Ball mill fly ash

.jpg)

Suppressing Heavy Metal Leaching through Ball Milling

2016年7月8日 Ball milling is investigated as a method of reducing the leaching concentration (often termed stablilization) of heavy metals in municipal solid 2017年12月1日 Class F fly ash (established by SEMEDS and XRF analysis) with average particle size 1345 μm was milled by using the laboratoryscale planetary ball mill to produce ∼ Grinding of ClassF fly ash using planetary ball mill: A simulation 2023年4月1日 After mechanical ballmilling modification, an accelerated carbonation technology of municipal solid waste incineration fly ash (FA) was proposed The effects of ballmilling on Accelerated carbonation of ballmilling modified MSWI fly ash 2015年12月10日 Mechanochemical experiment of raw fly ash was carried out by a highenergy pulverization ball milling (Premium line, FRISCH, Germany) in an air atmosphere with a Comparative study on the characteristics of ballmilled coal fly ash

.jpg)

Suppressing Heavy Metal Leaching through Ball Milling

2016年7月8日 Three heavy metals (Cu, Cr, Pb) loose much of their solubility in leachate by treating fly ash in a planetary ball mill, in which collisions between balls and fly ash drive various2023年3月30日 In this paper, we report a comparative study of the properties of alkaliactivated geopolymer materials prepared using both ballmilled and attritionmilled fly ashes Ball milling was carried out for 30 min and 60 min while Characterization of Alkali Activated Materials Prepared 2021年4月11日 Beneficiation treatments for coarse fly ashes comprise size classification or milling processes to extract or produce fine size fractions of higher pozzolanic reactivity This article compares the effect of size Classification and Milling Increase Fly Ash Pozzolanic In this study, fly ash was mechanically activated by high energy planetary ball mill for 1 hour at different speed, ranging from 100 to 350 rpm and with varied ball to powder ratio (2:1, 3:1 and Mechanical Activation of Fly Ash by High Energy Planetary Ball Mill

.jpg)

Comprehensive Extraction of Silica and Alumina from Coal Fly Ash

2023年11月30日 Coal fly ash (CFA) is an increasingly prevalent byproduct that necessitates more resourceful and ecofriendly processing methods Extracting aluminum from CFA is a The particle size of fly ash from micro to nano is reduced by using a planetary ball mill in a stainless steel chamber with a tungsten carbide and zirconia balls of 10 mm and 5 mm diameter The totalResearch Article Fabrication and characterization of nano Fly ash Fly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles Fly Ash Processing Plant Ball Mill, Raymond Mill,Differences between ball mill and vertical roller mill in fly ash processing Ball Milling A ball mill is a traditional and reliable equipment for grinding fly ash It uses steel balls as grinding media, which is able to grind the fly ash particles into fine powder Its principle is simple: the raw fly ash material is fed into the ball mill How do You Process Fly Ash?

