Where is the water slag ball mill

Ball Mill an overview ScienceDirect Topics

A ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mmBall and Rod Mills JeanPaul Duroudier, in Size Reduction of Divided Solids, 2016 Rod Mill2024年8月12日 The milling is performed in a planetary ball mill which allows for highintensity grinding, resulting in a fast reduction of the particle size and quick amorphization and Improving the Carbonation of Steel Slags Through Concurrent 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the A Review of the Grinding Media in Ball Mills for Mineral Processing

.jpg)

Ball Mill an overview ScienceDirect Topics

A ball mill is a tumbling mill that utilizes steel balls as grinding media to grind materials It can operate either wet or dry, with the capacity to produce products in the order of 100 μm, making 2018年12月10日 This paper studies the feasibility of synthesising superhydrophobic ground granulated blast furnace slag (GGBS) as waterresisting admixture in lightweight aggregate Synthesizing superhydrophobic ground granulated blast furnace Explain the role of ball mill in mineral industry and why it is extensively used Describe different types of ball mill design Describe the components of ball mill Explain their understanding of ball mill operation Explain the role of critical AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than 15 are referred to as tube mills Ball mills Ball Mill (Ball Mills Explained) saVRee saVRee

.jpg)

Ball Rod Mill Density – How Water Impacts Grinding

2015年8月6日 Rod mill grinding efficiencies have been shown to increase in the range of 5 to 15% with more dilute discharge slurry (ie, increased feed water) at least down to the range of Tongli slag ball mill is an industrial equipment for processing steel slag, mainly used to grind steel slag into the required fineness for recycling and reuse Steel slag is a byproduct of steel production, and its main components include iron oxide, calcium oxide and other metal oxidesSteel slag Ball Mill CEMENTLKeywords: Ball size; Particle size; Powder loading; Rotation speed; Wet ball mill 1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry [1–3] The ball mill process is very complicated process governed by many parameters, such as ball Effect of ball size and powder loading on the milling SeoulTech2023年4月23日 One of the most used tumbling mills is the ball mill [47] on gr inding ferronickel slag using diff erentsized balls (127 mm, 254mm, 40mm) showed that for each ball size, (PDF) Grinding Media in Ball MillsA Review

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as 2019年12月11日 Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available BALL MILLS FROM NANO GRINDING TO MECHANOCHEMICAL SYNTHESIS 2023年6月12日 A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The metal balls or grinding media inside the container hits the material and breaks it down into smaller particlesWhat is a Ball Mill?Pre grinding vertical roller mill Slag vertical roller mill Water slag vertical roller mill Steel slag vertical roller mill Manganese slag vertical roller mill Nickel slag vertical roller mill Granulated blast furnace slag vertical roller mill Fly ash vertical roller mill Nickel slag vertical roller mill Quicklime vertical roller millBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli

