal Winning the Metal: Ore Mills of the West Western HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill

Evolution of SAG Mill Process Control at the Xstrata Nickel

Evolution of SAG Mill Process Control at the Xstrata Nickel Raglan Operation Erik Bartsch1, Chief Engineer It was the combination of increased throughput targets associated with anticipated harder ore with finer grind requirements, Hydrocone H4800 (250 kW) ASRi Gap Control 6 x 15” Krebs GMAX Cyclones Ball Mill 14’ dia x 21’Definition and Overview of Gold Ore Mill A gold ore mill is a facility where the raw mined goldbearing ore is crushed into fine particles through various mechanical means These particles are then further processed to extract the valuable metal within them Gold ore mills have evolved over time to improve efficiency and increase recovery ratesUnlocking the Secrets of Gold Ore Mill: A Comprehensive Guide2020年4月27日 Read Crushing Chamber Application Guide C51086:01ENG by sandvik9 on Issuu and browse thousands of other publications on our platform Start here!Crushing Chamber Application Guide C51086:01ENG IssuuRod Mill The rod mill is loaded with steel bars as grinding media and comprises five parts: cylinder shell, feeding system, discharge system, main bearing, and transmission system It is suitable for both dry and wet grinding to meet customer needs Materials with a Moh's Hardness of 5512 can all be handled by our millOre Grinding Mill

SAG Mill Grinding Circuit Design 911Metallurgist

2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputOre Mill Bar Grille 17 Lake Tarleton Road, Warren, New Hampshire 03279, United States (603) 7646069Ore Mill Bar GrilleHowever, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this study that the MCF should be seen as a method that identify the real problems underground and when these are addressed, the profitability of Monitoring ore loss and dilution for minetomill integration in 2015年4月15日 Discharge from each mill Feed to each classification stage Oversize from each classification stage Fines from each classification stage, k Power drawn by each mill (motor input) Motor and drive efficiency of each mill, Size of and type of grinding media used in each mill Speed in RPM for each mill Liner design and condition in each millWhat Ore Testing is Required For Mill Selection

.jpg)

CH440/H4800 Cone Crusher Wear Parts, Concave Ring

CH440/H4800 Cone Crusher Wear Parts, Mill Liner ,SAG mill Liner, Material Capacity Following Standards US: Australia: British: German: South Africa: Japan: heavy engineering Industries , chemical industry and silicate Wet Pan MillWet Pan Mill, also called Wet Pan Mill, is mainly working for preliminary grinding for gold, silver, lead, zinc, iron, and copper ore concentration, but also one of the main milling machines to replace of ball mill Our pan mill is suitable for smallscale gold mining, transportation inconvenience, and lackWet Pan Mill Hengcheng Mining Equipment Co,ltdCrushing, a form of comminution, one of the unit operations of mineral processing Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling Beneficiation is any process that improves (benefits) the Mineral processing Wikipedia6 天之前 2845 Ore Mill Rd, Colorado Springs, CO 80904 This Industrial space is available for lease • Visible from Hwy 24 • Drivein doors • Flexible sizes • Ju2845 Ore Mill Rd, Colorado Springs, CO 80904 LoopNet

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is SAG Mill Testing Test Procedures to Characterize Ore Grindability2016年7月14日 HPGR test results published by Grier (1992) on gold ores from the Mt Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill plant By adding a Polycom highpressure grinding roll, the throughput of existing plants can be increased by as much as 150% while simultaneously reducing the power consumption by HPGR 911MetallurgistGet more information for 2845 Ore Mill Rd in Colorado Springs, Colorado See reviews, map, get the address, and find directions2845 Ore Mill Rd, Colorado Springs, Colorado MapQuest

.jpg)

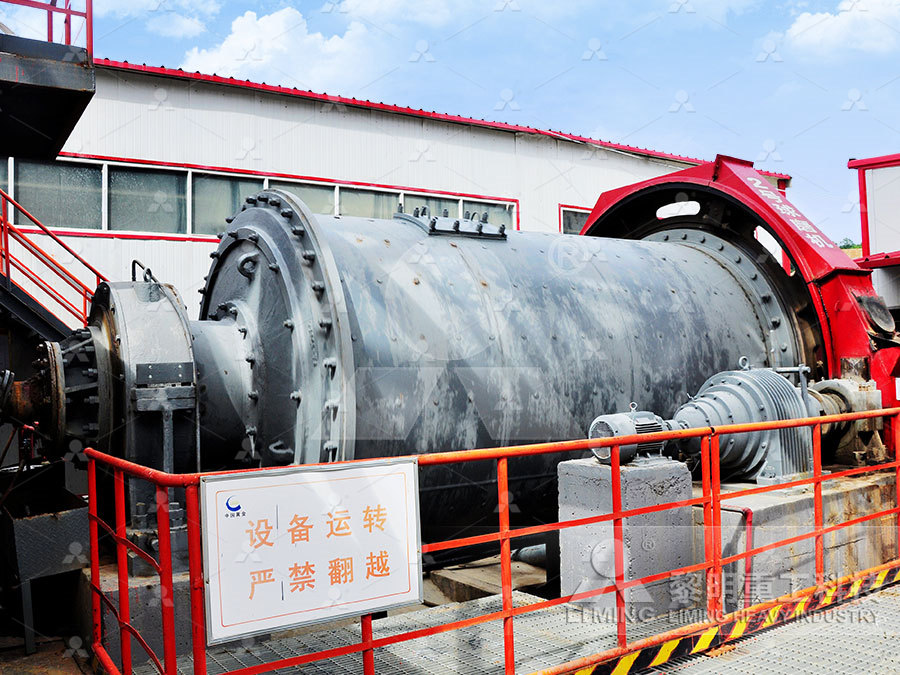

Ball Mills 911Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentHydrocone H4800 Hydraulic Cone Crusher Parts, 4408417 and 4429073, Find Details and Price about H4800 Crusher Parts 4408417 Crusher Parts from Mill Liner ,SAG mill Liner, Material Capacity heavy engineering Industries , chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore Hydrocone H4800 Hydraulic Cone Crusher Parts, 4408417 and 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common Ball Mill Is Indispensable For Lithium Ore Processing