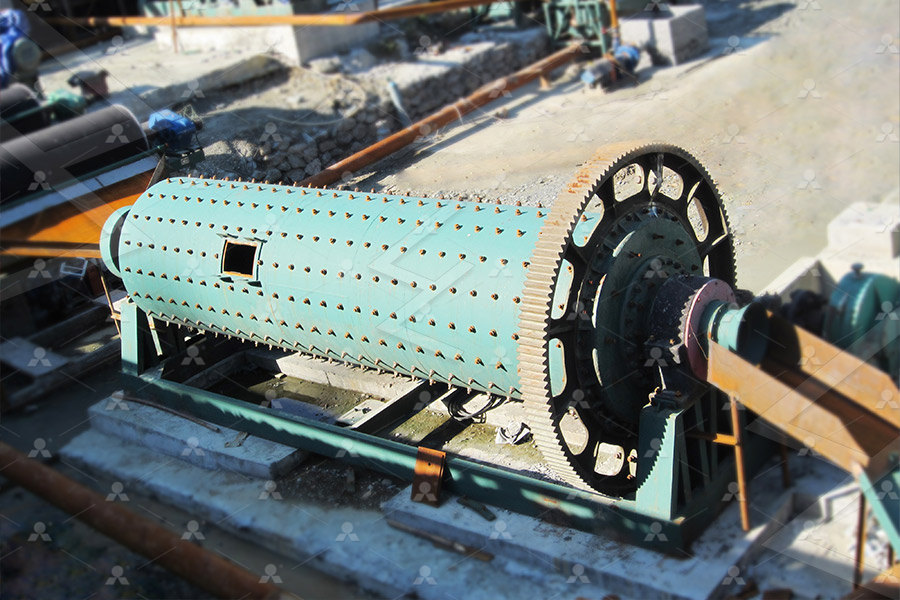

Use Fly Ash Ball Mill Make Flyash Cement Ball Mill Machine

The fly ash ball mill produced by AGICO GROUP is based on years of research on the characteristics of fly ash, after longterm practice and continuous technological upgrading, combined with market demand and user feedback, and finally built a 2017年12月1日 Mechanical activation of Class F fly ash using planetary ball mill • Bulk and surface characterization of milled ultra fine fly ash • Direct and backcalculation method to estimate breakage parameters • Specific rate of breakage and energyspecific breakage rate for fly ash particles •Grinding of ClassF fly ash using planetary ball mill: A simulation 2024年7月12日 Process your fly ash with a ball mill and make use of this valuable commodity for material construction and more Contact us to learn how! More Posts Main Office 14539 HWY 57 PO Box 237 Tollesboro, KY 41189 Call: (606) 7985724 Contact Contact UsWalking Through the Ball Milling Process Economy Ball Mill2024年2月1日 In addition, the ball mill jar can be heated and temperature is controlled with a thermocouple 2 g of fly ash, 20 g of stainlesssteel balls, and 20 mL NaOH solution with different concentrations (1–4 mol L −1) were added to the stainlesssteel ball mill jarOnestep high efficiency synthesis of zeolite from fly ash by

Grinding of ClassF fly ash using planetary ball mill: A simulation

Planetary ball mill Fly ash Population balance model Direct and backcalculation method Breakage parameters Parameter optimization abstract Dry grinding of Class F fly ash (FA) was carried out using the planetary ball mill to obtain mechanically activated nanostructured FA particles The resulting FA powders were2023年7月1日 In this study, the biomass fly ash/biochar composite (BFABiochar) was effectively prepared using wheat straw and biomass fly ash by ecofriendly ballmilling method The BFABiochar was characterized by scanning electron microscope (SEMEDS), BrunauerEmmettTeller (BET) surface area, Fourier transform infrared spectroscopy (FTIR) analysis, X Mechanisms and adsorption capacities of ball milled biomass fly ash 2023年10月10日 At Economy Ball Mill, we’re a leading manufacturer of custommade ball mills for various industries We have many years of experience in designing and producing highquality ball mills that can meet your specific requirements We can provide both dry ball mills and wet ball mills, and can complete attritor mill barrel rebuildsUnderstanding Dry Grinding Economy Ball Mill2024年10月3日 Process your fly ash with a ball mill and make use of this valuable commodity for material construction and more Contact us to learn how! More Posts Main Office 14539 HWY 57 PO Box 237 Tollesboro, KY 41189 Call: (606) 7985724 Contact Contact UsUnderstanding the Parts of a Ball Mill Economy Ball Mill

.jpg)

(PDF) Grinding of ClassF fly ash using planetary ball mill: A

2017年8月1日 PDF Dry grinding of Class F fly ash (FA) was carried out using the planetary ball mill to obtain mechanically activated nanostructured FA particles Find, read and cite all the research you 2016年7月8日 Ball milling is investigated as a method of reducing the leaching concentration (often termed stablilization) of heavy metals in municipal solid waste incineration (MSWI) fly ashSuppressing Heavy Metal Leaching through Ball 2024年6月5日 Process your fly ash with a ball mill and make use of this valuable commodity for material construction and more Contact us to learn how! More Posts Main Office 14539 HWY 57 PO Box 237 Tollesboro, KY 41189 Call: (606) 7985724 Contact Contact UsUse Ball Mills as Powder Mill Equipment Economy Ball MillSince planetary ball mills' s has been used for synthesizing of nonmetallic materials such as fly ash (Paul et al 2007), biochar (Peterson et al 2012) and zeolite (Charkhi et al 2010;Mukhtar a): Fresh micro fly ash b): Nano fly ash after 6 hours ball milling