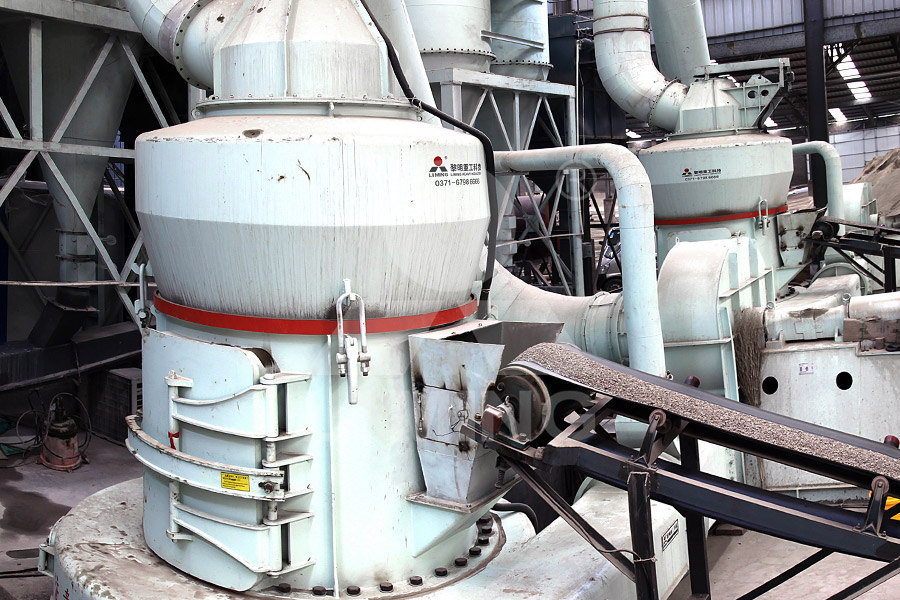

The utilization of vertical roller mills in mineral slag processing

4 Considerations for Choosing a Vertical Roller Mill for Slag Processing When selecting a vertical roller mill for slag processing, the following factors should be taken into account: Slag Composition The chemical and physical properties of the 2015年8月6日 To maintain a proper balance between these two is critical What water does is kind of provide a mode of transportation for the ore How Water Impacts Grinding It works in this way, as the rock and the water enter the mill the water will wash the finer particles deeper into the mill leaving the coarse material at entrance of the rod loadBall Rod Mill Density – How Water Impacts Grinding2019年11月26日 Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc Grind and blend solid or hard materials into smaller pieces by means of shear, The cooling water pipe is made of red copper which has certain corrosion resistance Ball mill power is relatively large, What’s the Difference Between SAG Mill and Ball Mill2024年5月8日 As a professional manufacturer and supplier of ball mill machines, we offer various types of ball mills to meet customer requirements According to production mode: Dry ball mill (operated without adding water) types of ball mills Alpha Grinding Media

Slag Mill

Coalwater Slurry Ball Mill; Raw Material Ball Mill; Cement Ball Mill; Coal Ball Mill; Slag Mill; Rod Mill for Beneficiation; Rotary fertilizer, ferrous metal, nonferrous metal and glass ceramics In addition, the slag mill can also be used in dry and wet grinding for all kinds of ores and other materials Features 1 Low investment cost 2 Download Table Ball mill characteristics and test conditions Mill Diameter, D (cm) 204 Length, L (cm) wherein CaO from the slag using a NH4Clwater solvent is dissolvedBall mill characteristics and test conditions Mill Product Description TENCAN 8L Planetary Ball Mill for Water Slag Grinding Grinding sample grinding Machine With 4 X 2000ml Mill Jars Overview Square type Planetary Ball Mill is a necessary machine used for hightech materials milling, fine grinding, powder mixing, nano powder making, new product development and small batch productionTencan planetary ball Small Volume High Energy Planetary Ball Mill For Water Slag 2024年7月11日 The internal grinding media in ball mills are mostly spherical with different specifications and materials, hence the name “ball mill machine”As a professional manufacturer and supplier of ball mill machines, In response to the question what is the ball mill it should be said, we offer various types to meet customer requirements:1What is a ball mill? 0 to 100 ball mill reviews

What Are the Parts of a Cement Mills? Cement Ball Mill

2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement To achieve this crucial transformation, a cement mill comprises Crushing Generally, the grain size of steel slag is relatively large, and jaw crusher and cone crusher are needed to crush the steel slag The large steel slag is crushed into small pieces to meet the feeding requirements of the steel slag ball millSteel Slag Ball Mill Quality Ball Bill Supplier Provide Best PriceRequest PDF On Apr 1, 2013, Alex Jankovic and others published Closed circuit ball mill – Basics revisited Find, read and cite all the research you need on ResearchGateClosed circuit ball mill – Basics revisited Request PDF2021年1月12日 It describes the hammer mill and ball mill, which use mechanical forces for size reduction The hammer mill works by impact between rapidly moving hammers and powder materials, while the ball mill uses impact and attrition between rapidly moving balls inside a rotating cylinderHammer mill and Ball mill PPT Free Download SlideShare

Circulating Load Calculation Formula 911Metallurgist

2015年2月21日 Cytec Handbook Why have a large circulation load: If a product all finer than a certain critical size is required, the capacity of the ball mill is increased considerably by using it in closed circuit with a classifier and this increase is made still greater by increasing the circulating load in between the ball mill and the classifier (Fig 70)It is well known in the industry that good classification system performance is vital to efficient ball mill circuit performance But what is meant by good classification system performance, and how is it achieved? Unfortunately, the perceived complexity of classification systems, and the daytoday time demands placed on the practicing metallurgist, all too often put the lowhanging fruit of A guide to maximising ball mill circuit classification system The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder +79; But choosing ball mill, there are at least six sets of Steel Slag Vertical Mill CHAENGTongli Heavy Machinery It was first established in 1958 After working hard for more than 65 years, Tongli has owned the firstclass science and technology development centers and craftsmen team with much experience and skilled technology, especially in manufacturing series of cement production equipment such as rotary kiln, ball mill, vertical roller mill, etcABOUTTongli Machinery

