What is the name of the machine for grinding steel slag powder

.jpg)

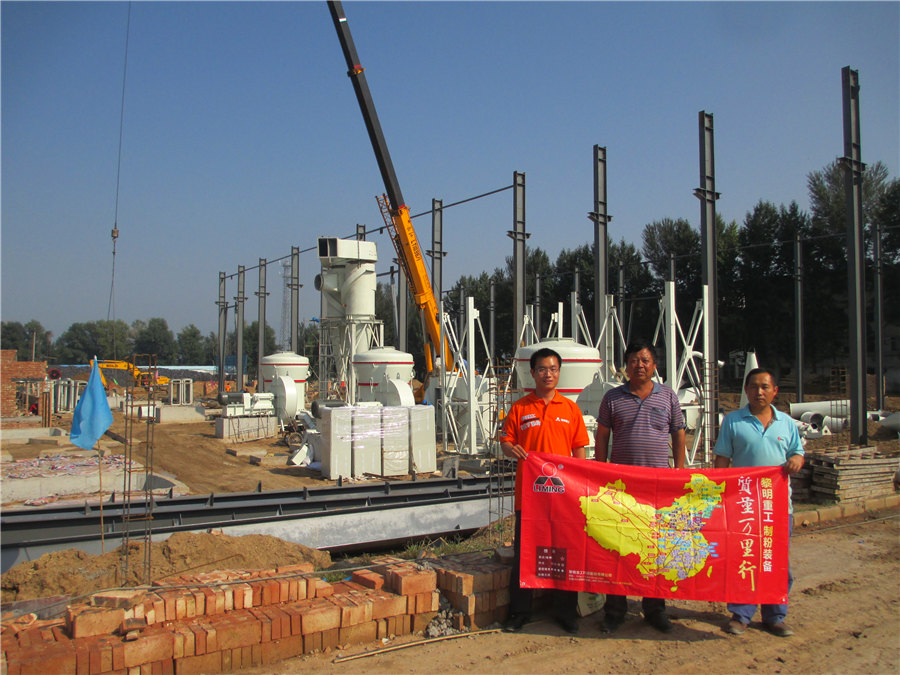

Steel Slag Processing Plant Equipment Selection

2023年12月27日 After introducing the use of steel slag, here is the process of steel slag: Steel slag uniformly enters the jaw crusher through a vibrating feeder for coarse crushing treatment After coarse crushing, the steel slag enters the 2020年1月30日 Slag grinding removes all heavy slag quickly and effectively, using rotating brushes that work in the opposite direction of the sheet metal being fed in order to grind and basically sand down the unfinished material These What is Slag Grinding? — Carlson Fabrication SolutionsSteel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500 Steel Slag Grinding Plant CHAENGgrinding track is empty or filled, through the use of a mechanical buffer stop The following features are new for clinker and granulated blast furnace slag: • Significantly higher specific 2 µm 5 µm Loesche

Slag Grinding Plant GGBS Plant Slag Mill, Slag

One of the main equipment in the slag powder production line is the slag mill There are so many types of cement mills that can be selected for slag grinding plants Vertical mills are generally used for grinding slag powder A vertical Our plants utilize stateoftheart magnetic separation equipment to maximize the recovery of metallics from the raw slagThe processing plants include the latest technology in crushing and screening plant design to cleanly separate the slag Slag Recycling and Metal Recovery MEKA2019年5月23日 Fine grinding of steel slag is helpful for “exposing” iron particles in steel slag, and these are magnetically separated to achieve the purpose of reducing the amount of iron in Comprehensive Utilization Technology of Steel Slag2023年3月2日 Slag Crusher Machines play a critical role in the steel recycling process by crushing and processing slag, a byproduct of steel production These machines help to reduce waste and environmental impact, while also What is a Slag Crusher Machine and How Does it Work?