.jpg)

Influence of Planetary Ball Milling Parameters on the

2015年5月1日 Since planetary ball mills' s has been used for synthesizing of nonmetallic materials such as fly ash (Paul et al 2007), biochar (Peterson et al 2012) and zeolite (Charkhi et al 2010;Mukhtar 2023年10月28日 Anthropogenic coal fly ash (CFA) Rajak DK, Raj A, Guria C, Pathak AK (2017) Grinding of classF fly ash using planetary ball mill: a simulation study to determine the breakage kinetics by directand backcalculation method S Sustainable Utilization of Anthropogenic Coal Fly Ash Through 2024年4月14日 Process your fly ash with a ball mill and make use of this valuable commodity for material construction and more Contact us to learn how! More Posts Main Office 14539 HWY 57 PO Box 237 Tollesboro, KY 41189 Call: (606) 7985724 Contact Contact UsParticle Size Reduction Milling Media Economy Ball Mill2007年7月11日 The Class F fly ash has been subjected to high energy ball milling and has been converted into nanostructured material The nano structured fly ash has been characterized for its particle size by using particle size analyzer, specific surface area with the help of BET surface area apparatus, structure by Xray diffraction studies and FTIR, SEM and TEM have been Preparation and Characterization of Nano structured Materials from Fly

Fly Ash Processing Plant Cement Equipment Manufacturing

The fly ash ball mill is the special equipment for fly ash grinding, which is designed and developed by our company after years of research and practice It is the most ideal equipment for further processing of fly ash The ball mill adopts the particular structure and grinding media2021年10月23日 Fly ash was treated in a twostage process using two types of stirredball mills in order to prepare nanoparticles in (Lee et al 2015) Also, the effect of different size of milling balls on the particle size in the second stage was investigated (at this stage, the rotation speed was set to 3750 rpm)Coal Combustion Fly Ash SpringerLinkSlag ball mill Steel Slag ball mill Ceramic ball mill Fly ash ball mill Over flow ball mill Wet ball mill Grid Ball Mill Rod mill Conical Ball Mill And Design Ore Ball Mill Center drive ball mill Edge drive ball mill Large Ball Mill For SaleBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli Since planetary ball mills' s has been used for synthesizing of nonmetallic materials such as fly ash (Paul et al 2007), biochar (Peterson et al 2012) and zeolite (Charkhi et al 2010;Mukhtar e Planetary ball mill data for the calculation of

Fly Ash Properties, Source, Advantages, Uses DASWELL

2023年6月15日 Fly ash can be made into polymer filling material after a certain refinement process, and the synthetic material can be modified 4Make agricultural fertilizer Fly ash is rich in trace elements, such as silicon, boron, sulfur, zinc, copper, calcium, magnesium and iron, etc It has a loose texture and can significantly improve the soil structure2021年1月1日 The curtailment in fly ash particle size to the Nanolevel was attained using a tumbler ball mill (model: Metrex Scientific Instruments Private Limited, Delhi, India) The following circs were maintained during the milling process: ball mill was loaded with stainless steel balls (8 mm ϕ and weight 165 g) at a ratio of 10:1 to the fly ashDevelopment and characterization of coal fly ash through low 2023年5月27日 If the content of fine powder with particle size ≤ 0044mm in the raw material is low, grind the fly ash with a ball mill, and then screen it with a powder separator Ftmmachinery can design a reasonable grinding process according to the specific conditions of fly ash and provide corresponding equipment Contact us 3How to Process Fly Ash and What Is It Used for? Fote Machinery2022年2月27日 Fly ash is one of the largest types of industrial wastes produced during the combustion of coal for energy generation Finding efficient and sustainable solutions for its reuse has been the subject of substantial research worldwide Here, we review the recent research data related to (i) the use of fly ash as a lowcost adsorbent for pollutants in wastewater and soils Applications of fly ash for pollutant adsorption in water Springer