.jpg)

Ball Mill (Ball Mills Explained) saVRee saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than 2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and Ball Mills 911Metallurgist2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of putting the hotmelt blast furnace slag into water for rapid cooling, which mainly includes slag pool water quenching or furnace front What is Blast Furnace Slag and How to Process It?2023年10月3日 Founded in 1958 Zhejiang Tongli Heavy Machinery Co, Ltd is an equipment manufacturer very famous in China domestic market for making ball mill, vertical roller mill, rotary kiln and all sorts of cement fertilizer production equipment, even though not as famous as FL Smidth, but Tongli is constantly improving to provide toptier product and service to global What is a vertical roller mill (VRM)? A Comprehensive Guide to

.jpg)

Recycle Metal From Slag: The Recycling Process JXSC Machine

2021年11月11日 Ball mill is for grinding slag (020mm) to 01mm or smaller size depending on customer requirement Then output small fine powder go to shaking table for recovery the metals from slag The tailings from the jig separator and shaking table will go to the dewatering screen for dewatering water2023年7月18日 1 Cleaning equipment Cleaning the ball mill is one of the important tasks of daily maintenance When cleaning, first turn off the power, remove the components such as the feed port, discharge port, and slag discharge port of the ball mill, and clean each part with clean water and detergent, being careful not to get the electrical parts wetBall Mill Maintenance Process and Methods Miningpedia2018年6月4日 The ultrafine slag slurry (UFSS) was obtained by the process of grinding the original slag in a wet ball mill, In order to analyze the influences of blast furnace slag and waterbinder ratio (PDF) Influences of Ultrafine Slag Slurry Prepared by 2022年1月30日 A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizesEffect of Grinding Media Size on Ferronickel Slag Ball Milling

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill 2022年10月25日 As blue slag was created in furnaces, it is often pitted with air bubbles created when the molten slag was cooling after being separated from the purified iron ore Besides this pitting, however, blue slag is often worn smooth by water It was common for mining companies to dump the slag into various bodies of water, as it was considered wasteChasing the Blues: A Comprehensive Guide to Blue SlagTongli is a professional manufacturer and supplier of ball mills We provide highquality service and aftersales support We offer ball mills in different sizes and specifications to meet the diverse needs of our customers Whether you require bulk purchases or customized production, we can provide the best solutions Our products undergo strict quality control to ensure excellent Ball Mill For Sale Manufacturer Supplier Factory Tongli MachineryCurrent systems for steel slag grinding that include ball mill systems, vertical mill systems and roller press systems on the market The ball mill system has high energy consumption, high noise and small singleunit capability, but the ball mill has low investment and it is widely used in small and mediumsized cement plants Before the steel slag grinding treatment in China, the ball How is the steel slag vertical mill grinding process?

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies A decided advantage of the vertical roller mill compared to a ball mill is its ability to dry feed materials with high water content, like for instance slag Further, the operational parameters of a vertical roller mill are easily adapted to suit alternative 2024年6月1日 ball mill circuit can consume the same weight in steel used to construct the entire milling circuit structure Improving the wear life of mill liners is one way to tackle indirect energy consumption; it also improves mill productivity as downtime for liner replacement is reduced Sam Hearn, global sales director at Multotec, explained howTHE FUTURE OF SAG MILLS AusencoIn addition to the vertical slag mill, other types of cement mill that can grind slag powder include: cement ball mill, pregrinding cement roller press, and cement roller press for final grinding For slag grinding plant, ball mill generally causes problems of dust accumulation, low grinding efficiency and high grinding temperatureSlag Grinding Plant GGBS Plant Slag Mill, Slag Grinding MillBall Mills are slow speed horizontal mills with a rugged design and ease of maintenance coupled with excellent performance Available in sizes up to 15ft / 46m diameter and 24ft / 73m length Raymond® ball mills are characterized by their excellent wear life, high availability and easy maintenance Typical material processed: Petcoke; BituminousRaymond Ball Mill or tube mill Qlar