Steel Slag an overview ScienceDirect Topics

Steel slag is an industrial byproduct obtained from the steel manufacturing industry It is produced in large quantities during steelmaking operations that use electric arc furnaces Steel slag can A pulverizer or grinder is a mechanical device for the grinding of many different types of materials When you pulverize something, Ultra Fine Automatic Powder Grinder Machine YF31 Powder Grinder also name Powder Mill Powder Grinder Machine Powder Milling Abstract Blast Oxygen Furnace (BOF) slag represents one of the largest waste fractions from steelmaking Therefore, slag valorisation technologies are of high importance regarding the use of slag as a secondary resource, both in the steel sector and in other sectors, such as the construction or cement prehensive Analysis of Steel Slag as Aggregate for Road 2021年6月28日 From the auto shop to the professional workshop to the home hobbyist’s basement, metal grinding tools have various applications for metalworkersThere are many, many types of grinders out there to choose Metal Grinding Tools Guide Empire Abrasives

.jpg)

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grinding Milling, sometimes also known as fine grinding, pulverizing or comminution, is the process of reducing materials to a powder of fine or very fine sizePrecision grinding is the process of removing metal from a workpiece to achieve a specific size, shape, or surface finish Surface grinding is a type of precision grinding that is used to create flat surfaces on metal workpieces This process involves using a grinding wheel to remove tiny bits of material from the surface of the workpiece until it is smooth and flatThe Ultimate Guide to Surface Grinding: Techniques, Applications, 2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guideWhat is a Slag Crusher Machine and How Does it Work?2020年6月29日 Grinding wheels should also be inspected prior to being mounted on a machine To test for damage, suspend the wheel with a finger and gently tap the side with a screwdriver handle for small wheels, and a wooden mallet for larger wheelsChapter 16: Grinding Wheels and Operations American Machinist

Metal Grinding Tools: The Complete Guide Red Label Abrasives

Quick Summary Metal grinding is a crucial process in various industries, using abrasive wheels or belts for tasks like deburring and precision finishing For best results, it’s essential to use the right metal grinding tools, such as angle grinders, belt grinders, bench grinders, die grinders, and surface grinders, as2016年10月28日 The converter steel slag cannot be widely used in building materials for its poor grindability In this paper, the grinding characteristics of untreated and pretreated (ie, magnetic separation) steel slag were compared Additionally, the grinding property of pretreated steel slag was also studied after adding grinding aids The results show that the residues (ie, oversize Comparison of Grinding Characteristics of Converter Steel Slag 2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience14 Types of Grinding Machines [Working, Diagram PDF] The 2019年10月29日 Along with iron and steel production, large amount of slag is generated Proper management on the iron and steelmaking slag is highly demanded due to the high cost of direct disposal of the slag to landfill, which The potential utilization of slag generated from iron

Surface Grinder Types of Grinders How They Work

2021年1月16日 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine 2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the continuous use of residue yards Application of Steel Slag as an Aggregate in Concrete What Is Grinding Slag Removal? Slag is a specific type of sand that’s traditionally made from steel It often forms as a coarse waste product resulting from deburring or smelting processes To remove slag, metal processing facilities require grinding and slag removal Slag grinding processes efficiently remove all of the heavy slag produced Grinding Slag Removal Apex Machine Group2024年1月23日 Initial Investment: Grinding machines, especially those used for precision applications, are costly Highend machines with advanced features like CNC systems are even more expensive Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000What is Grinding: Definition, Process, Types Specifications

.jpg)

Grinding machine Wikipedia

Rotating abrasive wheel on a bench grinder Pedalpowered grinding machine, Russia, 1902 A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grindingIt is a type of material removal using an abrasive wheel as the cutting tool [1] Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear Some of the most common fluxcored wires with rutile slag systems include those classified under AWS A520: Specification for Carbon Steel Electrodes for FluxCored Arc Welding and feature designators of T1, T9 and T12 T1 fluxcored wires provide good wetting action and are generally reserved for less critical applications since they don’t offer the best toughnessEverything You Should Know About Weld Slag (And Why2023年8月22日 Steel slag (SS) is a byproduct of steelmaking process, accounting for 15–20 wt% of crude steel [1, 2]Statistics show that the global crude steel production in 2021 was about 19512 Mt, of which China’s production was 10328 Mt []However, the comprehensive utilization rate of SS in China is less than 30%, which is far from the utilization level of developed The Effect of Removing HardtoGrind Minerals from Steel Slag 2023年9月5日 The choice of metal powder production method depends on the raw material, powder type, performance requirements of the powder material, and the efficiency of powder production As the application of powder metallurgy products becomes increasingly widespread, the requirements for the size, shape, and performance of powder particles are becoming Metal Powder Preparation Methods and Principles: A

.jpg)

Steel Slag Recycling: The Definitive Processing Solution

2024年3月12日 Steel slag recycling primarily involves extracting useful metal components (such as steel particles and iron powder) and properly managing the tailings Despite the large and challenging volume of steel slag production, it can be effectively recycled through methods such as mechanical, chemical (such as dissolution, leaching), and thermal treatments (such as hot 2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total Use of steel slag as sustainable construction materials: A review 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirect2022年10月28日 What Is a Grinding Machine? One of the power tools or machine tools used for grinding is a grinding machine, often known as a grinder Grinding is a type of machining that uses an abrasive wheel as the cutting An Introduction to the Types of Grinding Machines