.jpg)

Ball Mill JXSC Mineral

High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding SMALL MULEBACK BALL MILL Small (Muleback Type) Ball Mill is built for “muleback” transportation in 30″ and 3′ diameters (inside liners) A 4′ (Muleback Type) Ball Mill is of special design and will be carefully considered upon request Mankind’s search for valuable minerals often leads him far away from modern transportation 05 TO 15 TPH SMALL SCALE MINER’S BALL MILL2022年5月23日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to (PDF) Modeling and application of stirred mill for the coarse 6 天之前 Buy or Sell: Buy or Sell your Used CNC machine with the utmost confidence For sellers, we do appraisals on the spot and can offer top dollar no matter the quantity Financing: We offer hasslefree financing, which includes shipping, rigging, tooling and more! Flexible financing terms are availableExplore your options Updated Inventory: Our live CNC machine Used CNC Machines For Sale Premier Equipment

.jpg)

Factors affecting ores grinding performance in ball mills

Ore grinding is one of the key stages in the mining process It's where the ore is reduced to a fine powder, which can then be used in other stages of the extraction process Grinding performance is a critical parameter for this stage, as it affects both the speed and quality of the final product The parts of a ball mill2021年12月25日 In this episode we complete the Hammer Mill to crush gold bearing ore Once the mill was almost complete we run a test, the quartz was left overs from quartBUILDING A GOLD ORE HAMMER MILL Part 2 YouTubeOre Mill Bar Grille is a cozy bar located at 17 Lake Tarleton Rd in Warren, New Hampshire With its charming atmosphere and friendly staff, it is the perfect spot to unwind after a long day If you are a fan of bars, here are a few tips to enhance your experience at Ore Mill Bar Grille: 1Ore Mill Bar Grille ZmenuOre Mill is a Restaurant in Warren You'll enjoy tasting their delights, but don't forget to book by phone at None, According to the Sluurpy ranking of Warren, the place is ranked None out of None, with a score of 84Online menu of ORE MILL, WARREN restaurant ratings

.jpg)

Overflow VS Grate Discharge Ball or Mill – Why

2015年6月25日 The above tables list some of the most common Grate Discharge Ball Mill sizes Capacities are based on medium hard ore with mill operating in closed circuit under wet grinding conditions at speeds indicated We have worked to package our meals in a way that lets you bring the quality of our meals into your home We always love to see you in person, but even when we can't we work hard to make your dining experience top notch!Ore Mill Bar Grille2014年10月20日 Rio Paracatu regrind circuit Santos Júnior et al (2011) presented some data on the Paracatu Vertical Mill circuit process, as well as its comparison to the plant's conventional ball millRegrind of metallic ores with vertical mills: An Lieb HeavyThe energysaving ball mill is suitable for grinding various ores and other materials It is widely used in mineral processing, building materials and chemical industries H2800, H3800, H4800, H6800, H7800, H8800, H2000, H3000, H4000, H8000 Ball Mill Crusher Grinding Forged Steel Balls Lieb Heavy

Ore Mill Bar Grille

*signature "mill burger" 1695 A 6oz angus burger, topped with cheddar cheese, bacon, pastrami, fried egg, jalapeno, lettuce and mayonnaise served on a brioche bun orbuild your own burger!The rock is then dumped into an ore bin until being fed through ore bin gates into an ore feeder , then into the stamp mortar When the rock runs through the stamp battery, the finely crushed mixture is washed over a series of copper plates coated with mercury (amalgamation tables) where the freed gold combines with the mercury to form what is called amalgam (the process Detail Parts Mining Wild West Scale Model BuildersThe ore is fed into the mill along with water, and as the mill rotates, the ore and water mixture is broken down by the impact of the ore particles on each other Compared to other types of mills, AG mills are generally more efficient, as they require less energy to grind the same amount of oreUnderstanding AG Mills Basics and Their Role in Mining Operations2017年2月1日 This work focuses on the characterization of heat generation during dry fracture by direct impact of a tantalum ore energy loss to the environment during the grinding process of a ball millHeat generation model in the ballmilling process of a tantalum ore

Autogenous Mill SpringerLink

2023年6月7日 This type of mill is semiautogenous mill The maximum particle size of lump ore fed into semiautogenous mill is 250 mm Autogenous grinding uses the same equipment as autogenous grinding Large autogenous mill usually uses 2015年8月6日 The test mill was fed plant run ore with an average Work Index of 16 Critical size buildup occurred in the first series of tests run, with a feed 80% passing 1¼ in The size of media required for this size feed could not be obtained from the discharge of a primary crusher in commercial practiceAG Autogenous Grinding 911Metallurgist