.jpg)

Reaction kinetics of fly ash geopolymerization: Role of particle

2019年5月1日 Loss on ignition (LOI) is estimated by measuring the mass loss after heating at 900 °C To obtain different size fraction, 2 kg raw fly ash is milled in ball mill for 30, 60 and 90 min duration separately The fly ash samples are identified as JP0, JP05, JP10 and JP15, where numerical values indicate the milling duration in hourFly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA prioritizes production efficiency and the quality of finished fineness and has developed the TRM series VRM for fly ash grinding and the TRMF series for Fly Ash Processing Plant Superfine Final Product CNBMSINOMA2024年10月1日 Paul et al [34] used a highenergy ball mill to convert fly ash into nanostructured fly ash, and found that the intensity of OH stretching vibration peak increased after modification, amorphous degree enhanced, and surface free energy and adhesion work increased with increasing milling timeEffect of ball milling activation on CO2 mineralization 2023年7月17日 Industrialization has led to the massive production of fly ash (FA) and its accumulation over the years The global production of about 78017 billion tons of FA per year is one of the largest solid wastes in the world, but the utilization rate is only about 20–22% [1]Volcano ash materials like FA, metakaolin (MK) and slag (GGBS) are activated by alkali to Improving the properties of metakaolin/fly ash composite

Effect of Precursor Blending Ratio and Rotation Speed

2024年3月20日 This research used fly ash and slag to create geopolymer foam concrete They were activated with an alkali, resulting in a chemical reaction that produced a gel that strengthened the concrete’s structural integrity The To make the most of this valuable resource, fly ash must undergo a series of processing steps, including grinding A fly ash ball mill is an important piece of equipment in the grinding process Factors to Consider When choosing a fly ash ball mill, there are several factors to consider These factors include:Key Considerations When Choosing a Fly Ash Ball MillDOI: 101016/JAPT201903003 Corpus ID: ; Reaction kinetics of fly ash geopolymerization: Role of particle size controlled by using ball mill @article{Nath2019ReactionKO, title={Reaction kinetics of fly ash geopolymerization: Role of particle size controlled by using ball mill}, author={Sanatan KrReaction kinetics of fly ash geopolymerization: Role of particle A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shellBall mill Wikipedia

.jpg)

What is a Ball Mill?

2023年6月12日 A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The metal balls or grinding media inside the container hits the material and breaks it down into smaller particles2019年3月1日 Request PDF Reaction kinetics of fly ash geopolymerization: Role of particle size controlled by using ball mill Fly ash is milled for 0, 30 and 90 min and used to study the role of particle Reaction kinetics of fly ash geopolymerization: Role of particle size 2018年7月1日 The effect of planetary ball mill speed on the particle size of the fly ash was in accordance with the data of Tsai et al (2008), who studied the effect of various speeds of planetary ball milling (100, 200, 300, 400, 500, and 600 rpm) on the particle size of egg shellPreparation and characterization of thermoplastic starch 2022年3月1日 Fly ash samples were ground by ball mill with a rotating speed of 1200 r/min, a filling ratio of the grinding ball of 25% and a grinding time of 30 min Fly ash is black after grinding and the carbon particles can be fully dispersed in itEffect of particles micro characteristics destroyed by ball milling

Reaction kinetics of fly ash geopolymerization: Role of particle

2019年5月1日 To obtain different size fraction, 2 kg raw fly ash is milled in ball mill for 30, 60 and 90 min duration Fly ash characterizations The chemical composition of fly ash is given in Table 1 Fly ash is ball milled for 30 and 90 min duration to obtain two finer fractions