Can steel slag Raymond mill be used to processed steel slag powder

Finally, after understanding the Raymond mill’s ability to grind steel slag powder, let’s take a closer look at the uses of steel slag powder Mainly used in the cement concrete industry, it can be mixed with water slag powder, fly ash, tailings powder, etc Typical morphology of steel slag [](a) BOF steel slag(b) EAF steel slag(c) LF steel slagBOF steel slag is the solid waste produced in the converter steelmaking process, and its discharge is approximately 100–150 kg per ton of BOF steel [20,21,22,23]BOF steel slag commonly has a grayishwhite appearance and a vesicular nature, with many noninterconnected pores []Application of Steel Slag as an Aggregate in Concrete Production: There are so many types of cement mills that can be selected for slag grinding plants Vertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grindingSlag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill2021年11月27日 Composition of The Powder Grinding Mill The powder grinding mill is composed of a host, a classifier, a blower, a finished cyclone separator, a pipeline device, and a motor The main host machine is composed of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, a cover, and a motorWhat is Powder Grinding Mill? JXSC Machine

.jpg)

Slag Crusher Plant Machine Manufacturer Bhupindra Machines

To develop the slag crushing plant is the big achievement for Bhupindra Machine PvtLtd We have developed the 100 TPH fully automized slag crushing plant on key basis Today BMPL have achieved the excellence and created a distinct identity for themselves in the business areaJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2024年7月10日 Grinding Machines: These machines perform flat, cylindrical, or centerless grinding operations They feature motordriven wheels that remove material from surfaces Common types include bench grinders, hand grinders, pedestal grinders, portable grinders, flexible shaft grinders, and precision grinders, each suited for specific applications and What is Grinding: Definition, Types, Uses, and Working Processgrinding available Range Information: » Supplied as machine only or complete milling system » Large range – from lab to production » 3 hp to 125 hp » Grinding media options include turbine and screen, pinned disc, and rib track The Kek Universal Mill is designed for highperformance fine grinding, versatility and safety Available with Powder Processing Equipment Systems Qlar

What is the technical scheme of the slag powder process?

5Application case of slag powder technology scheme: the expansion project of large building materials enterprise in Hebei, the grinding material is water slag of steel mills, which needs to be processed into S95 grade ore powder, and is used downstream for the production of building materials productsFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L Powder mill, Powder grinding mill All industrial 2018年11月21日 For use in rough grinding applications where high stock removal is required This grain is associated with high tech resin bonds Aluminium Oxide Generally recommended for grinding materials of high tensile strength, such as stainless steel and tool steels but it can also be used on some high tensile aluminium and bronze alloysWhich Grinding Wheel Should I Choose? Norton Abrasives UK2024年8月18日 The grinding wheel for a portable grinding machine can have a diameter of 9020mm 1) Be familiar with the performance of tools It is advisable not to frequently change the tools such as the grinding machine and grinding wheel granularity Having knowledge and familiarity with the tools’ performance is an essential aspect of identifying sparksGrinding Sparks: Identifying Carbon Steel and Stainless Steel

.jpg)

Understanding the 4 Main Types of Grinding Machines

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting There are various grinding machine types, each with a different purpose Here’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas Surface Grinders A surface grinder consists of an abrasive wheel, a chuck (a workpiece A man grinding on metal using an angle grinder, causing a lot of sparks Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool A wide variety of machines are used for grinding, best classified as portable or stationary: Portable power tools such as angle grinders, die grinders and cutoff saws; Stationary power tools such as bench Grinding (abrasive cutting) Wikipedia2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry Grinding Chapter 17: Grinding Methods and Machines American Machinist2000年12月15日 Next, consider the severity of the grinding action This is defined as the pressure under which the grinding wheel and the workpiece are brought and held together Some abrasives have been designed to withstand severe grinding conditions when grinding steel and steel alloys Grinding machine horsepower must also be consideredChoosing The Right Grinding Wheel Modern Machine Shop

Chemical, Mineralogical, and Morphological Properties of Steel Slag

2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes These oxidized components combine with lime (CaO) to form slag As the steel is refined, carbon powder is also injected through the slag phase floating on the surface of the molten steel, leading to the formation of carbon monoxide